Patents

Literature

110results about How to "Ensure electrical insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soft magnetic composite powder and production method of the same, and production method of soft magnetic compact

ActiveCN1830043AAvoid direct contactReduce frictionInorganic material magnetismInductances/transformers/magnets manufactureMetallurgyMagnetic characteristic

A soft magnetic compact which is produced by using soft magnetic composite powder in which the surface of magnetic powder is covered with an electrical insulating material containing at least an inorganic insulating material, and a resin material is fusion-bonded to the surface of the inorganic insulating material so as to partially cover the surface of the soft magnetic powder. Accordingly, it is possible to ensure an electrical insulating property between pieces of soft magnetic material powder to secure a good magnetic characteristics and to easily mold a compact.

Owner:NTN CORP

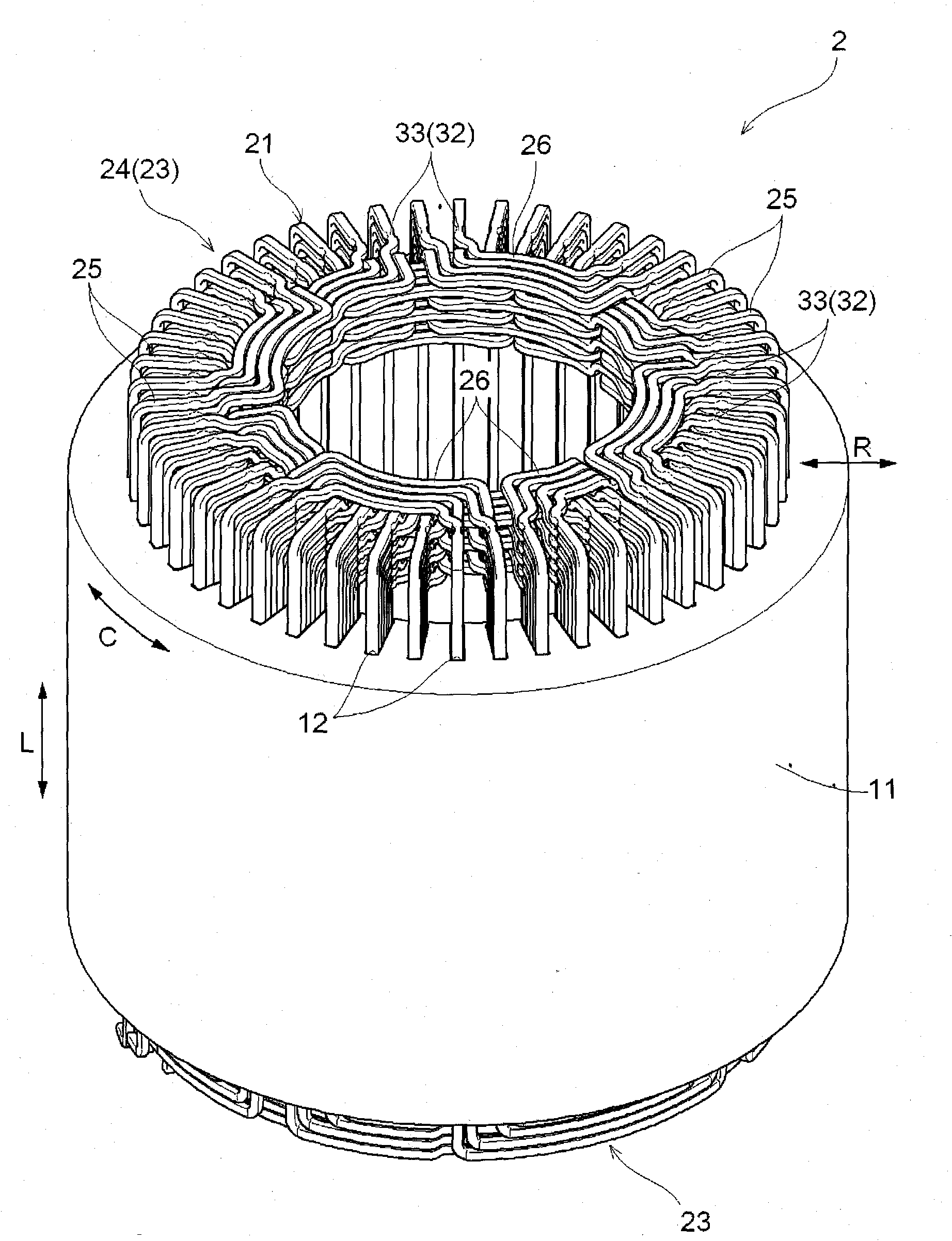

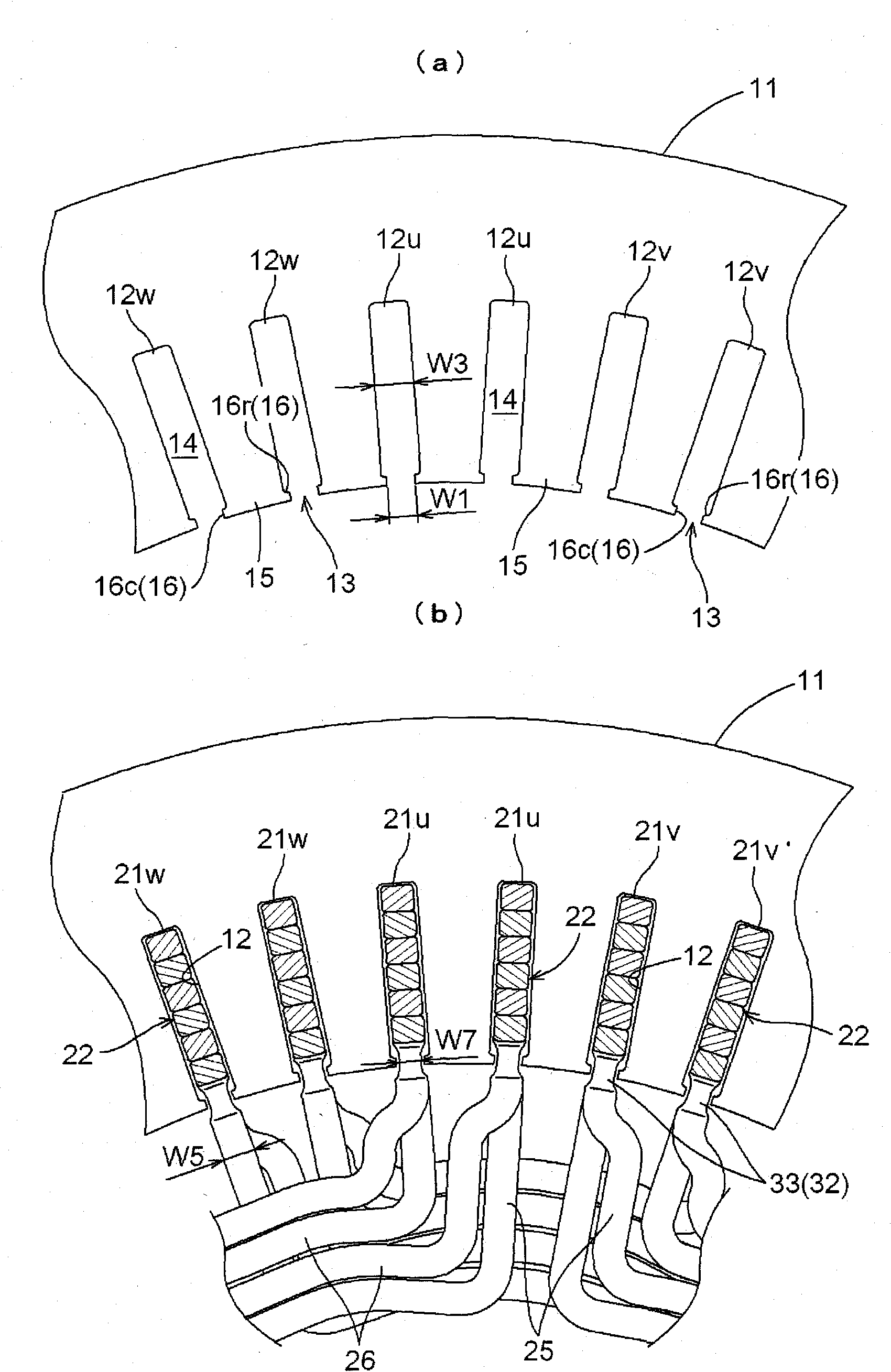

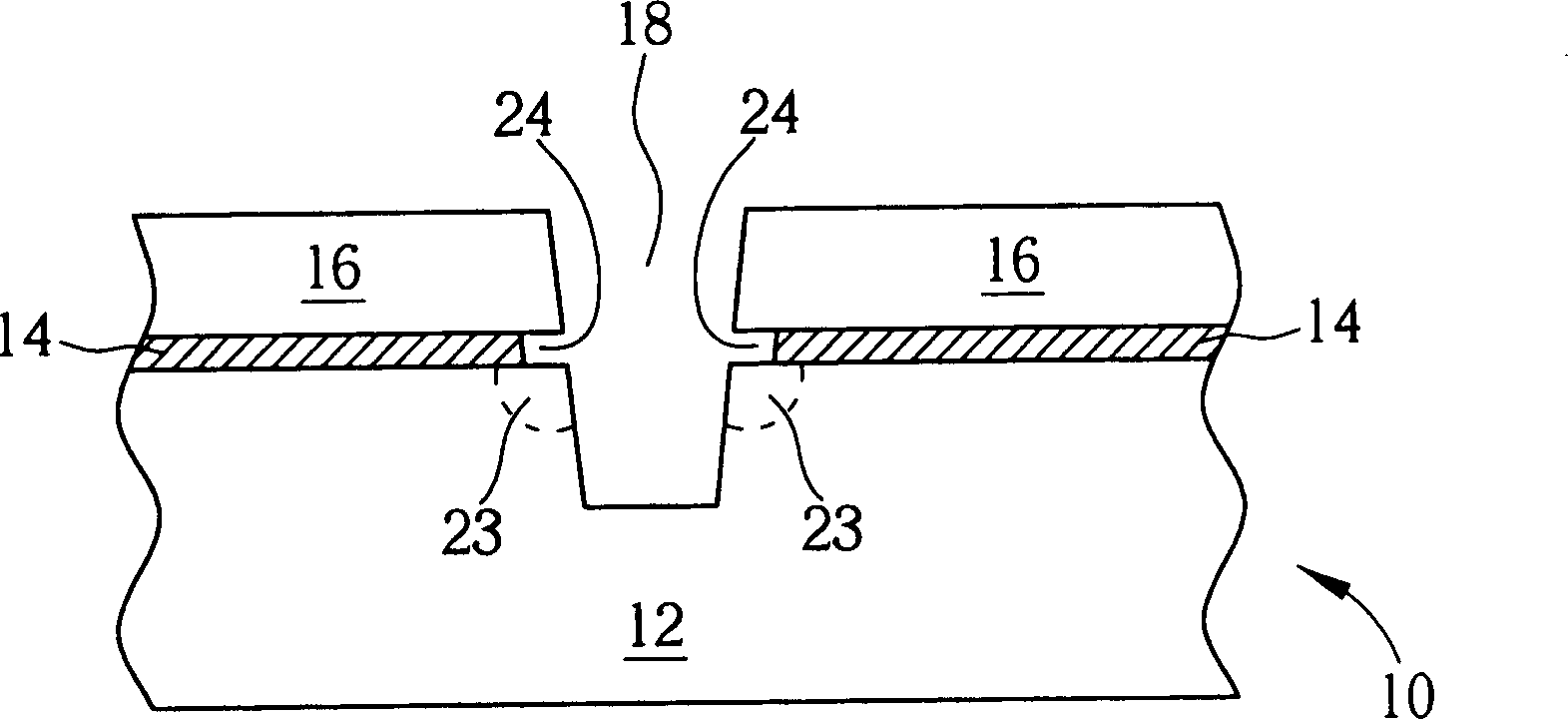

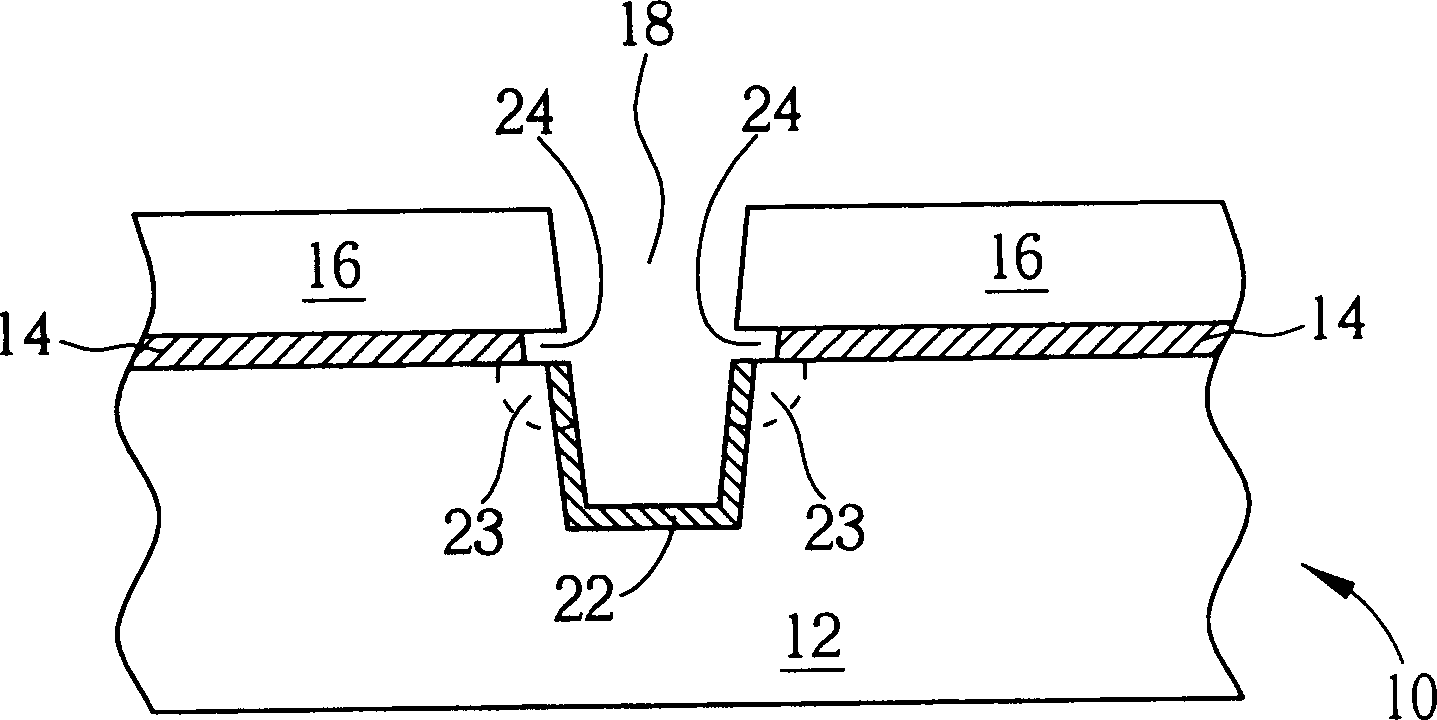

Armature for electric rotating machine and method of manufacturing same

InactiveCN102160266AReduced insulation performanceReduce stressWindings insulation shape/form/constructionEmbedding prefabricated windingsElectrical conductorElectric machine

Provided is an armature for an electric rotating machine wherein the eddy current loss can be reduced while enhancing the space factor of coil. The present invention relates to an armature (2) for an electric rotating machine including a cylindrical core (11) where a plurality of slots (12) extending in the axial direction are positioned in a dispersion manner in the circumferential direction, and a coil (21) wound in the slots (12) each of which is formed in such a manner that the circumferential width of the inner circumferential opening of the slot (12) is narrower than the inner circumferential width of the slot, the circumferential width of a linear conductor constituting the coil is wider than the circumferential width of the inner circumferential opening, the coil end (23) of the coil (21) on one side in the axial direction thereof is a bent coil end (24); which is bent radially inward and provided with a radial conductor (25), and at a radial position in the radial conductor (25) corresponding to the inner circumferential opening, a narrow recess (32) which is recessed for other portion of the radial conductor (25) is provided so that the circumferential width becomes narrower than that of the inner circumferential opening.

Owner:AISIN AW CO LTD

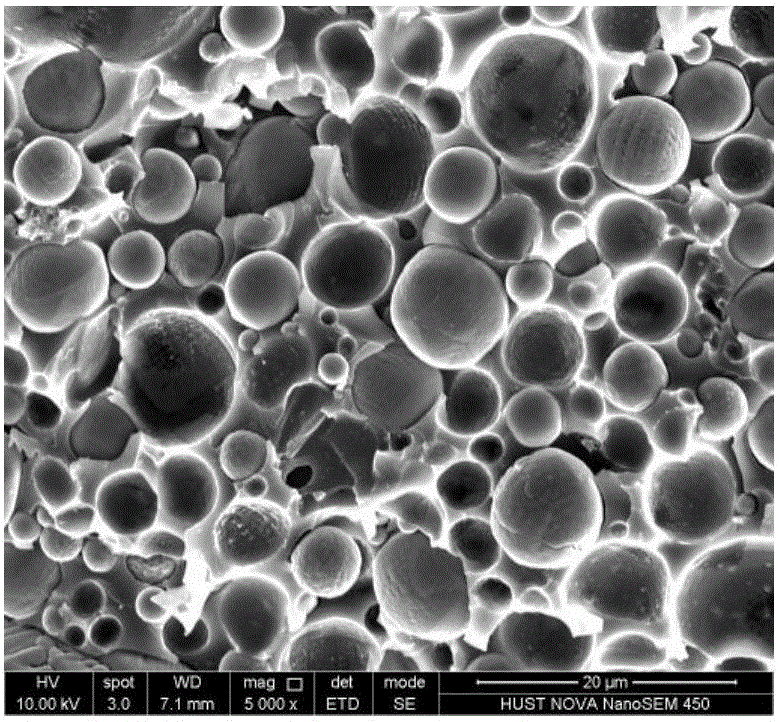

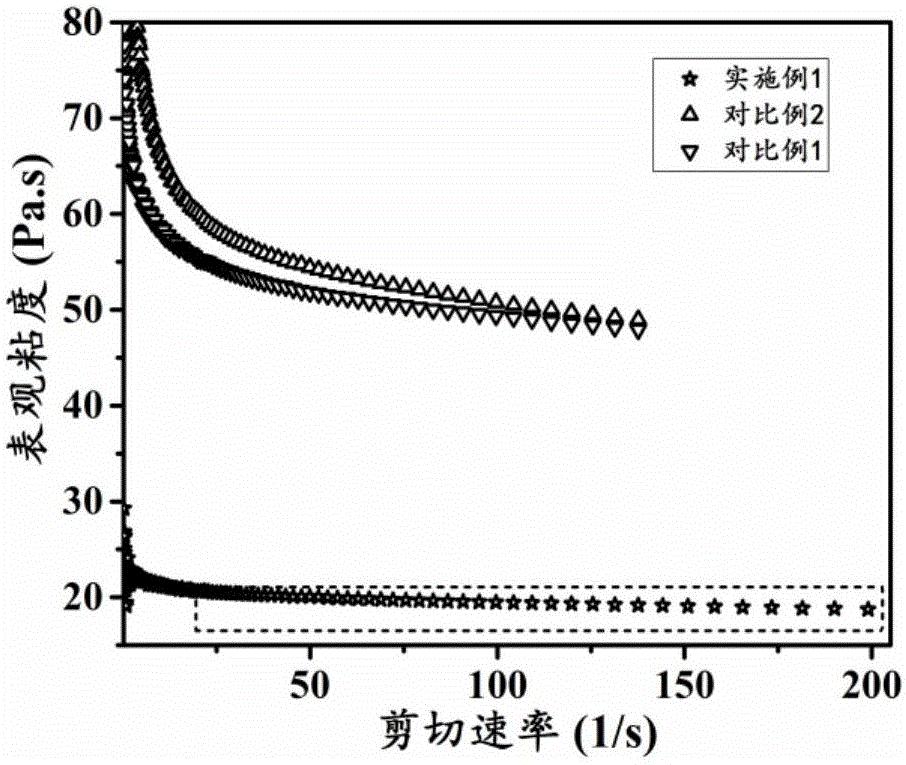

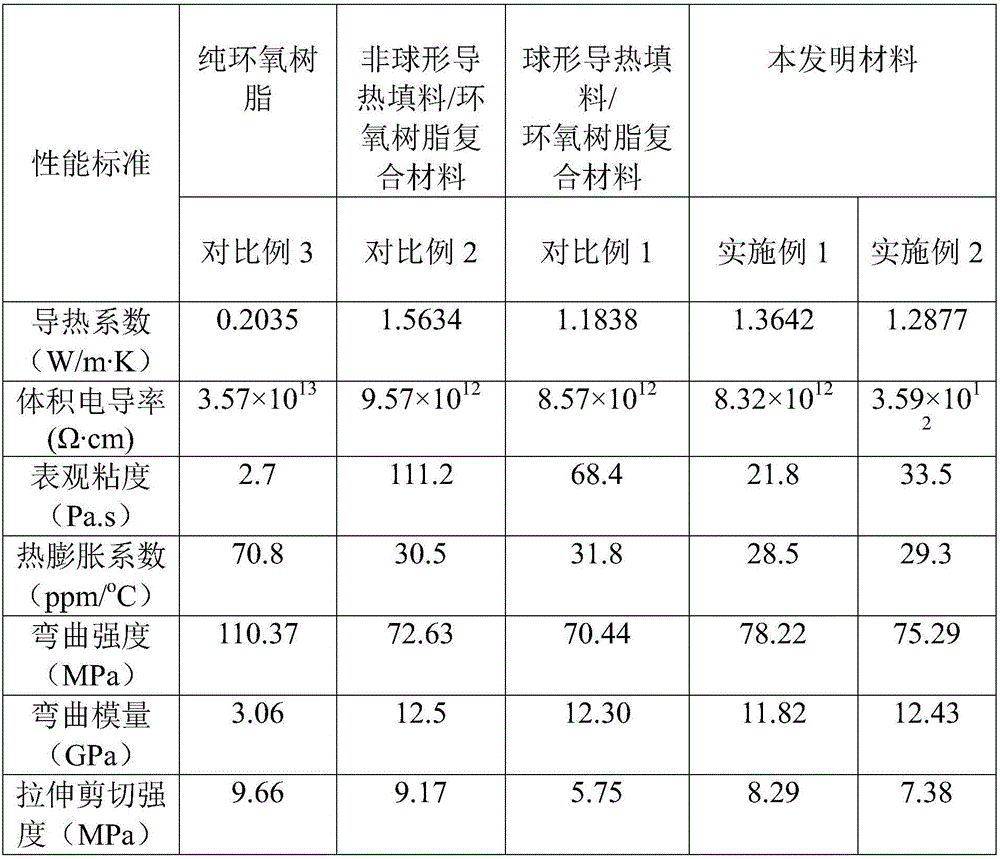

High-heat-conductivity low-viscosity epoxy resin composite, and preparation method and application thereof

ActiveCN106519581AImprove flow propertiesIncrease filling volumeFilling materialsEpoxy resin composite

The invention discloses a high-heat-conductivity low-viscosity epoxy resin composite, and a preparation method thereof. The epoxy resin composite comprises, by volume, 25 to 60 parts of a first spherical heat-conducting filling material, 5 to 30 parts of a second spherical heat-conducting filling material and 30 to 70 parts of epoxy resin, wherein the median particle diameter of the first spherical heat-conducting filling material is no less than 30 [mu]m, and the median particle diameter of the second spherical heat-conducting filling material is no more than 20 [mu]m. The preparation method comprises the following steps: (1) subjecting the spherical heat-conducting filling materials to vacuum drying, then successively adding epoxy resin, a curing agent and the spherical heat-conducting filling materials into a planetary centrifugal mixer and carrying out mixing and defoaming; and (2) carrying out vacuum pumping and bubble removing and then carrying out curing molding. The invention has the advantages that the spherical heat-conducting filling materials with different particle sizes and proportions are used for compounding with the epoxy resin, so the filling density of the filling materials is improved, friction between the filling materials and between the filling materials and a matrix is reduced, and the processing flowing performance of the composite is obviously improved.

