Patents

Literature

243results about "Impregnation spraying apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

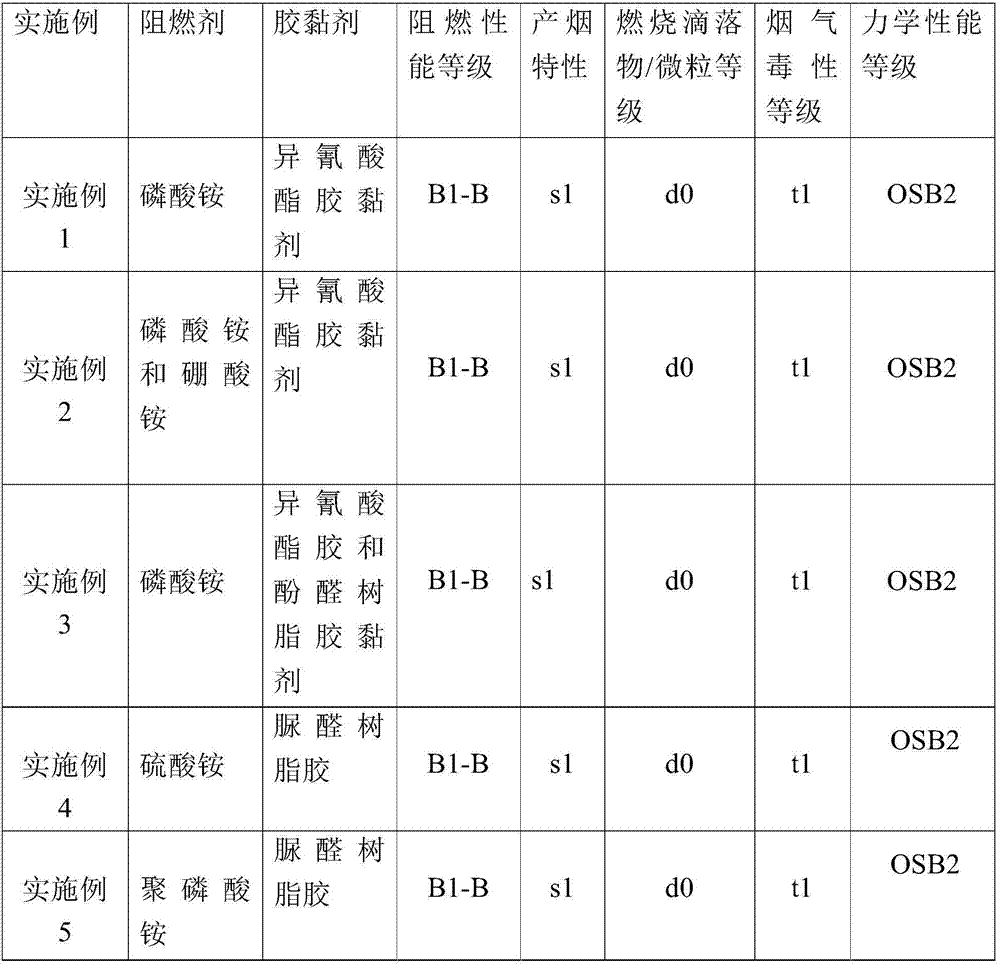

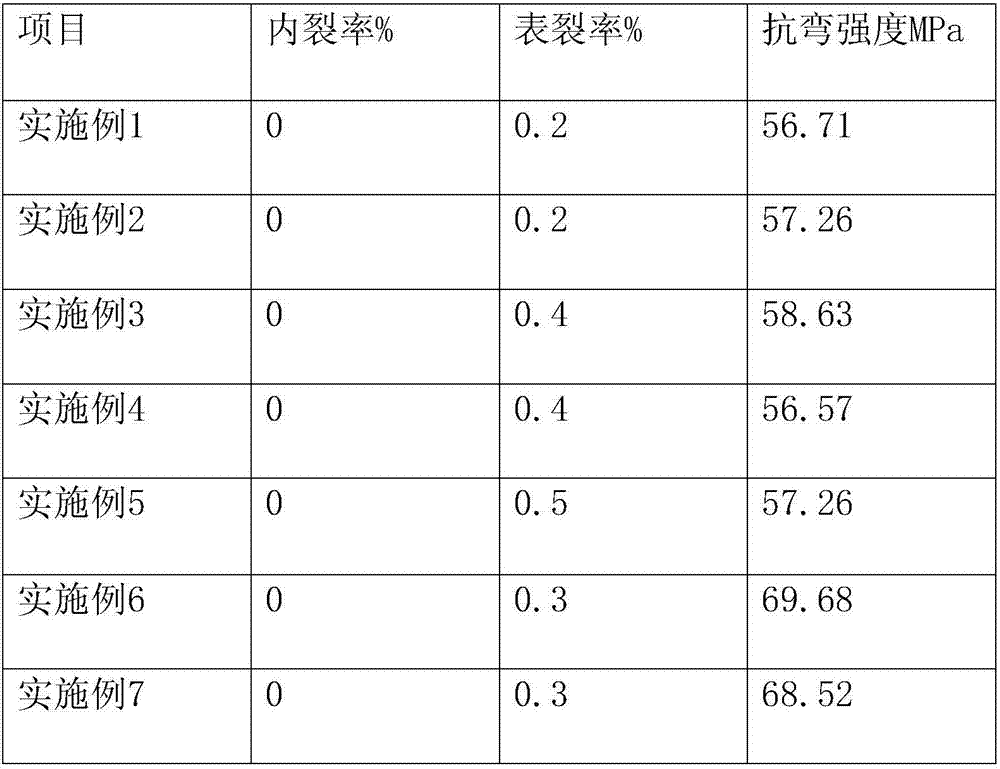

Modified flame-retardant oriented strand board and preparation method thereof

InactiveCN107379141AImprove flame retardant performanceImprove stabilityImpregnation spraying apparatusWood treatment detailsPolymer scienceAdhesive

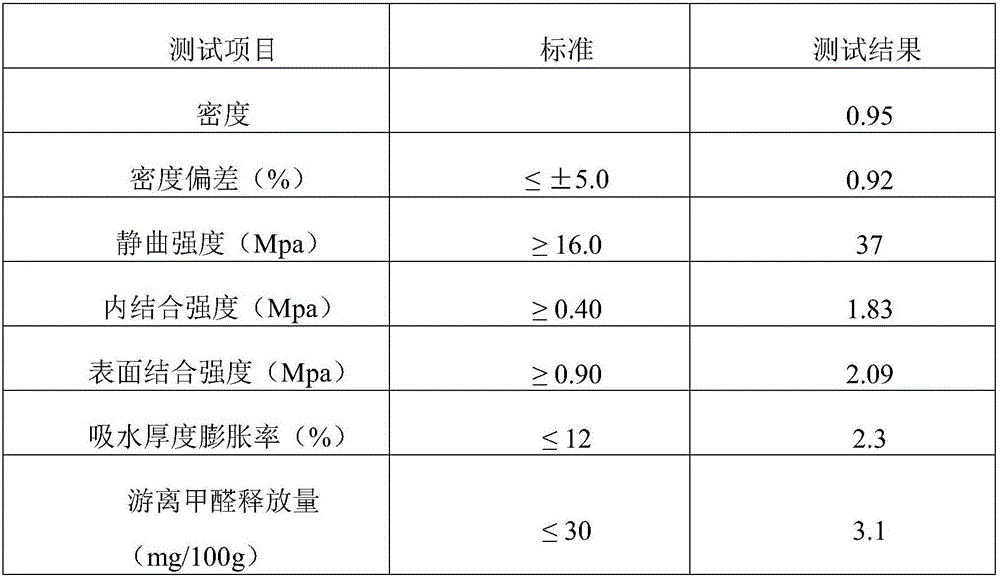

The invention discloses a modified flame-retardant oriented strand board. The modified flame-retardant oriented strand board comprises, by weight, 1-5% of nano silicon dioxide, 10-30% of nitrogen and phosphorus flame retardants, 43-79.5% of wood flakes, 2.5-22% of adhesive and 0.5-3% of an auxiliary agent. The invention further discloses a preparation method of the modified flame-retardant oriented strand board. Compared with a common secondary processing method, a silicon dioxide modified flame retardant and the auxiliary agent are added into a primary shaping technology of the oriented strand board, so that the prepared oriented strand board is better in flame retardant effect and higher in flame retardancy stability. According to the flame-retardant oriented strand board prepared by adopting the preparation method, only simple spraying equipment needs to be additionally arranged in a sizing technology, the device transformation cost is low, a secondary processing device is avoided, and the cost is saved.

Owner:天津北新木业有限公司

High-strength straw board and preparation method thereof

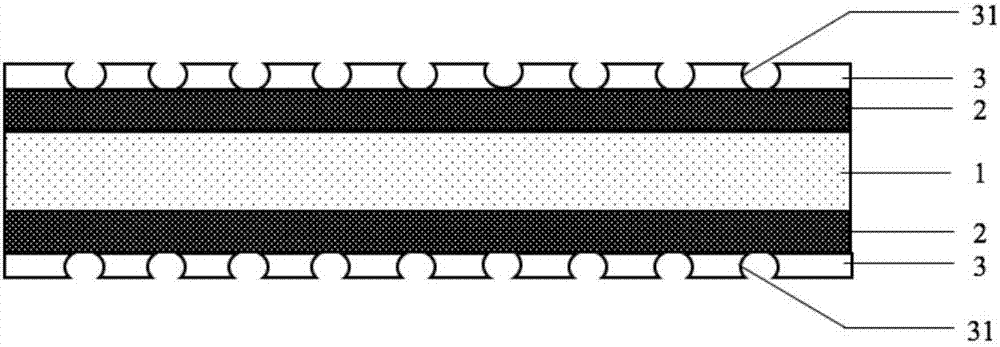

ActiveCN106182214AHigh strengthSolve the strength problemLayered productsImpregnation spraying apparatusFiberAdhesive

The invention relates to a high-strength straw board. The high-strength straw board comprises a straw base plate, wherein six side faces of the straw base plate are successively bonded to a sound-resistant layer, a waterproof layer and a fireproof layer through an adhesive; the straw base plate is made of wheat straws; the adhesive is a thermoplastic adhesive; the sound-resisting layer is prepared from PU matrix resin and a foam material plate which is prepared from hollow polymeric microspheres; the waterproof layer is a high-performance fiber board; the fireproof layer is a glass magnesium board. The production method of the high-strength straw board comprises the following main steps: S1, preparation of the straw base plate: 1, preparation and conveyance; 2, punch forming; 3, hot-pressing and paper-coating; and 4, cooling, segmenting and blocking; and S2, preparation of the straw board. The high-strength straw board provided by the invention has the advantages of relatively high strength, good sound-resistant effect, good fireproof performance, good waterproof performance, insect prevention and bacterial resistance and the like, can effectively replace various building panels in the current market, and can be widely applied to manufacturing exterior walls, interior walls, partition walls, roofs, doors, active houses and quick houses.

Owner:高唐融知融智科技服务有限公司

Wood conditioning method

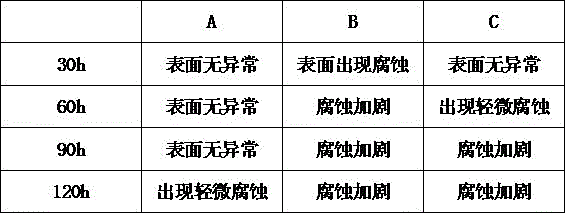

ActiveCN107116643AIdeal elastic strengthIdeal compressive strengthImpregnation spraying apparatusWood treatment detailsCell wallHigh-temperature corrosion

The invention discloses a wood conditioning method. The method comprises following steps of immersion treatment, primary heating and humidifying treatment, primary drying, primary cooling, secondary heating and humidifying treatment, secondary drying, secondary cooling and ventilation drying. According to the wood conditioning method, the high-temperature and low-temperature alternative drying manner is adopted to reduce the wood water containing rate, through immersion treatment, ammonium bicarbonate is guided into the wood, due to alkalescence of an ammonium bicarbonate solution, cellulose on the wood cell wall can be swelled up, introduction of subsequent heat and water flowing can be facilitated, according to high-temperature and high-humidity treatment, overheat water steam is used for forming partial pressure so as to move water out of the wood, through cooling, temperature gradient is used for diffusing water to the outer portion, the high temperature drying and the low temperature drying are alternatively carried out, the water containing rate of the wood is reduced to the proper range, the anti-mildew anti-corrosion property of the wood can be increased, consumed time is short, and energy consumption is small.

