Laminated ceramic capacitor and process for producing the same

一种陶瓷电容器、制造方法的技术,应用在叠层电容器、电容器、固定电容器等方向,能够解决最高温度偏差大、成品率下降、BCT结晶粒子晶粒成长偏差等问题,达到提高成品率、提高绝缘性、提高特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089]

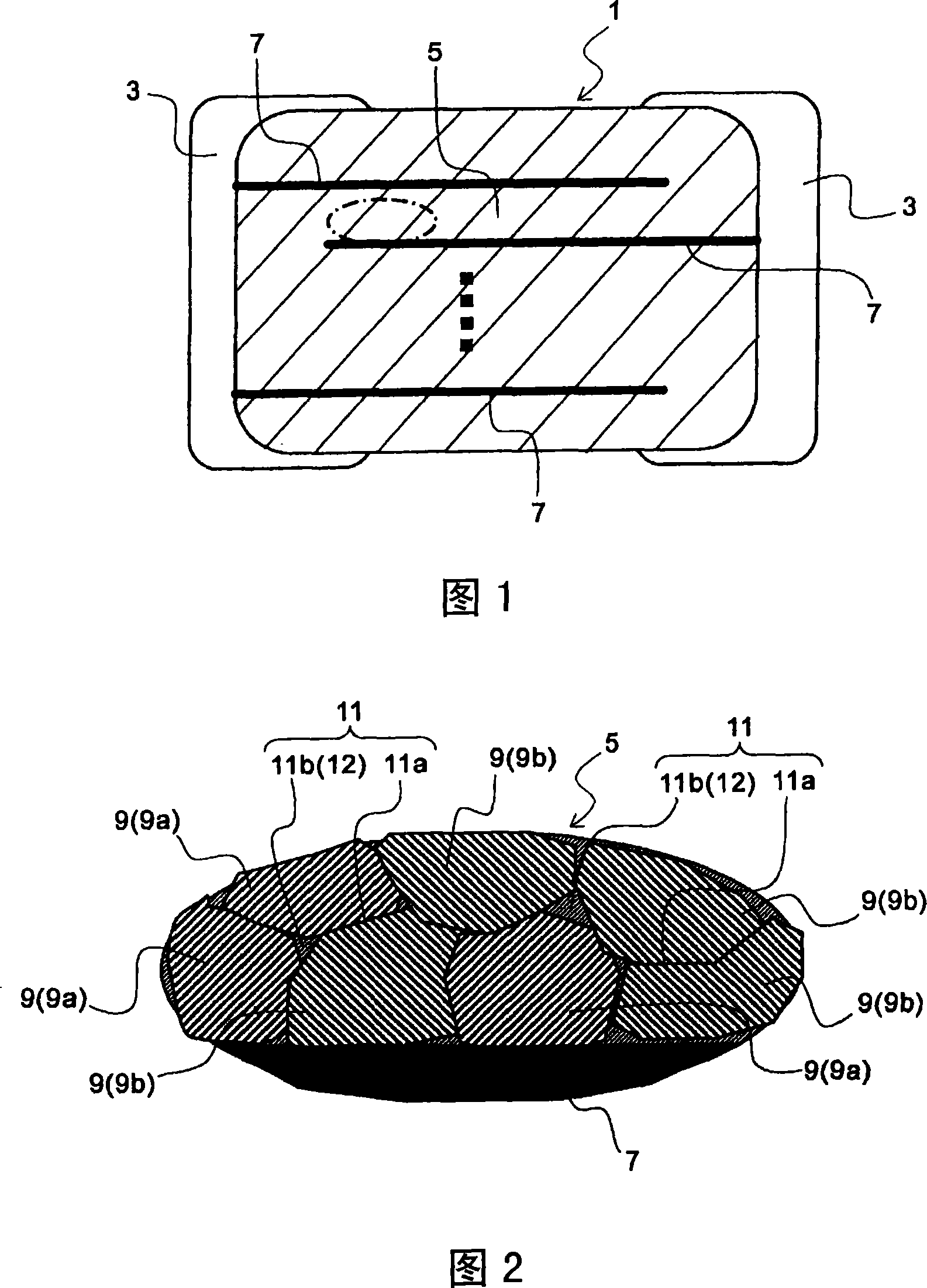

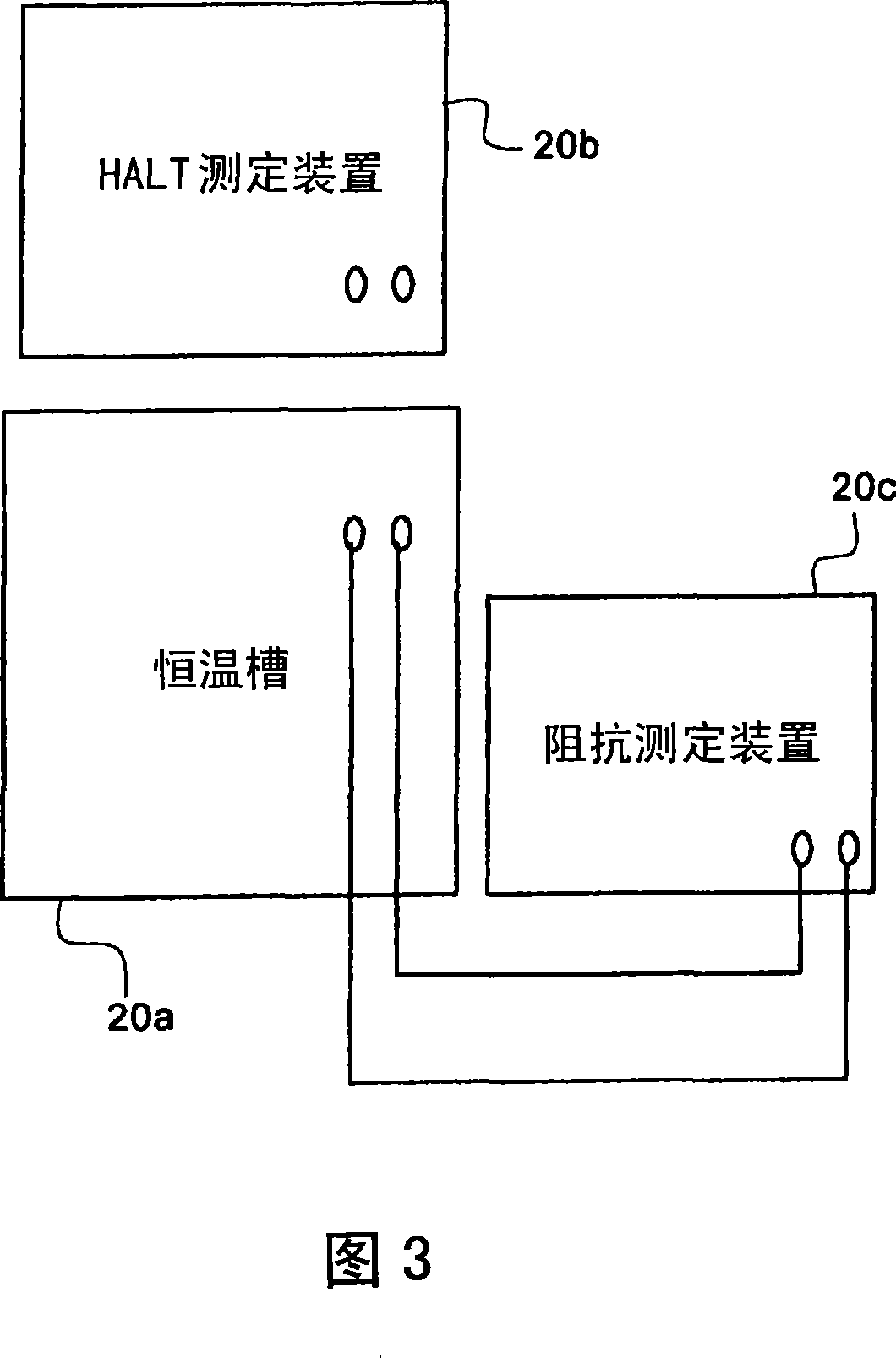

[0090] A multilayer ceramic capacitor was fabricated as follows. Also, the A / B site ratio in the BT powder and BCT powder used here is 1.003. In addition, the particle size of the BT and BCT powders is 0.2 to 0.4 μm. The BT powder and the BCT powder were coated with Mg, Y, and Mn, respectively. The coating amount is set to MgO=0.022 mass parts with respect to 100 mass parts of BT powder, Y 2 o 3 =0.122 parts by mass, MnO=0.023 parts by mass, with respect to 100 parts by mass of BCT powder, set MgO=0.065 parts by mass, Y 2 o 3 =0.37 parts by mass, MnO=0.069 parts by mass.

[0091] Glass powder whose composition is SiO 2 =50, BaO=20, CaO=20, Li 2 O=10 (mol %), the average particle diameter was 0.5 μm, and the amount added was 1.2 parts by mass based on 100 parts by mass of the dielectric powder. Table 1 shows the alumina content in the glass powder used in this case. In addition, the amount of added barium carbonate is also shown in Table 1. In addition, Tab...