Owner:HUAZHONG UNIV OF SCI & TECH

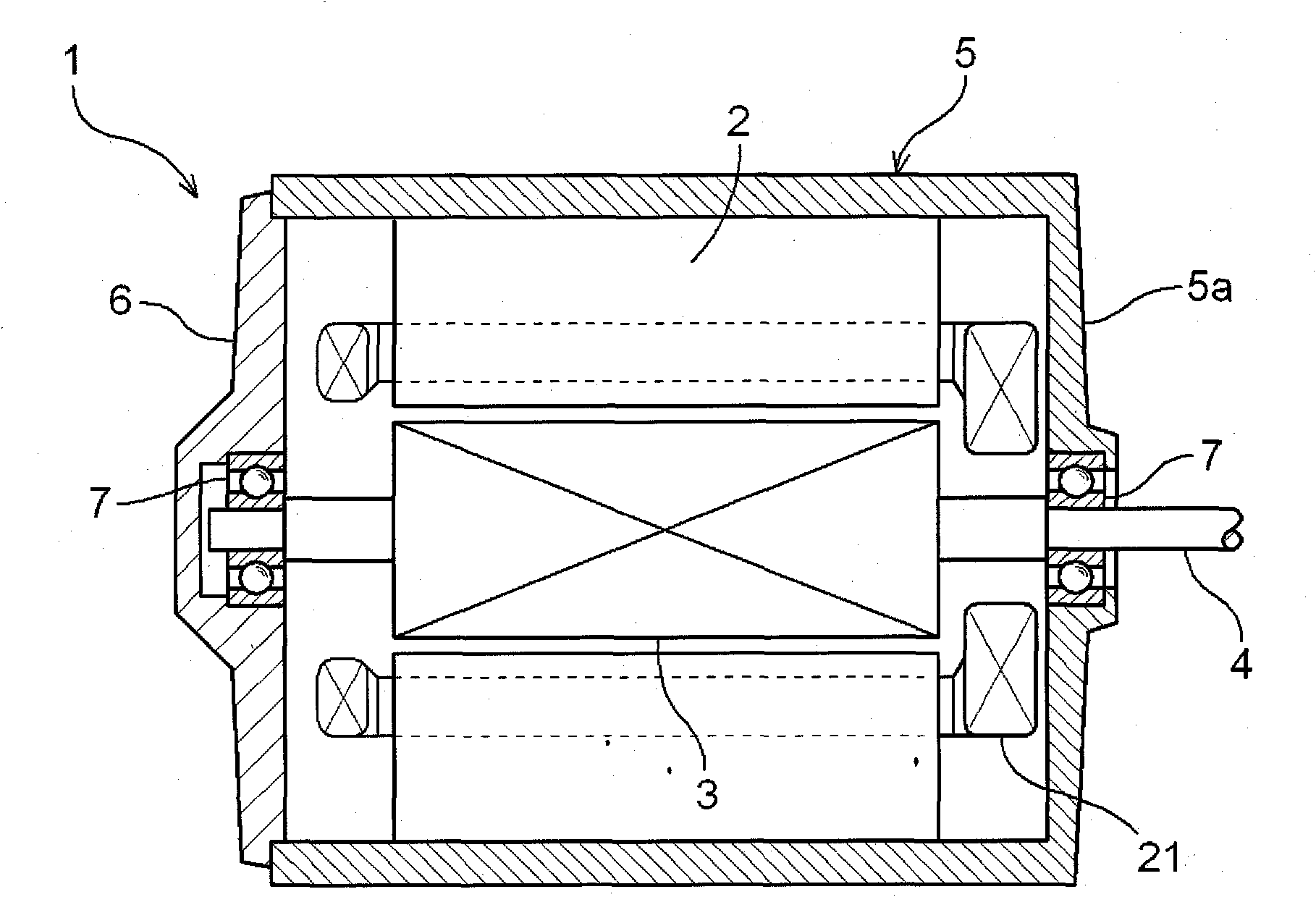

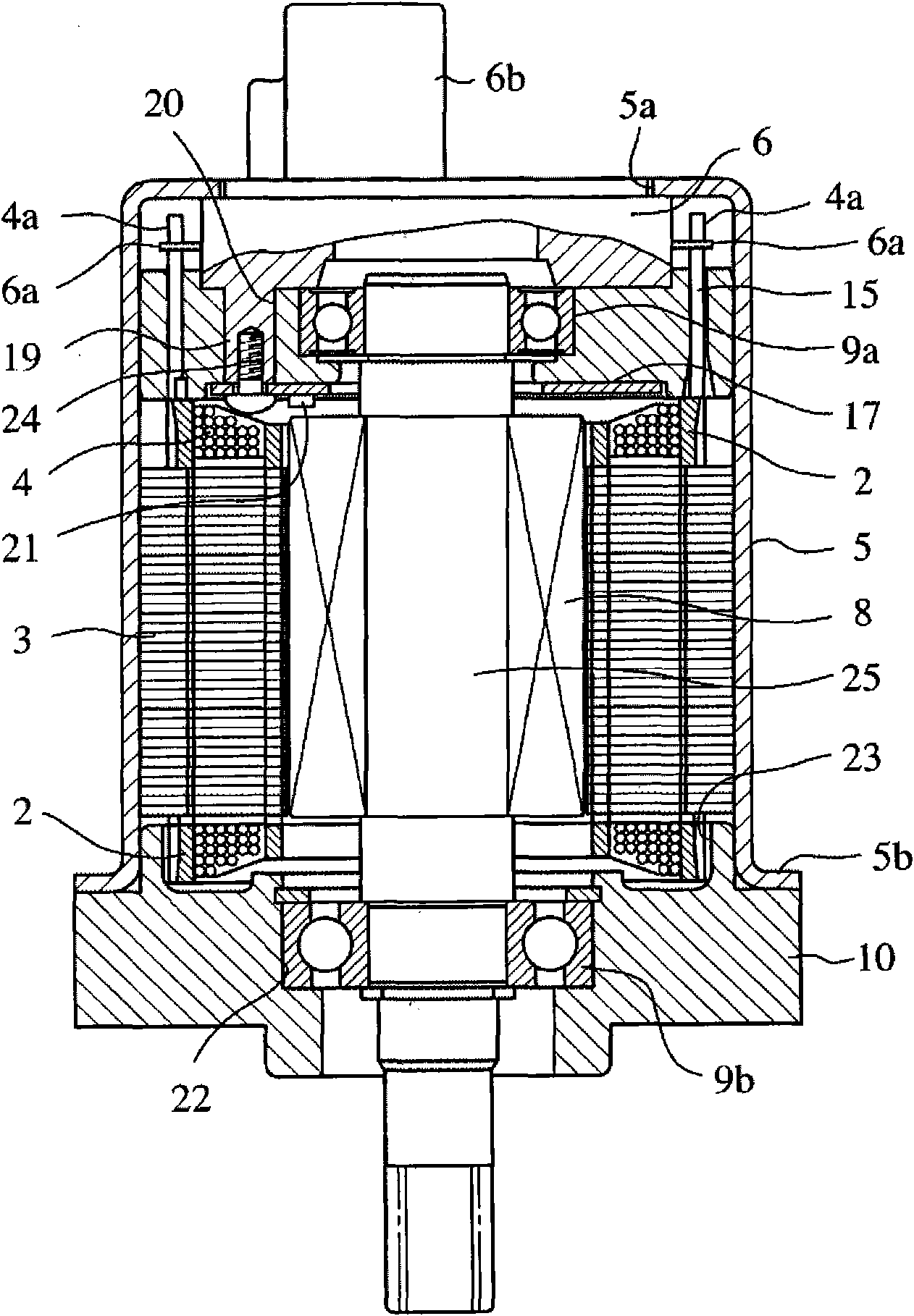

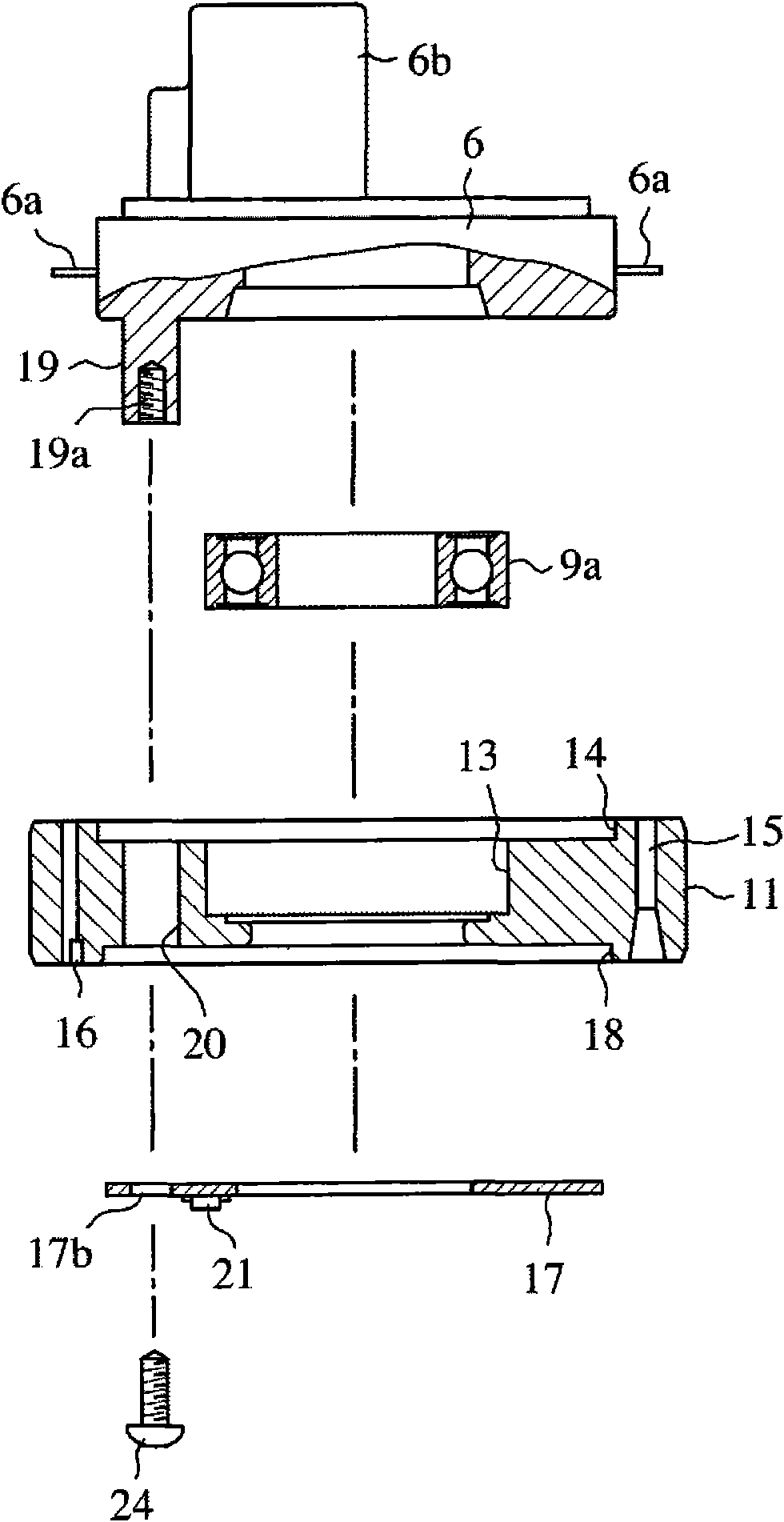

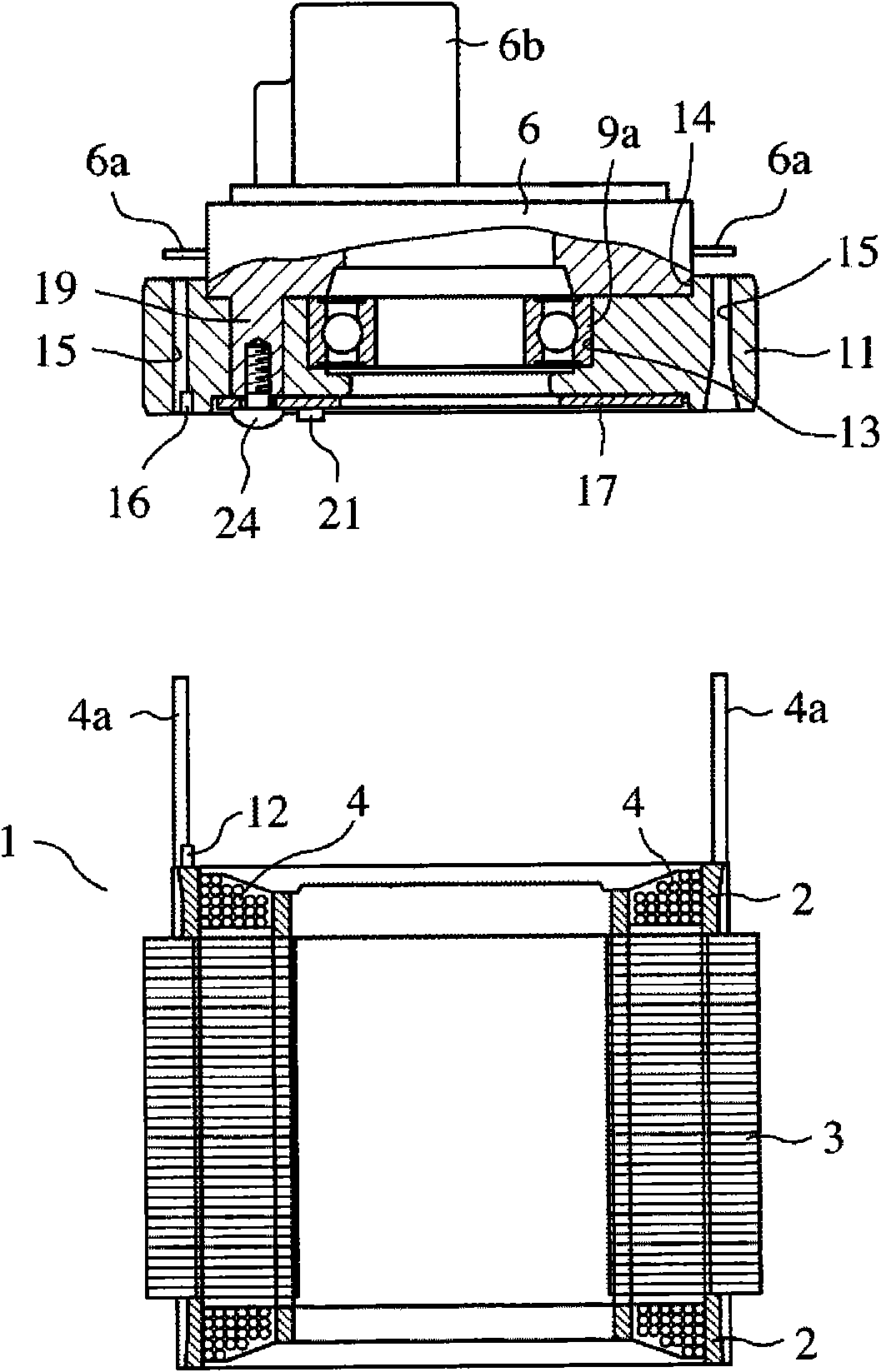

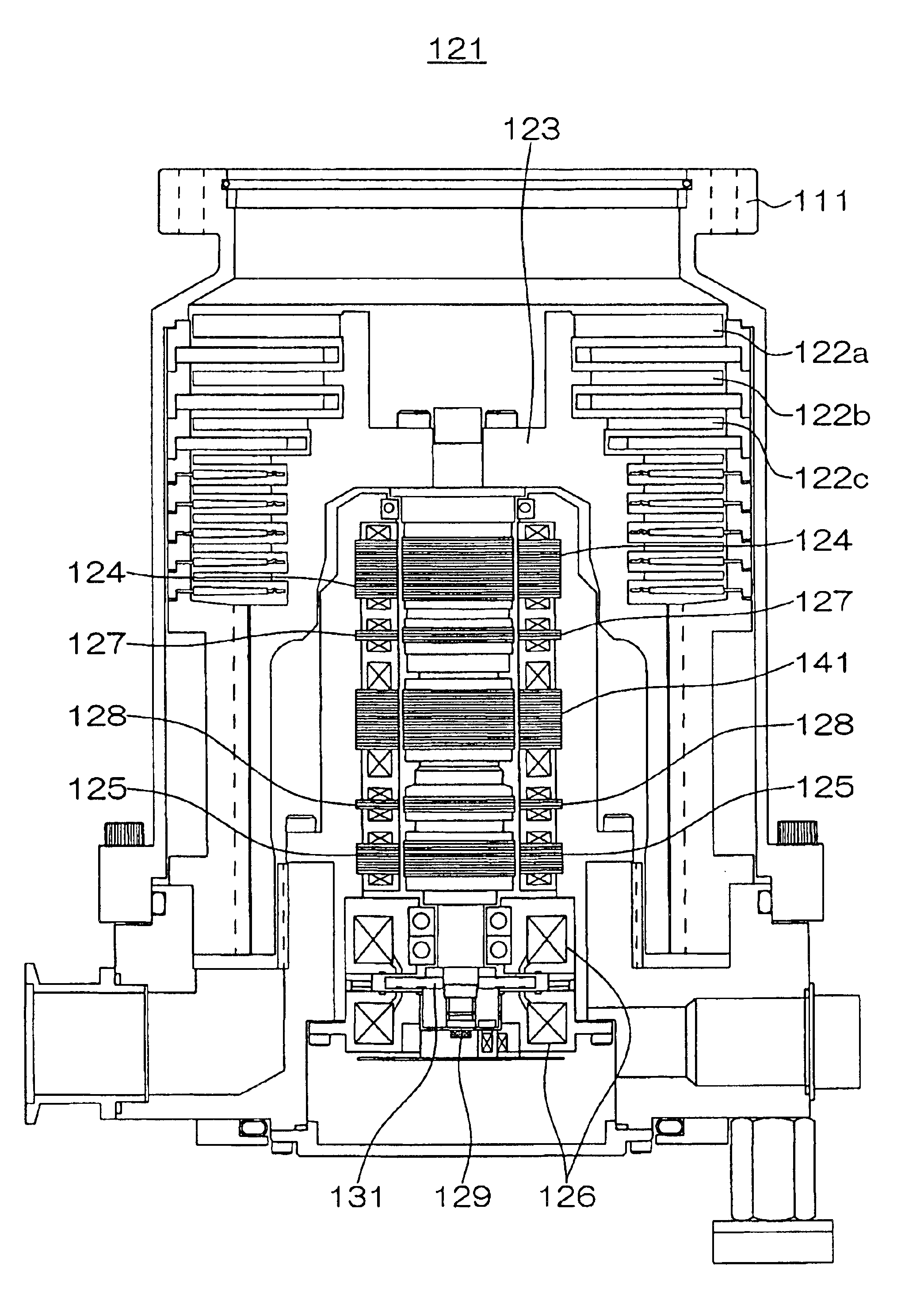

Brushless motor

InactiveCN101682246AEnsure electrical insulationHigh positioning accuracyWindingsCentering/balancing rotorsBrushless motorsMagnetic poles

In a brushless motor comprising an external stator constituted by electrically forming a magnetic circuit by winding wire on a core, a bus bar forming an external input terminal by tying the wound wire together, and an internal rotor integrated with a permanent magnet and rotatably supported to the external stator through bearings, an insulating plate is held at one end side of the external stator, and a magnetic pole sensor for detecting the magnetic pole of the permanent magnet is attached to the insulating plate.

Owner:MITSUBISHI ELECTRIC CORP

Anti-icing coating for surface of ultra-high voltage transmission line

The invention discloses anti-icing coating for the surface of an ultra-high voltage transmission line. The anti-icing coating for the surface of the ultra-high voltage transmission line is prepared from the following raw materials in parts by weight: 45-60 parts of fluorosilicon resin, 5-10 parts of functional nano ions, 5-8 parts of TiO2, 8-12 parts of nano SiO2, 0.5-1 part of an emulsifying agent, 0.5-1 part of a defoaming agent, 0.3-1 part of a flatting agent, 1-2 parts of a silane coupling agent and 20-30 parts of a solvent. The prepared anti-icing coating for the surface of the ultra-high voltage transmission line has the advantages that a contact angle with water is 128-168 degrees; compared with the condition that no anti-icing coating is coated, vertical adhesive force between a coating coated with the anti-icing coating and ice is reduced by 76-91.5%; and the anti-icing coating for the surface of the ultra-high voltage transmission line has good electric heating effect, average temperature rise is 10.8-16.5 DEG C, and the anti-icing coating for the surface of the ultra-high voltage transmission line also has good acid resistance, alkali resistance and insulating properties.