Owner:浙江润格木业科技有限公司

Corrosion and mould resistant process for bamboos

InactiveCN106738144AAvoid stayingPrevent regenerationImpregnation spraying apparatusWood treatment detailsFiberHigh pressure

The invention provides a bamboo corrosion and mould resistant process with high processing efficiency. The process comprises the steps that bamboos are placed in an environment with the superheated steam pressure being 0.4-0.6 MPa and the steam temperature being 125-135 DEG C to be processed for 80-100 min; and when the bamboos are subjected to superheated steam treatment, a mould inhibitor stock solution is sprayed to steam, and 1.54 kg of the mould inhibitor stock solution is sprayed to every 1 m3 of the bamboos. The corrosion and mould resistant process has the beneficial effects that under the high-pressure and superheated steam state, the surfaces of the bamboos are carbonized, so that the situation that alien insects stay on the surfaces of the bamboos is avoided, germs and eggs inside the bamboos can be killed completely with the high pressure at the high temperature, meanwhile, sugar, air, impurities and the like inside the bamboos can be extracted out under vacuum, nutriment needed by moths is removed, only wood fibers remain, bacterium regeneration is avoided, and damage to the bamboos by worms is not liable to occur.

Owner:FUJIAN LONTAI BAMBOO HOUSEHOLD CO LTD

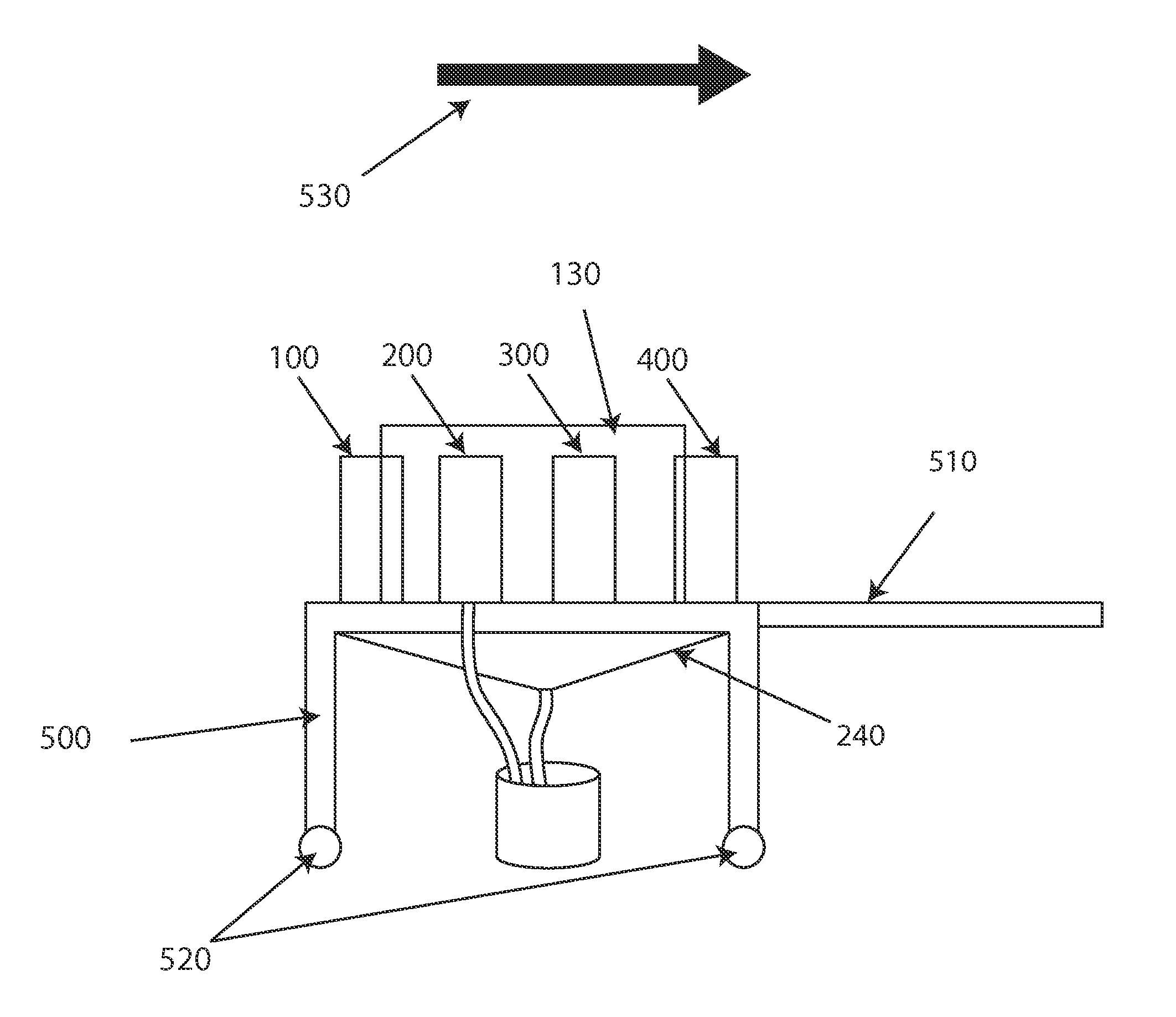

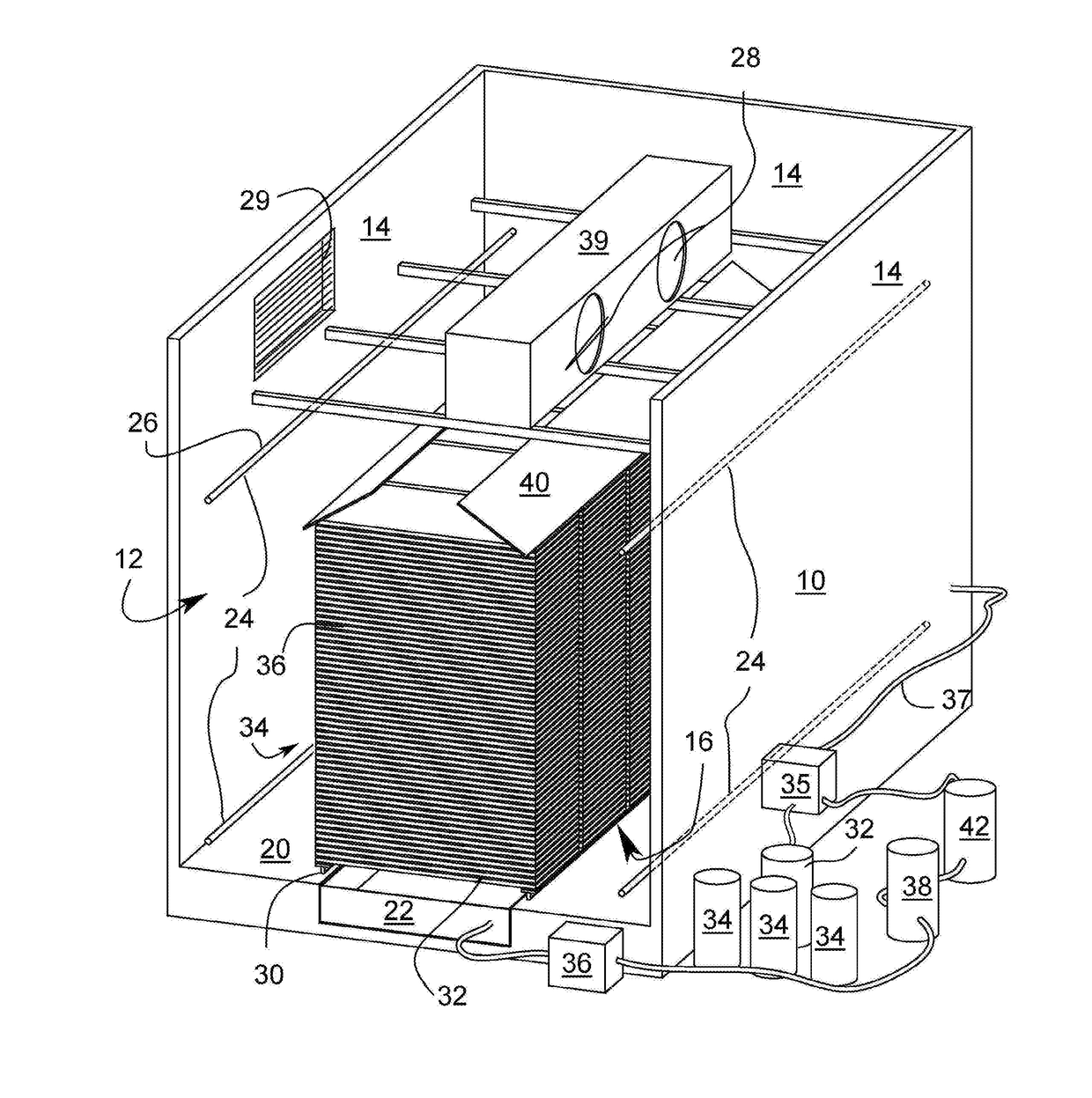

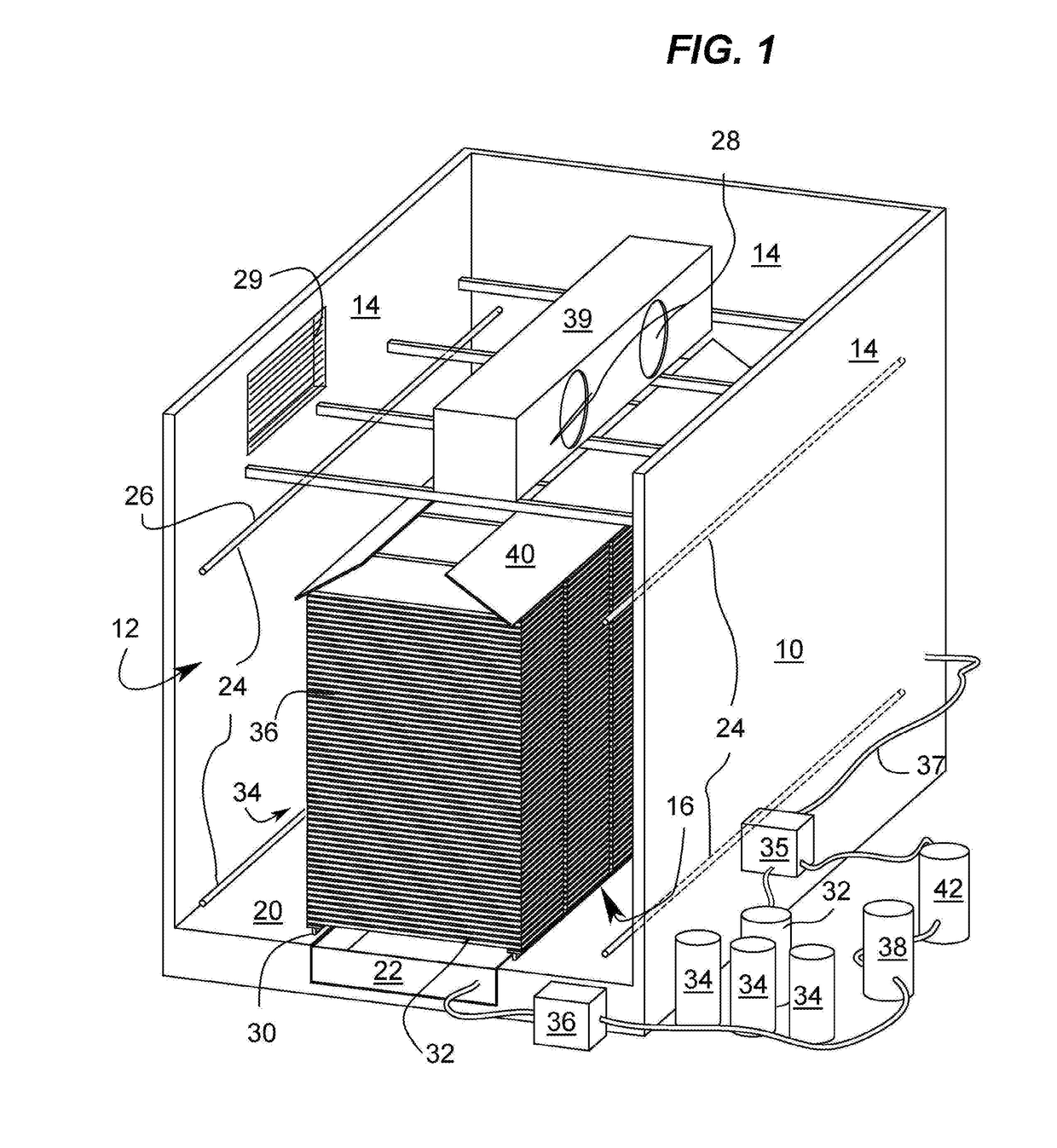

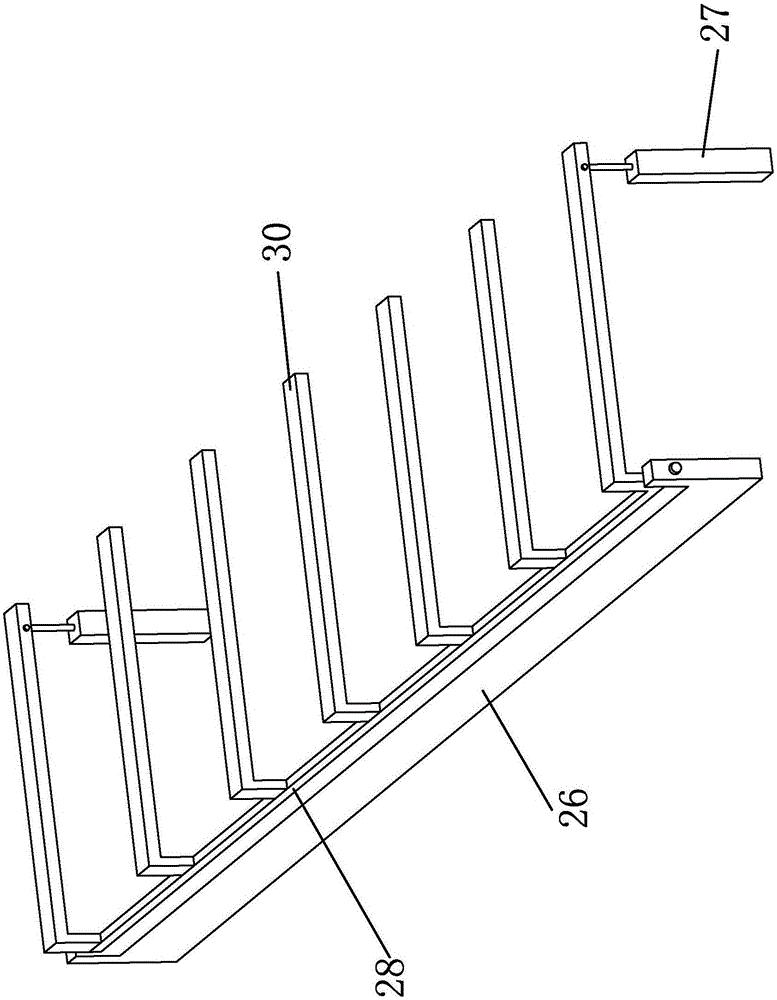

Apparatus and Process for Applying Liquid to an Object

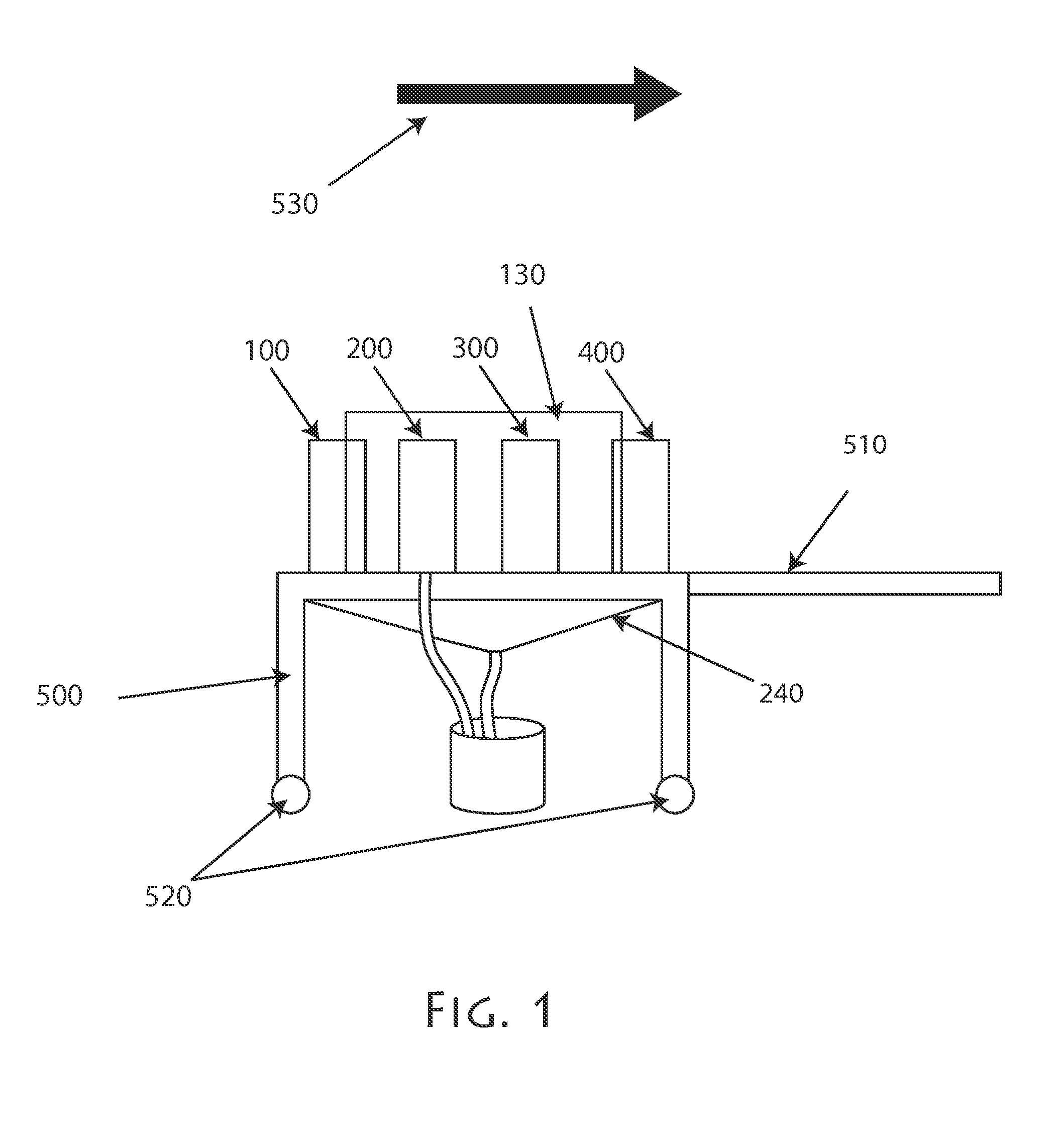

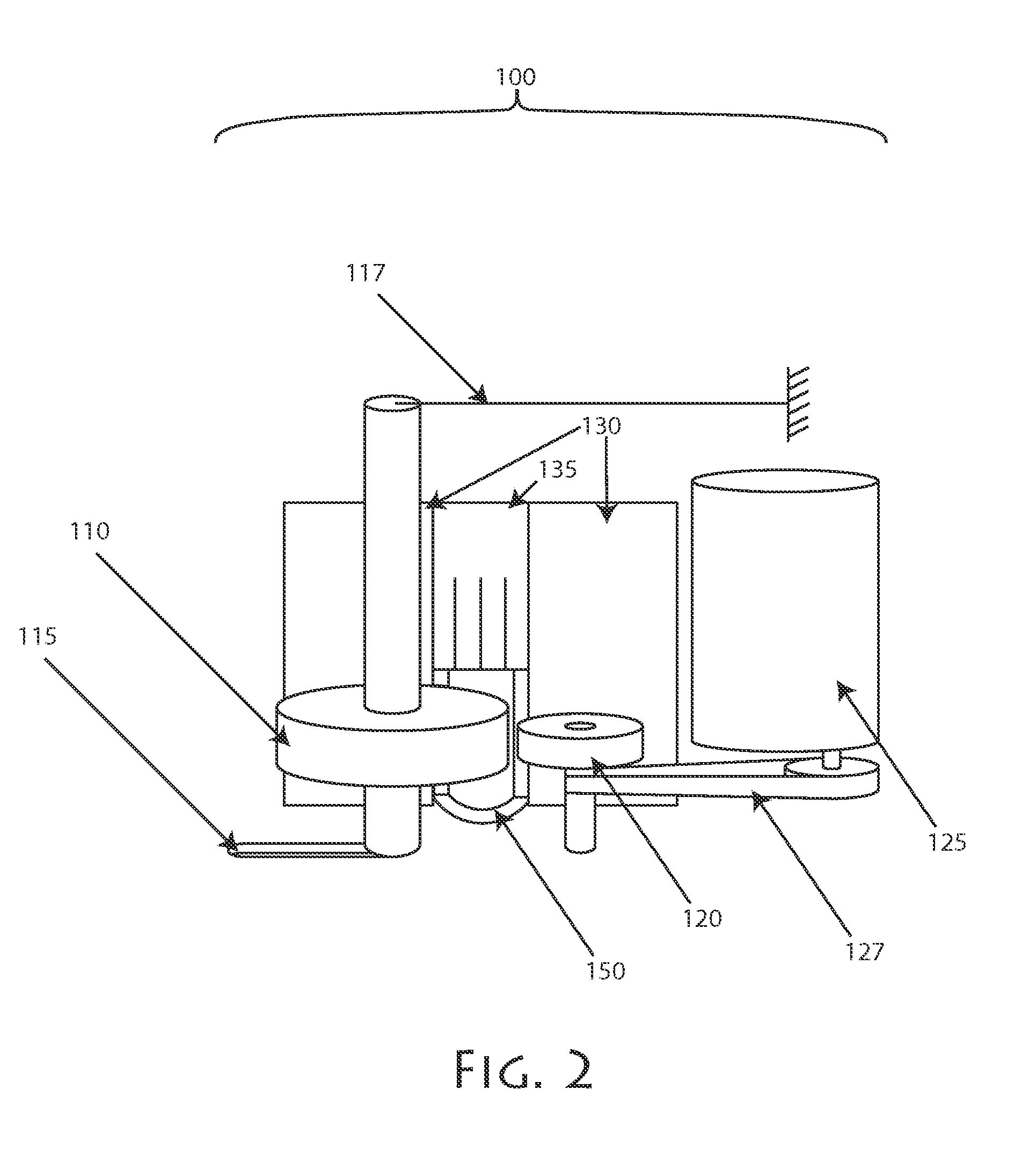

A portable machine and process is described for covering all sides of an elongated object with a liquid without the use of brushes. The machine is particularly useful with manufactured building products such as a fence picket, trim, molding, or any other type of board. The machine generally has four stations, an entry station that drives the object down a track, a liquid application station where the object is covered by liquid that is poured over the object, a blower station where the fluid is spread evenly over the object and excess fluid is blown off, and an exit station that continues to pull the object down the track and directs the object as the object leaves the exit station. Finally, the object may enter a releasably attached drop track.

Owner:MASSEY MICHAEL

Method for preventing deformation and cracking of pines

