Armature for electric rotating machine and method of manufacturing same

A technology for rotating electrical machines and armatures, which is applied in the field of armatures for rotating electrical machines, and can solve problems such as the improvement of coil slot fullness rate and the reduction of eddy current loss, and the inability to insert coils into slots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

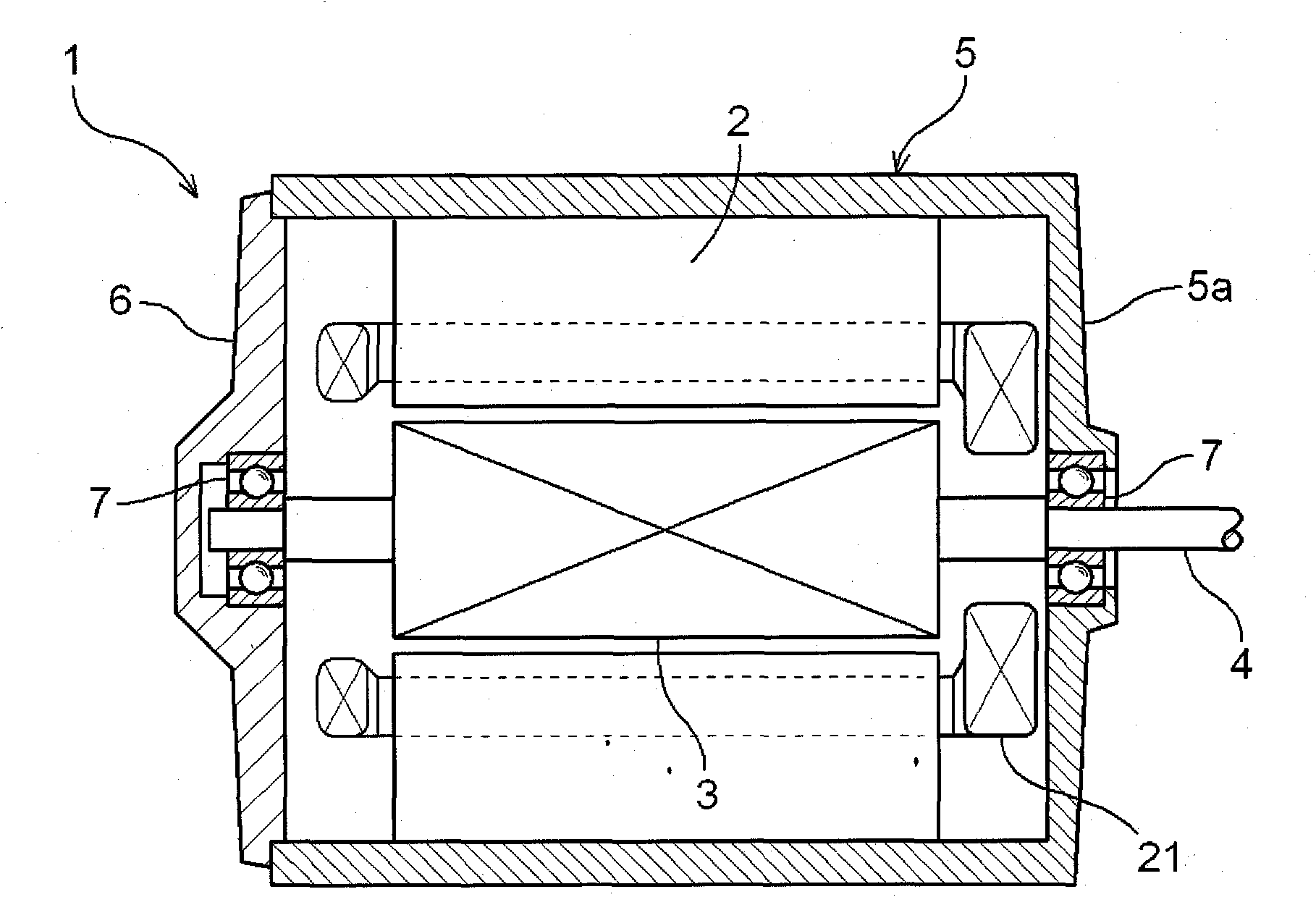

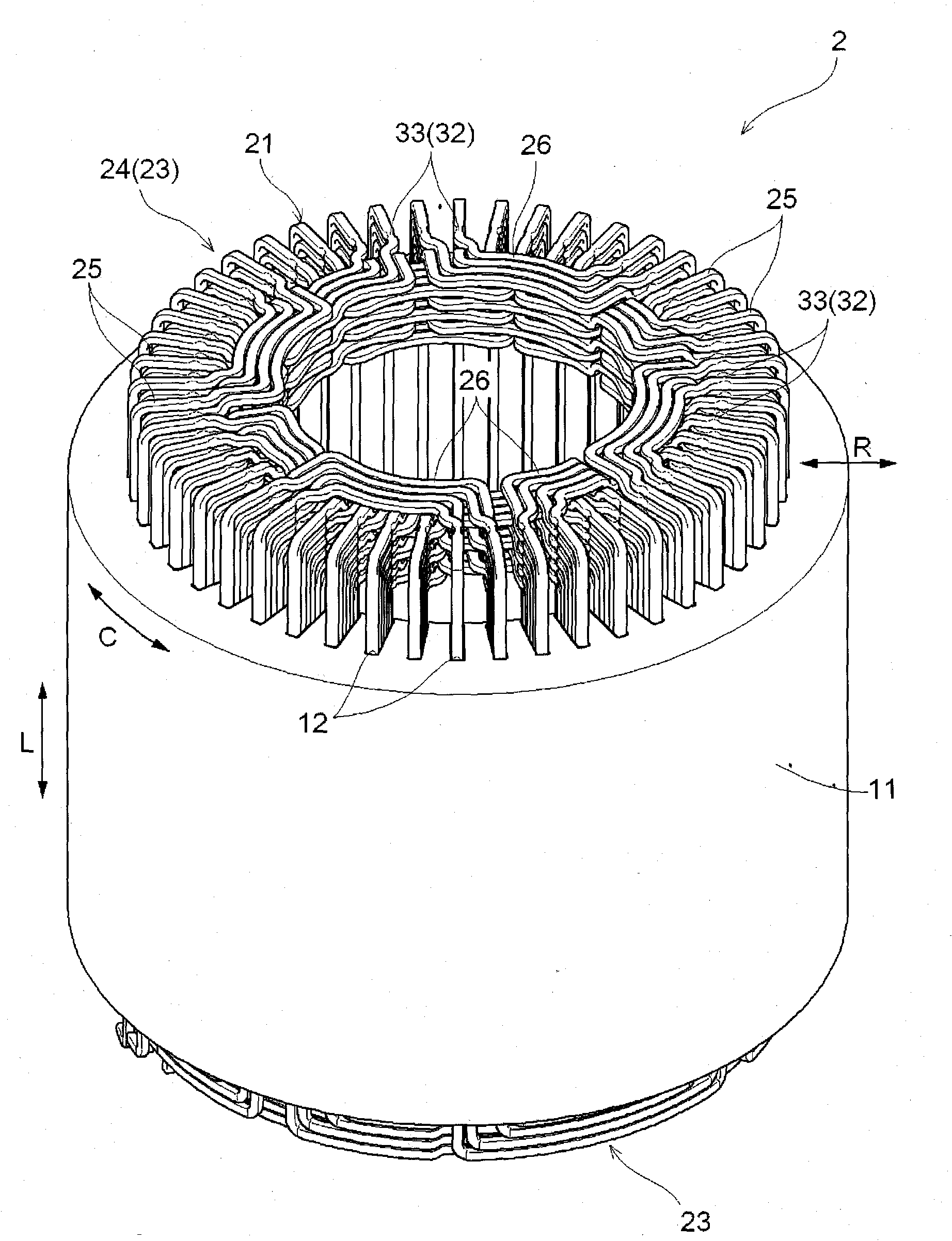

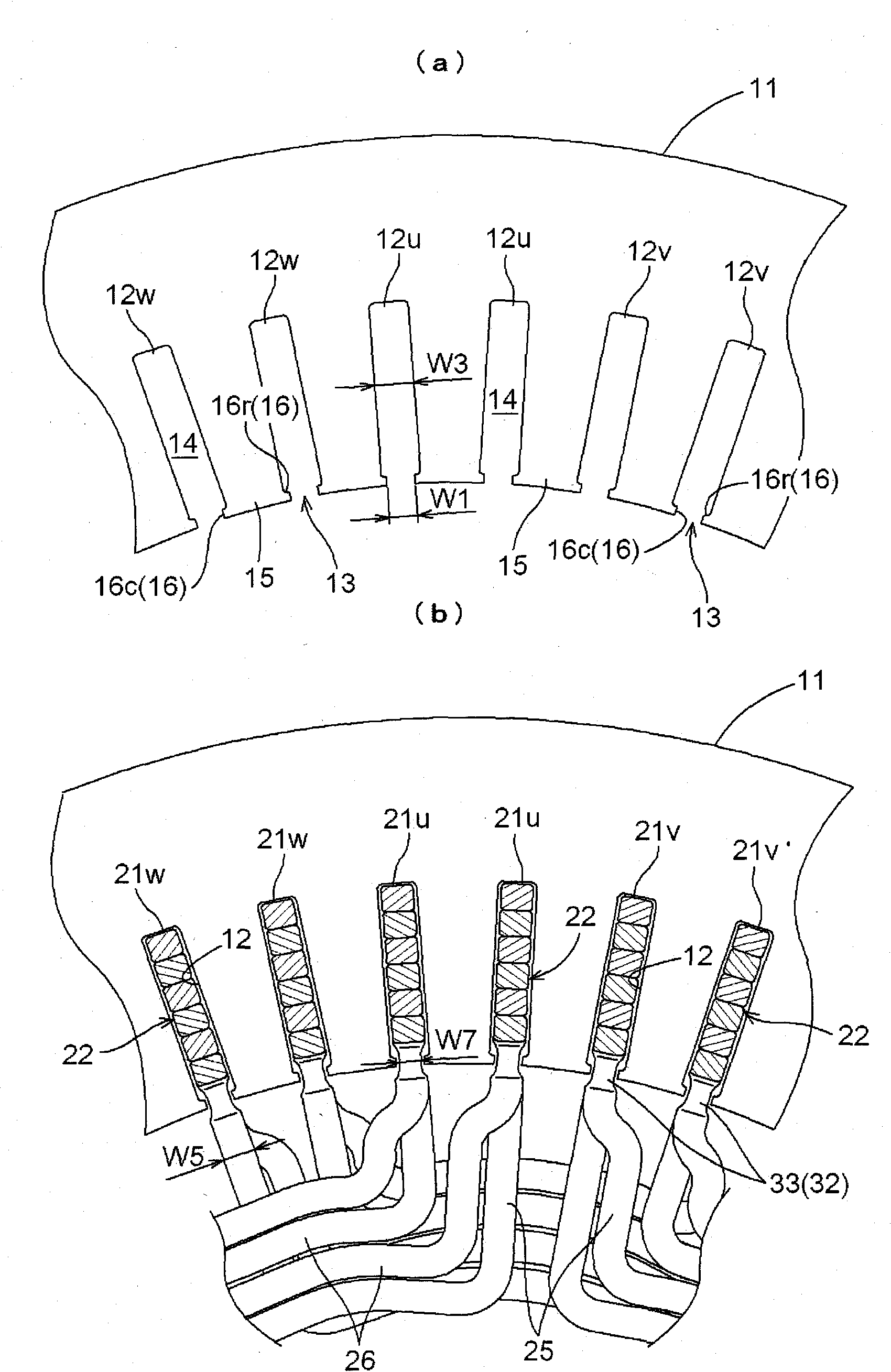

[0071] A first embodiment of an armature for a rotating electric machine according to the present invention will be described with reference to the drawings. In this embodiment, a case where the armature for a rotating electrical machine of the present invention is applied to the stator 2 of the rotating electrical