Owner:STATE GRID CORP OF CHINA +1

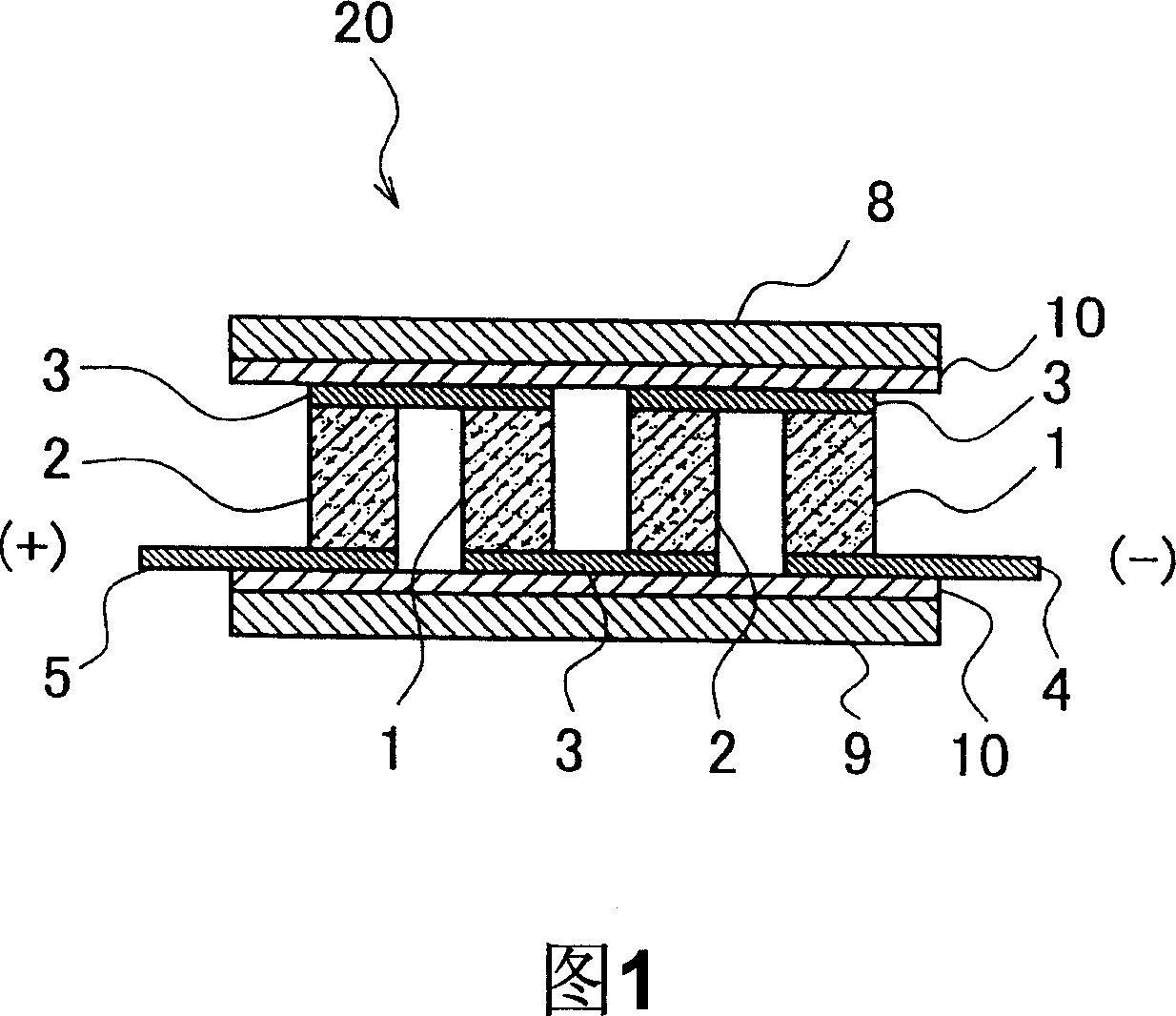

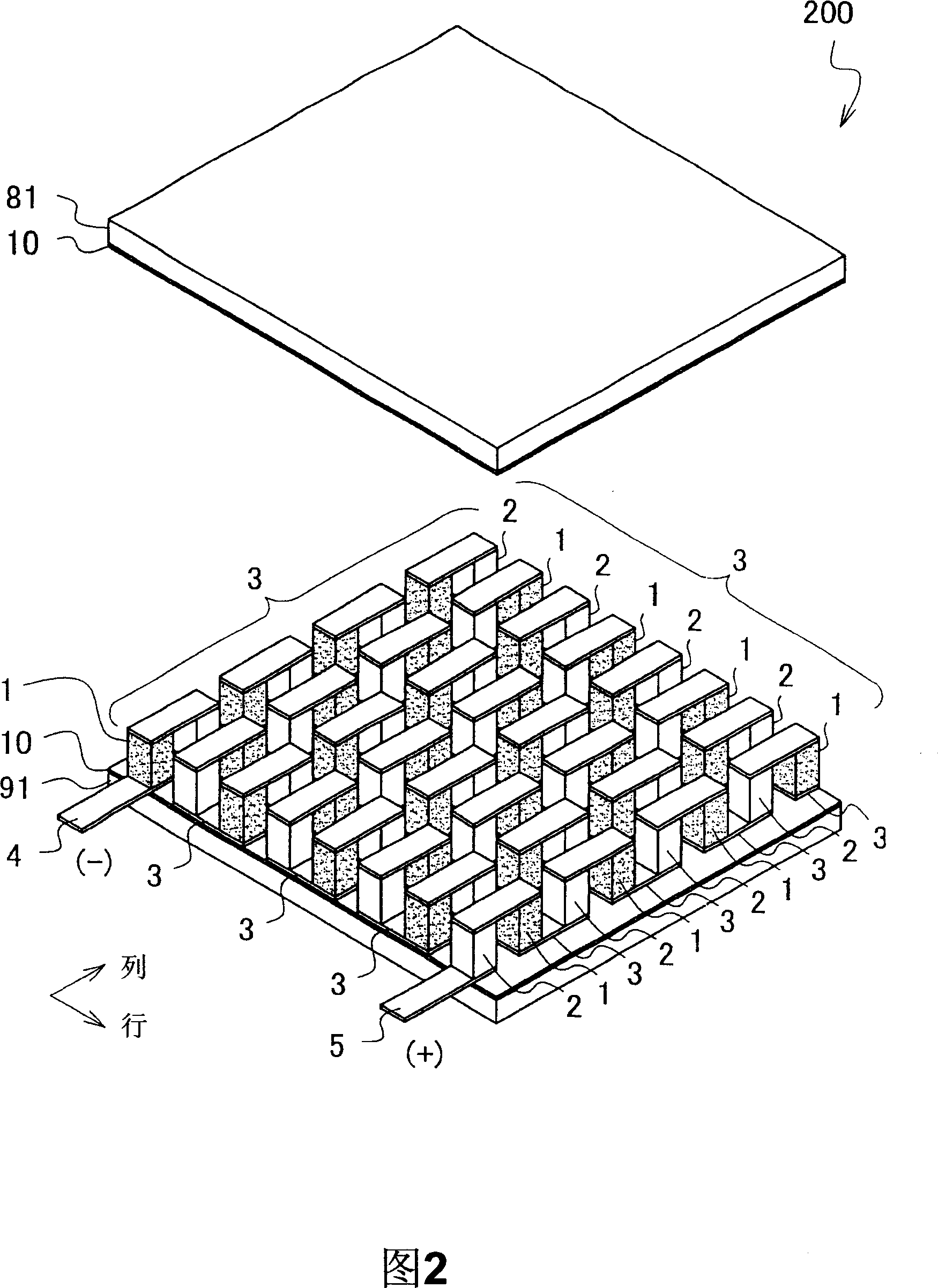

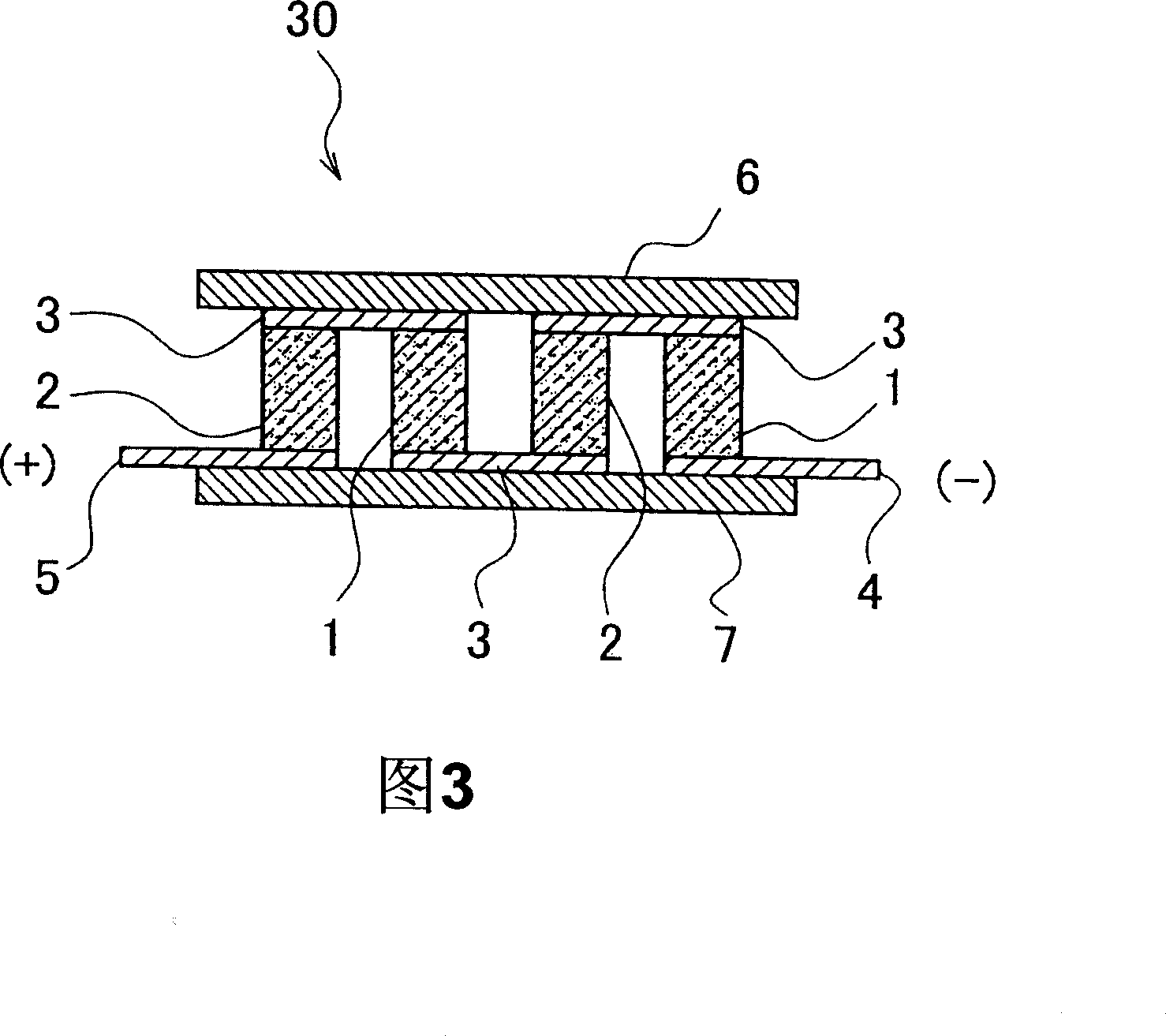

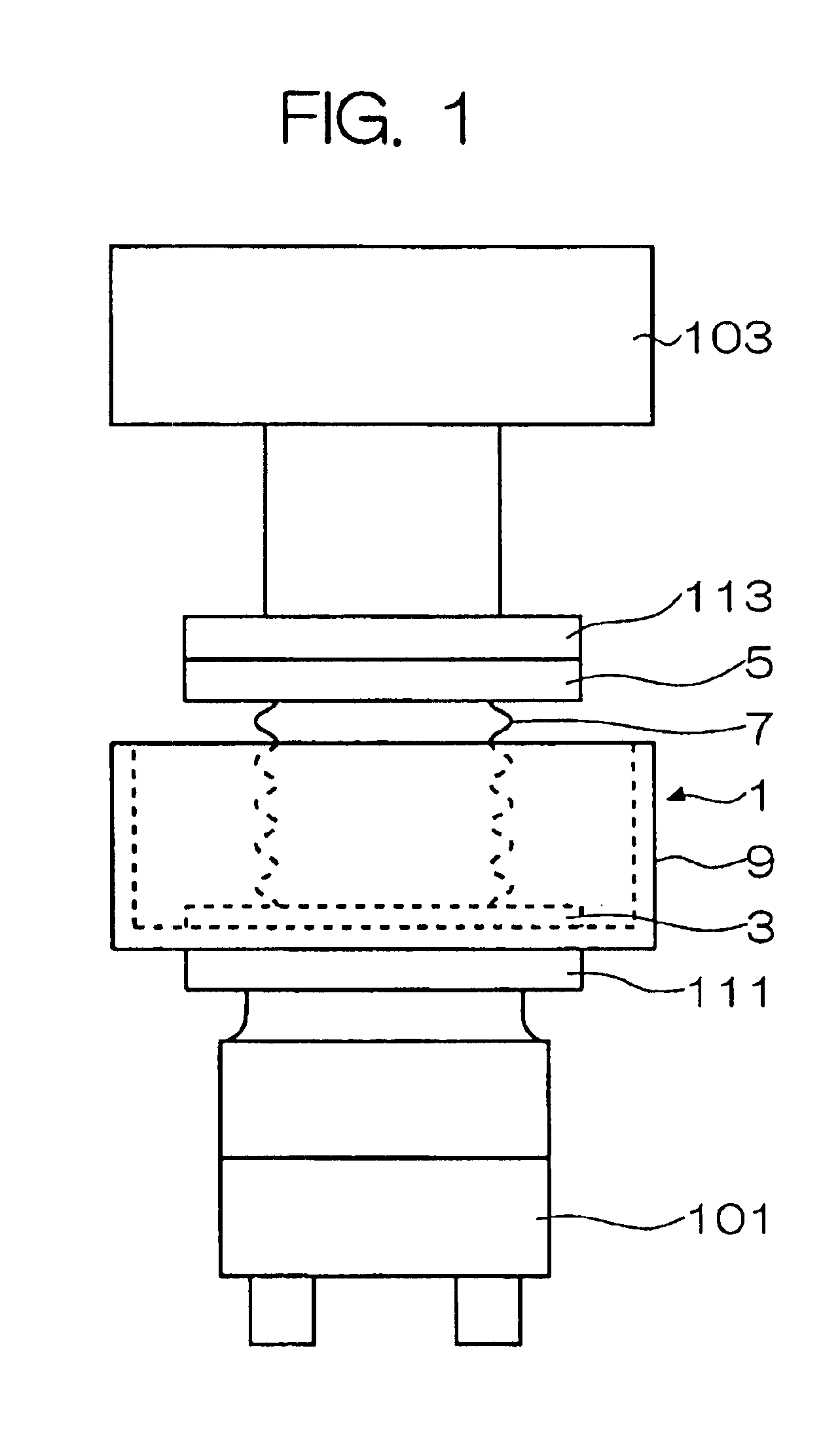

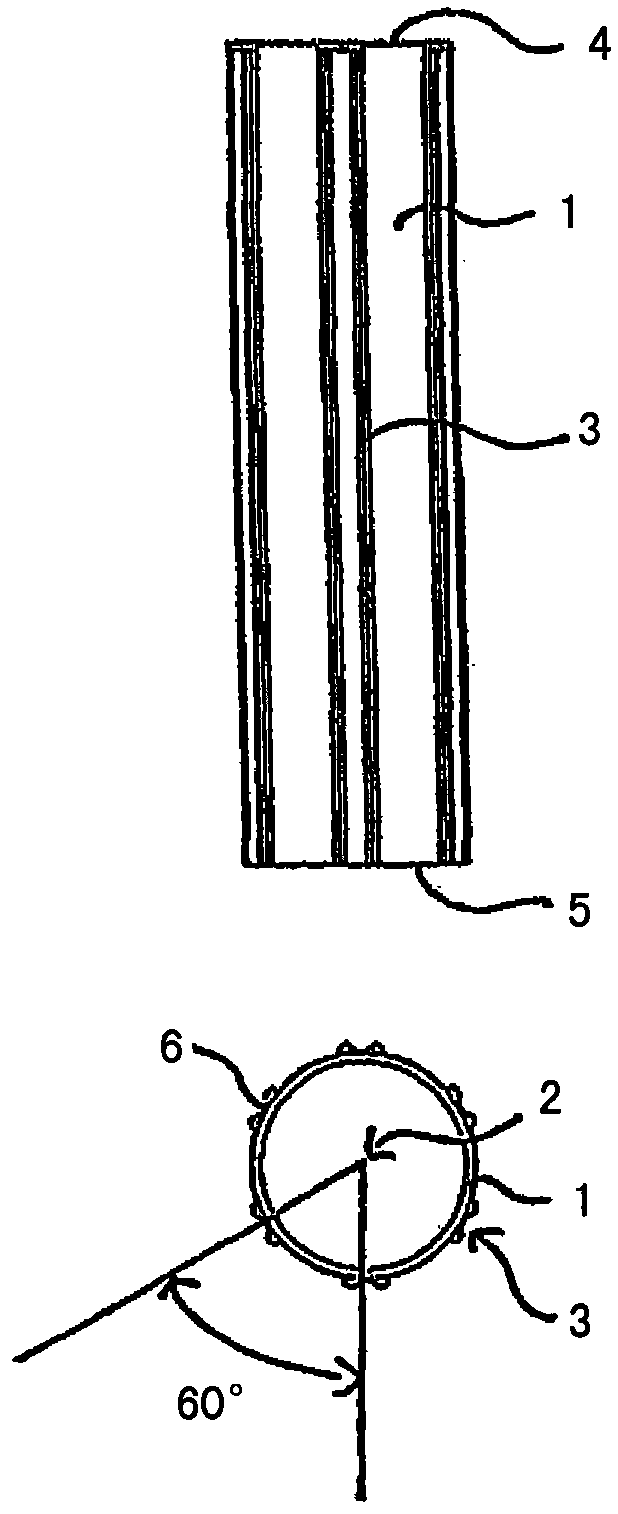

Thermoelectric conversion module

InactiveCN1969398AEnsure electrical insulationThermoelectric device with peltier/seeback effectGenerators/motorsThermoelectric conversionSemiconductor

A thermoelectric conversion module comprising an inexpensive good thermal conductivity substrate in which electric insulation is secured between the good thermal conductivity substrate and an electrode. A thermoelectric conversion element consists of a P type semiconductor (1) and an N type semiconductor (2) connected in a shape of pi. Electrodes (3-5) are connected with the both end faces of the thermoelectric conversion element. Good thermal conductivity substrates (8, 9) abut against the electrodes (3-5). The good thermal conductivity substrates (8, 9) are composed of aluminium or an aluminium alloy and an anodic oxidation film (10) is provided between the good thermal conductivity substrates (8, 9) and the electrodes (3-5). The thermoelectric conversion module (20) comprises the good thermal conductivity substrates (8, 9) composed of inexpensive aluminium or aluminium alloy and can secure electric insulation between the anodic oxidation film (10) and the good thermal conductivity substrate.

Owner:UNIVERSAL ENTERTAINMENT CORP

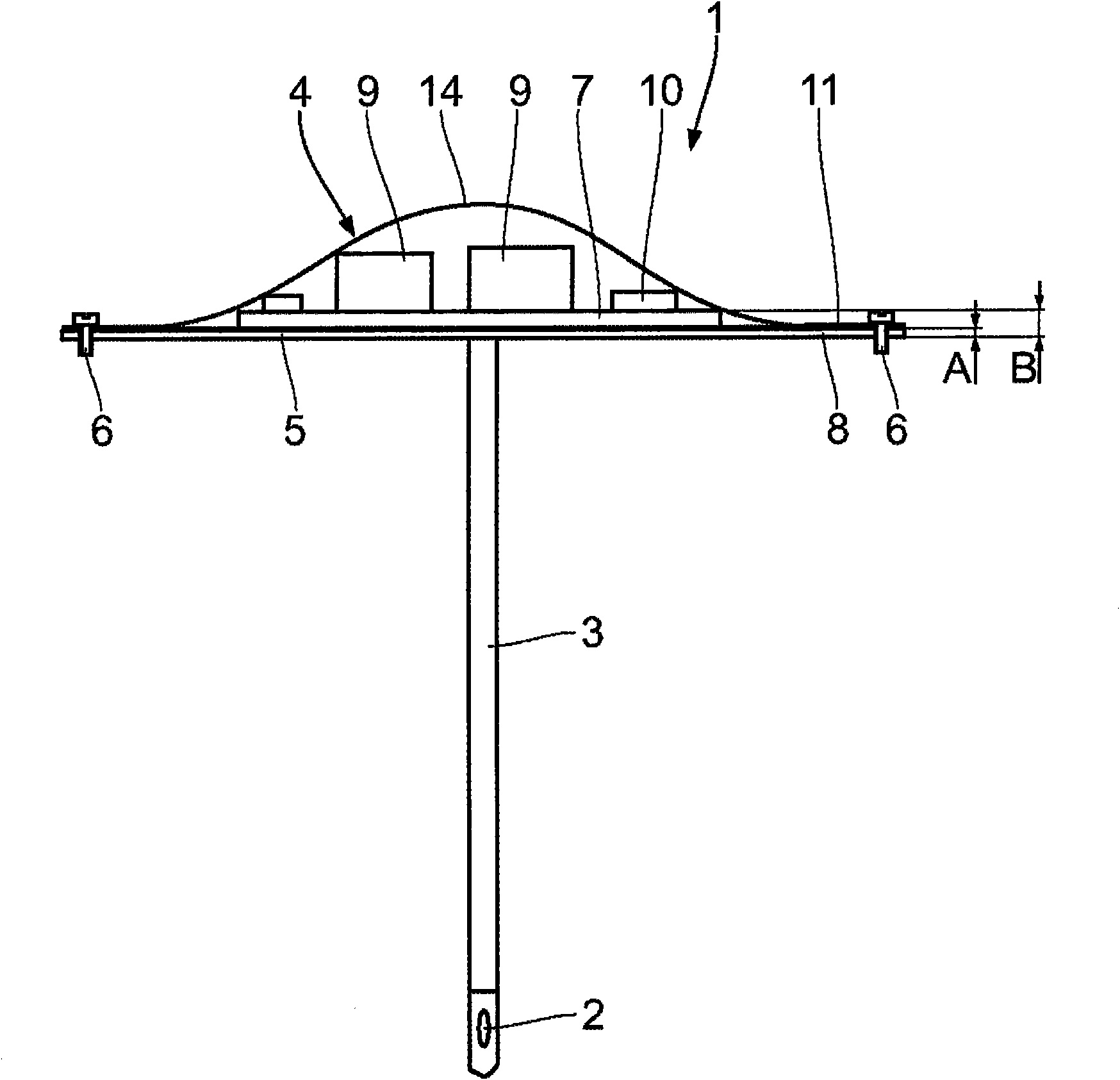

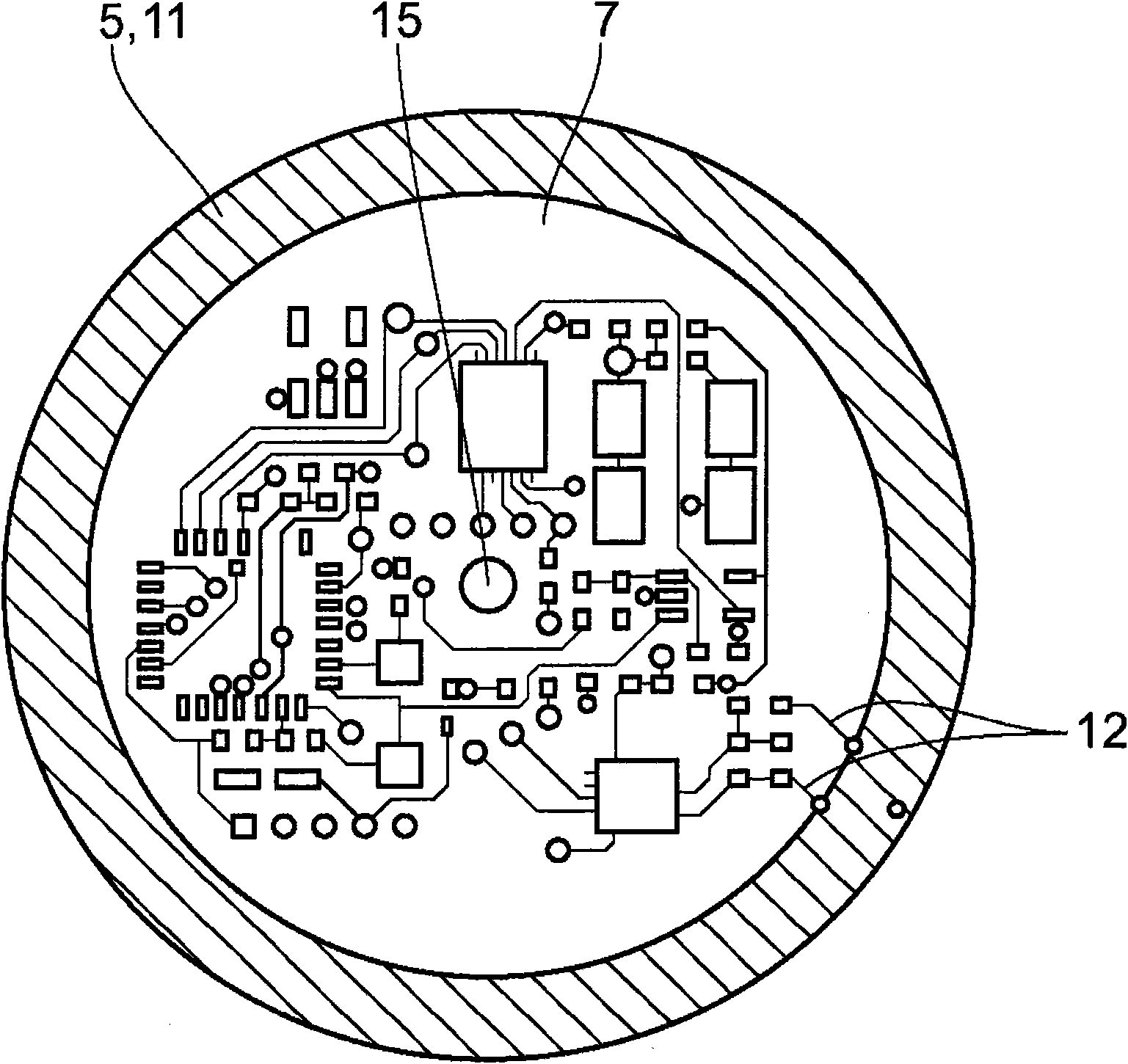

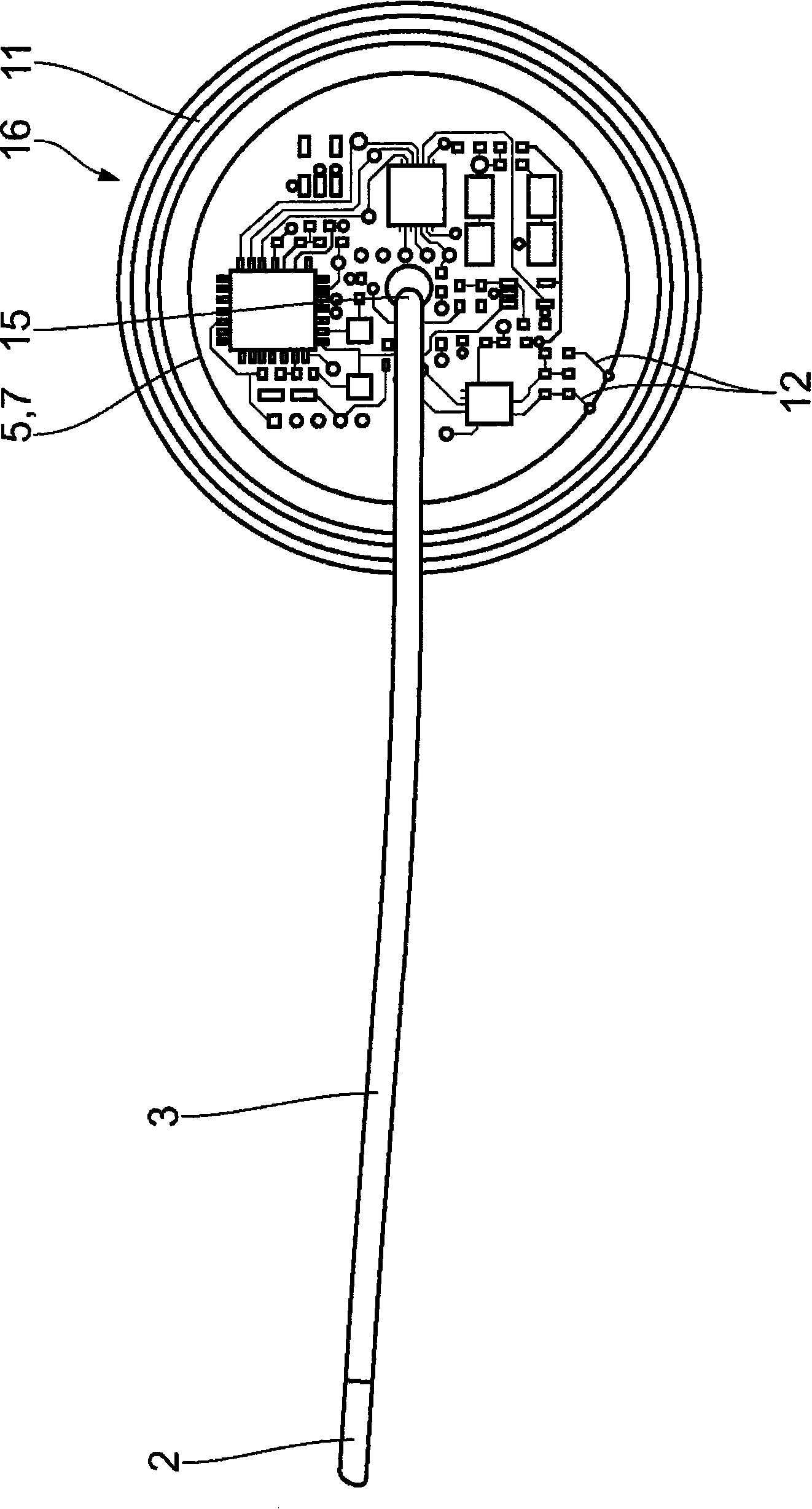

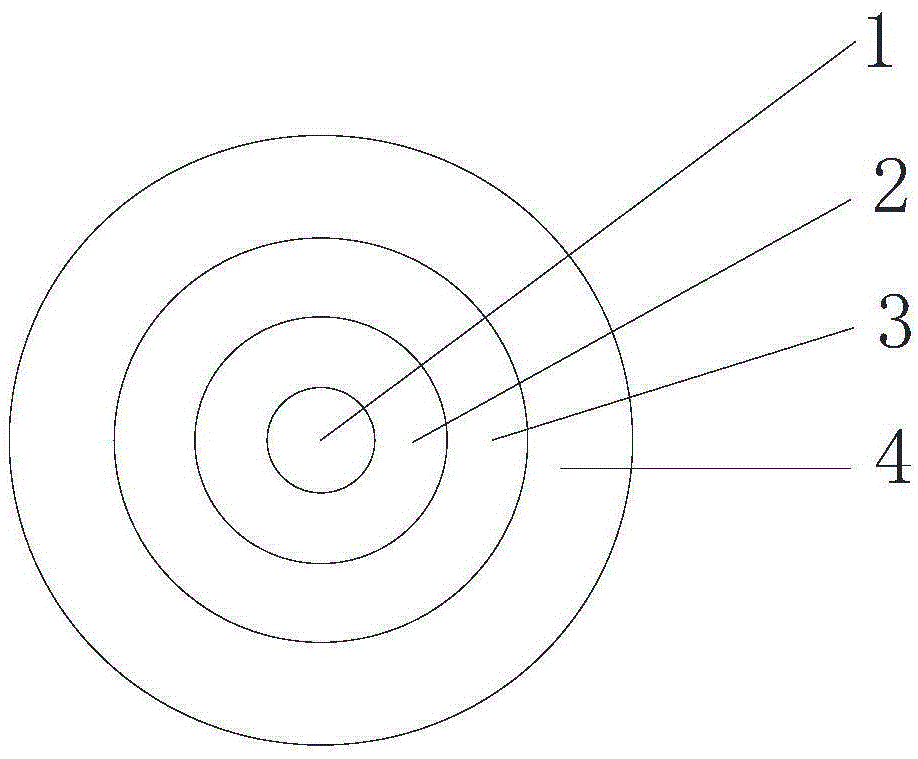

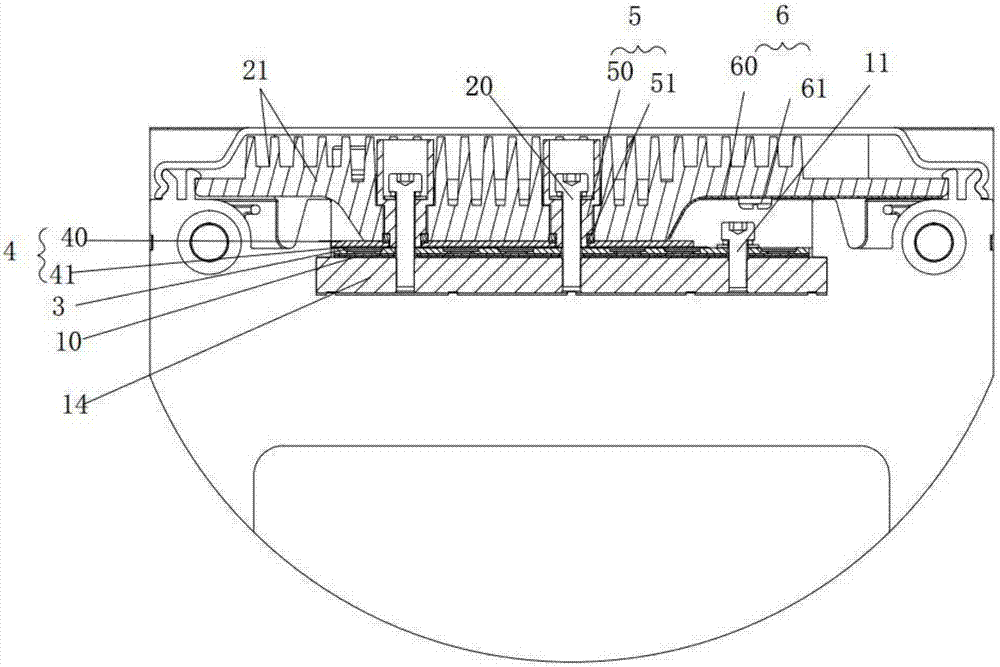

Patient data sensor device

ActiveCN101959448AEnhanced couplingGood adhesionPrinted electric component incorporationPrinted circuit aspectsExternal dataPatient data

The invention relates to a patient data sensor device (1), having an implantable patient data sensor (2) and an implantable data transmission apparatus (4), which is in signal connection to the patient data sensor (2). The data transmission apparatus (4) has an antenna (11) for the telemetric data transmission to an external data processing unit. The data transmission apparatus (4) further comprises a support plate (5, 7) for electronic components (9, 10). The latter are covered on the support plate (5, 7) by a cover (14), at least toward one side. The antenna (11) is configured in an edge region (8) of the support plate (5, 7), and about the same, and about the electronic components (9, 10) in a circumferential manner. The result is a patient data sensor device that is configured in a more tolerable manner for the patient.

Owner:RAUMEDIC AG

Flame-retardant power cable

InactiveCN105602252AImprove tear resistanceImprove impact resistanceRubber insulatorsInsulated cablesDicumyl peroxideInsulation layer

The invention discloses a flame-retardant power cable which comprises a wire, a high-temperature-resistant insulation layer coated on the wire, a shielding layer coated on the high-temperature-resistant insulation layer and a protective layer coated on the shielding layer. The protective layer is prepared from the following raw materials in parts by weight: 40-60 parts of silicon rubber, 40-60 parts of ethylene propylene diene monomer rubber, 20-25 parts of modified carbon fiber, 30-50 parts of nano kaolin, 1-3 parts of trioctyl trimellitate, 2-4 parts of epoxy soybean oil, 15-25 parts of microcapsulated red phosphorus, 10-15 parts of melamine, 1-3 parts of Si69, 0.5-1 part of dicumyl peroxide, 0.5-1 part of di-tert-butyl peroxide, 0.4-0.6 part of accelerator TMTD, 0.3-0.5 part of accelerator BZ, 2-4 parts of Ca / Zn composite stabilizer, 1-2 parts of butyl tin mercaptide, 0.4-0.6 part of antioxidant 1076, 0.2-0.3 part of anti-aging agent and 2-4 parts of silicone powder.

Owner:ANHUI WUZHOU SPECIAL CABLE GRP

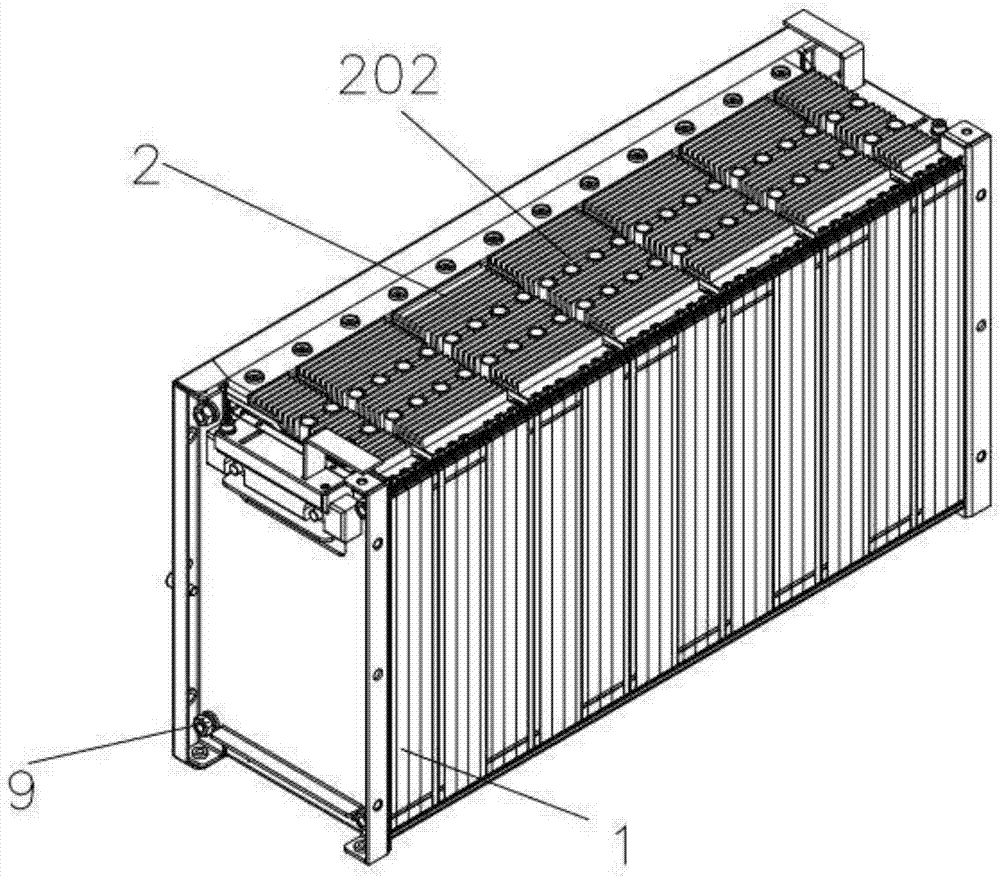

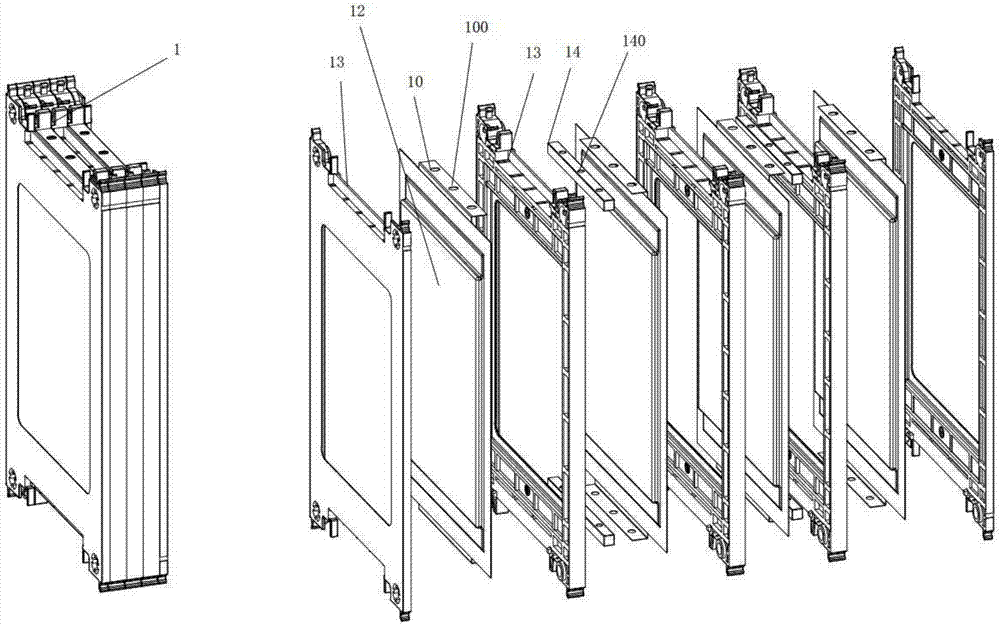

Battery pack device

ActiveCN107275559ATemperature controlEnsure electricity safetySecondary cellsCell component detailsElectricityEngineering

The invention discloses a battery pack device. The battery pack device comprises a plurality of basic parallel units, heat radiators, bus bars and insulation parts, wherein the bus bars are positioned between the heat radiators and the multiple basic parallel units, and are connected by screws of the heat radiators; pole lugs of the basic parallel units are connected in parallel by the bus bars; each basic parallel unit comprises a voltage collecting terminal; the insulation parts comprise first insulation parts, second insulation parts and third insulation parts; each first insulation part is fixedly arranged between each bus bar and the corresponding heat radiator through the screw of the heat radiator; each second insulation part is positioned around the screw of the corresponding heat radiator; each third insulation part is positioned at the boundary, corresponding to the voltage collecting terminal, of the corresponding heat radiator. The battery pack device has the advantages that when the heat is transferred by the pole lugs, the problem of electric insulation between the heat radiators and the basic parallel units is reliably solved, and the safety in use is improved.