InactiveCN107379178APrevent deformation and crackingDeformation and cracking are easyImpregnation spraying apparatusWood treatment detailsFiberBatch processing

The invention mainly relates to the technical field of wood product processing, and discloses a method for preventing deformation and cracking of pines. The method comprises arrangement, refrigeration, fermentation, primary drying, humidification and secondary drying; the method is simple and convenient in batch processing; no poisonous reagent is added in the treatment process to achieve safety and health; the water content of the treated pines is stable, and the water absorbing capacity is reduced, so that deformation and cracking are radically prevented, the service life is prolonged by 14.5%, and the use value of pine products is obviously improved; the cut pines are cut according to needed lengths; pine barks are retained; the protecting effect of the pine barks is improved, so that the color change in the pine treatment process is inhibited, and later unified bleaching treatment is convenient; and pine sections are put in a treatment chamber to gradually cool for refrigeration, so that the water in the pines is reduced under low-temperature environment, gaps among pine fibers are increased, the resistance of the pines to temperature and humidity is improved, the influence of environmental change to the pines is relieved, and deformation and cracking of the pines are prevented.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

Liquid-state temporary reinforcing material, preparation method and applications thereof

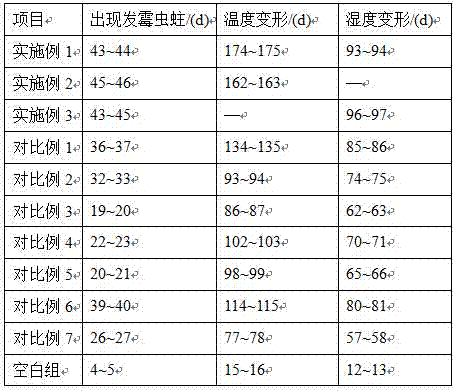

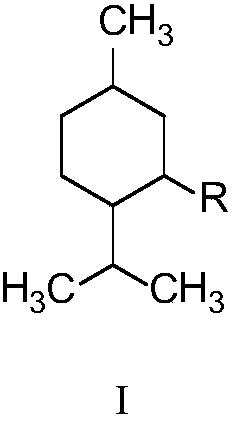

ActiveCN108360256AMeet temporary reinforcement needsEasy to useImpregnation spraying apparatusCoating impregnationMenthoneLiquid state

The invention relates to a liquid-state temporary reinforcing material, a preparation method and applications thereof, wherein the liquid-state temporary reinforcing material comprises a reinforcing material and a crystallization inhibitor, the reinforcing material comprises any two or more than two molecules selected from menthol, menthone, menthol ester and menthol ether, and the content of thecrystallization inhibitor is less than 50 ppm. According to the present invention, the menthol and the derivatives thereof are integrally mixed to form the composite material for temporary reinforcing, the composite material is the liquid and volatilization-controllable at the room temperature, the temporary reinforcing requirements of cultural treasure extraction at the archaeology excavation site can be met, and the use is convenient.