machine 1 will be described as an example. figure 1 is a cross-sectional view showing the overall configuration of the rotating electric machine 1 according to the present embodiment, figure 2 It is a perspective view showing the overall structure of the stator 2 of this embodiment. The stator 2 of this embodiment is characterized by the combination of the stator core shape and the coil shape in order to improve the slot fill factor of the coil 21 in the slot 12 of the stator core 11 and reduce eddy current loss. Next, the configuration of each part of the rotary electric machine 1 will be described in detail.

[0072] 1-1. The overall configuration of the rotati...

no. 2 approach

[0114] Next, a second embodiment of the armature for a rotating electric machine according to the present invention will be described. Figure 13 It is a top view showing a part of the stator 2 of this embodiment. The stator core 11 included in the stator 2 has the same configuration as that of the above-mentioned first embodiment. However, in terms of the configuration of the coil 21 included in the stator 2 , specifically, the constricted concave portion 32 included in the coil 21 In terms of configuration, it is different from the first embodiment described above. Hereinafter, for the configuration of the armature for a rotating electrical machine according to the present embodiment, reference will be made as appropriate to Figure 13 to Figure 18 At the same time, the description will focus on the points of difference from the above-mentioned first embodiment. Moreover, it is the same as that of the said 1st Embodiment about the point which is not demonstrated especially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com