Owner:深圳市欣旺达电气技术有限公司

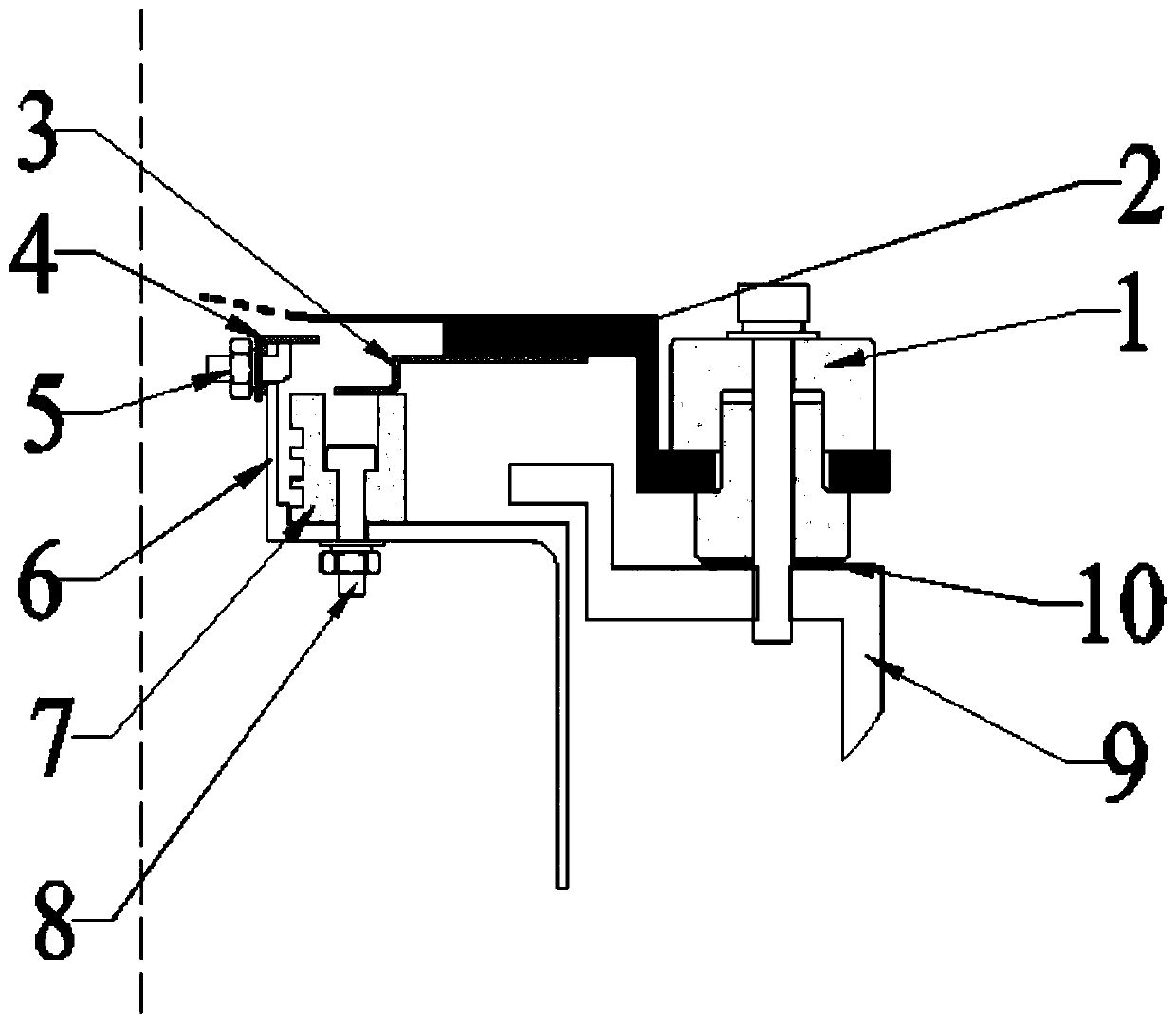

Connecting structure for vacuum pump

InactiveUS6899529B2Ensure electrical insulationHinders its propagationPositive displacement pump componentsPump controlPipingElectricity

Provided is a connecting structure for a vacuum pump, which can block propagation of electrical noise, generated by a main body of the vacuum pump. Between both ends of a connection piping for connecting the vacuum pump to a vacuum chamber of an apparatus to be connected with and evacuated by the vacuum pump, there is interposedly provided an electrical insulating portion formed of an insulating material so as to provide electrical insulation therebetween. The electrical insulation portion may be provided to a connection piping member such as a damper (or a valve depending on the connection arrangement) for absorbing mechanical vibrations.

Owner:EDWARDS JAPAN

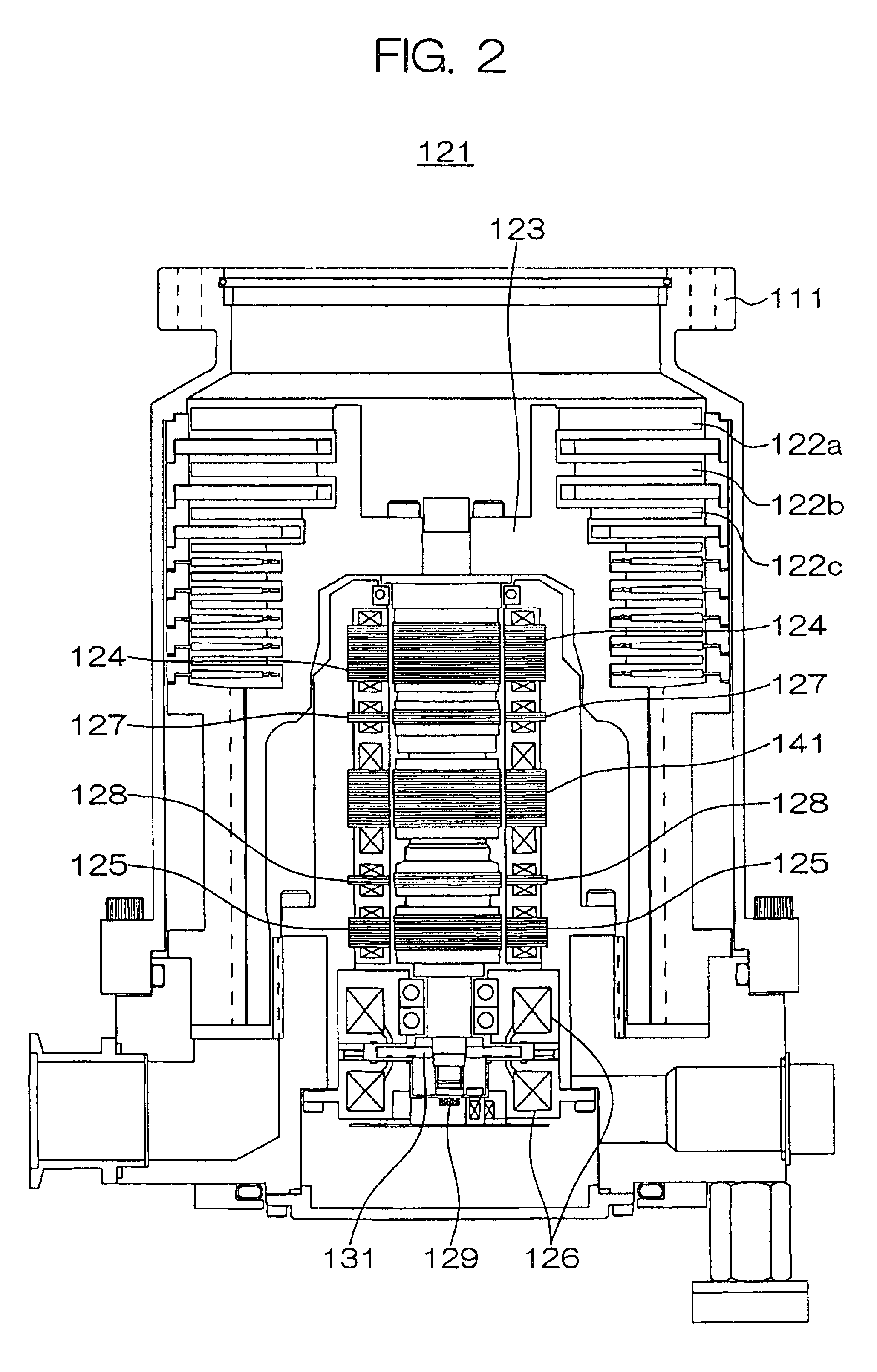

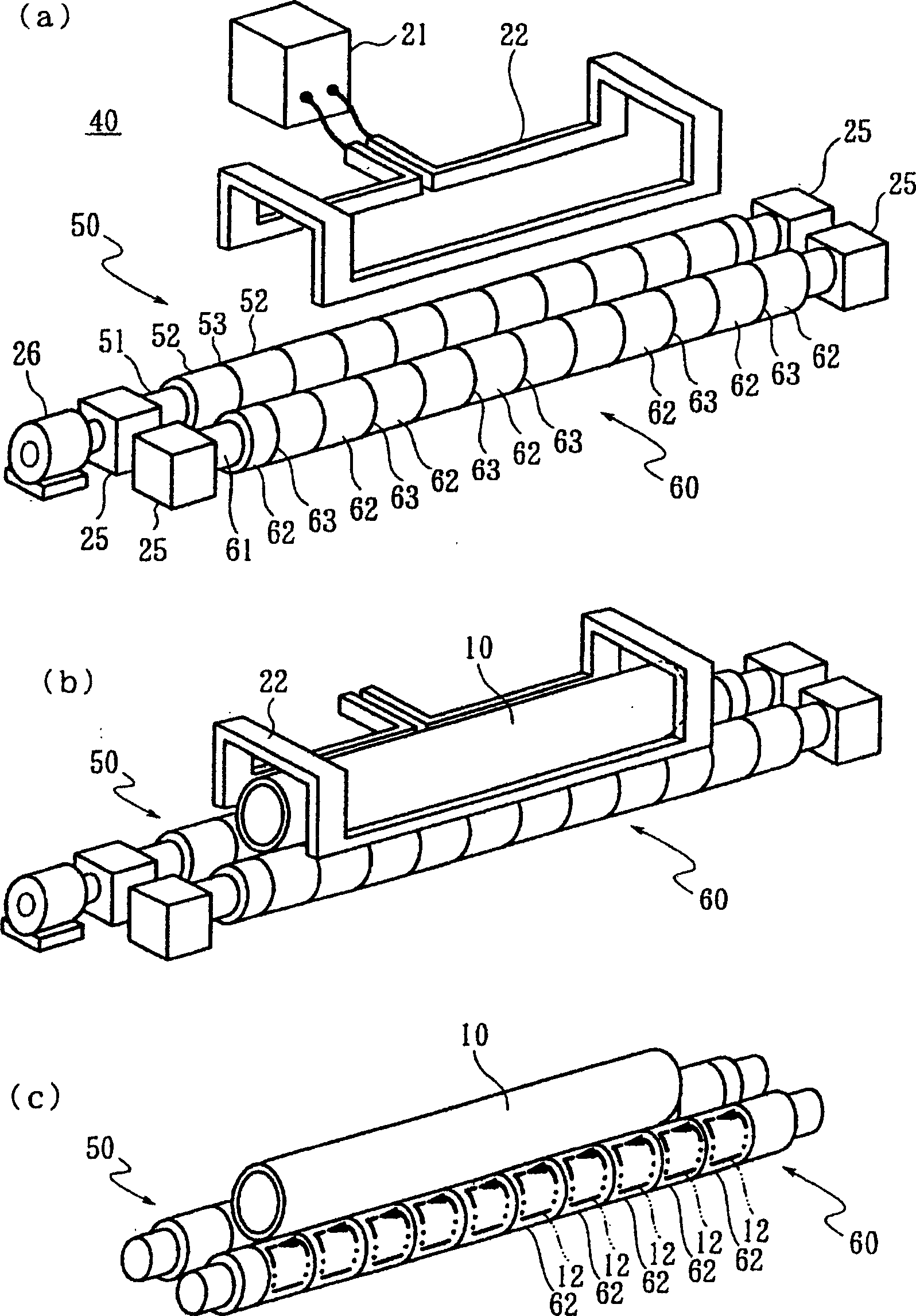

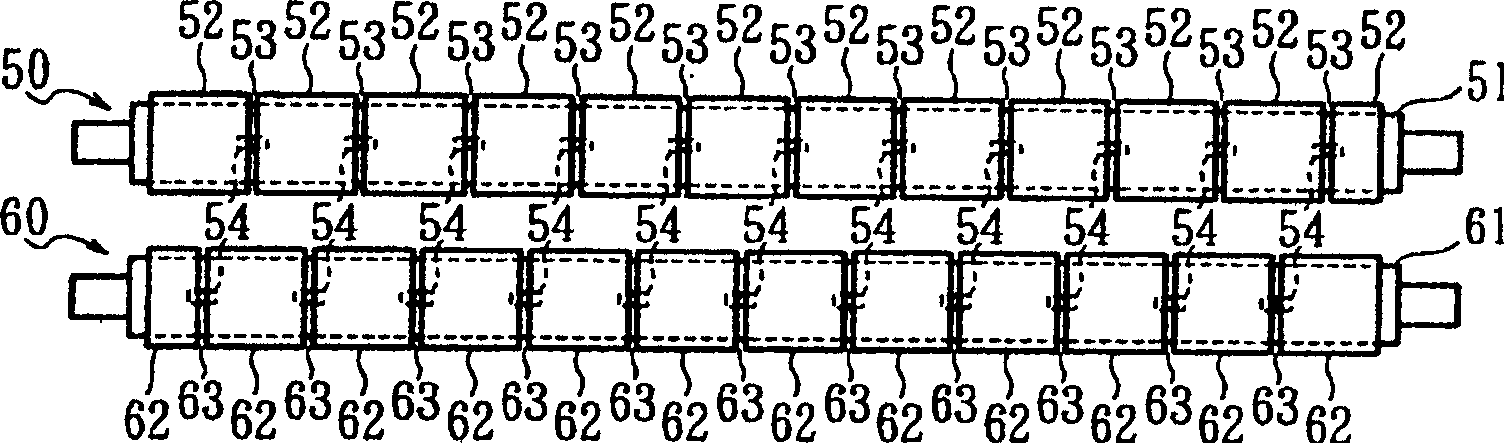

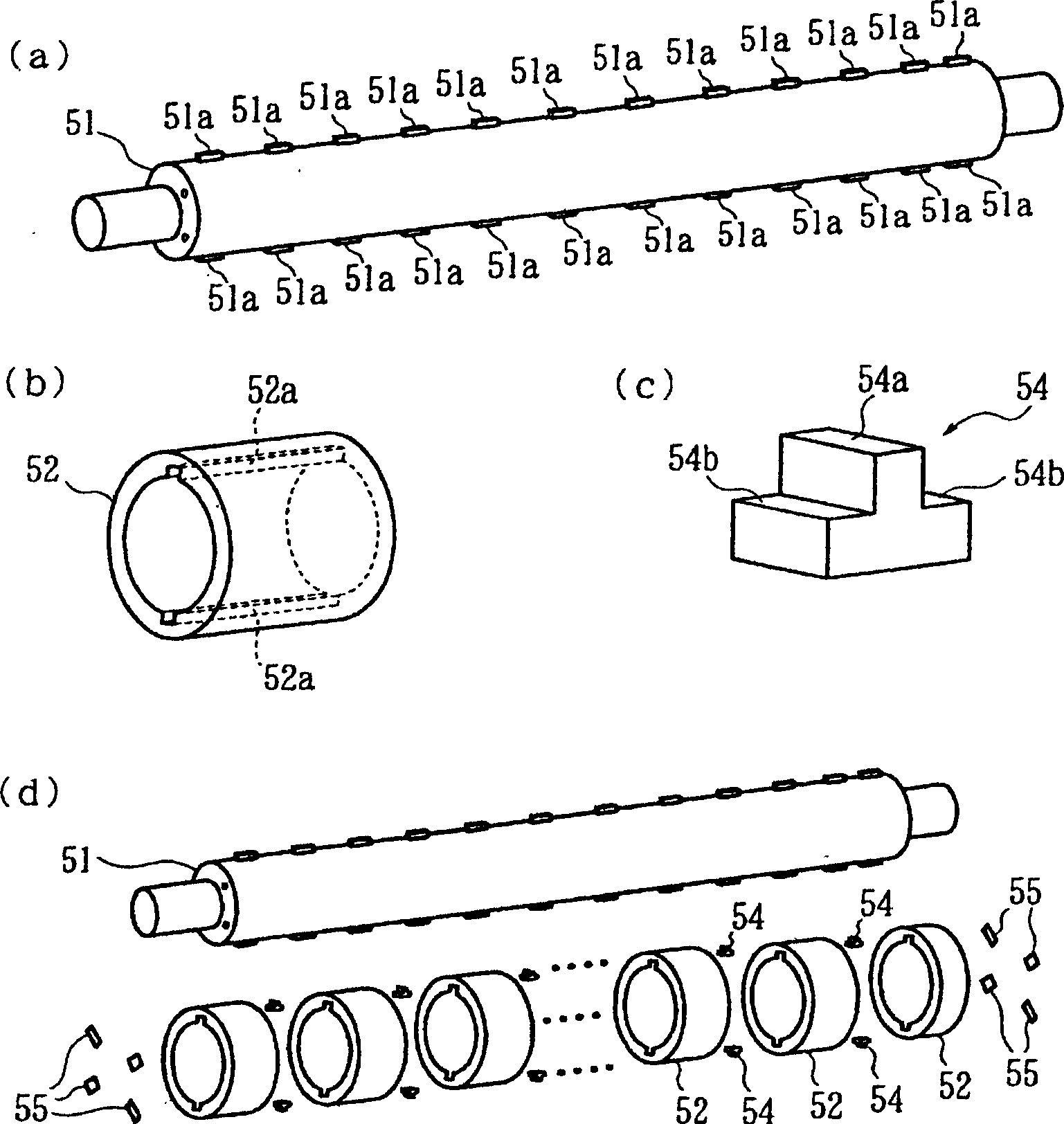

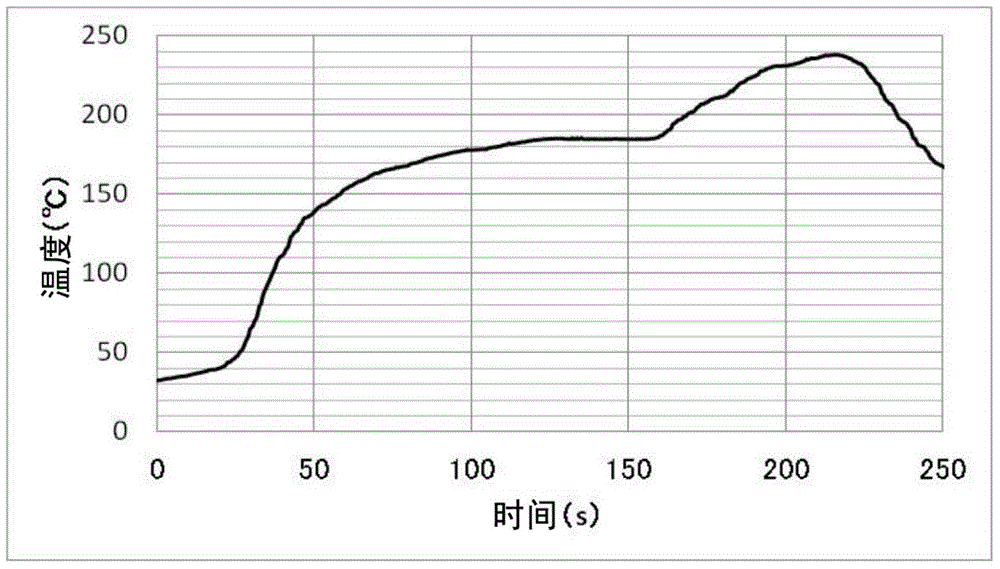

Heater of metal cylinder

InactiveCN1652641AEasy to destroyReduce generationFurnaces without endless coreIncreasing energy efficiencyLong term durabilityMetallic materials

To form each receiving roller with an inexpensive metal material easy to purchase and to compose a heating device with a structure capable of preventing spark between workpiece receiving rollers for providing long-term durability, in a heating device of a metal tube body for induction-heating the total length of a workpiece while rotatably supporting it with two receiving rollers. This metal tube body heating device 40 is equipped with: the receiving rollers 50 and 60 for mounting the metal tube body 10 in a manner capable of horizontally and rotatably transmitting it; roller driving devices 25-26 for rotatably driving them by pivoting them; and induction heating devices 21-22 for induction-heating the total length of the metal tube body 10. The rollers 50 and 60 are composed of: metallic core members 51 and 61; a plurality of metallic short sleeves 52 and 62 each having an axially split form; and spacers 53 and 63 serving as mutual insulation thereof.

Owner:DAI ICHI HIGH FREQUENCY

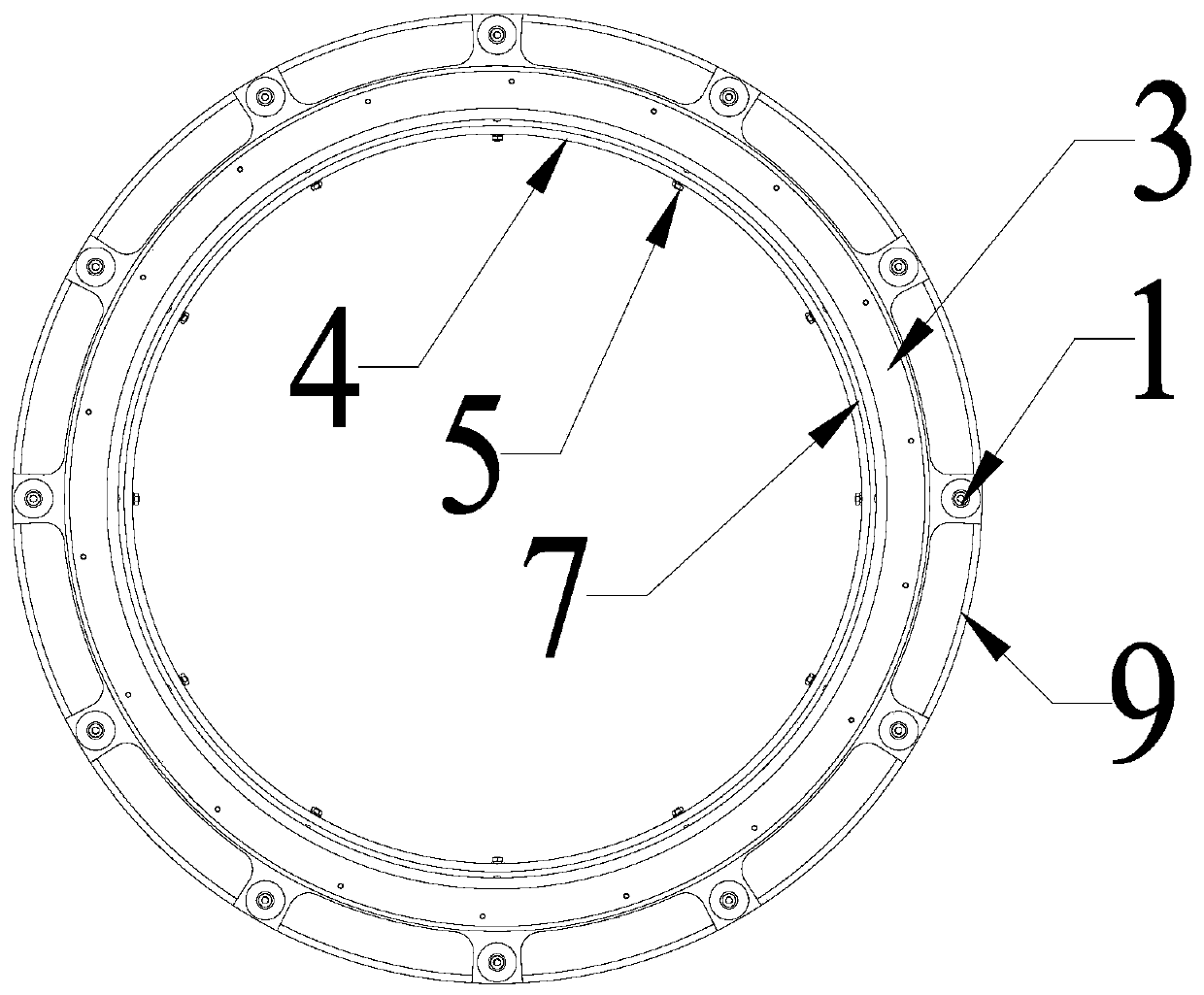

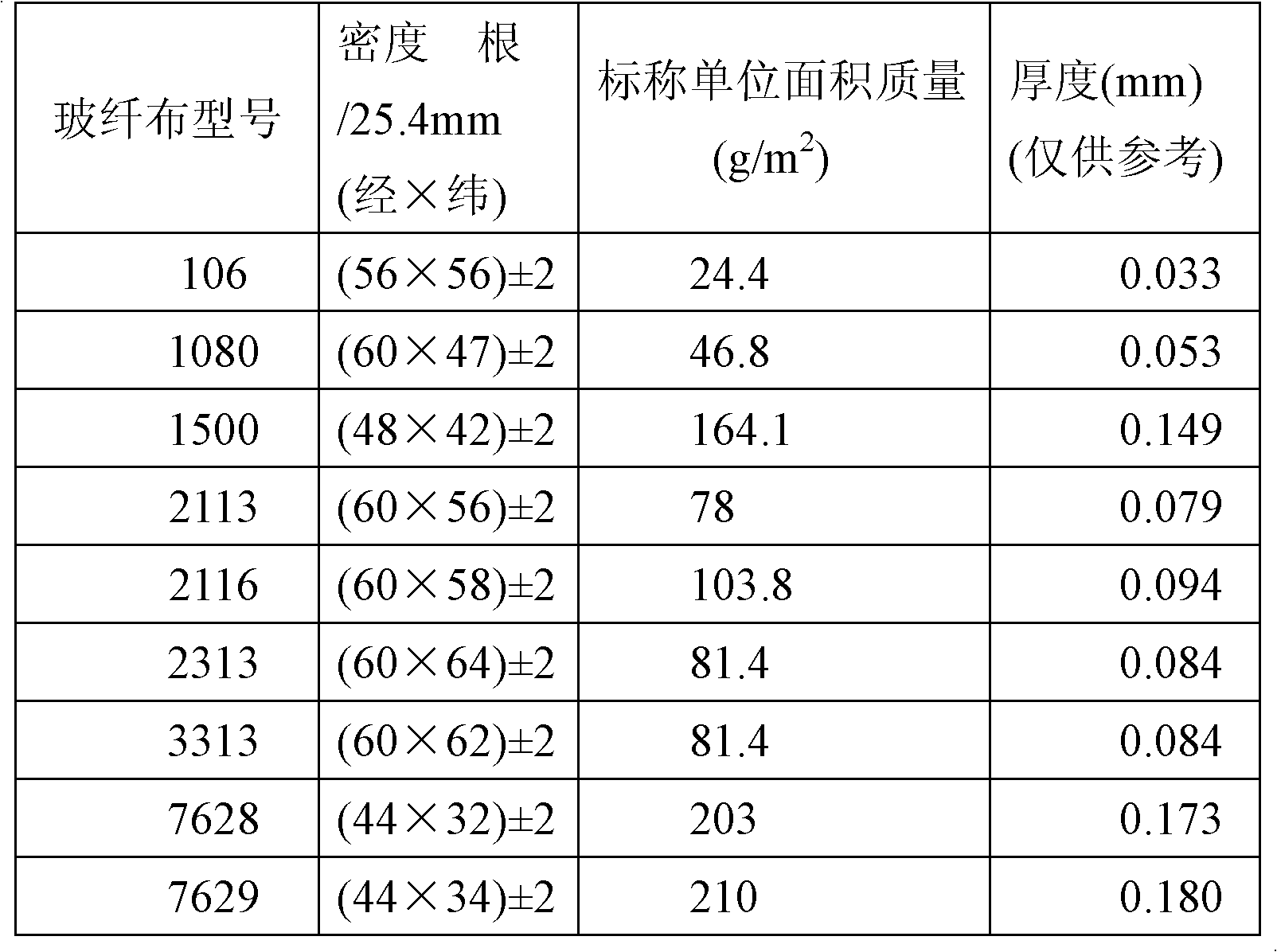

Plasma sealing structure for discharge chamber of annular magnetic steel ring cutting field ion thruster

ActiveCN111005849AGuaranteed long-term insulation capabilityEnsure electrical insulationMachines/enginesUsing plasmaStructural engineeringMechanical engineering

The invention provides a plasma sealing structure for a discharge chamber of an annular magnetic steel ring cutting field ion thruster. The plasma sealing structure comprises a ceramic ring, a shielding cover and a Z-shaped sealing ring; peripheral equipment comprises a grid assembly, an anode, an insulation supporting assembly and a supporting ring of the ion thruster, and the anode is of a stepped cylinder structure and comprises a large-diameter cylinder and a small-diameter cylinder; the shielding cover is installed on the outer wall of the upper end of the small-diameter cylinder of the anode, the ceramic ring is located below the shielding cover and fixed to the end face between the large-diameter cylinder and the small-diameter cylinder of the anode, and the shielding cover shieldspart of the end face of the ceramic ring and the inner wall face of the ceramic ring to realize shielding and realize electric insulation between the anode and the grid assembly; and the horizontal end face of one side of the Z-shaped sealing ring is fixed to the bottom face of the grid assembly, and the horizontal end face of the other side is compressed at the top end of the ceramic ring to complete plasma sealing of the discharge chamber. The problems of electric insulation between the grid assembly and the anode of the ion thruster in a long-term plasma environment and plasma sealing of the discharge chamber are solved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Alkali-free phosphate glass and preparation method thereof

InactiveCN102173578AEnsure electrical insulationMeet low temperature sealing requirementsAlkali freeThermal expansion

The invention relates to alkali-free phosphate glass and a preparation method thereof. The glass comprises the following components in percentage by weight: 30-57% of P2O5, 8-30% of ZnO, 15-45% of SnO, 15-40% of B2O3, 1-4% of SiO2 and 1-8% of Al2O3. The preparation method comprises the following steps of: (1) uniformly mixing all components, and melting the mixture in a silicon carbide rod furnace to obtain a glass liquid; (2) forming the molten glass liquid in a preheated die, annealing and cooling the die, and finally machining and forming to obtain the alkali-free phosphate glass. The alkali-free phosphate glass does not contain alkali or lead, so that the electrical insulating property of electronic devices is ensured, and the glass is friendly to the environment. The hermetical sealing temperature and the thermal expansion coefficient of the glass meet the low-temperature sealing-in requirement on electronic parts and components, the chemical stability is good, and the glass can be applied to the sealing-in and sealing of electronic components such as diodes, silicon controlled components, and the like. The preparation method has the advantages of simple process, low cost andgood application prospect.