Owner:SHANGHAI UNIV

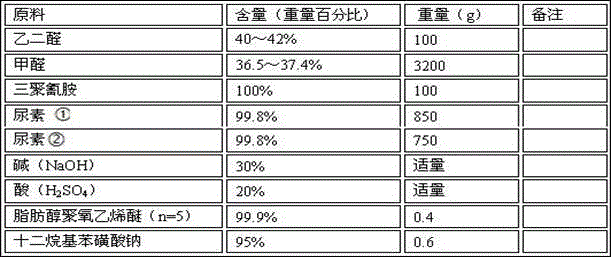

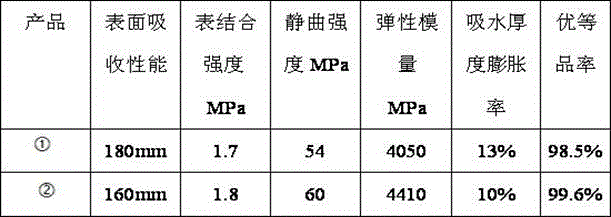

Preparing method for fiberboard surface treating agent and application method of fiberboard surface treating agent

ActiveCN105666611AHigh reactivityHigh bonding strengthImpregnation spraying apparatusWood treatment detailsSurface-active agentsTwo step

The invention discloses a preparing method for a fiberboard surface treating agent and an application method of the fiberboard surface treating agent. The preparing method for the surface treating agent comprises the two steps of synthesis of melamine-urea-glyoxal-formaldehyde copolycondensation resin and blending modification of the resin and a surface active agent. When a facing fiberboard is produced, firstly, the fiberboard surface treating agent is evenly sprayed to the surface of the fiberboard, and then melamine impregnated paper is tiled. Then, the melamine impregnated paper and the fiberboard are placed in a press to be subjected to hot press molding. A fiberboard base material used in the production process of the melamine facing board is treated through a chemical means, the water content, the surface smoothness and the strength of the base material are adjusted through the surface treating agent, uncontrollability of the base material in the production process is reduced, and the production waste caused by instability of the quality of the fiberboard base material is avoided.

Owner:DONGYING TOROYAL MATERIAL TECH

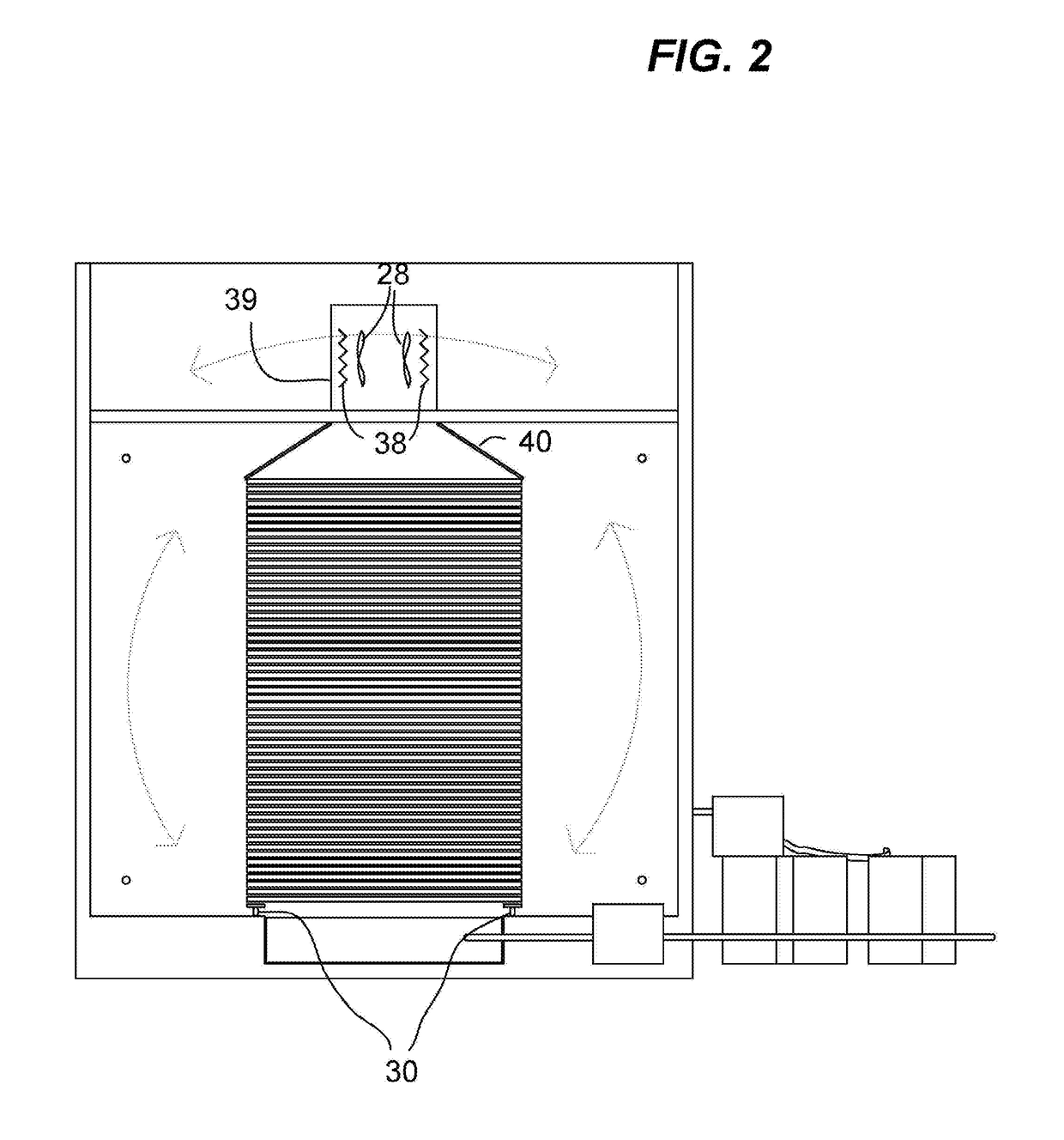

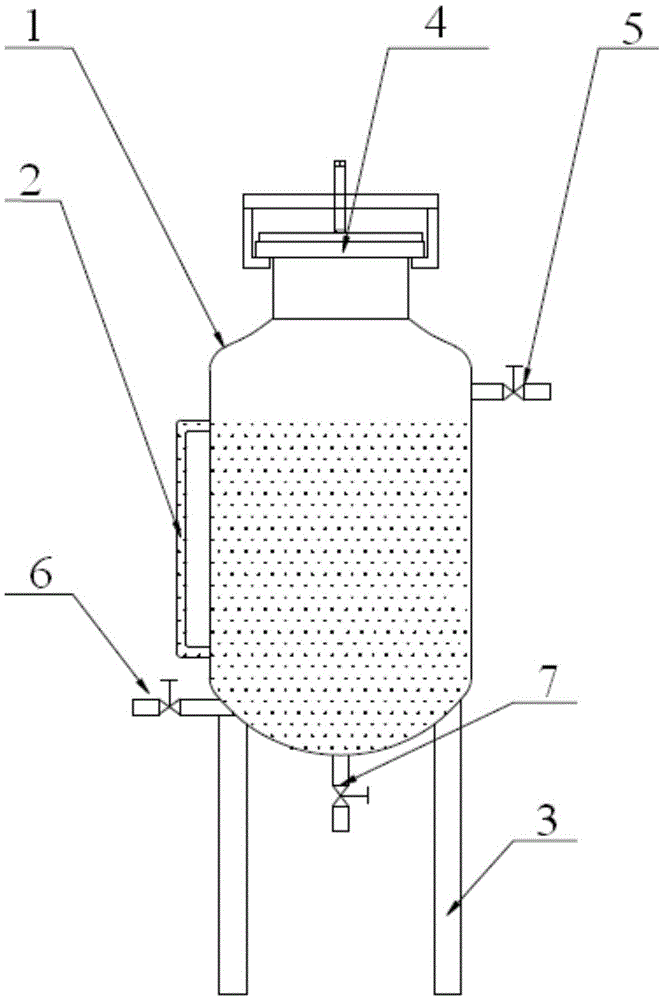

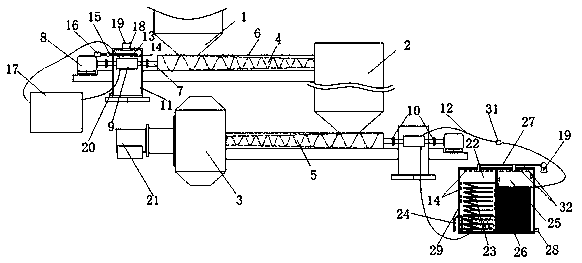

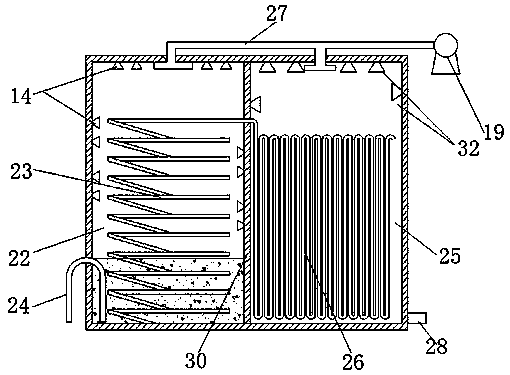

Integrated unit for treatment and drying lignocellulosic material

InactiveUS20170320090A1Allow useLow costDrying solid materials with heatSpraying apparatusCelluloseHigh humidity

An integrated boiler-dryer consisting in a sealable vessel capable of sustaining high humidity and variable gas pressures and into which is placed a lignocellulosic material, and a compound in mist form. The sealable vessel provides dry heat so as to dry the lignocellulosic material while the compound is impregnated within the lignocellulosic material.

Owner:ROY JACQUES

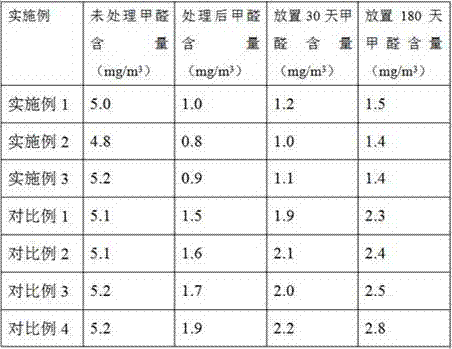

Method for removing formaldehyde from artificial plate

ActiveCN106914961AIncrease contentPlay a protective effectImpregnation spraying apparatusWood treatment detailsVacuum pumpingNitrogen gas

The invention provides a method for removing formaldehyde from an artificial plate. The method comprises the following steps: (1) putting the artificial plate in an enclosed space, injecting nitrogen gas, spraying a solution A till the humidity reaches 30-60%, heating to 60-70 DEG C, and carrying out heat preservation for 2-4 h; (2) drying till the humidity reaches 10-15% and carrying out heat preservation for 1-2 h; (3) carrying out vacuum pumping, cooling to 30 DEG C, and carrying out heat preservation for 2-5 h; and (4) spraying a solution B onto the artificial plate, heating to 40-50 DEG C, carrying out heat preservation for 0.5-2 h, cooling to 25-30 DEG C, and drying. The method provided by the invention has the advantages that the removing effect is good; the cost is low; the process is simple; and formaldehyde in linear resin can be removed.

