Heater of metal cylinder

A heating device and metal cylinder technology, applied in induction heating devices, induction heating, heat treatment furnaces, etc., can solve the problems of undiscovered, long time to manufacture, expensive, etc., to achieve maintenance life, short-term replenishment is easy, suitable for long-term effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

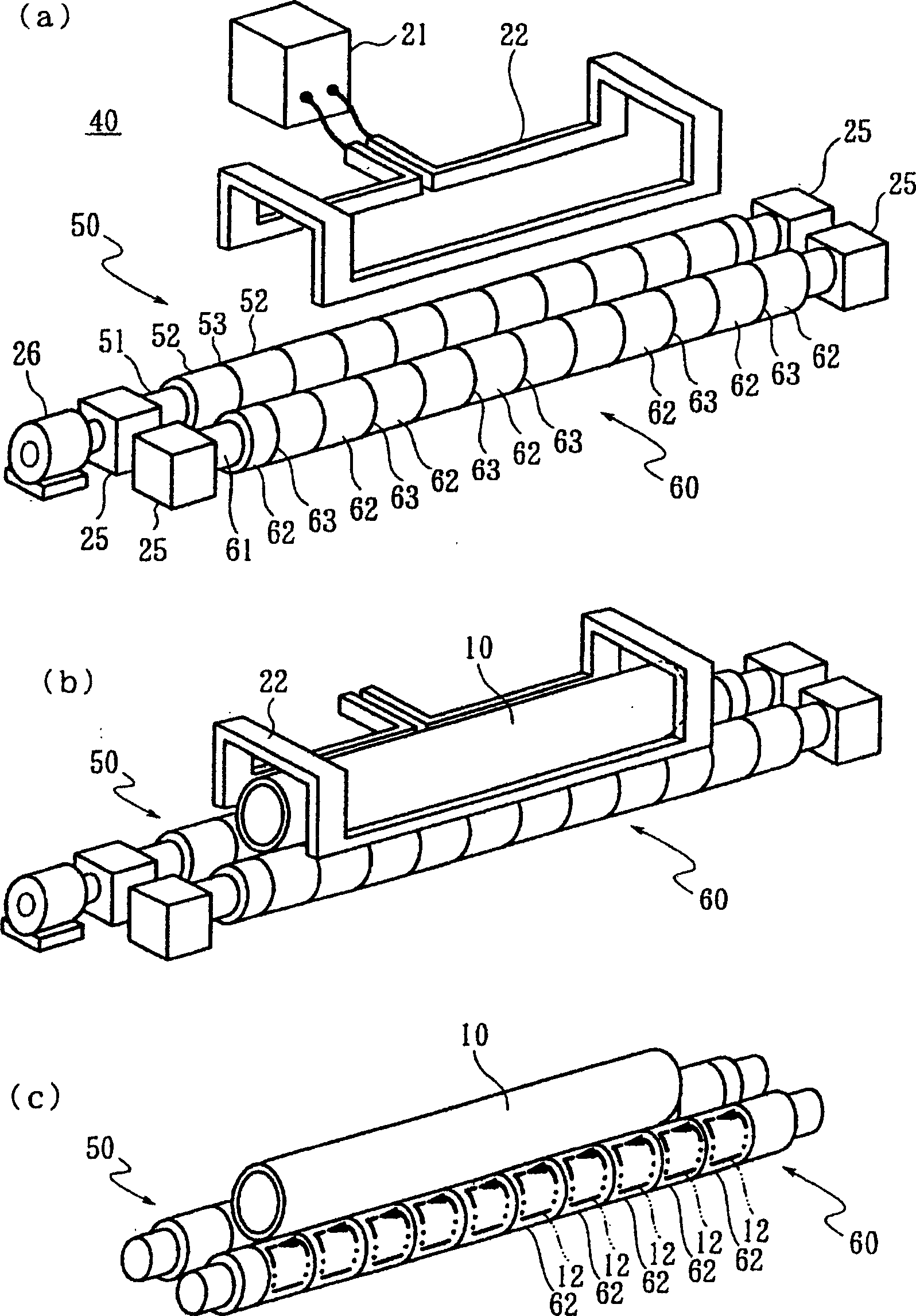

Embodiment 1

[0107] The metal cylinder heating device 40 and the metal cylinder heating device 70 mentioned above were manufactured as a trial, and the insulation state of the short bushing, the vibration of the back-up roller under no load and load, and the number of times of use until spark marks were found were investigated. The temperature of the intermediate bearing portion 72 is also measured for the metal cylinder heating device 70 .