Owner:DONGHUA UNIV

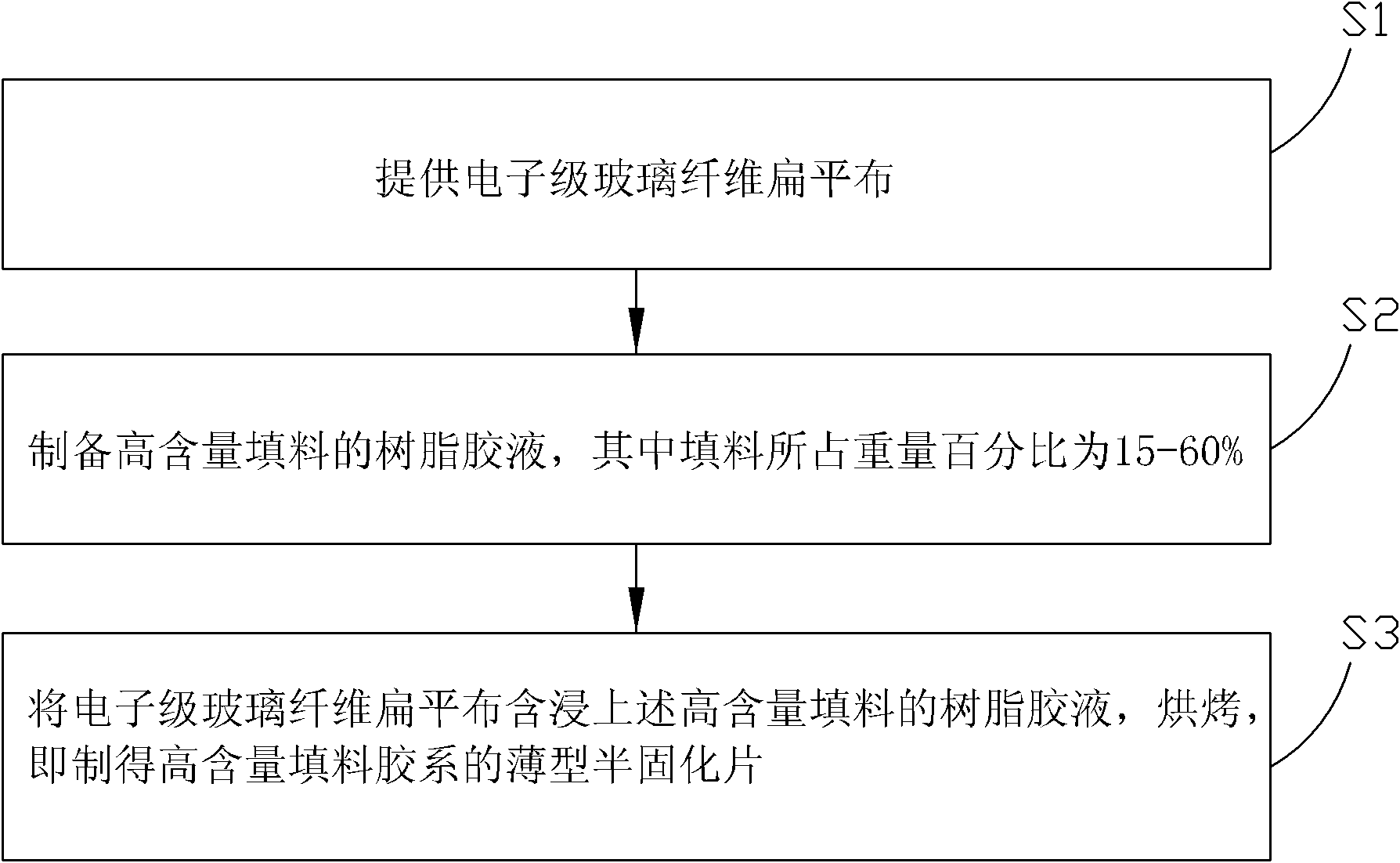

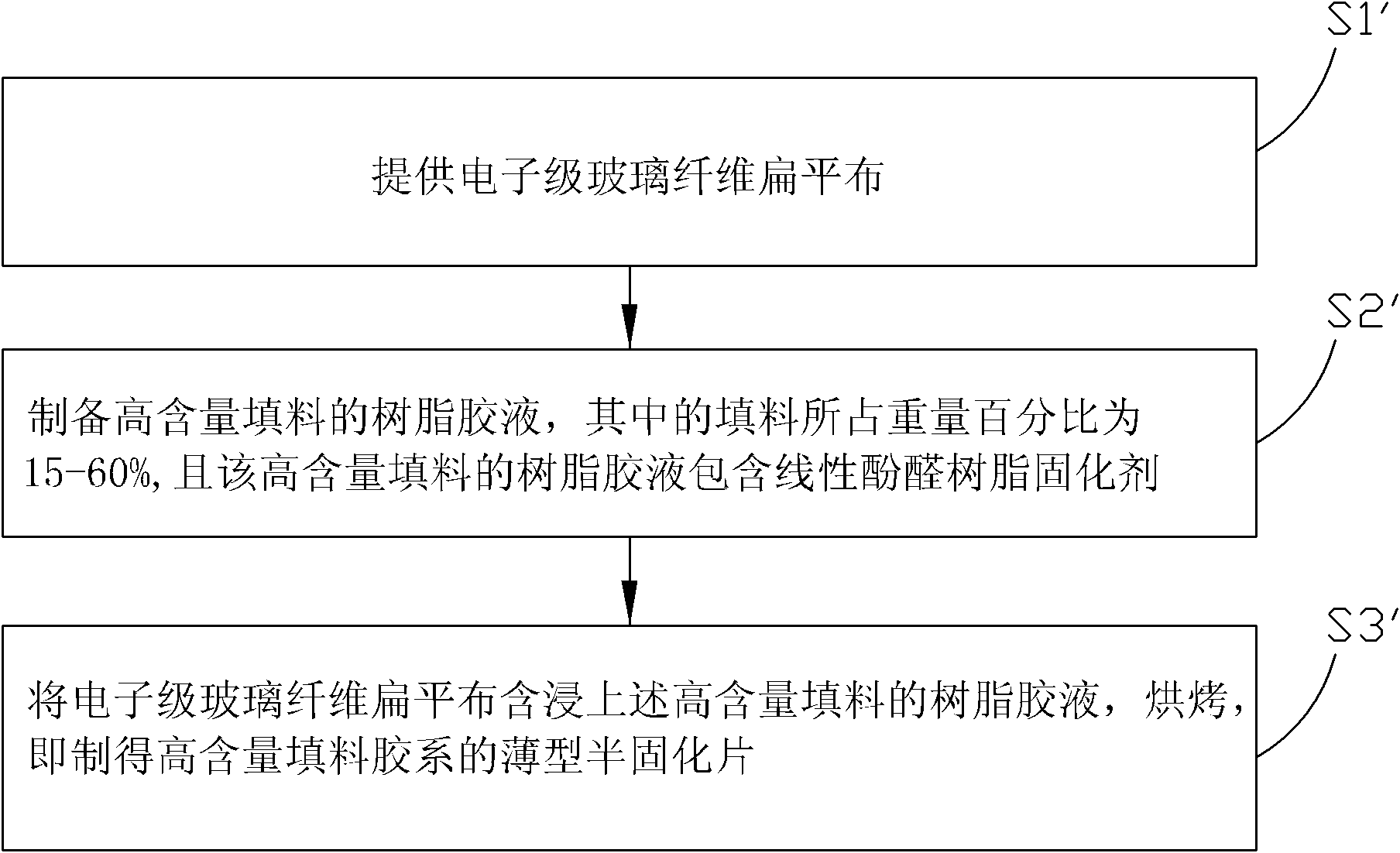

Production method of thin prepreg with high-content filler adhesive system

ActiveCN102031008AAddresses apparent pinhole defectsGuaranteed electricityCircuit susbtrate materialsMetal layered productsGlass fiberElectricity

The invention relates to a production method of thin prepreg with a high-content filler adhesive system, comprising the following steps: step 1, providing an electronic-grade fiberglass flat cloth, wherein the nominal mass per unit of the electronic-grade fiberglass flat cloth is 15-50g / m<2>, and the weft clearance area is 0-0.01mm<2>; step 2, preparing a resin adhesive solution containing a high-content filler, wherein the filler accounts for 15-60% by weight; and step 3, impregnating the electronic-grade fiberglass flat cloth in the resin adhesive solution containing a high-content filler, and baking to obtain the thin prepreg with a high-content filler adhesive system. The production method of the thin prepreg with a high-content filler adhesive system provided by the invention effectively solves the apparent pinhole defect of the thin prepreg, improves the percent of pass, and ensures the electrical property and reliability of a copper-clad plate made from the thin prepreg, thereby ensuring the electrical insulation property of a printed circuit board (PCB) and improving the quality of products.

Owner:GUANGDONG SHENGYI SCI TECH

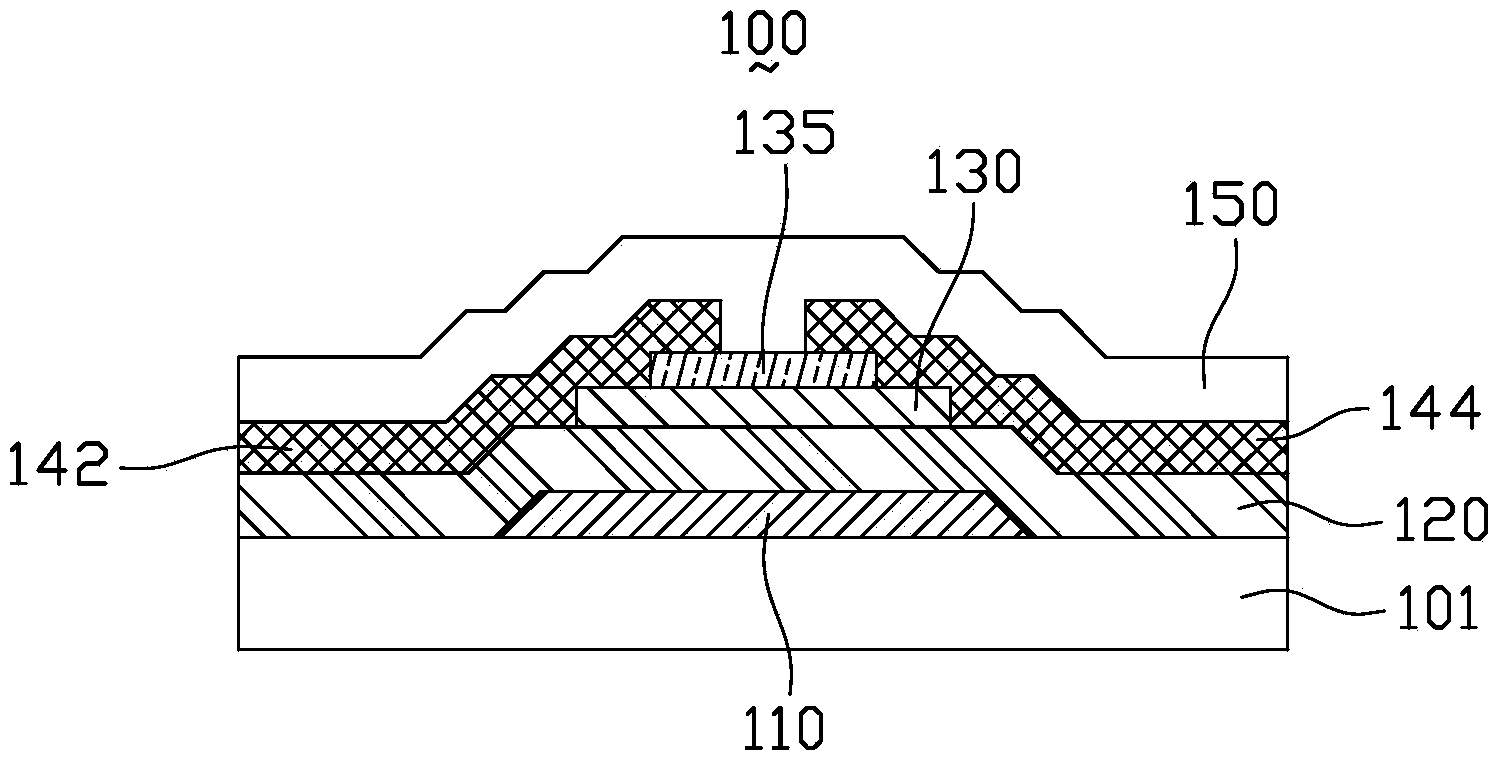

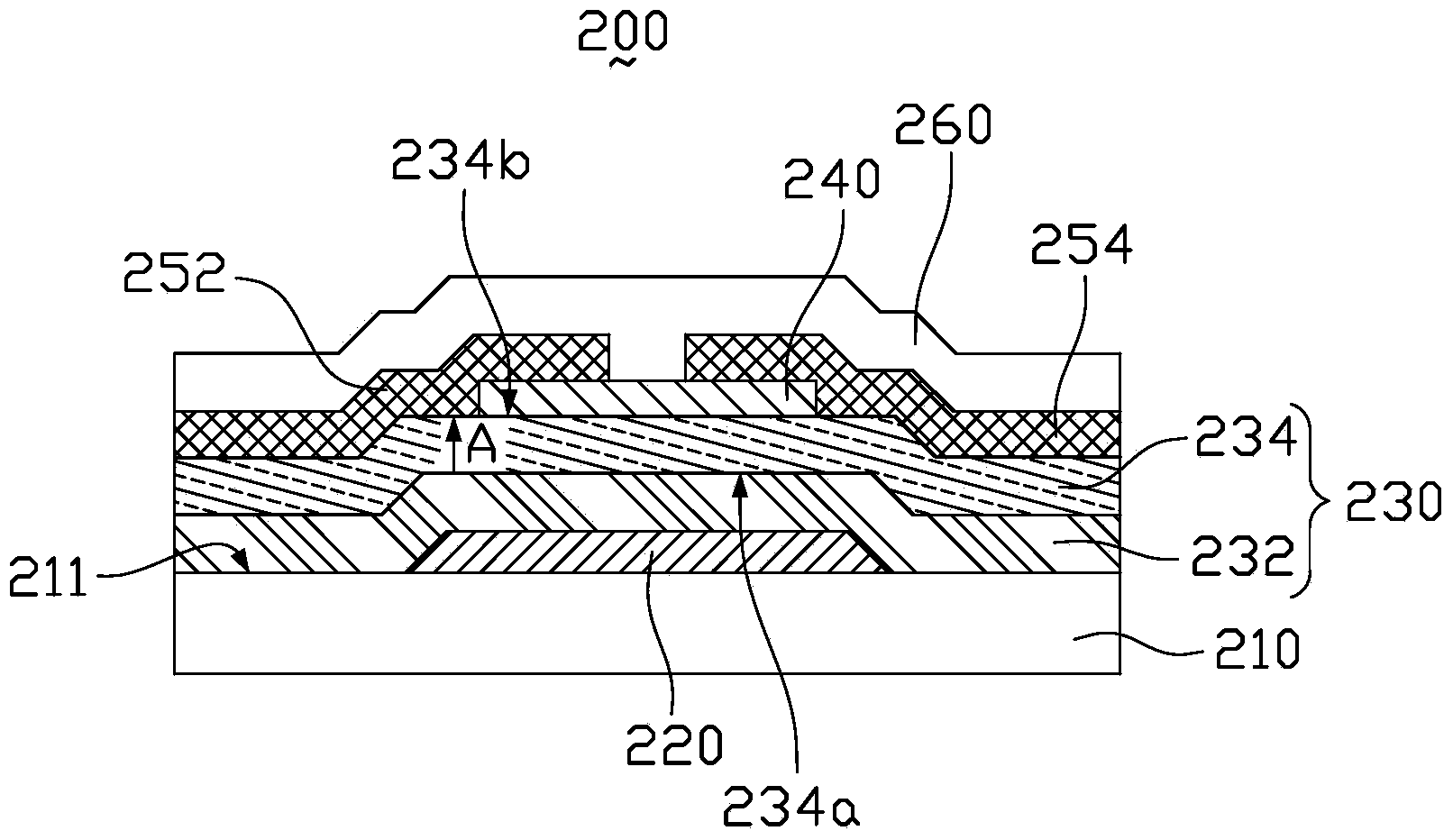

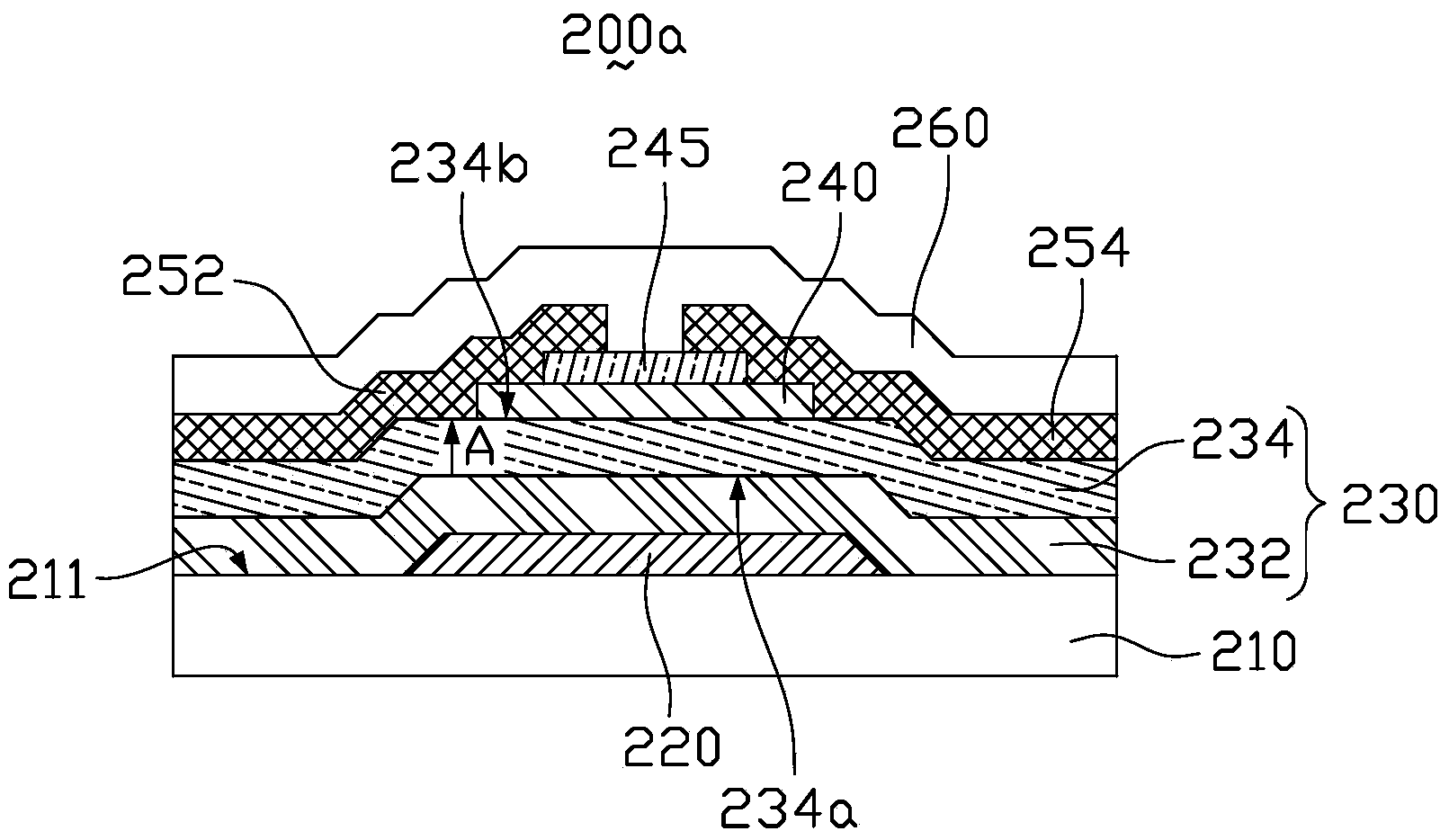

Metallic oxide semiconductor thin film transistor and manufacturing method thereof

ActiveCN103824887AImprove stabilityReduce oxygen contentTransistorSemiconductor/solid-state device manufacturingSilicon oxideOptoelectronics

A metallic oxide semiconductor thin film transistor comprises a grid electrode, a grid electrode insulating layer and a metallic oxide semiconductor layer. The grid electrode insulating layer is located between the grid electrode and the metallic oxide semiconductor layer. The grid electrode insulating layer comprises a silicon oxynitride layer and a silicon oxide layer. The silicon oxynitride layer is located between the grid electrode and the silicon oxide layer. The silicon oxide layer is located between the silicon oxynitride layer and the metallic oxide semiconductor layer. The silicon oxide layer is provided with a first surface making contact with the silicon oxynitride layer and a second surface making contact with the metallic oxide semiconductor layer. The density of oxygen atoms, close to the second surface, of the silicon oxide layer is larger than the density of oxygen atoms, close to the first surface, of the silicon oxide layer. According to the metallic oxide semiconductor thin film transistor, the process time is shortened, the problem that a glass substrate can be easily broken due to the excessively large film forming stress is effectively solved at the same time, and the metallic oxide semiconductor thin film transistor is beneficial for reducing influences of the grid electrode insulating layer on the oxygen content in the metallic oxide semiconductor layer.