Owner:浦北县美良木业有限公司

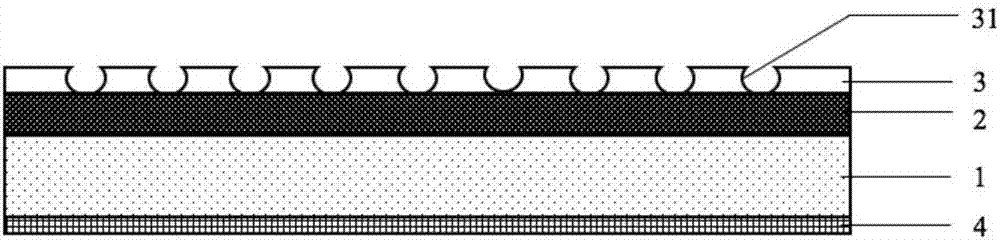

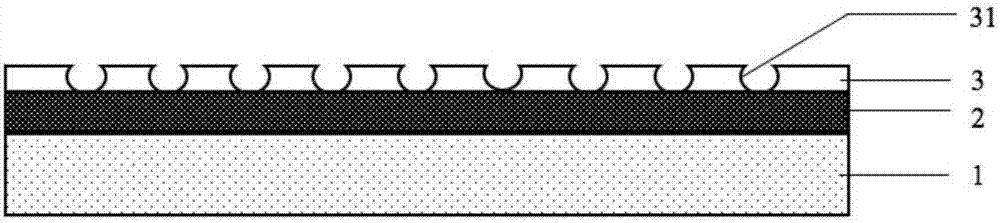

Wood material with formaldehyde removal function and preparation method thereof

InactiveCN107953424AWith purification functionGood chemical stabilityImpregnation spraying apparatusDispersed particle separationSolventPolyvinylpyrrolidone

The invention belongs to the technical field of air purification, and relates to a wood material with a formaldehyde removal function and a preparation method thereof. The material has a layered structure comprising a base layer, a formaldehyde removal layer and a surface layer and is made through high-temperature hot pressing, wherein the base layer is a solid wood board, a particle board or a fiber board; the formaldehyde removal layer is a formaldehyde removing agent and consists of, by weight, 2-10 parts of polyvinylpyrrolidone, 1-4.5 parts of water-soluble high-molecular compounds, 3-10 parts of waterborne polyurethane, 4-42 parts of chiral amino alcohol, 1-7 parts of titanium dioxide and 1-7 parts of stannic oxide, 1-7 parts of silicon dioxide, 2-6 parts of magnesium oxide, 1-13 parts of activated carbon, 1-9 parts of calcium chloride, 1-13 parts of soluble weak acid salt and 500-800 parts of solvent; and the surface layer material is a veneer with waterproof and breathable micropores. The material can be used for rapidly and efficiently removing the formaldehyde, the raw materials are cheap and easy to obtain, and the process is simple and feasible.

Owner:秦素洁

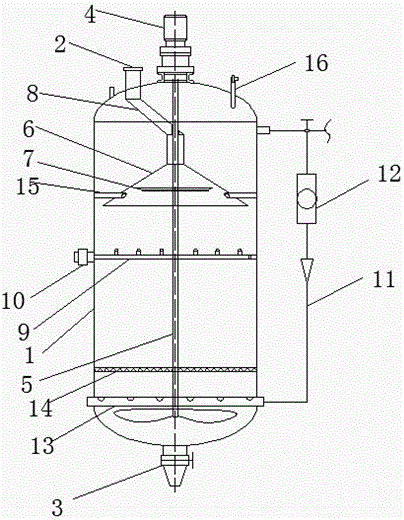

Comprehensive reaction kettle used for wood modification

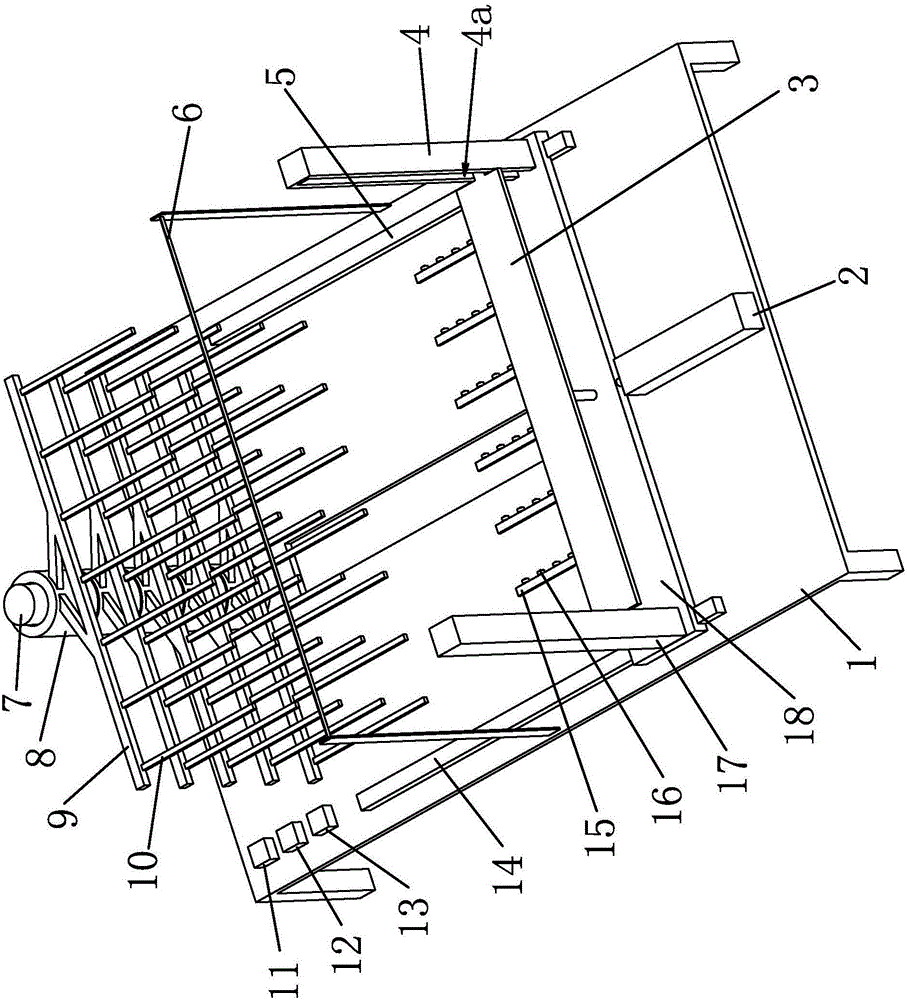

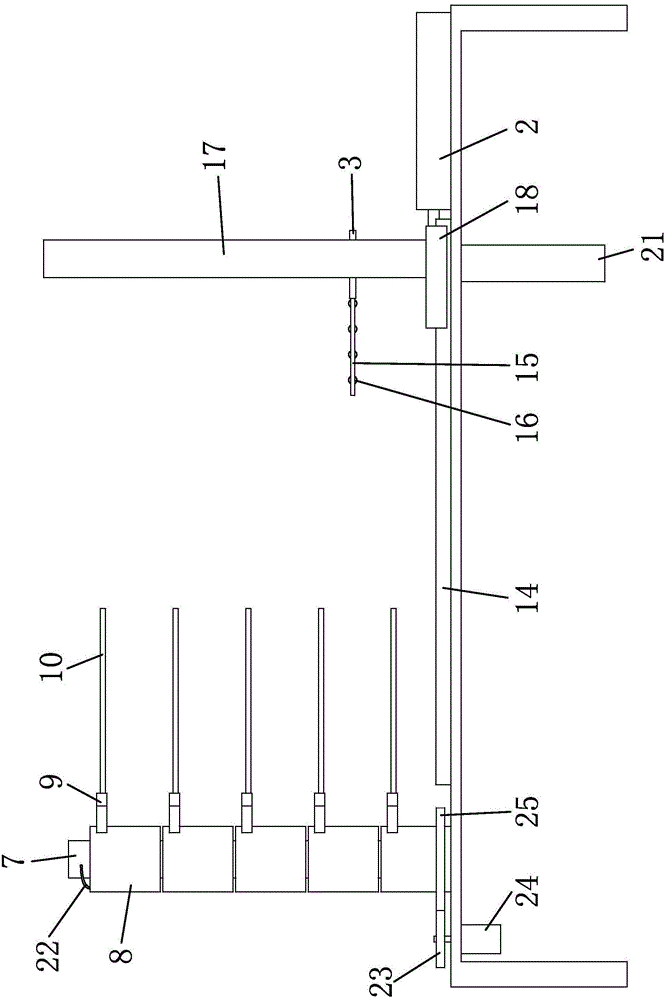

InactiveCN106393339ASpray evenlyFully contactedImpregnation spraying apparatusChemical/physical/physico-chemical nozzle-type rreactorsContact timeProcess engineering

The invention discloses a comprehensive reaction kettle used for wood modification. The comprehensive reaction kettle is a sealed cylindrical shell which is internally provided with a stirring shaft. A solid feed inlet and a gas feed inlet are formed in the top of the shell, and a liquid feed inlet is formed in the middle of the shell. A conical material distributor is arranged on the upper portion of the shell and mounted on the stirring shaft in a sleeving mode, and a material distributing circular truncated cone is arranged on the portion, located in the material distributor, of the stirring shaft. The top of the material distributor is connected to the solid feed inlet through a material guiding pipe. An annular liquid spraying pipeline is arranged below the material distributor and connected to the liquid feed inlet. The comprehensive reaction kettle is used for three raw materials, namely solid, liquid and gas, which need to react simultaneously in wood modification production, the liquid and the solid are evenly sprayed under the action of the material distributor and the liquid in the gas environment of the upper portion of the shell, the solid, the liquid and the gas make full contact under the action of a gas jetting pipeline and a blocking screen in the liquid environment of the lower portion of the shell, the contact time of the solid, the liquid and the gas is prolonged, and an efficient reaction is guaranteed.

Owner:NANJING AIBUNA SEALING TECH CO LTD +1

Synthetic fiberboard moisture and mildew prevention treatment technology

InactiveCN105538447AImprove heat resistanceHigh strengthImpregnation spraying apparatusWood treatment detailsMass ratioMoisture absorption

The invention provides a synthetic fiberboard moisture and mildew prevention treatment technology. The technology comprises the following steps: 1, processing sodium silicate crystals Na2O.nSiO2 and sodium fluorosilicate crystals to prepare solutions, uniformly mixing the sodium silicate solution with the sodium fluorosilicate solution according to a mass ratio of 1:999-999:1, disposing the obtained mixed solution for 24h or above, and filing a container with the mixed solution; and 2, coating the surface of a synthetic fiberboard with the mixed solution through adopting a pressure spraying method or an in-container impregnation method to complete moisture and mildew prevention treatment. The technology can prevent influences of mildews induced by moisture absorption of synthetic fiberboards on the environment quality and the property loss, promotes development of the synthetic fiberboard industry, and is in favor of protecting the natural ecological forest. The treatment technology has the advantages of simplicity, low cost, short treatment time, and effective solving of the synthetic fiberboard moisture and mildew prevention problem.

Owner:万华禾香生态科技股份有限公司

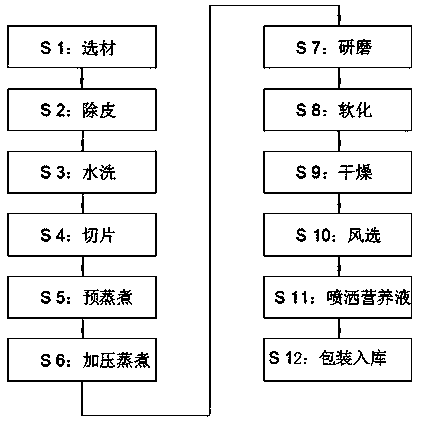

Wood fiber production method

ActiveCN110195372AImprove water absorptionImprove water retentionPretreatment with water/steamImpregnation spraying apparatusWood fibreNutrient solution

The invention discloses a wood fiber production method, which comprises: S1, material selection; S2, skin removal; S3, water washing; S4, slicing; S5, pre-cooking; S6, pressurizing cooking; S7, grinding; S8, softening; S9, drying; S10, air selection; S11, nutrient solution spraying; and S12, packaging warehousing. According to the present invention, the wood fiber produced through material selection, skin removal, water washing, slicing, pre-cooking, pressurizing cooking, grinding, softening, drying, air selection, nutrient solution spraying, packaging warehousing and other steps can be well used in spray seeding technologies; the wood fiber produced by the method has good softness; and during the spray seeding, when the wood fiber, the water and the binder are mixed, the wood fiber has good water absorption, such that each wood fiber can absorb a large amount of water so as to achieve good water content.