Embodiment 2

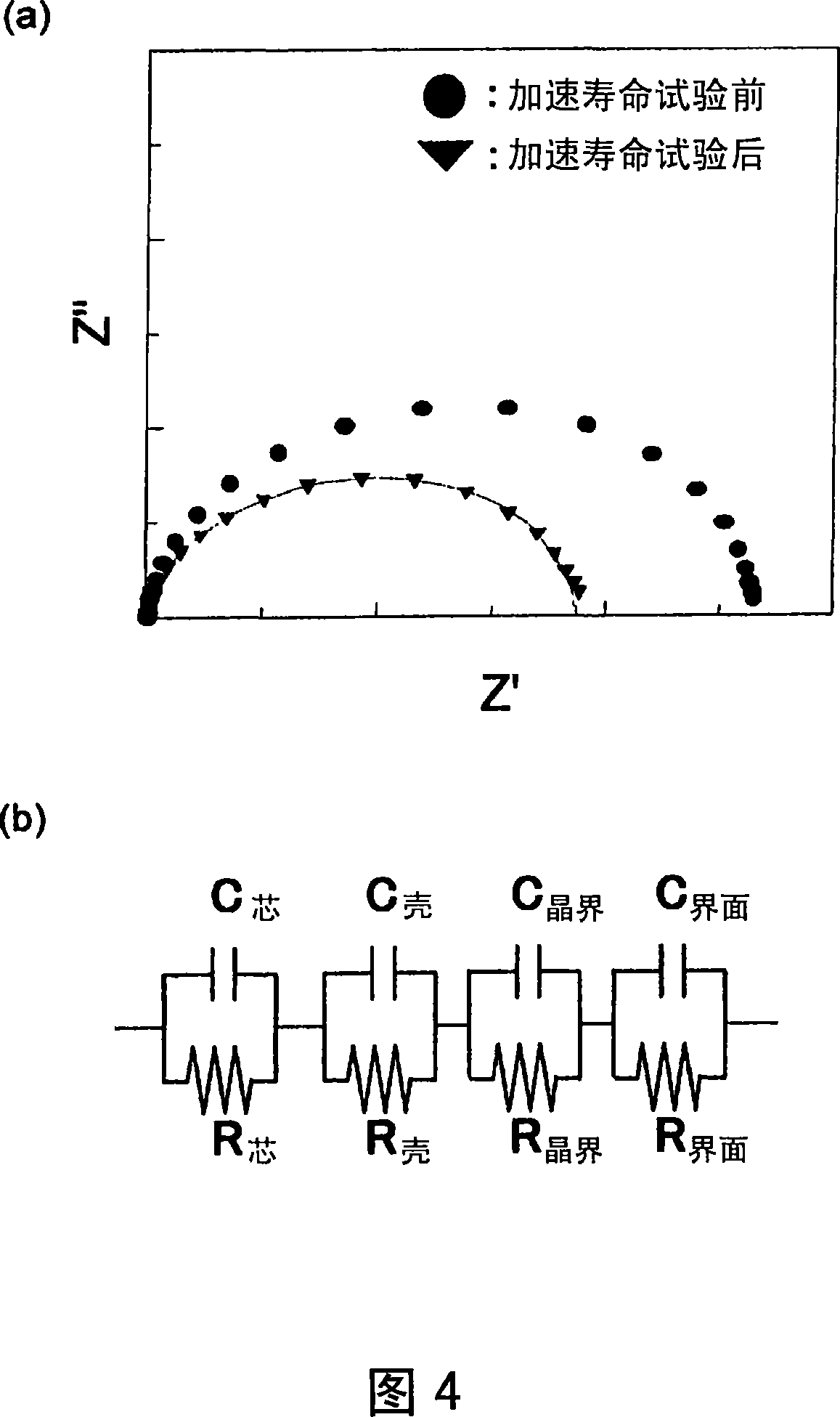

[0122] Multilayer ceramic capacitors (sample Nos. 8 to 12 in Table 2) were produced in the same manner as in Example 1 above except that barium carbonate having the specific surface area shown in Table 2 was used. Next, for the obtained multilayer ceramic capacitor, A was measured in the same manner as in Example 1. BT / A BCT , the result is 0.8~1.2. In addition, the concentration gradient has a concentration gradient of 0.05 atomic % / nm or more.

[0123] Next, for these multilayer ceramic capacitors (sample Nos. 8 to 12 in Table 2), in the same manner as in the above-mentioned Example 1, the capacitance, relative permittivity, temperature characteristics of relative permittivity, and breakdown voltage were measured. (BDV), X7R standard, high temperature load test (MTTF, impedance method), average grain size (average value, D90) and grain boundary phase evaluation (triple point grain The presence or absence of Si-Ba-O compounds on the boundary · elemental analysis on the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com