Owner:KUSN INFOVISION OPTOELECTRONICS

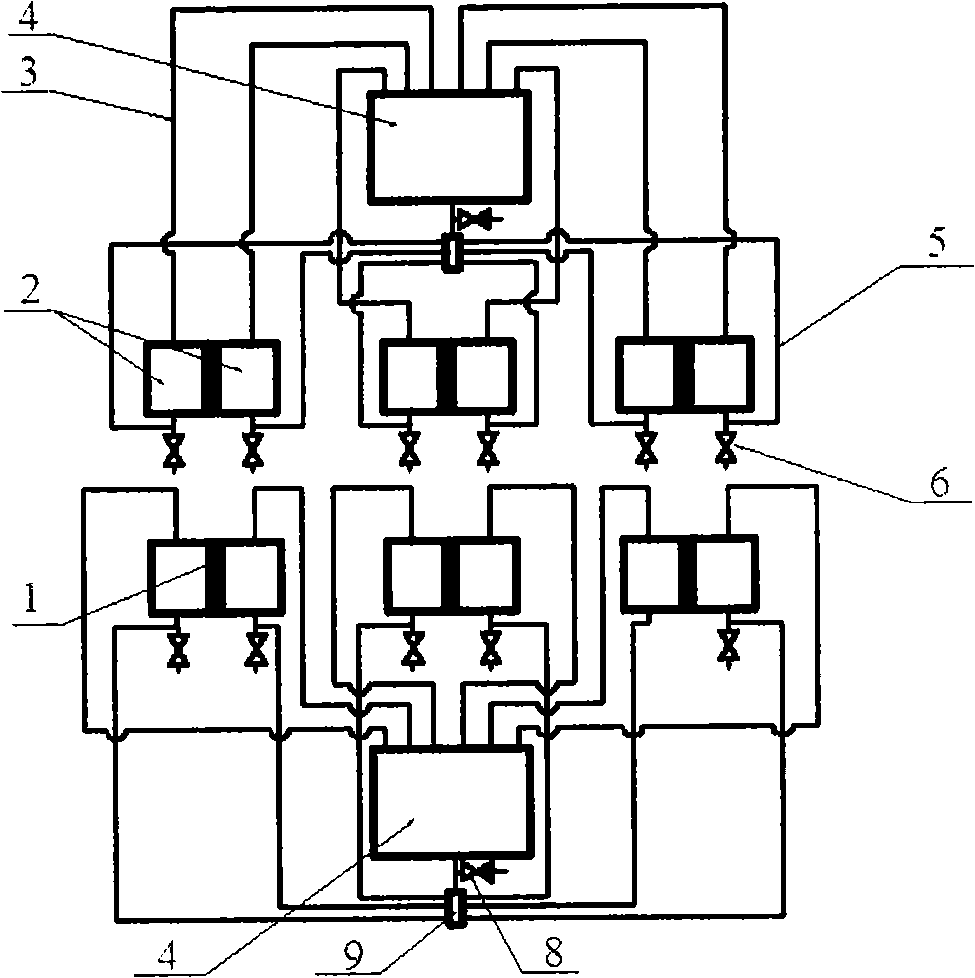

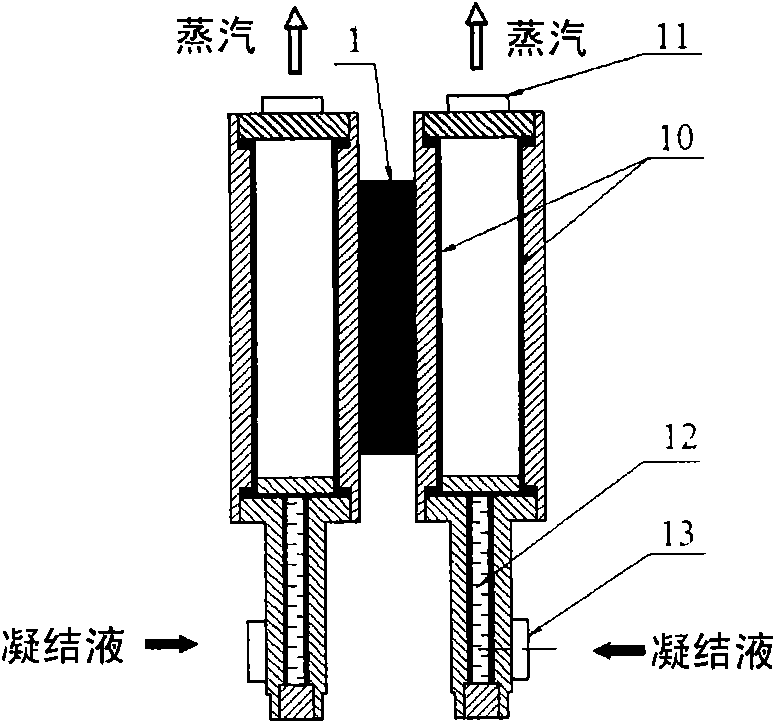

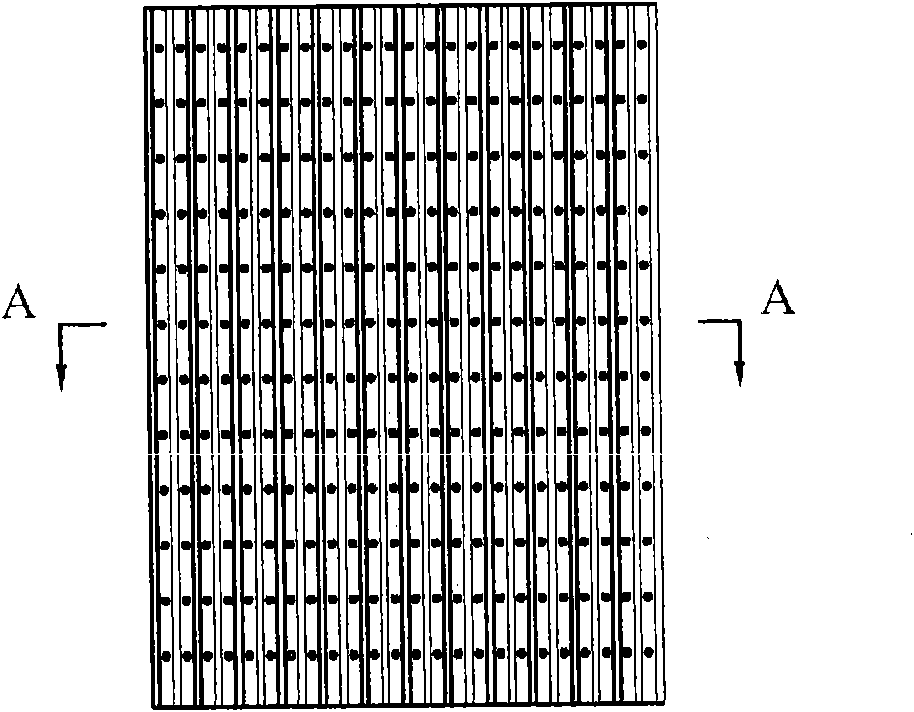

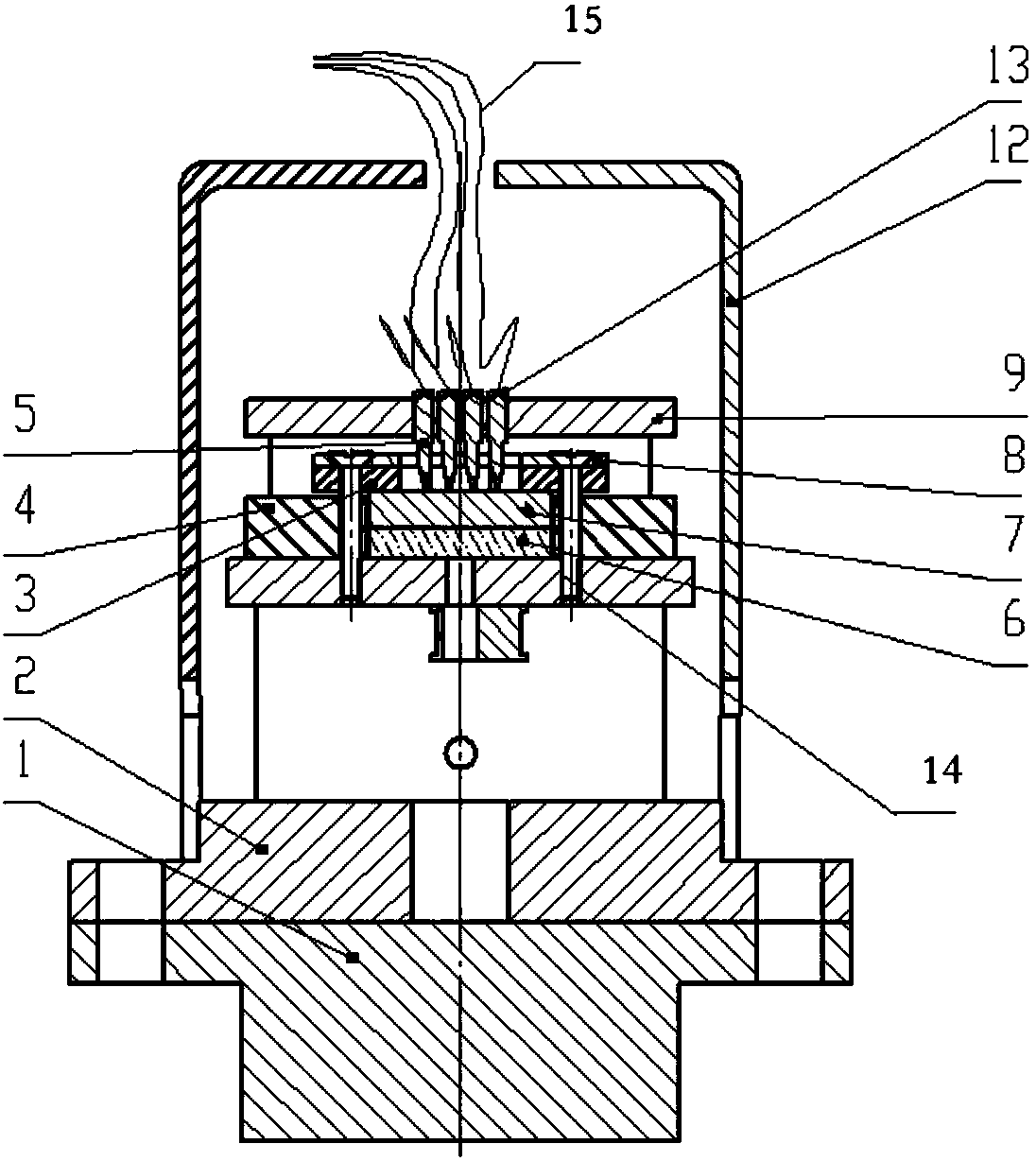

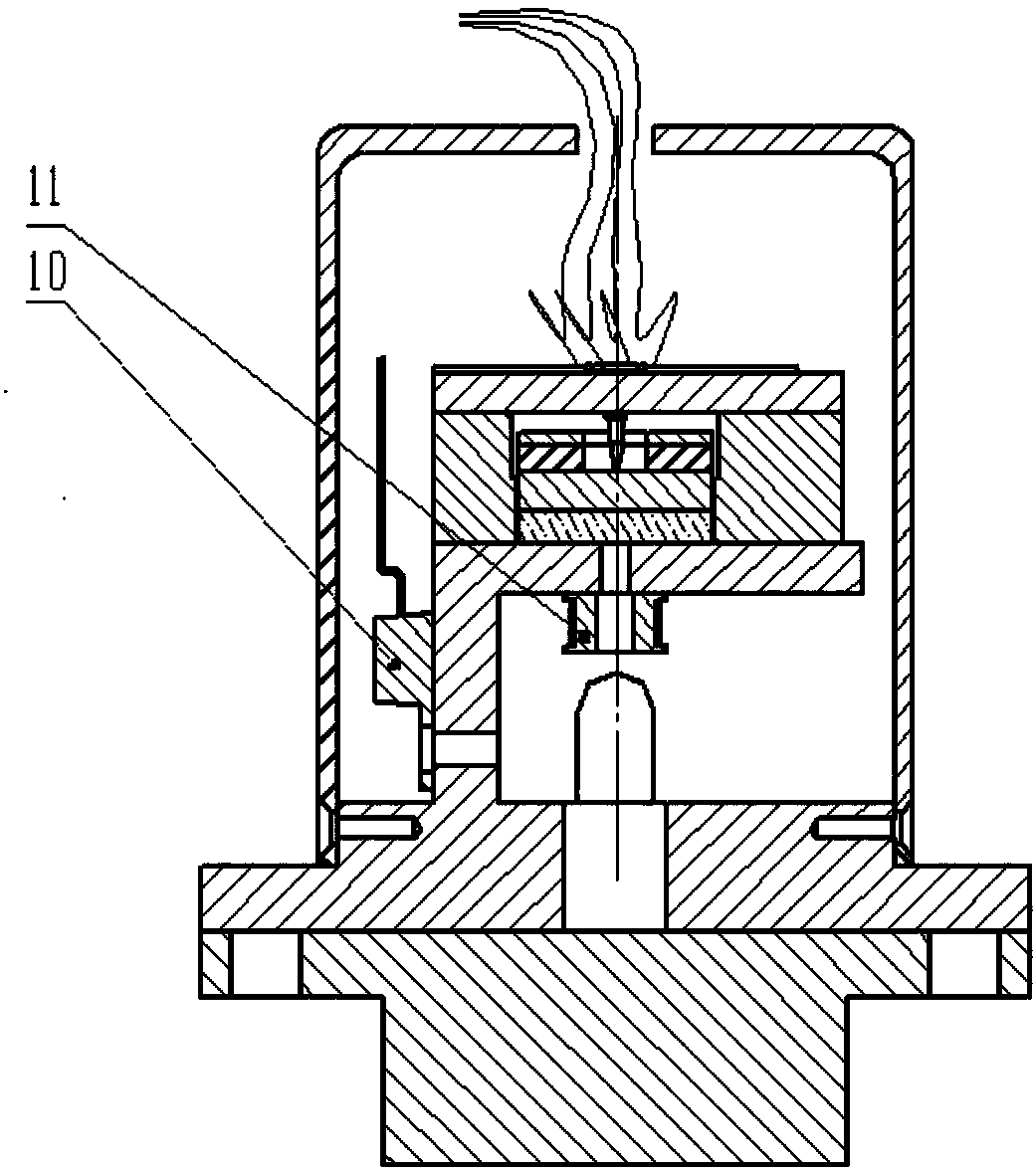

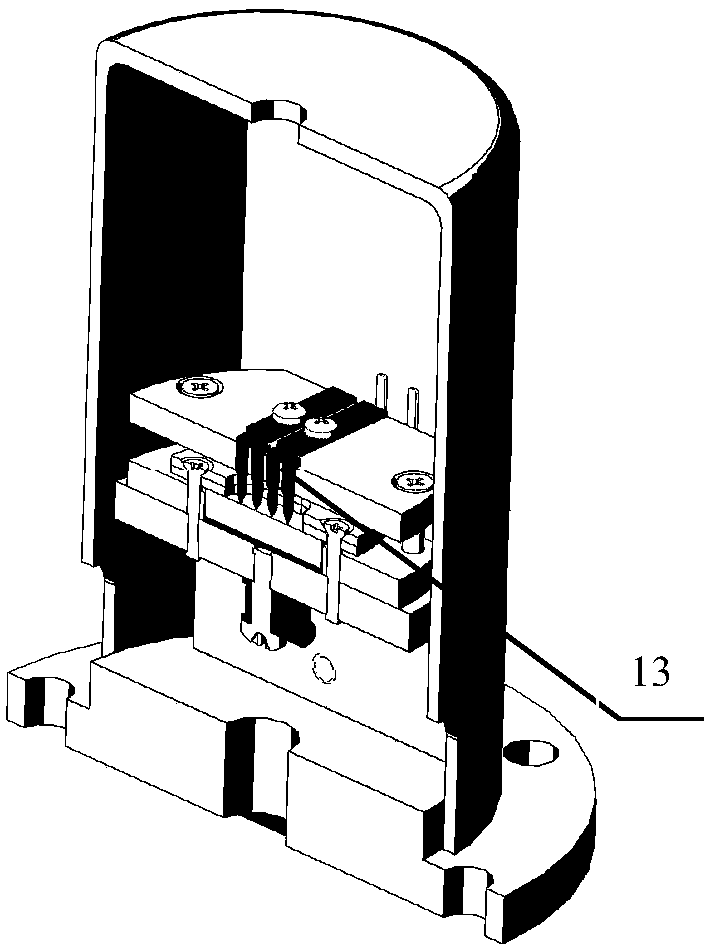

Silicon controlled thyristor device micro slot group composite phase change integrated cooling heat dissipation method and device

InactiveCN101814464AHigh strengthImprove stabilityThyristorSemiconductor/solid-state device detailsTemperature controlHeat flow

The invention provides a silicon controlled thyristor micro slot group composite phase change integrated cooling heat dissipation method and device, relating to the heat dissipation technology. The method includes that micro dimension composite phase change heat transfer characteristic of thin liquid film evaporation and thick liquid film boiling of liquid in open composite phase change micro slot group in a micro slot group composite phase change heat remover is utilized to remove heat. The device is provided with a micro slot group composite phase change heat remover at the two sides of single silicon controlled thyristor respectively, the silicon controlled thyristor removes heat in multiple groups, each group is provided with a wall type condenser heat dissipation structure, heat emitted by each silicon controlled thyristor can be taken out respectively and is carried into the wall type condenser by steam, condensation heat dissipation is carried out in condensation micro slot thereof, heat is taken away by external cooling water or air, condensed liquid reflows to the micro slot group composite phase change heat remover, and heat dissipation of silicon controlled thyristor with high power, large quantity and strong electric field is realized. The invention is safe and reliable, has small area, high heat-flow density, strong temperature control capability, high efficiency and low energy consumption and can be applicable to integrated cooling heat dissipation of a plurality of high power heat-emitting silicon controlled thyristors.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

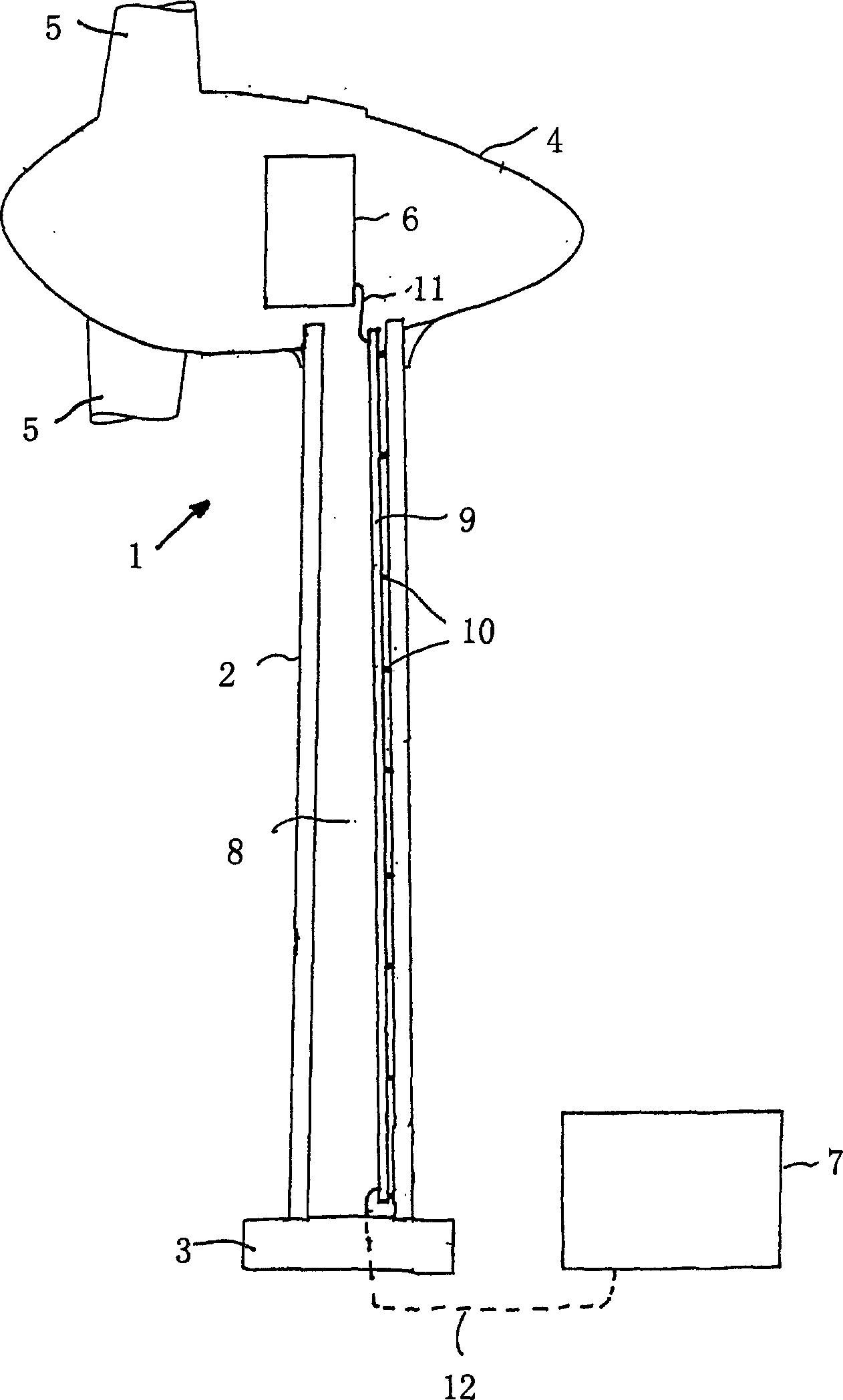

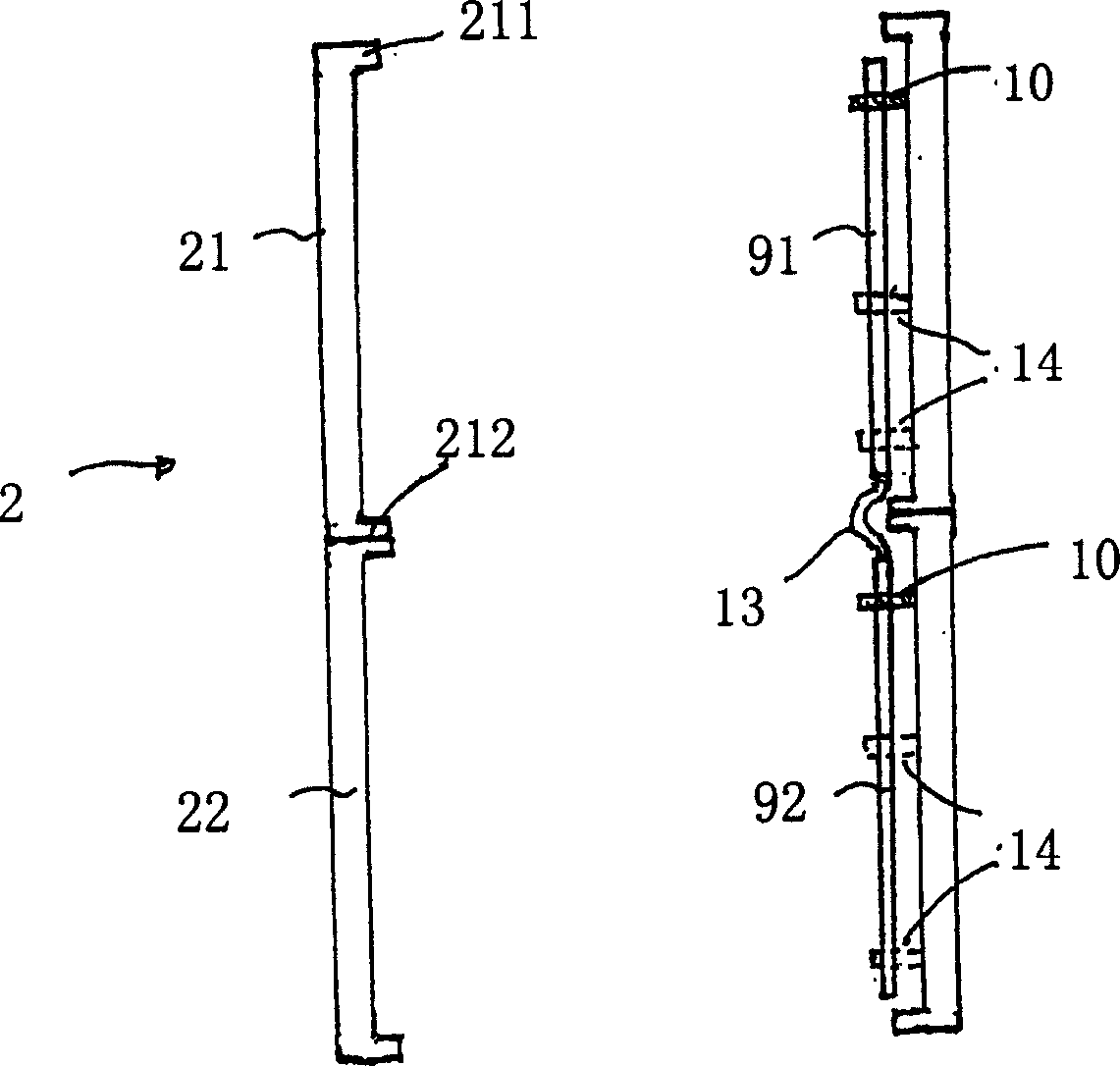

Wind power station with current bus

InactiveCN1575379AContact free fromSo as not to damageWind motor assemblyBus-bar installationPower stationEngineering

The present invention concerns a wind energy plant for generation of alternating current with a tower constructed of several tower segments, a generator arranged in the region of the top of the tower, a power module arranged in the region of the base of the tower, and current carrying means for transferred current from the generator to the power module. In order to enable faster, easier and thereby cheaper erection of the wind energy plant, it is provided in accordance with the present invention that the current carrying means be premounted in the tower segments in segmented form.

Owner:阿洛伊斯沃本

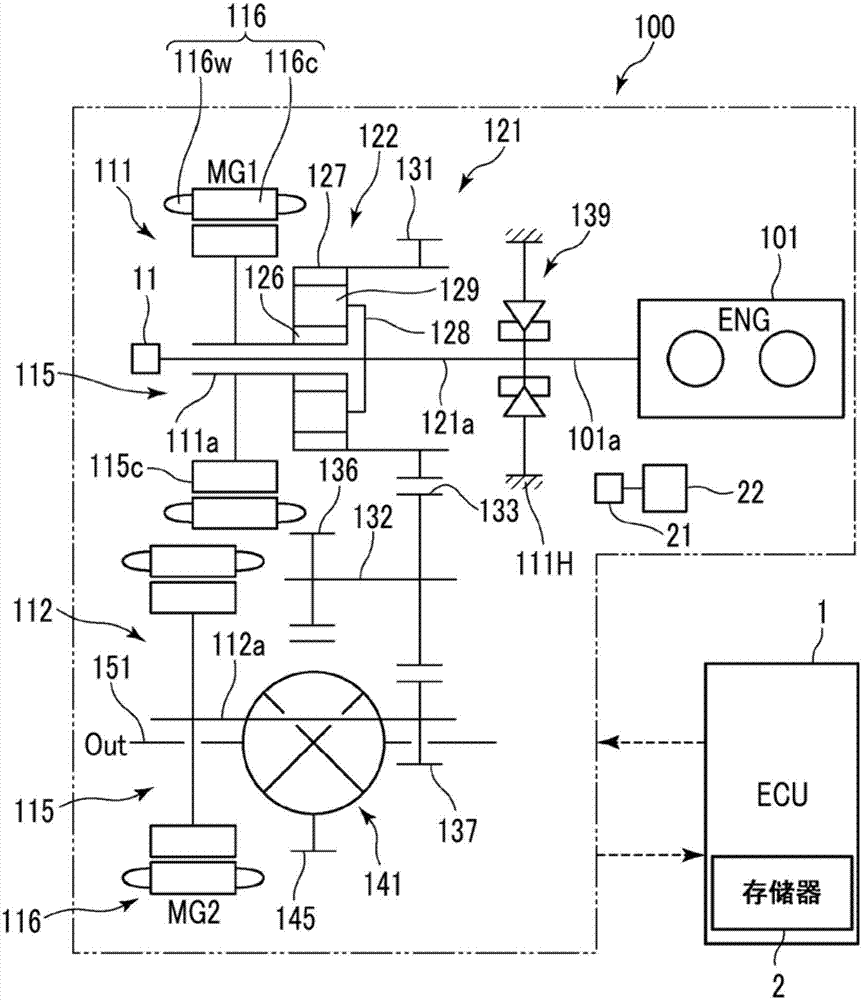

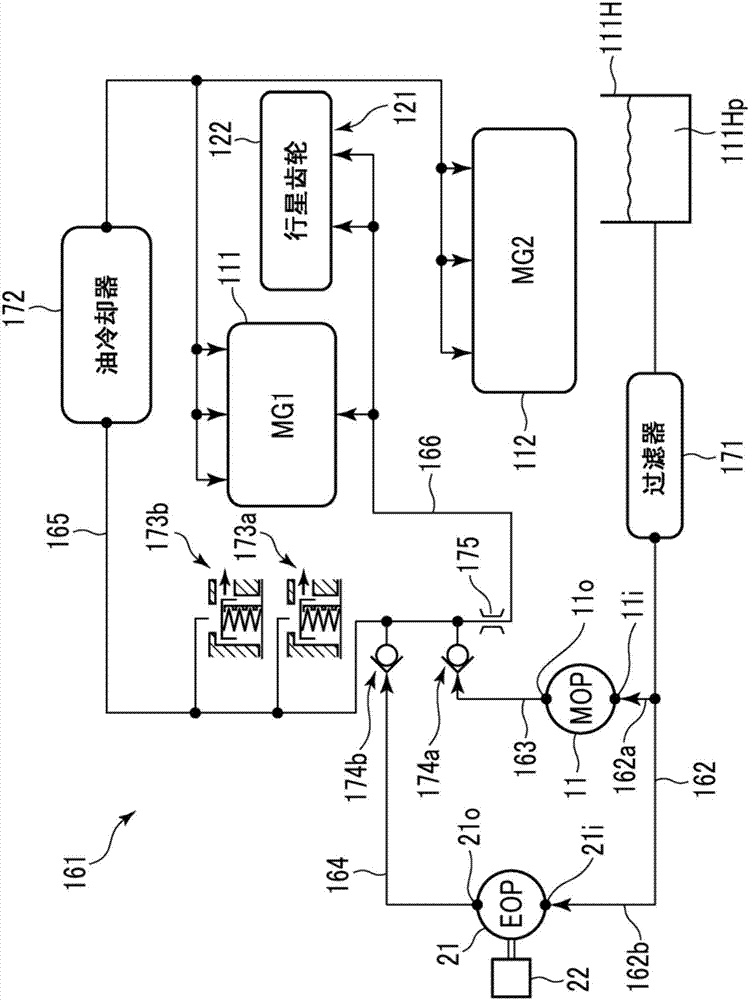

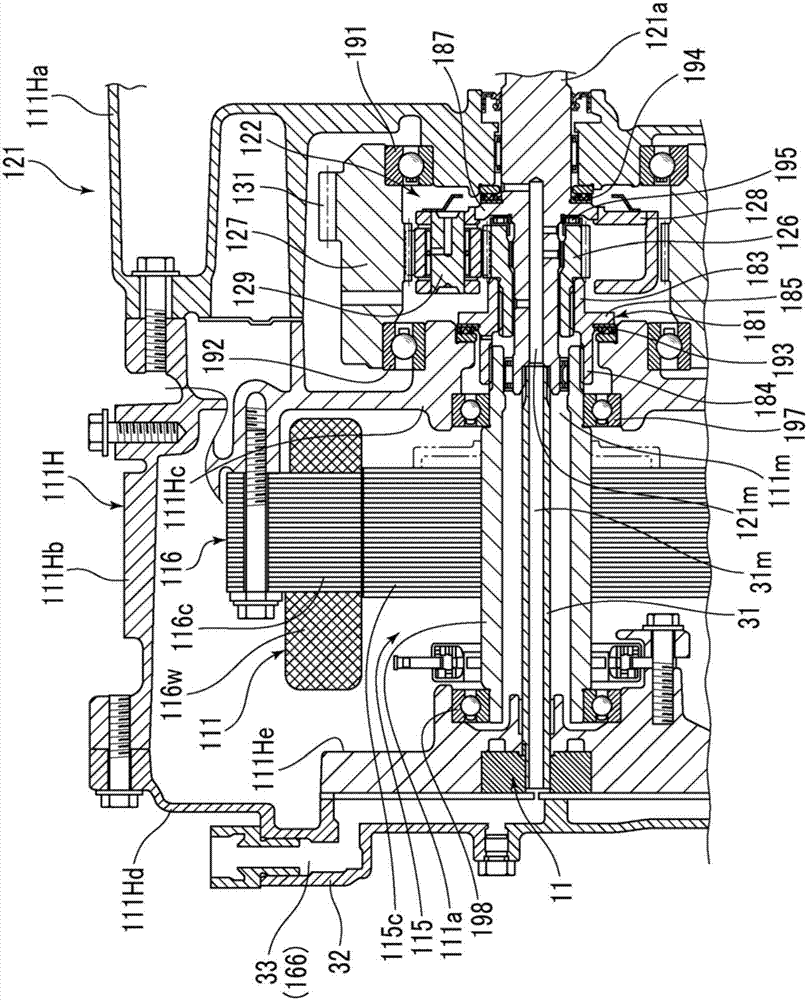

Rotary electric machine system

InactiveCN107878442AIncrease supplyAvoid smallHybrid vehiclesElectric motor controlElectric machineLubrication

A rotary electric machine system includes: a rotary electric machine; a lubrication mechanism configured to supply lubricating oil to a bearing of the rotary electric machine; and a control unit configured to control the supply of lubricating oil from the lubrication mechanism. The control unit is configured to acquire an operation status of the rotary electric machine and determine whether thereis a possibility of occurrence of electrolytic corrosion in the bearing. The control unit is configured to, when it is determined that there is a possibility of occurrence of electrolytic corrosion, increase the supply of lubricating oil to the bearing by controlling the lubrication mechanism as compared to the supply of lubricating oil to the bearing at a time when it is not determined that thereis a possibility of occurrence of electrolytic corrosion.

Owner:TOYOTA JIDOSHA KK

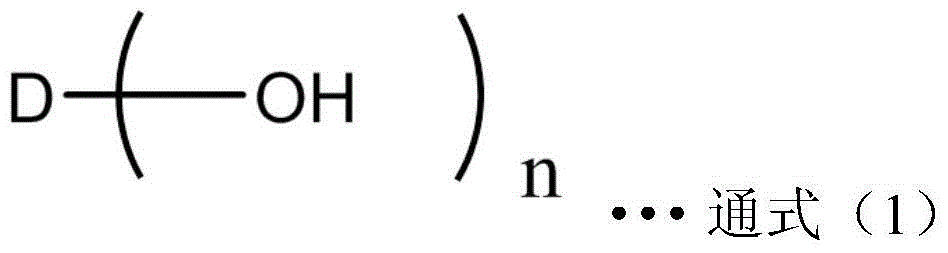

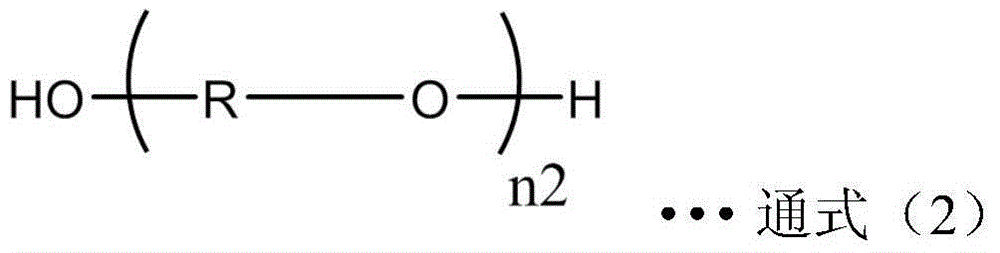

Soldering flux composition with abietate for soldering and soldering paste composition

ActiveCN104073167ACrack suppressionEnsure electrical insulationWelding/cutting media/materialsNatural resin chemical modificationAlcoholChain structure

The invention provides a soldering flux composition with abietate for soldering and a soldering paste composition, wherein crack does not easily occur on soldering flux residue on condition that the soldering flux composition with the abietate is exposed in an intensive cold-and-heat cycle for a long time. A rosin derivative compound is obtained through dehydration condensation between (A) a rosin carboxyl-containing resin and (b-1), (b-2) or (b-3); wherein (b-1) is a dimer acid derivative flexible alcohol compound; in the formula (1), D is a dimer-acid-derived aliphatic chain, and n is 1-3; (b-2) is a dimer acid derivative flexible alcohol compound which is obtained through dehydration condensation between the dimer acid and the compound of the formula (1); (b-3) is a dimer acid derivative flexible alcohol compound which is obtained through dehydration condensation between the dimer acid and the compound of the formula (2); and in the formula (2), R represents an alkyl connecting group with 2-10 carbon atoms and comprises a straight-chain or branched-chain structure, and additionally, n2 is 1-10.