Owner:东南生态修复有限公司

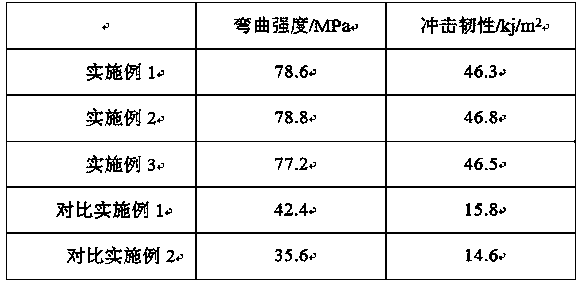

High performance fiberboard

ActiveCN110239168AImprove bending performanceImprove impact resistanceImpregnation spraying apparatusSynthetic resin layered productsAdhesivePolyvinyl alcohol

The invention discloses a high performance fiberboard. The prepared board has superior bending property and impact property, and is better in mechanical properties. By reasonably compounding camphor wood powder, birch wood powder and maple wood powder, the fiberboard is enabled to be uniform in size and density and better in harmony; the wood powder is subjected to modification treatment by using glucuronolactone, acetaminophen and polyvinyl alcohol, so that the fiberboard is enabled to contain multiple active groups, the gluing effect between the fiberboard and an adhesive component is facilitated; furthermore; furthermore, the compatibility of the fiberboard with modified basalt fibers is promoted, so that the mechanical properties of the board are improved; diatomaceous earth and tapioca flour are used for modifying basalt fibers, and a porous interface is formed on the surface of basalt, so that the interaction between the basalt fibers and wood fibers as well as between the basalt fibers and an adhesive is promoted, and a framework effect is achieved; therefore, the bending strength and impact toughness of the board are remarkably improved.

Owner:阜阳大可新材料股份有限公司

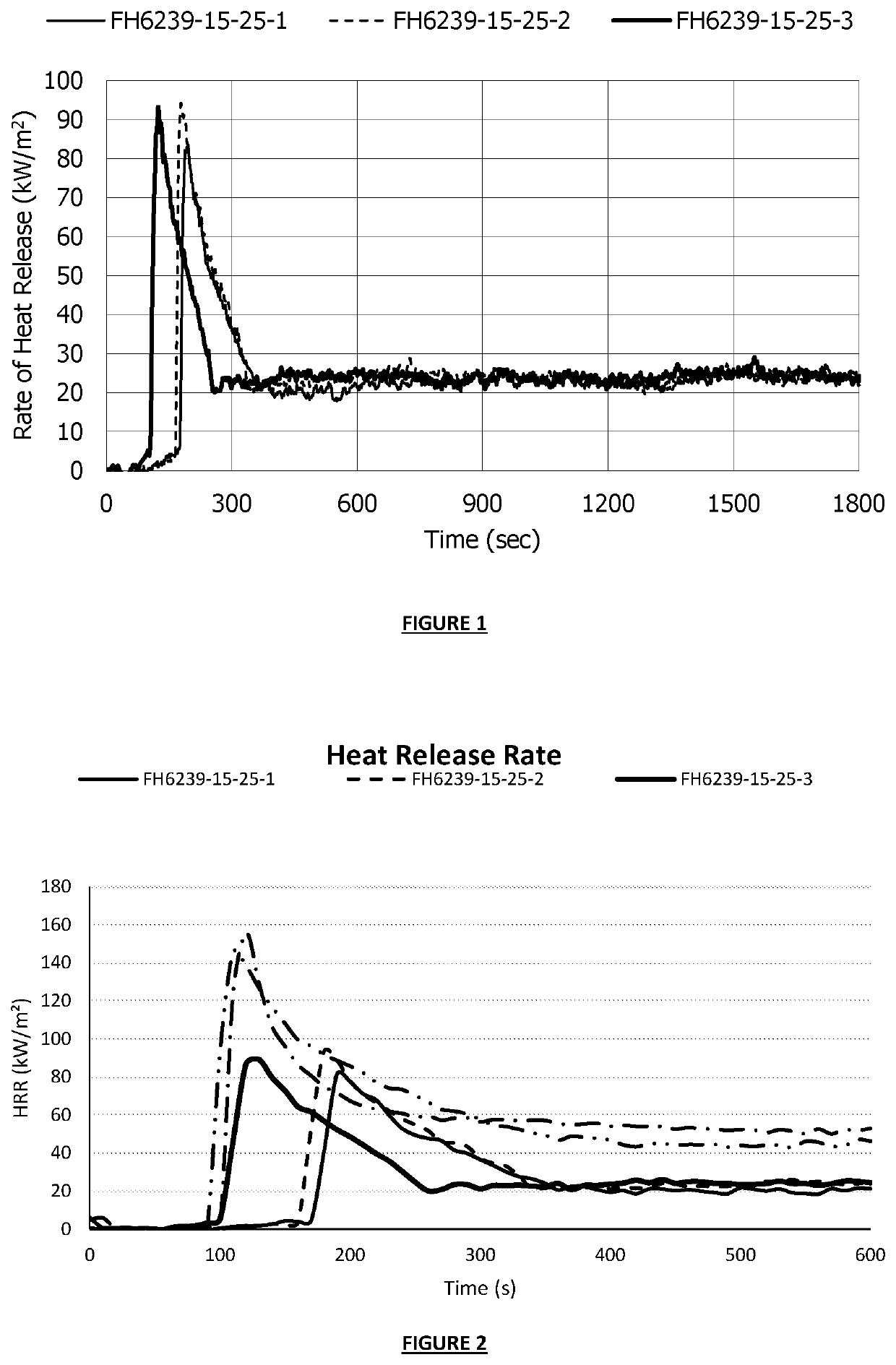

Enhanced performance of wood and engineered wood products using combined durability and flame retardancy

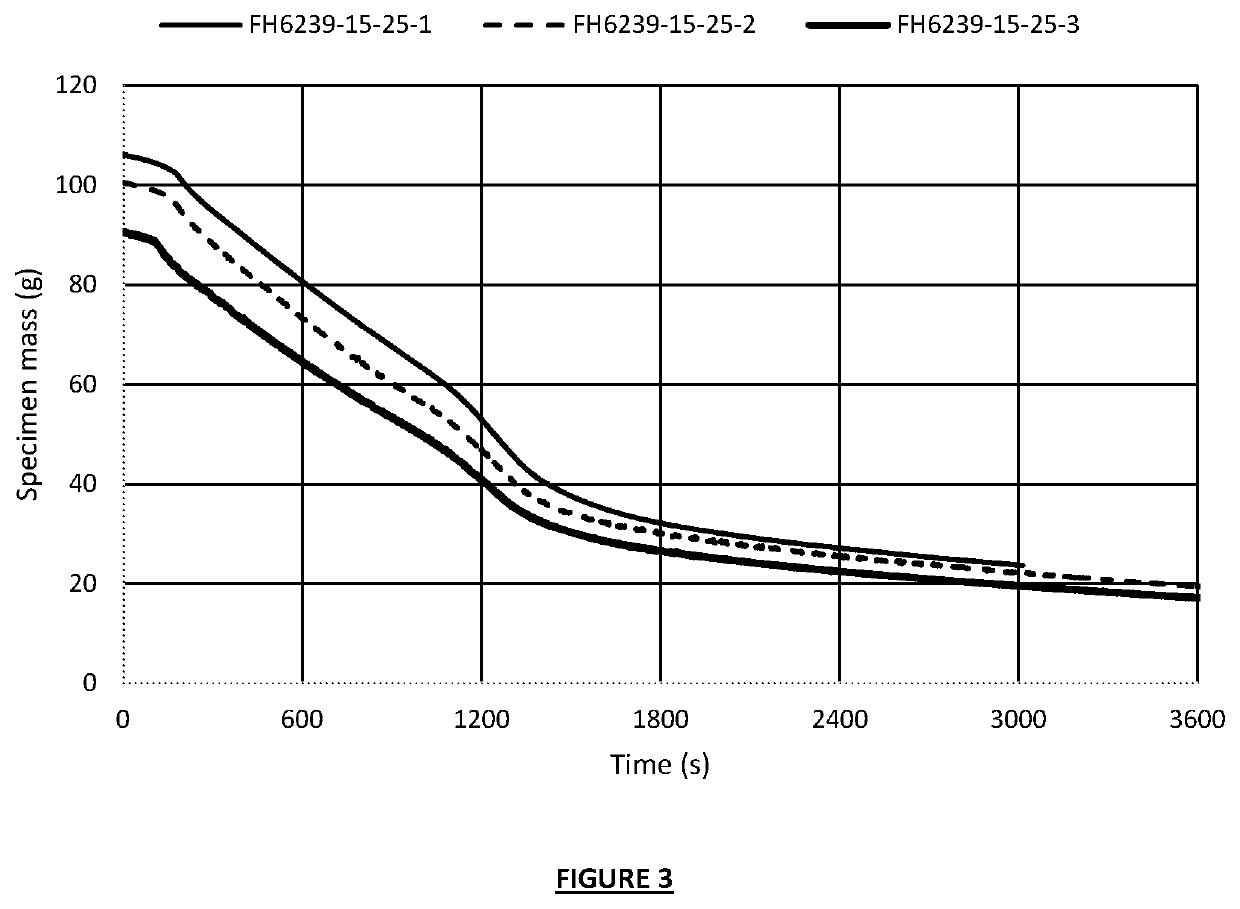

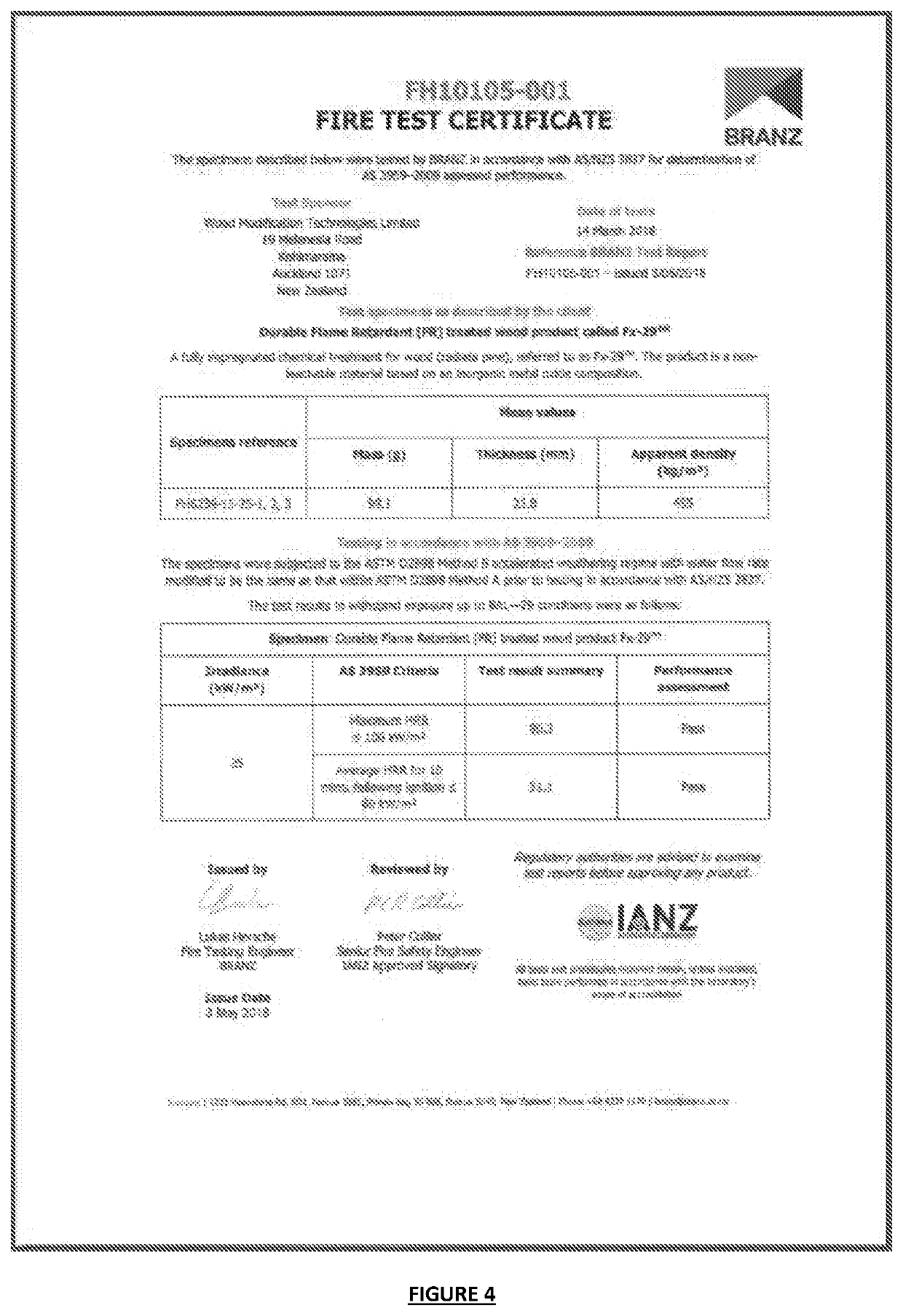

ActiveUS20200139574A1Increased durabilityImprove flame retardant performanceBiocideImpregnation spraying apparatusPulp and paper industryPinus radiata

A treatment process and wood products thereof including a product formulation of a single phase solution combining a wood preservative (durable component) with a Flame Retardant component (FR) to produce a durable Flame Retardant (dFR) treated wood product. The durable component comprises a range of copper based and non-copper based wood preservatives, while the FR component comprises alkali metal silicates and alkali metal aluminate compounds. The dFR working solution undergoes chemical impregnation (treatment) followed by a heat (fixation) process step that locks the chemical into the wood making it non-leachable. The dFR treated wood products are tested for their enhanced fire performance properties. When heated, wood undergoes thermal degradation and combustion producing gases, vapors, tars and chars. Using a cone calorimeter burn test method, dFR treated wood products show a significant reduction in heat release rate, mass loss rate and smoke generated values compared to untreated radiate pine.

