Thermosetting resin composition, and prepreg, laminated board and metal foil coated laminated board using the same

A resin composition, thermosetting technology, applied in the field of prepreg, laminate and metal foil clad laminate, thermosetting resin composition, can solve the problem of poor dielectric properties, deterioration of dicyclopentadienyl phenol type active ester halogen-free system Dielectric properties and heat resistance, etc., to achieve the effects of low dielectric constant, increased glass transition temperature, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-16

[0106] Embodiments 1-16 provide a thermosetting resin composition glue, a prepreg and a copper-clad laminate using it, and the preparation method is as follows:

[0107] (1) Preparation of thermosetting resin composition glue:

[0108] Component (B) dicyclopentadiene phenolic active ester, (C) curing agent and (D-2) phenoxyphosphazene compound SPB-100 are prepared respectively with MEK solvent so that the solid content is 60%, 50% and Add the 25% solution into a 1000mL beaker in turn, then add (A) halogen-free epoxy resin, (D-1) phosphorus-containing phenolic XZ92741 and (F) filler in turn, and add an appropriate amount of (E) curing accelerator 4-di For methylaminopyridine, adjust the gelation time (GT) to 200-300s, add MEK solvent to control the solid content to 65%, continue to stir for 2 hours to mature, and obtain a thermosetting resin composition glue;

[0109] Wherein, the type and amount (in parts by weight) of each component are shown in Table 1 and Table 2.

[0110...

Embodiment 11

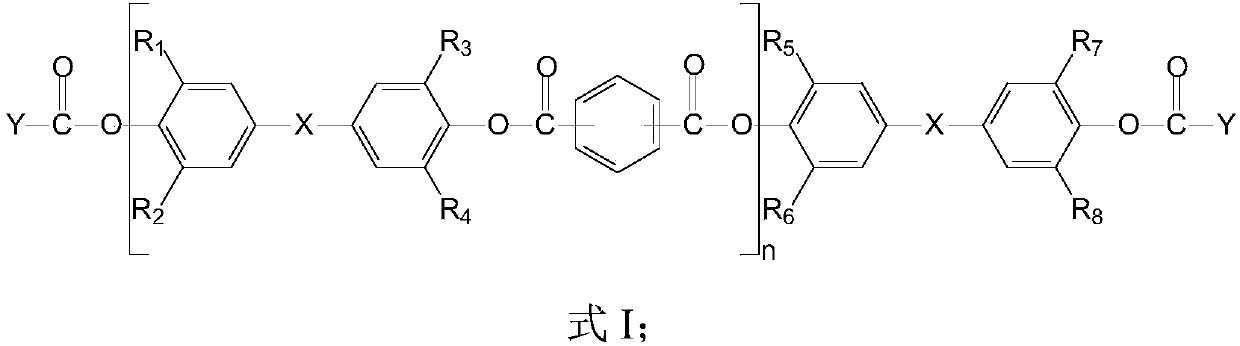

[0148]In Example 11, 75 parts of dicyclopentadiene novolac epoxy resin HP-7200H were compositely cured with an ester curing agent having a structure of formula I and dicyclopentadiene phenolic active ester HPC-8000-65T, and the plate had high Tg and low CTE, but due to the excessive amount of dicyclopentadiene novolac epoxy resin HP-7200H, the curing is incomplete, and the final board has high water absorption, poor dielectric properties and unsatisfactory heat resistance.

Embodiment 12

[0149] In embodiment 12, use 27 parts of ester curing agents with the structure of formula I and dicyclopentadiene phenolic active ester HPC-8000-65T to cure 38 parts of dicyclopentadiene novolac epoxy resin HP-7200H, and the board has high Tg, High peel strength, high heat resistance and good toughness, but due to the incomplete reaction of excessive curing agent, the board has high water absorption and poor dielectric properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com