Owner:TAMURA KK

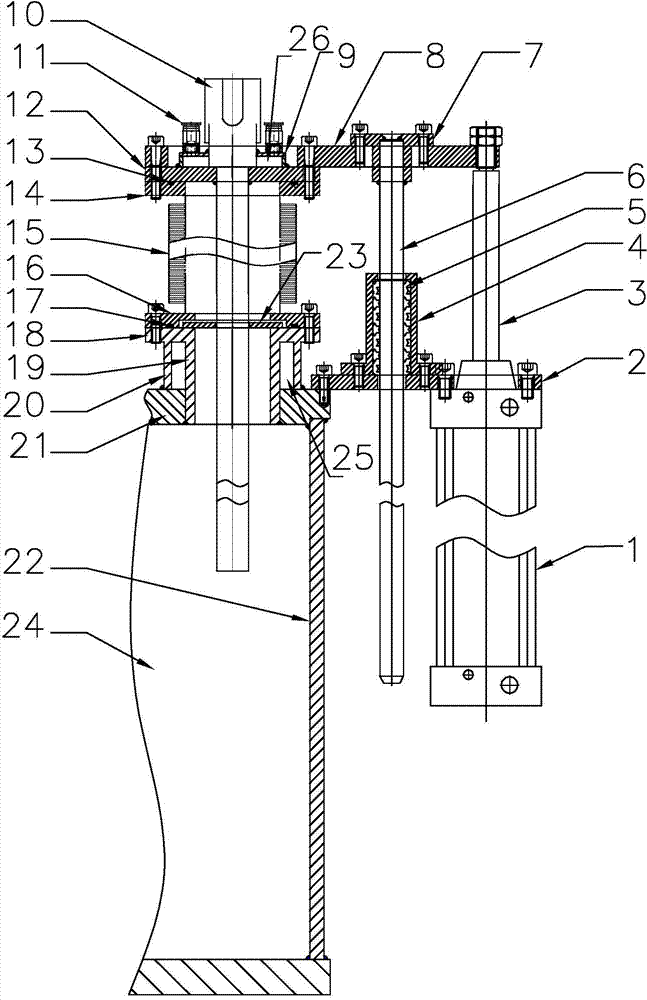

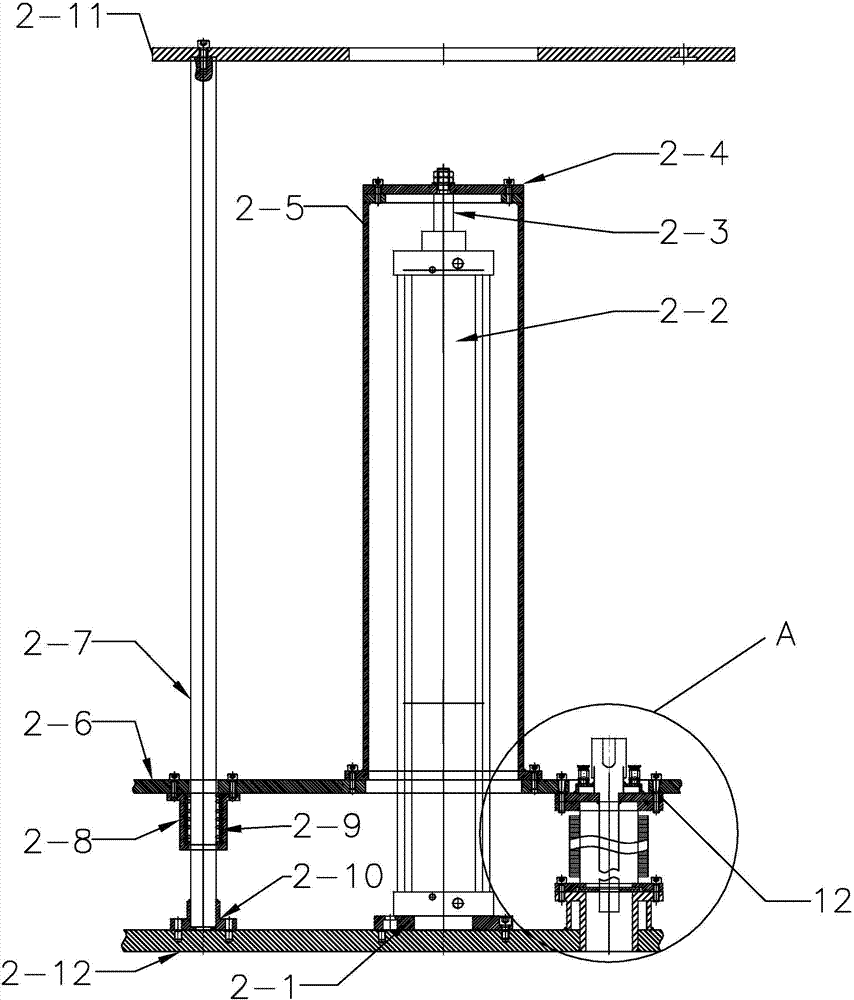

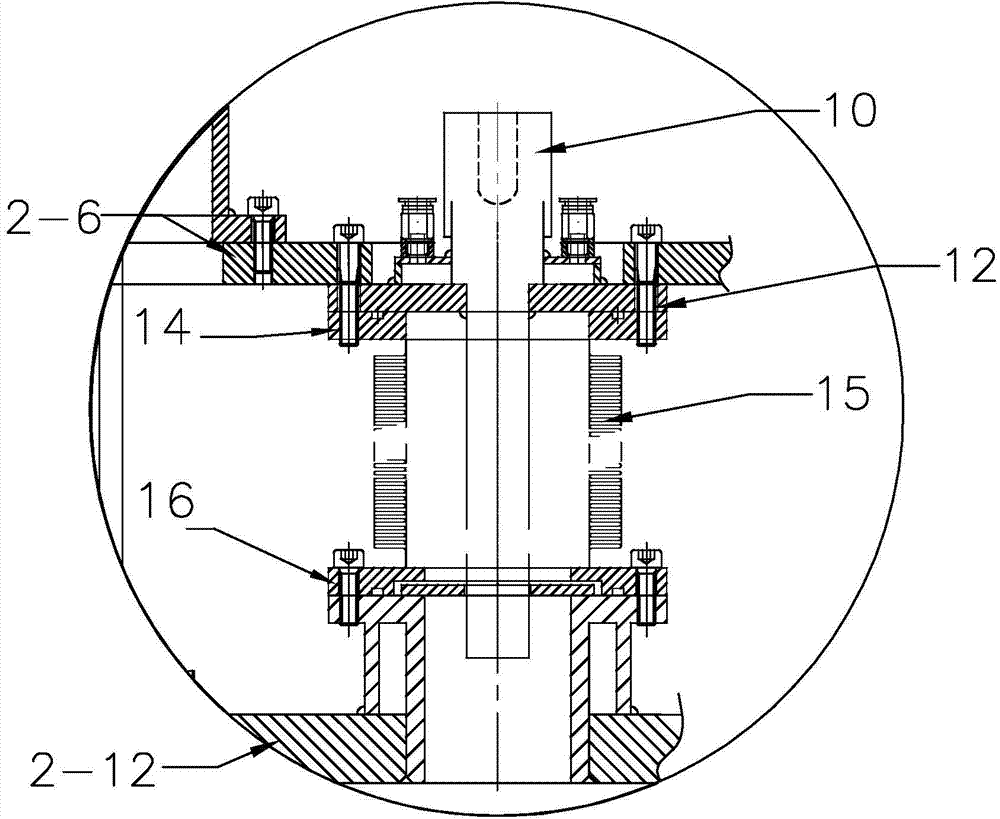

Pollution-free heating tube device of vertical vacuum ion film plating machine

ActiveCN103695845AAvoid secondary pollutionCompact structureVacuum evaporation coatingSputtering coatingEngineeringTube cleaning

The invention discloses a pollution-free heating tube device of a vertical vacuum ion film plating machine. The pollution-free heating tube device comprises a heating tube assembly, a corrugated tube assembly, a corrugated tube supporting seat assembly and a lifting mechanism, wherein the heating tube assembly comprises heating tubes, the upper ends of the heating tubes are insulating conducting wire lead-out ends, heating tube flanges are slightly below the heating tubes and are downwardly connected with the corrugated tube assembly, the corrugated tube assembly is downwardly connected with the corrugated tube supporting seat assembly, the corrugated tube supporting seat assembly is downwardly communicated with a furnace through heating tube access ports formed in a top plate of a furnace body, and the heating tubes penetrate through the hollow internal cavities of the corrugated tube assembly and corrugated tube supporting seat assembly, extend into the heating tube access ports in the top plate of the furnace body, enter the furnace and are connected with the lifting mechanism through the heating tube flanges. The heating tubes are not located in a film plating room during film plating, and then, plated layers cannot be attached and remained onto the heating tubes, so that the problem of secondary pollution caused by the heating tubes is solved; the pollution-free heating tube device has the advantages that the structure is simple and compact, and the work of heating tube cleaning is avoided, the quality of the plated layers is improved, the work efficiency is increased, and the production cost is reduced.

Owner:DONGGUAN HUICHENG VACUUM TECH

Radiation-sensitive composition, laminate, process for producing the sane and electronic part

ActiveCN1961261AGood shape retentionHigh transparencySemiconductor/solid-state device manufacturingPhotosensitive material processingElectronPolymer chemistry

The invention provide a radiation-sensitive composition that excels in electrical properties, being free from any film thickness decrease and developed film detachment at the time of development and that even after heating at high temperature, exhibits high shape retention capability and transparency, also excelling in chemical resistance. Provide is a laminate having a resin film of this radiation-sensitive composition superimposed on a basal plate; and a process for producing the laminate. There is provided a radiation-sensitive composition comprising a polymer having a polar group reactive with an epoxy group, a crosslinking agent containing a polyepoxy compound which has an alicyclic structure in its main chain skeleton and has three or more epoxy groups, and a radiation-sensitive compound. Further, there is provided a laminate comprising a basal plate and a resin film of this crosslinkable resin composition.

Owner:ZEON CORP

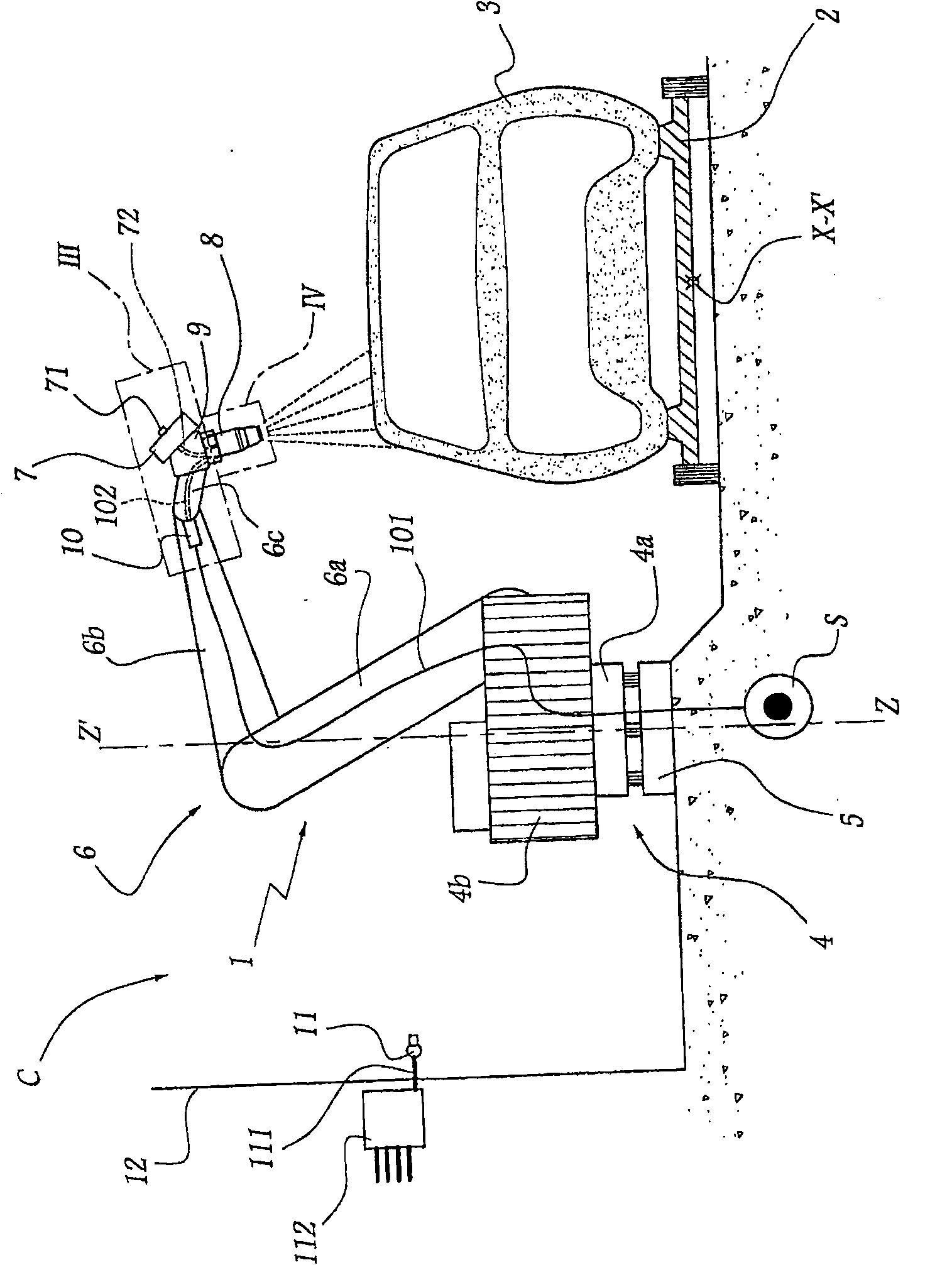

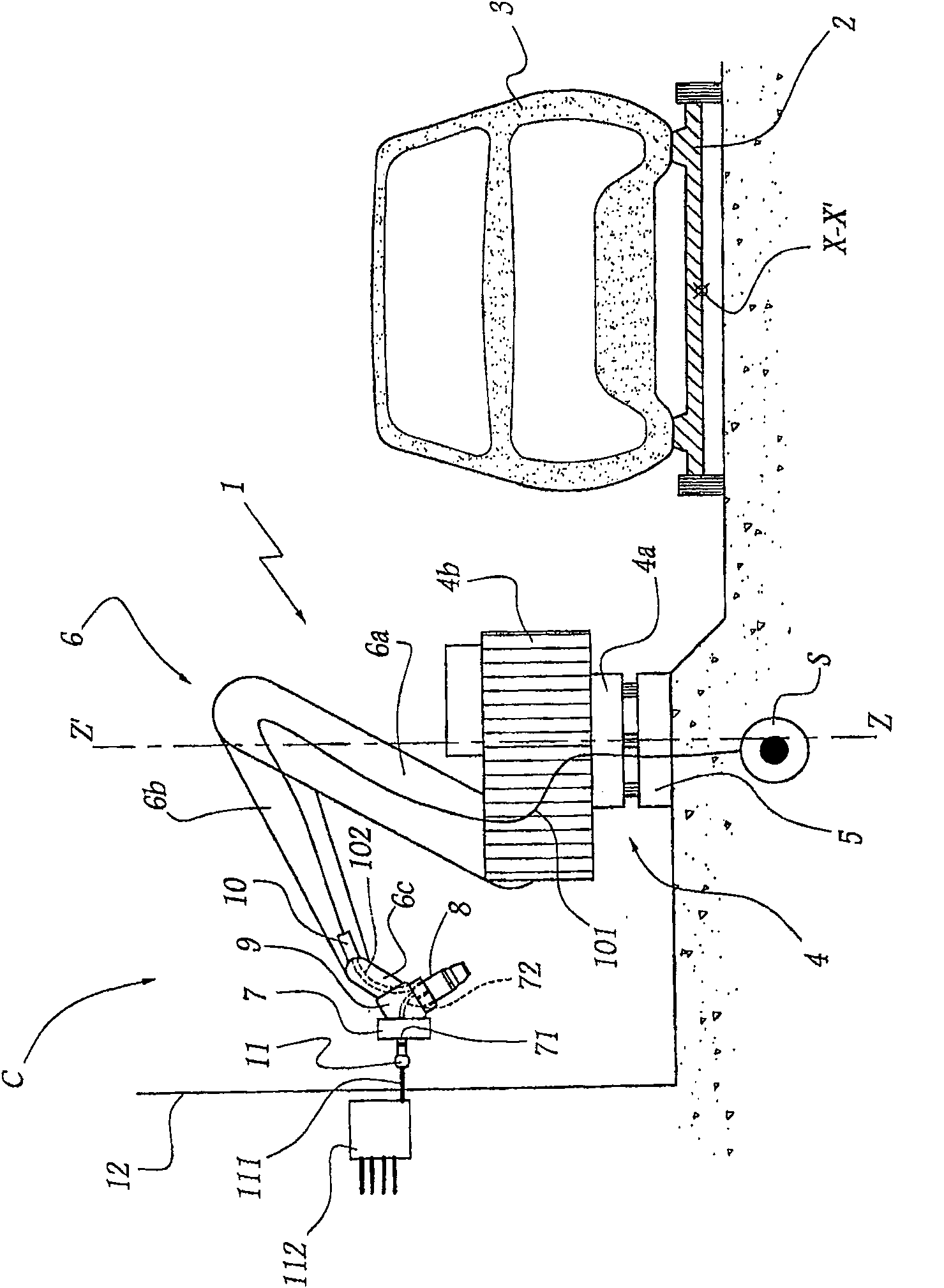

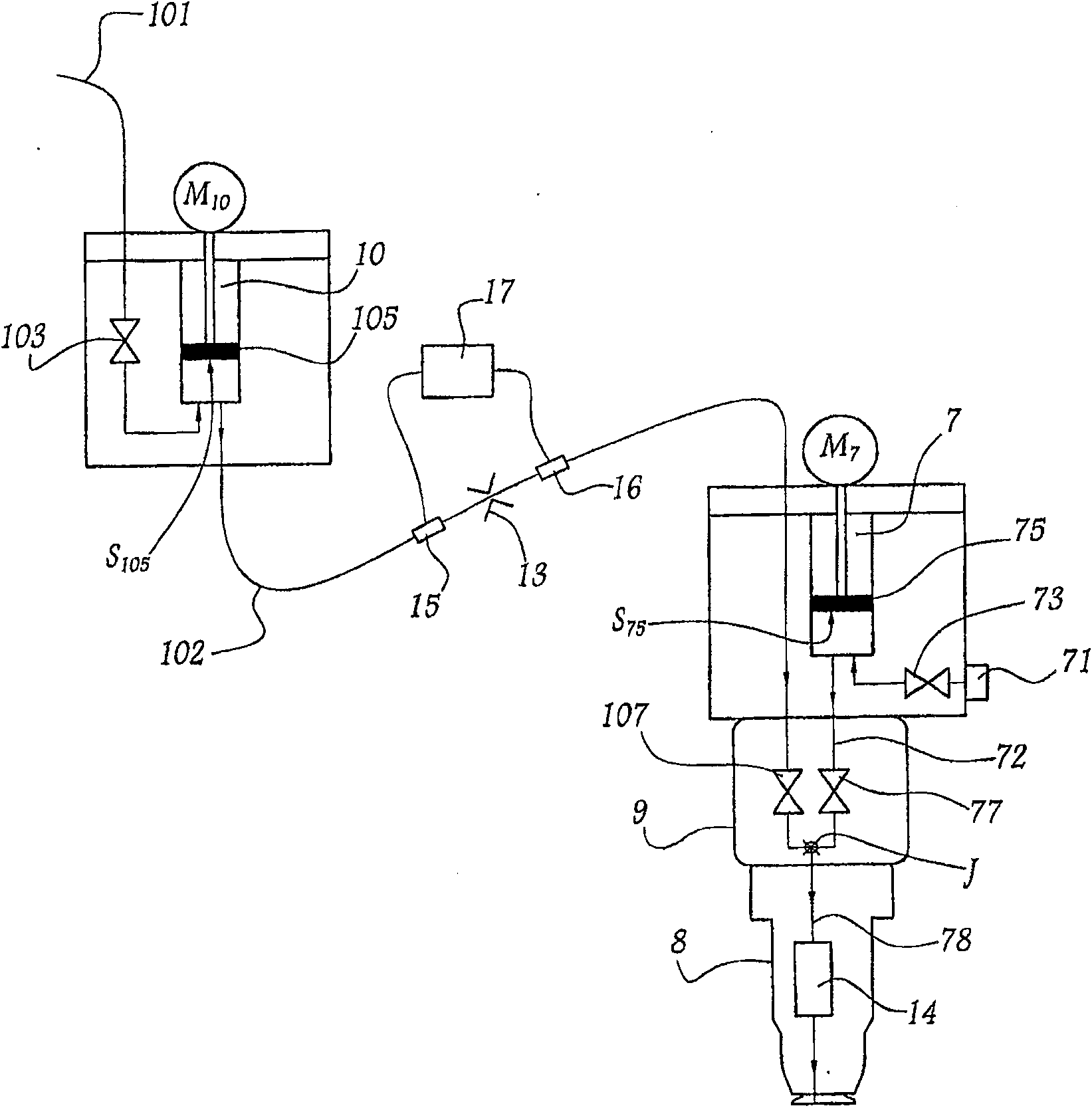

Installation for spraying a multicomponent coating product

An installation for spraying a multi-component coating material composed of at least one robot having a moving portion carrying at least one electrostatic sprayer, the coating material having an electrically-conductive component together with at least one second component that is electrically insulating or poorly conductive. The installation further includes a main tank fitted with a unit for making a temporary connection with a circuit for dispensing the first component, and being raised to a high voltage when the connection unit not connected, and a feed circuit for continuously feeding the at least one second component. The main tank and the at least one second component feed circuit are carried by the moving portion of the robot and connected to feed the sprayer.

Owner:サムクレムリン

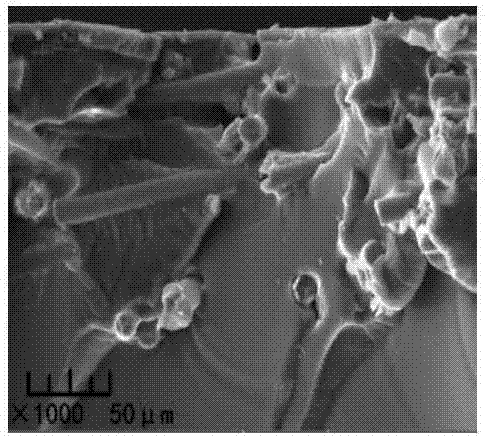

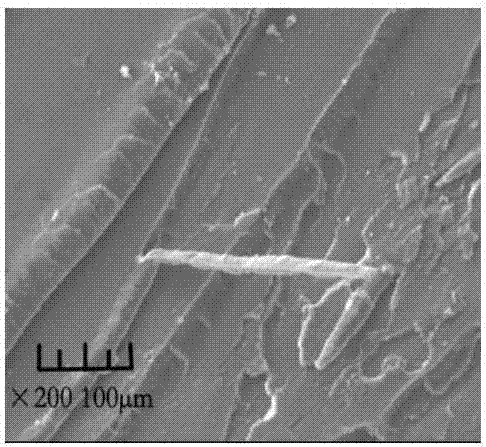

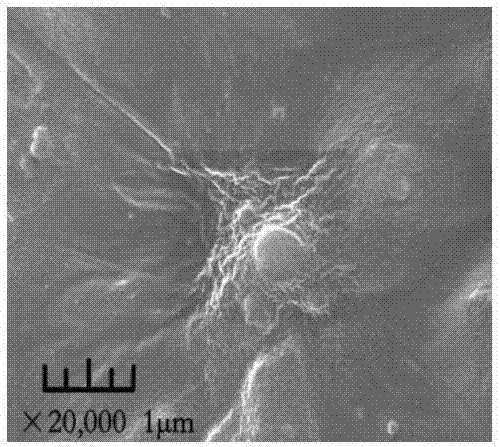

Glass fiber/carbon nanotube co-modified epoxy composite and preparation method thereof

ActiveCN107337902AHigh electrical insulationEnsure electrical insulationHeat-exchange elementsGlass fiberCarbon nanotube

The invention discloses a glass fiber / carbon nanotube co-modified epoxy composite. The composite is composed of, on the basis of 100 g of epoxy resin, 0.2 g of carbon nanotubes, 10-40 g of glass fibers, 80 g of a curing agent, 0.1 g of an accelerator and 20 g of a coupling agent. The glass fiber / carbon nanotube co-modified epoxy composite has both electrical isolation properties and improved thermal conductivity. The invention also discloses a preparation method for the glass fiber / carbon nanotube co-modified epoxy composite.