Owner:WOOD MODIFICATION TECH LTD

Processing method for health wood

InactiveCN106272776AImprove qualityPenetrate fastImpregnation spraying apparatusWood impregnation detailsSurface layerEngineering

The invention relates to the technical field of functional wood processing and especially relates to a processing method for health wood. The method comprises the following steps: firstly, preparing a health solution containing Chinese herbal medicine components; removing the surface layer of the wood; putting the wood into an airtight room at interval; atomizing the health solution and then spraying into the room, and meanwhile, spraying high-temperature air into the room; collecting the health solution falling onto the ground and then atomizing and spraying into the room till the health solution is completely consumed. According to the processing method for health wood provided by the invention, the health solution is atomized, the health solution can quickly penetrate into the wood under the coordination of high temperature air, the efficiency is high, the soaking is not required, the fastness of the wood is prevented from being influenced and the wood quality is increased.

Owner:桐乡市美意家具有限公司

Ailanthus degreasing method

InactiveCN105538442ASpeed up degreasingMake sure to degrease completelyImpregnation spraying apparatusWood treatment detailsSodium bicarbonateAilanthus

The invention discloses an ailanthus degreasing method. The method comprises the following steps that firstly, color-change-prevention pretreatment is carried out, wherein a sodium bicarbonate solution with the concentration ranging from 0.5% to 0.8% is sprayed three times, and the spraying interval is two days to four days; secondly, first-time digesting is carried out, wherein ailanthuses are put into a digester containing alkali liquor with the concentration ranging from 4% to 6% to be digested, the temperature is controlled to range from 30 DEG C to 50 DEG C, and the time is controlled to range from 2 hours to 4 hours; thirdly, the ailanthuses which are subject to treatment in the first step and the second step are put into a digester containing alkali liquor with the concentration ranging from 2% to 4% to be digested, the temperature is controlled to range from 30 DEG C to 50 DEG C, and the time is controlled to range from 2 hours to 4 hours; fourthly, rinsing is carried out, wherein the digested ailanthuses are rinsed with clean water two times to three times, the temperature is controlled to range from 20 DEG C to 40 DEG C, and the rinsing interval is 0.2 hour to 1 hour; and fifthly, drying is carried out, wherein a drying machine is used for drying the ailanthuses, and after the ailanthuses are cooled, the ailanthuses are painted with varnish. The method is low in cost, good in degreasing effect and free of affecting the color of the ailanthuses.

Owner:ANHUI HUIRUN WOOD IND CO LTD

Anti-corrosion and anti-mildew treatment process for plate production and manufacturing

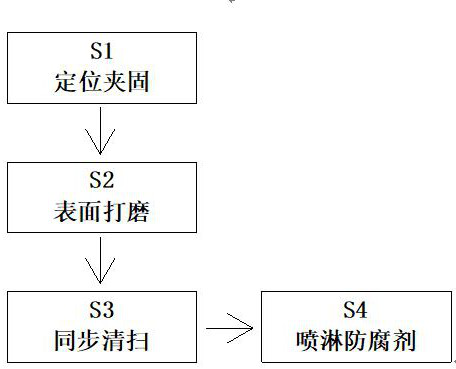

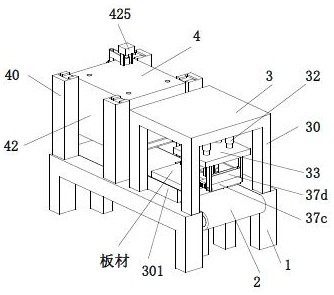

ActiveCN111687975AImprove the finishGood molding effectImpregnation spraying apparatusWood treatment detailsPreservativeProcess engineering

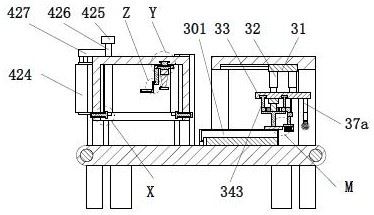

The invention relates to an anti-corrosion and anti-mildew treatment process for plate production and manufacturing. An anti-corrosion and anti-mildew treatment device for plate production and manufacturing is adopted. The anti-corrosion and anti-mildew treatment device for plate production and manufacturing comprises a workbench, a belt conveyor, a cleaning mechanism and a spraying mechanism. According to the invention, the design concept of a structure combining cleaning and spraying is adopted to carry out anti-corrosion and anti-mildew treatment on plate production and manufacturing; the arranged cleaning mechanism can be used for polishing the surface of the plate before spraying a preservative; by the adoption of a closed spraying structure, the situation that other structures are polluted due to the fact that the preservative splashes around is avoided, and meanwhile the splashed preservative is prevented from hurting workers.

Owner:NANJING SHI DAN LI DEORATION MATERIAL CO LTD

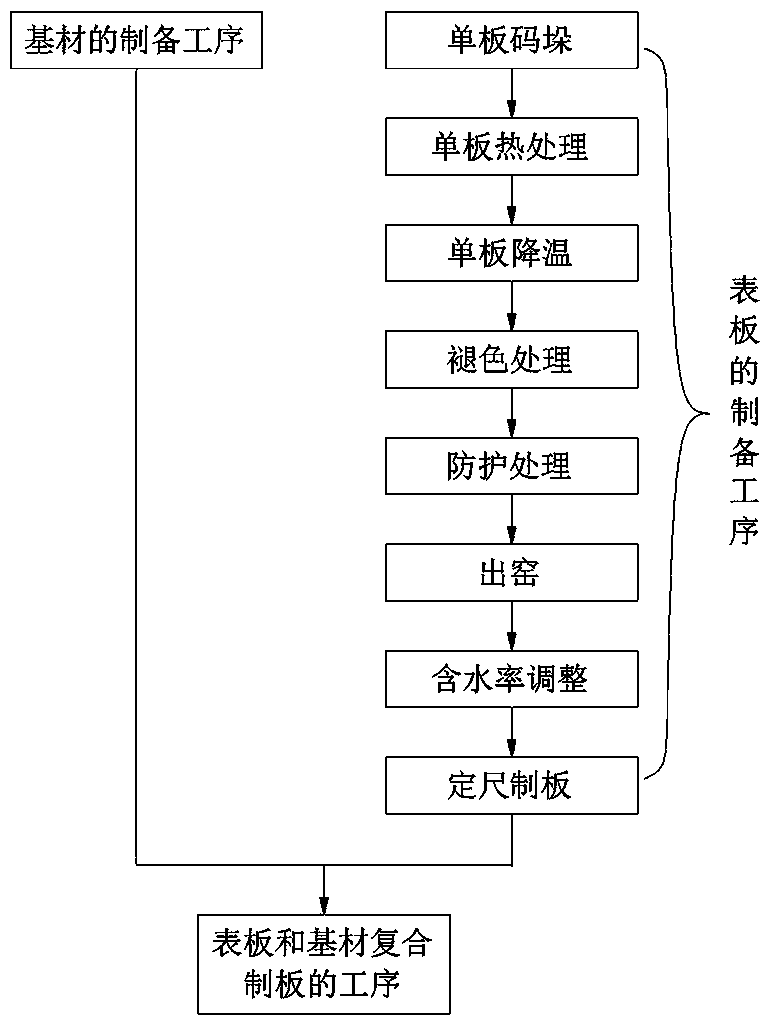

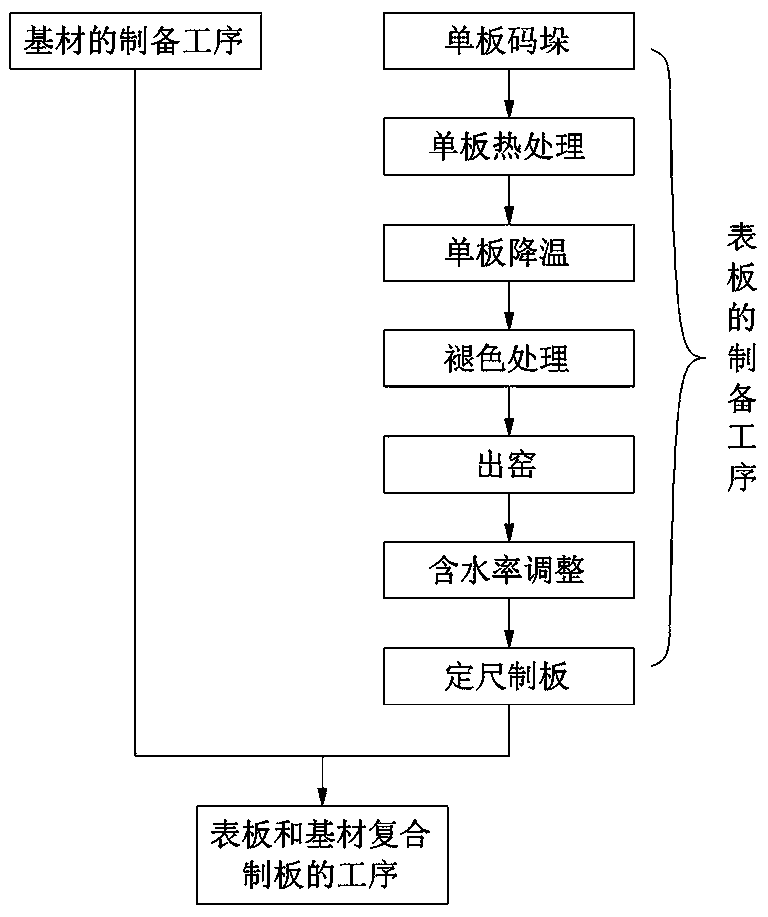

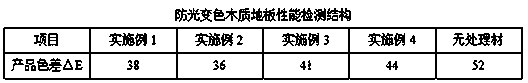

Manufacturing method of light-induced discoloration prevention wooden floor

InactiveCN108943257AImprove the decorative effectNo chromatic aberrationImpregnation spraying apparatusWood treatment detailsRoom temperatureFree cooling

The invention discloses a manufacturing method of a light-induced discoloration prevention wooden floor. The preparation process of a surface board of the wooden floor sequentially comprises the following steps: veneers are stacked, the interval between veneer layers is 2-3 mm, a horizontal airflow channel is arranged among every four or five veneer layers, and a vertical airflow channel is arranged among every nine or ten veneer columns; the veneers are subjected to thermal treatment in a thermal treatment kiln at the temperature of 140-150 DEG C, and the preservation time of the highest temperature is 3-4 h; the veneers are cooled, specifically, atomized water is injected into the thermal treatment kiln to reduce the temperature in the thermal treatment kiln; color fading treatment is carried out, specifically, when the temperature in the thermal treatment kiln is reduced to 80+ / -2 DEG C-85+ / -2 DEG C, a sodium hydroxide solution is added in the injected atomized water, the concentration of the sodium hydroxide solution is 18-20%, and the addition quantity of the sodium hydroxide solution in per liter of atomized water is 300-400 g; the veneers are discharged out of the kiln, specifically, when the temperature in the kiln is reduced to 50-55 DEG C, injection of the atomized water is stopped, and the veneers are discharged out of the kiln after being naturally cooled to the room temperature; the water content is adjusted; and fixed-length manufacturing is carried out to obtain the surface board. The floor is free of slow discoloration and color difference and has the characteristic of long-lasting decoration effect.