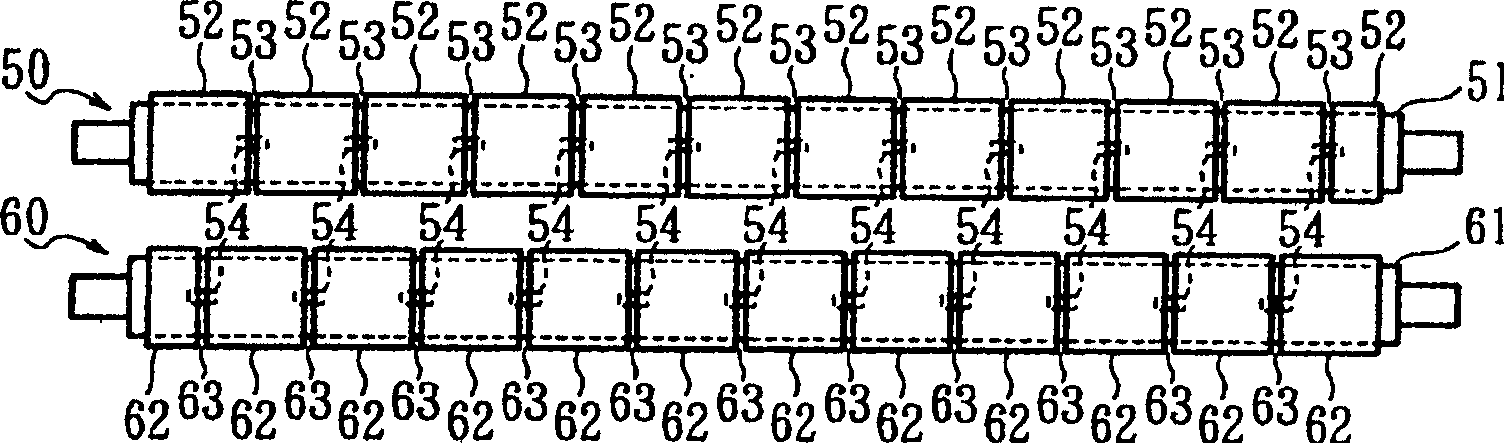

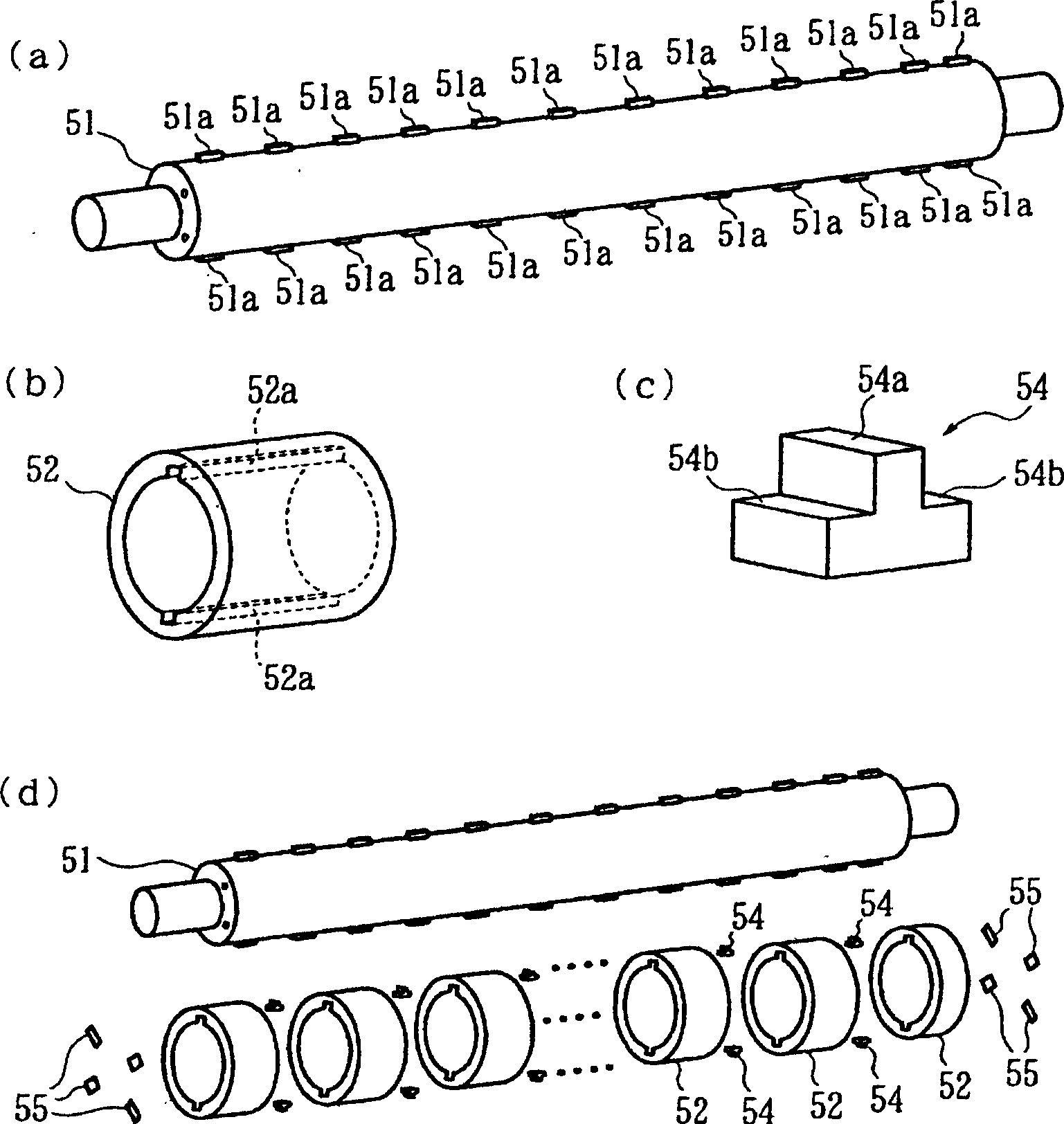

[0108] The core parts 51, 61 of the support rollers 50, 60 of the metal cylinder heating device 40 are made of JIS / SCM440, the outer diameter is 120mm, and the length is 1920mm; the insulating coating layer is made of alumina and has a thickness of 0.3mm. Formed by spraying.

[0109] The short sleeves 52 and 62 are made of JIS / SUS304, have an outer diameter of 150 mm, an inner diameter of 120 mm, and a length of 155 mm. In addition, the length of one arranged at one end is only half.

[0110] The core members 81, 91 of the support rollers 80, 90 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com