Owner:XIAN UNIV OF TECH

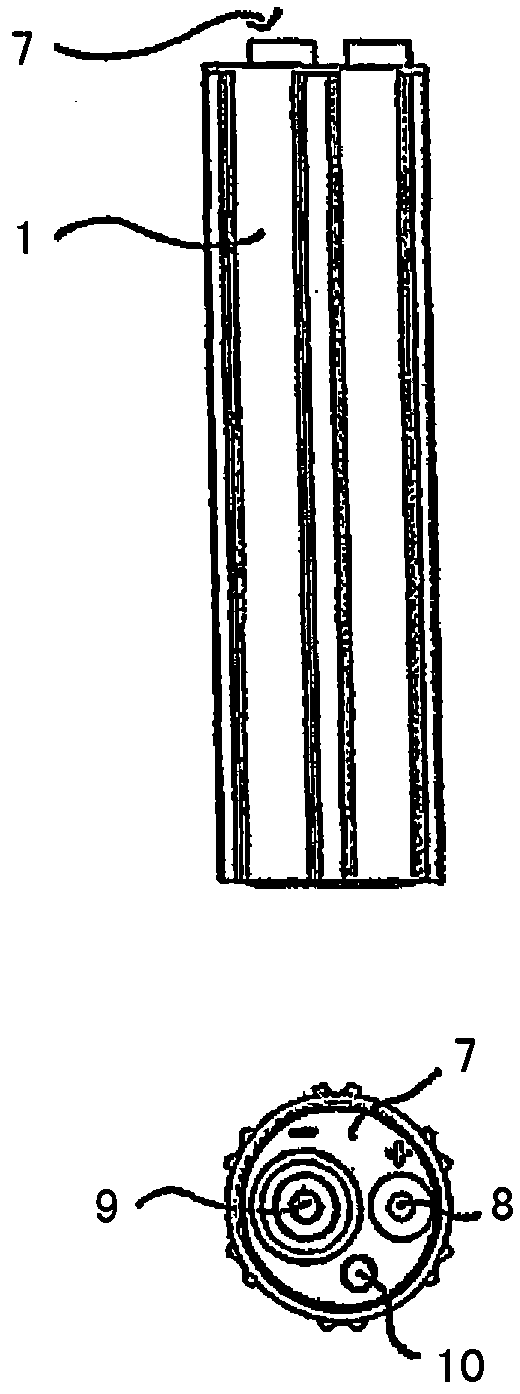

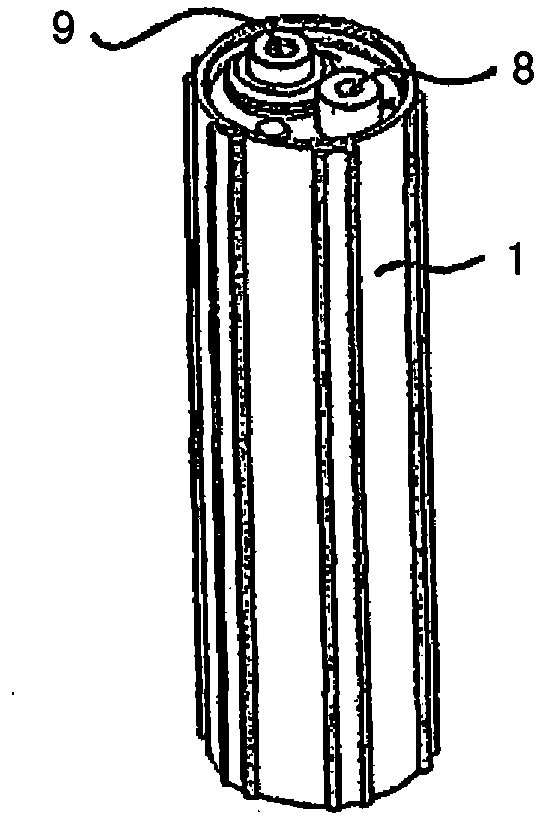

Round cell battery

ActiveCN102084516AEnsure electrical insulationIncrease contactFinal product manufactureCells cooling/heatingElectricityRound cell

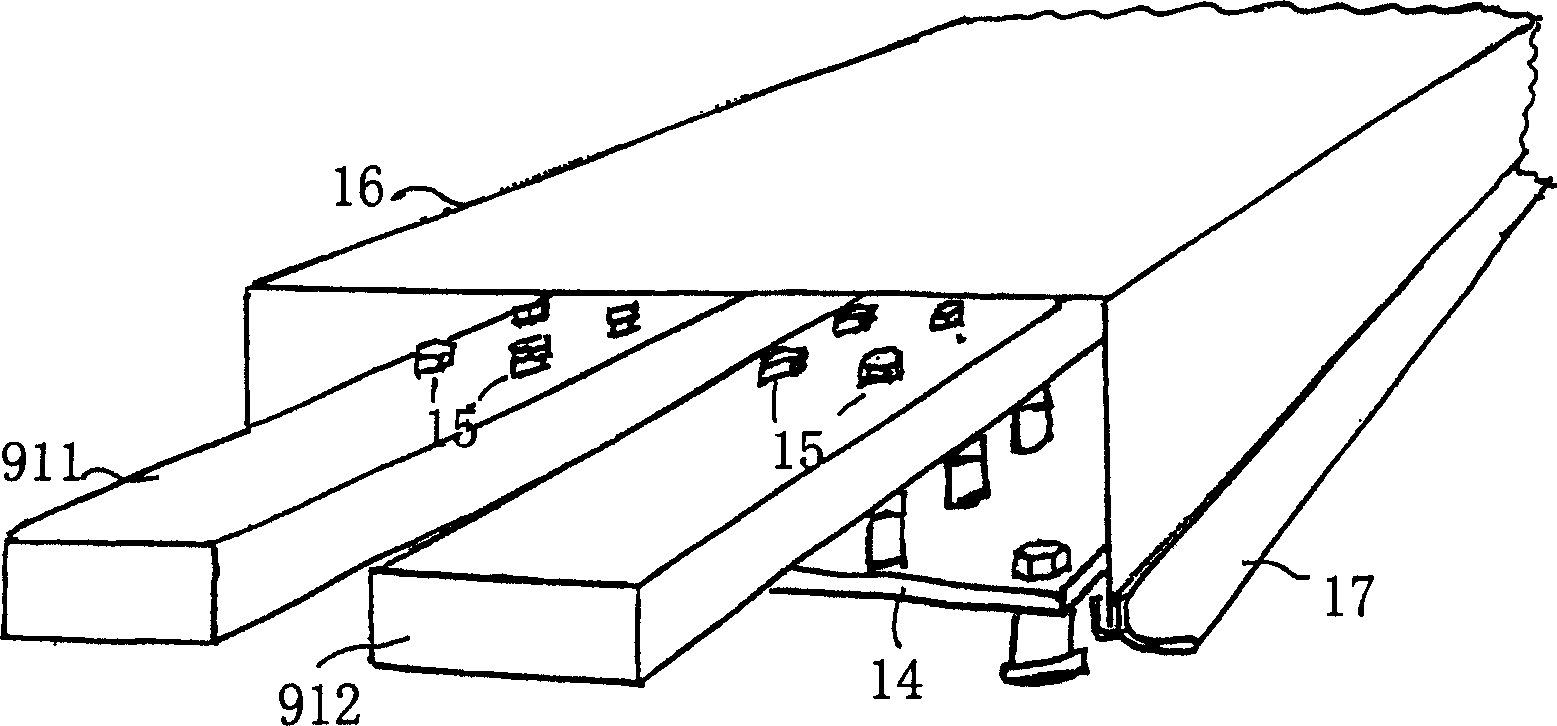

The present invention relates to a round cell battery, comprising a) a plurality of round cells (7) arranged next to each other, b) at least one dissipation element (14), which is electrically insulated with respect to the round cells (7) and has a rod-shaped configuration and is bent such that it runs in a zigzag-shaped manner alternately along the lower side (5), an adjoining lateral wall and an upper side (4) of the round cells (7), thereby interconnecting a group of round cells (7) in a thermally conductive manner for the dissipation of heat, and c) a electrically insulating, thermally conductive and rubber-elastic thermoplastic elastomer, which is arranged at least partially between the at least one dissipation element (14) and the round cells (7) in order to insulate the dissipation elements (14) electrically from the round cells (7) and to dissipate heat from the round cells (7) to the dissipation elements (14), exhibits good thermal conductivity from the round cells (7) to the dissipation elements (14).

Owner:科瑞斯技术与再循环有限责任公司

Environment-protecting flame-retardant composite filling reinforced polyamide 66 resin composition

InactiveCN101440216AImprove flame retardant performanceNot harmful to the environmentGlass fiberHeat resistance

The invention provides an environment-friendly flame retardant composite filling reinforced polyamide 66 resin composition, which consists of a mixture. The mixture consists of the following compositions by weight percentage: 40 to 67 percent of nylon 66, 12 to 25 percent of red phosphorus master batch, 1 to 10 percent of compatilizer, 10 to 20 percent of glass fiber, 10 to 20 percent of talcum powder, 0.1 to 1 percent of antioxidant, and 0.1 to 1 percent of lubricant. The flame retardant polyamide composition has high-efficiency flame retardant performance with flame retardant rating reaching V0 grade of UL94 standard, greatly improves rigidity and heat resistance of nylon with good dimension stability, and belongs to an environment-friendly product. The environment-friendly flame retardant composite filling reinforced polyamide 66 resin composition is applicable to injection molding of electronic equipment and household appliances with various environment-friendly and flame retardant requirements.

Owner:SHANGHAI SUNNY

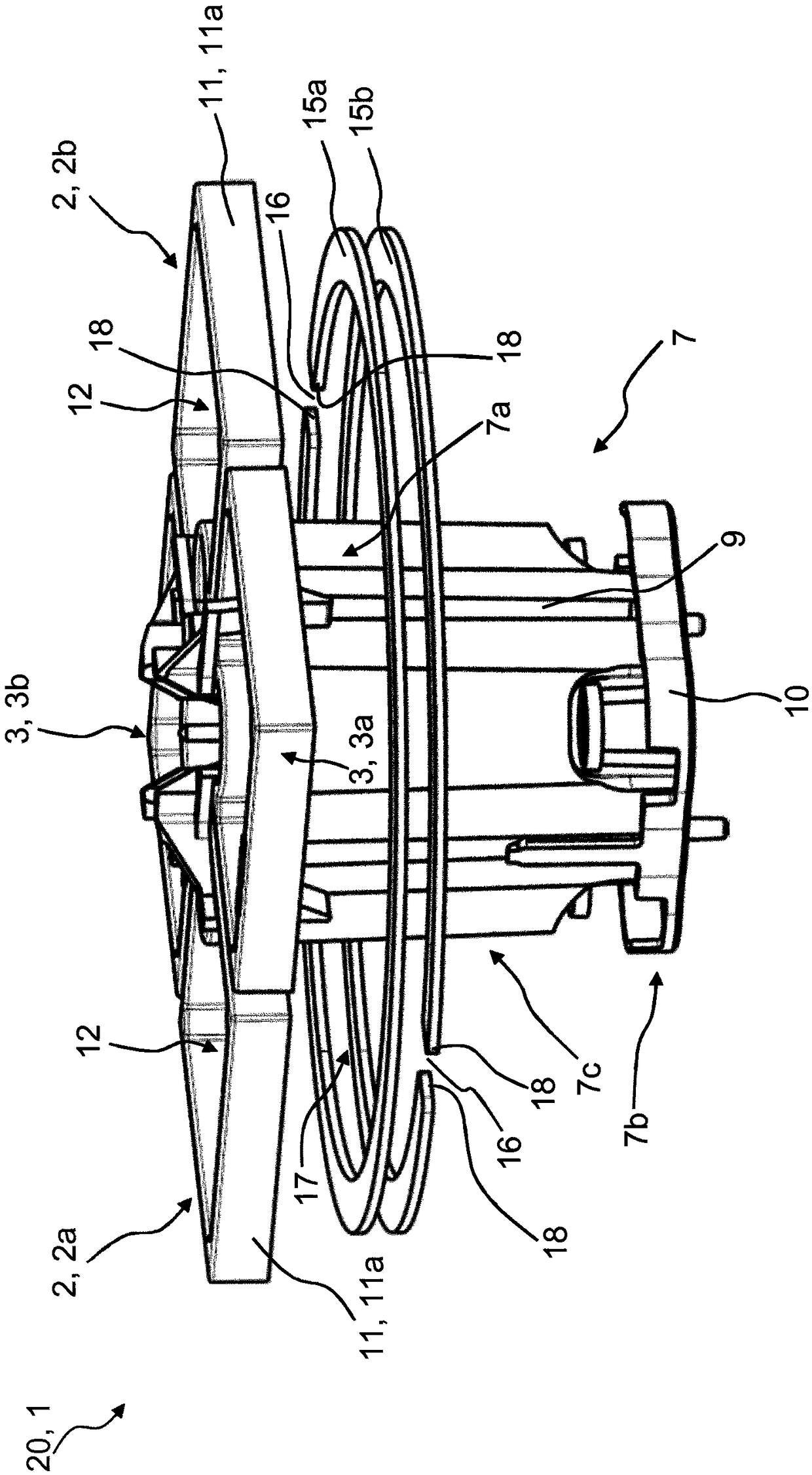

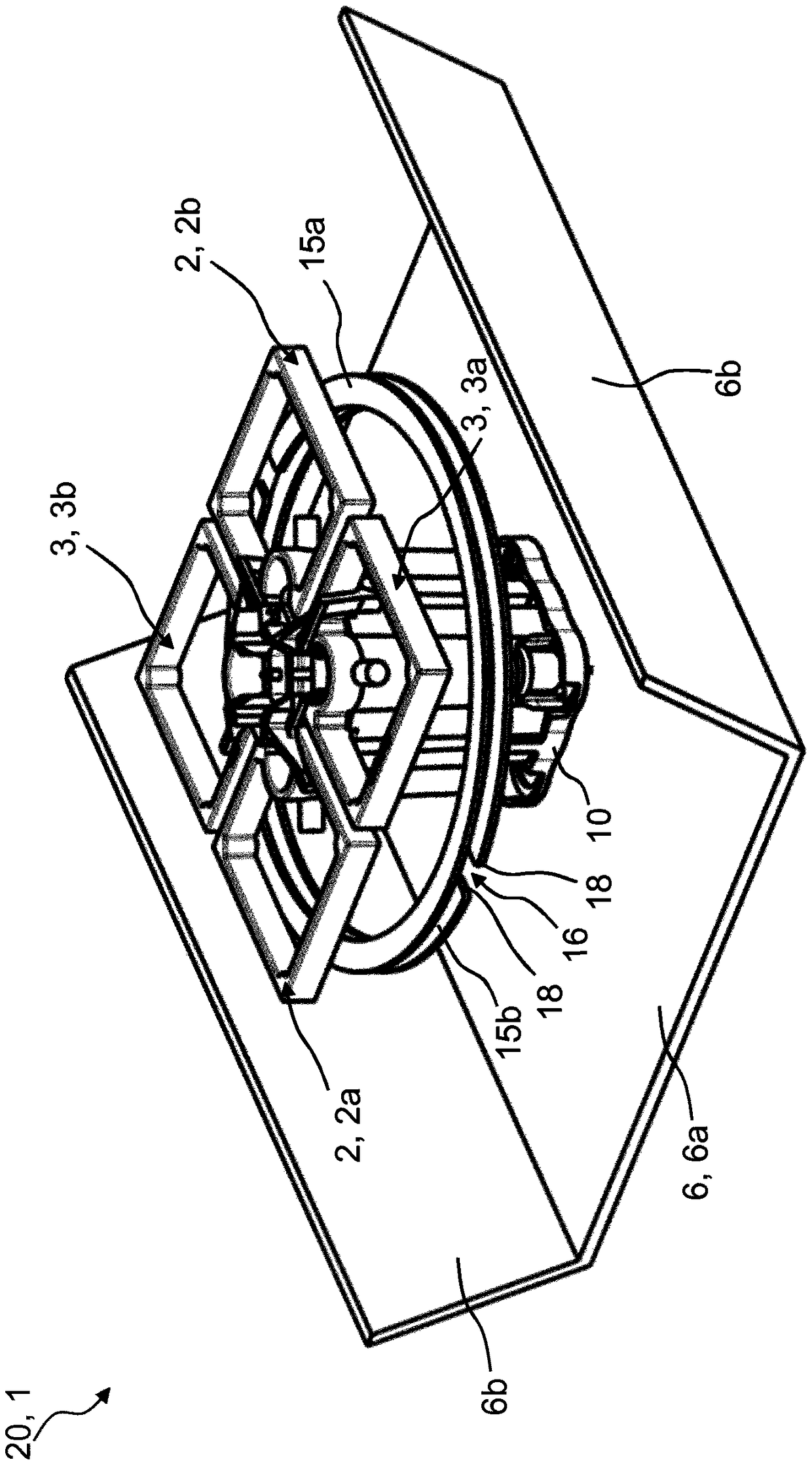

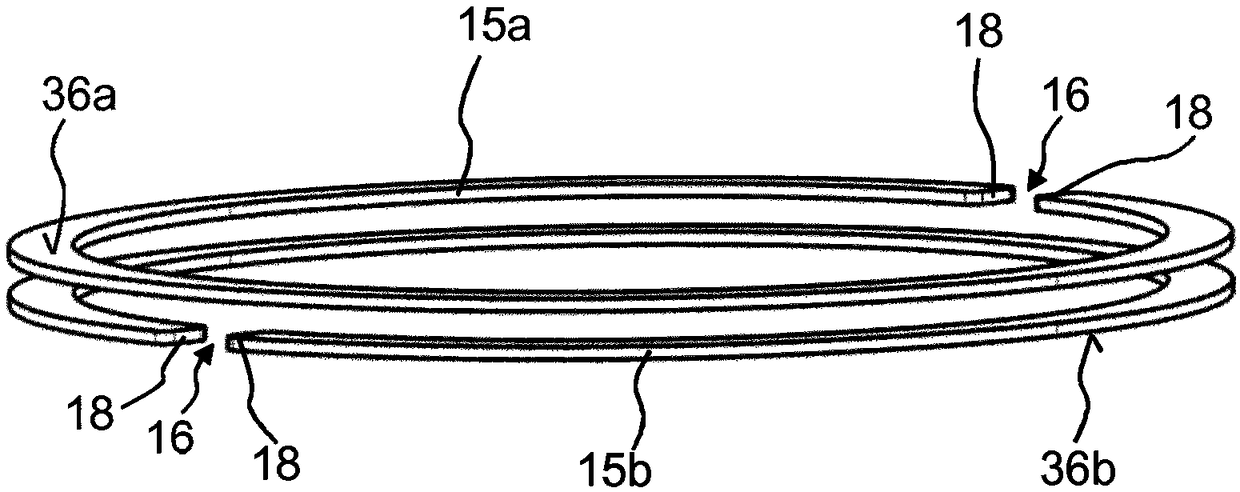

Antenna array with at least one dipole-type emitter arrangement

ActiveCN109417219AAdjustable coupling heightAvoid connectionSimultaneous aerial operationsAntenna supports/mountingsPolarization planeAntenna array

An antenna array (20) with at least one dipole-type emitter arrangement (1), wherein the at least one dipole-type emitter arrangement (1) comprises two pairs (2, 3) of emitter halves (2a, 2b, 3a, 3b),which transmit and / or receive on two polarization planes (4a, 4b) that are perpendicular to one another. The emitter halves (2a, 2b, 3a, 3b) can be or are arranged on an emitter plane (5) at a distance from a reflector (6) and run parallel to said reflector. Two electrically conductive partial circumferential frames (15a, 15b, 15c) are provided, which are disposed between the emitter plane (5) and the reflector (6) at a distance from one another, wherein the at least two electrically conductive partial circumferential frames (15a, 15b, 15c) define one opening (17). The at least two partial circumferential frames (15a, 15b, 15c) are oriented parallel to the emitter plane (5). Each of the two partial circumferential frames (15a, 15b, 15c) comprises at least one gap (16), which extends through the entire width of the partial circumferential frame (15a, 15b, 15c), so that each partial circumferential frame (15a, 15b, 15c) comprises at least two ends.

Owner:TELEFON AB LM ERICSSON (PUBL)

Preparation method of high-surface inner-heat-conduction insulation composite membrane

ActiveCN108219757AHigh in-plane thermal conductivityEnsure electrical insulationHeat-exchange elementsMicrometerBoron nitride

The invention belongs to the technical field of fine chemistry industry, and particularly relates to a preparation method of a high-surface inner-heat-conduction insulation composite membrane. According to the method, a graphene oxide water solution is used as a raw material; boron nitride micrometer sheets are added; ultrasonic agitation is performed to obtain the uniform mixed solution; then, the mixed solution is casted and dried to obtain a graphene oxide-boron nitride micrometer sheet composite membrane. The prepared composite membrane has high in-surface heat conduction rate; meanwhile,the electric insulation performance is maintained. The method has the advantages that the operation is simple; the environment-friendly effect is good; the scaled production is easy; wide applicationprospects are realized in the field of micro-electronic materials.

Owner:FUDAN UNIV

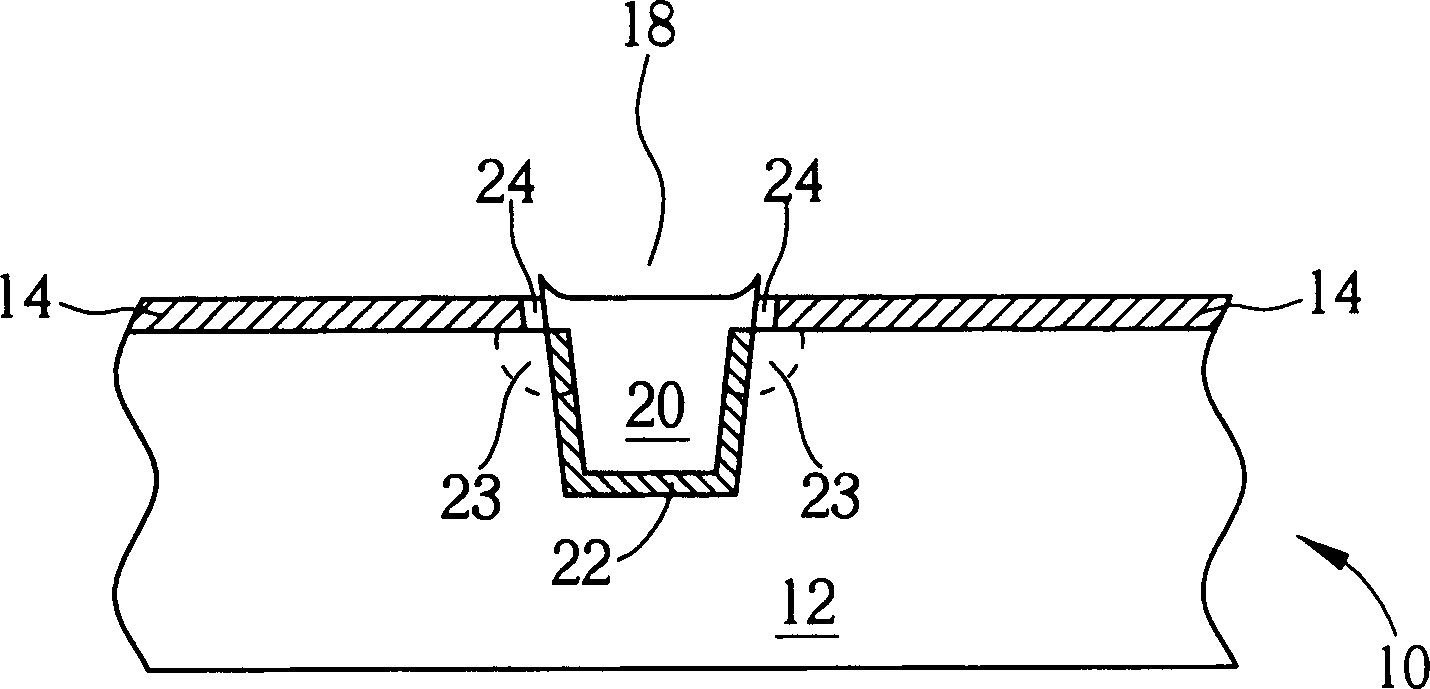

Shallow-channel insulation making process

InactiveCN1417850AAvoid abnormal conductivityImprove leakage currentSemiconductor/solid-state device manufacturingOptoelectronicsDielectric layer

The present invention provides shallow-channel insulation making process, which includes: providing substrate material and forming stacked mask layer comprising backing oxide layer and barrier layer,which at least one opening to expose the substrate and on the substrate; drying itching the substrate via the opening to form shallow channel and depositing CVD lining layer; oxidizing the CVD lininglayer to form oxide lining layer and depositing one dielectric layer to fill the shallow channel; and final flattening, eliminating the dielectric layer and oxide lining layer over the barrier layer to expose the barrier layer and eliminating and barrier layer.

Owner:MACRONIX INT CO LTD

Low-temperature electrical resistivity measuring apparatus and installation method thereof

PendingCN108362743AEnsure electrical insulationElectrical insulation coolingMaterial resistanceMeasurement deviceEngineering

The invention discloses a low-temperature electrical resistivity test apparatus which is connected with an external cold source and used for measuring the electrical resistivity of a sample to be tested at a low temperature. The low-temperature electrical resistivity measuring apparatus is characterized by comprising a heat sink, a sample frame, at least two probes, an insulation frame, a positioning pressure plate, an insulation pressing ring, a fixed bolt and a reinforcing pressure plate. The invention also discloses a test method of the low-temperature electrical resistivity measuring apparatus. By adopting the low-temperature electrical resistivity measuring apparatus, an electrode can be accurately positioned, the accuracy for measuring the electrical resistivity can be effectively ensured, the sample to be tested can be reliably fixed, the completeness can be ensured, and the application prospect is wide.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

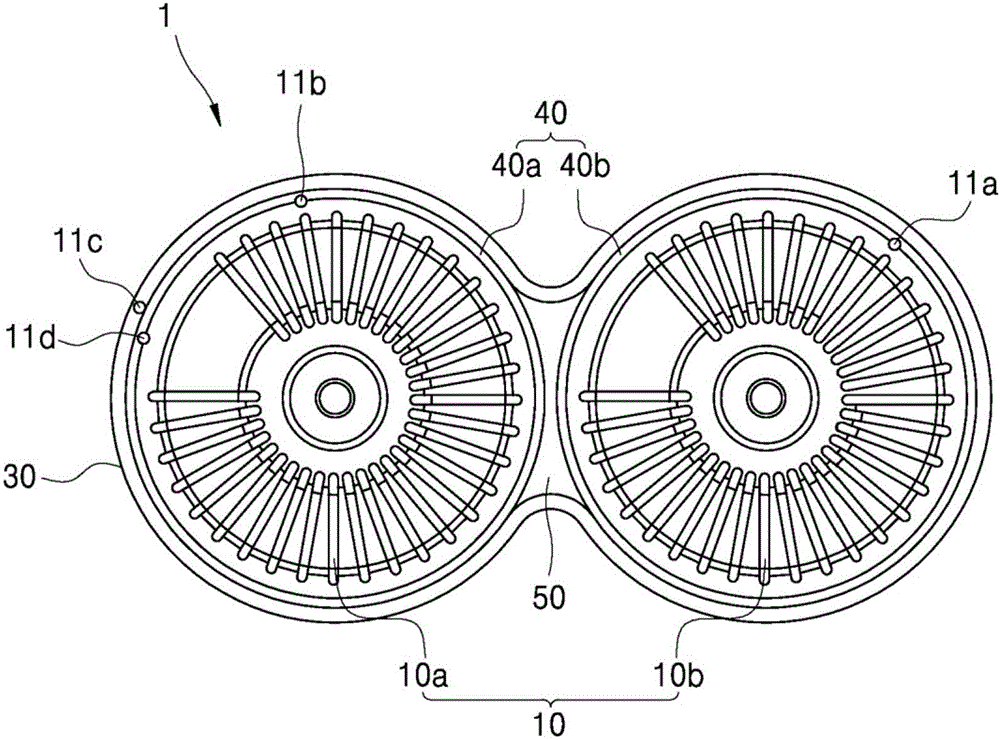

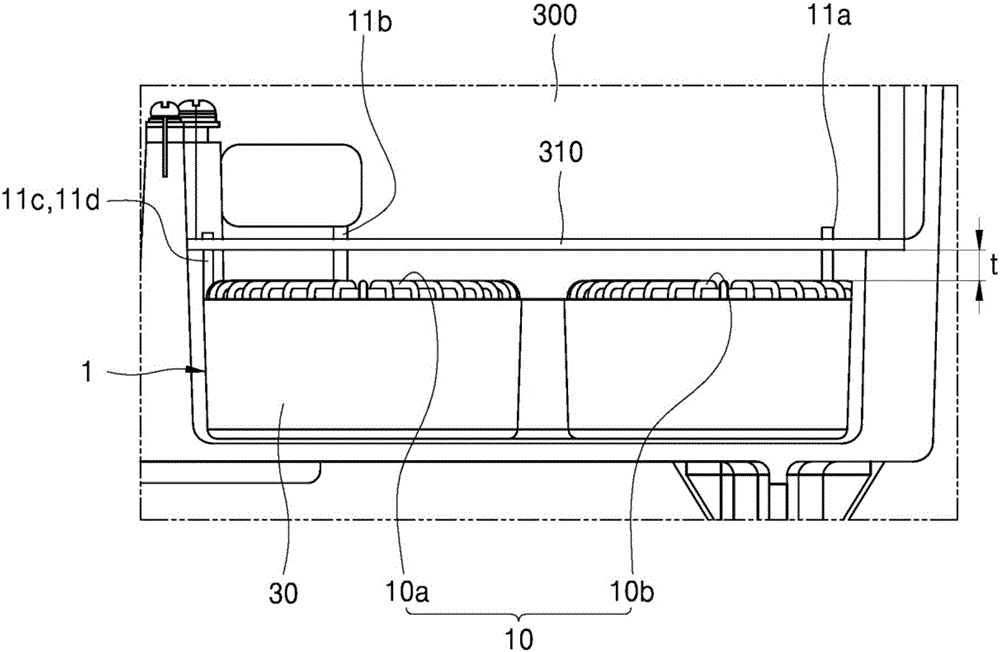

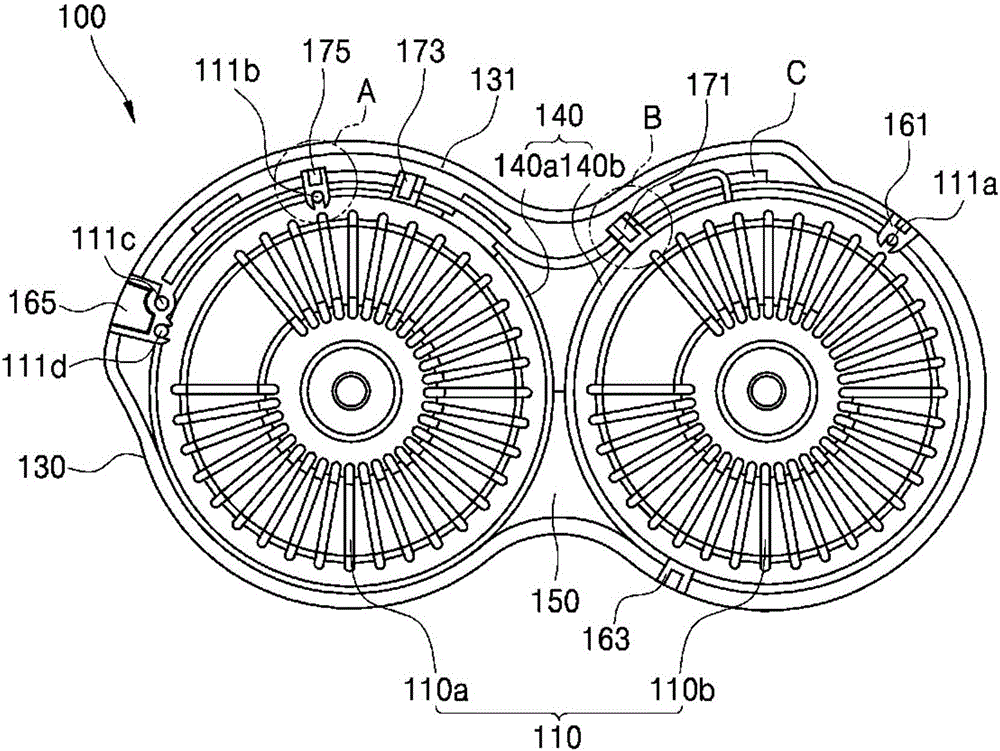

Inductor assembly for obc of electric vehicle

InactiveCN106057404AEnsure electrical insulationImprove assembly effectTransformers/reacts mounting/support/suspensionBatteries circuit arrangementsIn vehicleElectric cars

Disclosed herein are embodiments of an inductor assembly for an on-board charger (OBC) of an electric vehicle capable of improving insulation and heat dissipation property, with improved assembling performance. The inductor assembly includes: a pair of inductors; a case for accommodating the inductors therein; a pair of insulating cases installed in the case for maintaining electrical insulation between the inductors; a mold molded in the case for integrally fixing the inductors, the insulating cases and the case; and a cover coupled to an upper portion of the case for insulating the inductors accommodated in the case from the outside.

Owner:LSIS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com