Owner:BAROQUE WOOD IND ZHONGSHAN CO LTD

Mosquito driving and antiseptic antibacterial processing technology for folding-fan bamboo ribs

ActiveCN104924402AGuaranteed contactEvenly distributedRadiation/waves wood treatmentBiocideAdditive ingredientMaterials processing

The invention discloses a mosquito driving and antiseptic antibacterial processing technology for folding-fan bamboo ribs and belongs to the field of folding-fan bamboo material processing technologies. The technology is characterized by including the steps of preparation of an antibacterial antiseptic solution and an antibacterial antiseptic cooking material, material cooking, spraying and smoke curing. Besides, antiseptic antibacterial ingredients are enabled to be fused consistently by adding a surface active agent, purification dispersant and sodium carboxymethylcellulose into the antibacterial antiseptic solution, and antibacterial antiseptic effect is maximized and optimized under cooperative action. The antibacterial antiseptic solution and the antibacterial antiseptic cooking are selected from pure natural materials, purchase cost is economical and practical, mosquito driving and antiseptic antibacterial effect is good, no harmlessness is caused to environment and human beings, success is achieved via experimental stages and batch tests, and the technology is suitable for popularization in trade unions.

Owner:QIDONG CHUANGLYU GREENING ENG CO LTD

Preparing method for environment-friendly composite floor base material

ActiveCN106272844AFill in the gapsIncrease contact areaNon-macromolecular adhesive additivesImpregnation spraying apparatusWood fibrePre treatment

The invention discloses a preparing method for an environment-friendly composite floor base material. The preparing method includes the following steps that firstly, early wood and late wood are selected, and first raw materials and second raw materials are obtained; secondly, the first raw materials and the second raw materials are stacked respectively, and a pretreated first raw material is obtained; thirdly, the pretreated first raw material is put into a cooking tank to be cooked and is then subjected to fiber separation through an overheating mill, and first wood fiber is obtained; fourthly, a pretreated second raw material is treated according to the method in the third step, and second wood fiber is obtained; fifthly, the first wood fiber and the second wood fiber are mixed to obtain mixed fiber, then glue applying and hot pressing are conducted, and a floor base material is obtained; and sixthly, the floor base material is subjected to cooling hardening and tempering and sanding sawing, and the composite floor base material is obtained. The prepared composite floor base material has the beneficial effects of being high in strength, resistant to impacts, good in humidity resistance, environment-friendly and high in popularization value.

Owner:上海亚美利加实业有限公司

Preservative treatment method for paulownia wood

InactiveCN106313225AAnti-corrosion treatment method is simpleAvoid corrosionRadiation/waves wood treatmentImpregnation spraying apparatusSaline waterPaulownia

The invention discloses a preservative treatment method for paulownia wood. The preservative treatment method comprises the following steps: coating and brushing the surface of the paulownia wood by adopting an aqueous solution of sodium carbonate; spraying the surface of the paulownia wood by adopting pressed clear water and saline water; soaking the paulownia wood into water containing ozone; putting the paulownia wood into a pressure tank for treating; treating the paulownia wood under the conditions that the temperature is 47DEG C and the relative humidity of air is 35 percent; then spraying the surface of the paulownia wood with a potassium citrate solution; and treating the paulownia wood under the conditions that the temperature is 32DEG C and the relative humidity is 10 percent, and reaching the balance. The preservative treatment method for the paulownia wood, provided by the invention, is simple; by treatment through all the steps disclosed by the invention, mildew of the paulownia wood, worm damage and corrosion of the paulownia wood caused by bacteria breeding can be effectively prevented; in addition, the preservative treatment method has strong resistance to salt-spray corrosion, is good in permeability and is high in leaching resistance; and the preservative time of the paulownia wood is greatly prolonged.

Owner:阜南县中泰工艺品有限公司

Treatment method for removing formaldehydes in board

InactiveCN107175746AShorten the timeEasy to dryRadiation/waves wood treatmentImpregnation spraying apparatusSodium bicarbonatePreservative

The invention provides a treatment method for removing formaldehydes in a board, and the treatment method solves the technical problems such as too simple steps, needed manual operation and low treatment speed of an existing treatment process. The treatment method for removing formaldehydes in the board comprises the following steps of: a, preparing a formaldehyde remover which consists of the following components in parts by weight: 50-60 parts of a plant extracting solution, 6-10 parts of sodium bicarbonate, 1-4 parts of nano titanium dioxide, 6-9 parts of hydrogen peroxide, 2-6 parts of a nano antibacterial agent, 1-3 parts of a penetrating agent, 1-2 parts of a preservative, 2-4 parts of a surfactant and 30-40 parts of water; b, spraying the formaldehyde remover to the surface of the board by spraying equipment with spraying thickness of 0.8-1.2mm, standing for 4-6 hours, and irradiating for 1-3 hours through ultraviolet ray lamp; and c, drying the board in the step b by air-curing equipment for 20-40 minutes at an air-curing temperature of 40-60 DEG C. The treatment method has the advantage of high treatment efficiency.

Owner:海宁永欣科技咨询有限公司

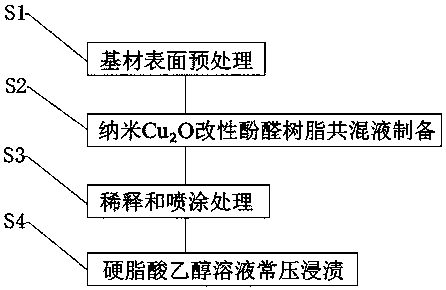

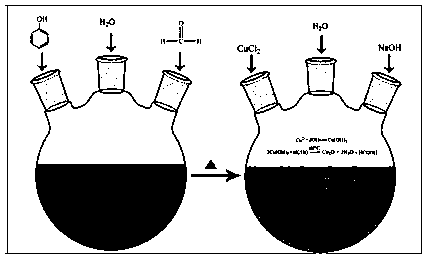

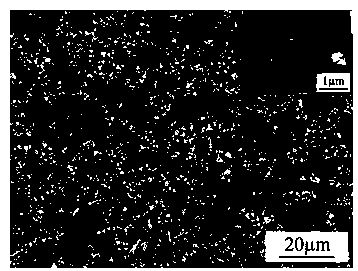

Construction method of typical softwood superhydrophobic surface

InactiveCN110936452AReduce manufacturing costImprove hydrophobicityImpregnation spraying apparatusWood treatment detailsAdhesive cementHydrophobic effect

The invention provides a construction method of a typical softwood superhydrophobic surface. The construction method includes: S1, pretreatment of surface of a base material; S2, preparation of a nanoCu2O modified phenolic resin blend liquid; S3, diluting and spray coating treatment; S4, normal pressure impregnation of stearic acid ethanol solution. In the invention, with the phenolic resin adhesive as a carrier and the nano Cu2O as a hydrophobic material, through the spray coating method with combination of the low surface energy substance, stearic acid, constructive modification of a superhydrophobic surface of typical softwood is carried out to achieve excellent hydrophobic effect. The spray coating is simple and is low in raw material cost, wherein the nano Cu2O can be generated during the synthesis of the phenolic resin adhesive, so that the preparation cost of the superhydrophobic surface of typical softwood is significantly reduced, and the method is low in cost, is simple in operation and has good hydrophobic protective effect, allows large-scale production, has extensive application prospect, is good in practicability, has high industrial promotion value, and brings beneficial condition to industrial production of large-size superhydrophobic wood material at large scale.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Willow product non-toxic dyeing method

InactiveCN107042561AUniform colorNot easy to fadeImpregnation spraying apparatusWood treatment detailsWater contentChemistry

The invention discloses a willow product non-toxic dyeing method. The method comprises the following steps that (1) a formed willow product is dried until the water content is 13-16%, and then stationary liquid is sprayed on the surface of the formed willow product; (2) pitaya peels are cut up, juiced and filtered, addition liquid 0.1-0.3 time of the weight of the pitaya liquid is added into the pitaya liquid, the temperature of the mixture is increased to 60-70 DEG C after uniform mixing, then rapid cooling is conducted, and dyeing liquid is prepared; and (3) the dyeing liquid is brushed on the willow product, then stationary matrixes are sprinkled on the willow product evenly, then the willow product is put into a drying oven to be dried, and the finished willow product is obtained.

Owner:阜南县环宇柳木工艺制品有限公司

Processing method for color protection and abrasion resistance of wicker products

InactiveCN106272819AExtended service lifeImprove toughnessImpregnation spraying apparatusWood treatment detailsBiologyWillow

The invention discloses a processing method for color protection and abrasion resistance of wicker products. The method comprises the steps that one month before wickers are cut down, treating fluid A is used for spraying willows, and then, after the wickers are cut down and dried in the sun, treating fluid B is used for soaking the wickers. By adopting the method to treat the wickers, wicker raw materials with high quality can be obtained, and the knitted wicker products keep unfaded for a long time, are good in tenacity and will not deform.

Owner:安徽阜南县万家和工艺品有限公司

Wood antique finish technology for historic building

ActiveCN106217549AExtended service lifeControllableImpregnation spraying apparatusWood treatment detailsWax treatmentPreservative

The invention discloses a wood antique finish technology for a historic building. According to the technical scheme, the wood antique finish technology for the historic building comprises following steps: S1, the wood surface is cleaned and aired; S2, the portion, required to be subject to antique finish, of the wood is subject to waxing treatment, standing is carried out, and wax is solidified and molded; S3, the remaining portion, except for the antique finish portion, on the wood is coated with an anti-corrosion agent; S4, the antique finish portion in the S3 of the wood is subject to wax removal treatment until the antique finish portion of the wood is exposed in the air; S5, the wood in the S4 is immersed in a pit mud solution to be soaked for 20 min and then is taken out, a sodium bicarbonate solution is used for cleaning the pit mud solution on the surface of the wood, and clean water is used for cleaning the wood surface; S6, the wood in the S5 is treated for 2 h to 3 h at the high temperature, rapid cooling and standing are carried out, and a product is obtained; the technology has the following beneficial effects that the portion, required to be subject to antique finish, of the wood is subject to antique finish, the antique finish technology has the higher flexibility, and meanwhile the treated wood is good in moth prevention performance.

Owner:浙江鎏增古建园林工程有限公司

Weaving processing method for improving the service life of wicker products

InactiveCN108772928AEasy to absorb and fixRelieve stress concentrationRadiation/waves wood treatmentPressure wood treatmentEngineeringHigh heat

The invention discloses a weaving processing method for improving the service life of wicker products. The method includes the following steps: (1) cleaning treatment; (2) steaming, boiling, and softening treatment; (3) steam explosion treatment; (4) immersion treatment; (5) drying treatment; (6) weaving treatment; and (7) high temperature treatment. According to the weaving processing method, theshape stability, strength and impact resistance of the wicker products can be effectively improved, the service life of the wicker products can be prolonged by more than 2 times, and the economic value and market competitiveness of the wicker products are significantly improved.

Owner:阜南县金威工艺品有限公司

Preparation method for wood capable of releasing negative oxygen ions

InactiveCN109352774AHas the function of removing formaldehydeImprove ventilation functionRadiation/waves wood treatmentImpregnation spraying apparatusOxygen ionsIsopropylamine

The invention discloses a preparation method for wood capable of releasing negative oxygen ions. The preparation method comprises the following steps that 1, ionized water, isopropylamine, phenol, inorganic nanometer silicon, tea polyphenol, proanthocyanidins, nanometer titania, a sterilization material and a radiation protection raw material are quantitatively weighed and mixed, and a negative oxygen ion solution is obtained; 2, high-temperature-resistant high-quality wood is selected and put in the environment with the temperature being 50-60 DEG C to be soaked in the obtained negative oxygen ion solution for 1-3 h, and then, the wood is taken out; 3, the negative oxygen ion solution is uniformly sprayed onto the wood soaked by the negative oxygen ion solution in the 50-60 DEG C environment for 2-5 h; 4, the wood obtained in the step 3 is subjected to drying treatment and cooled in the 50-60 DEG C environment; and 5, the wood obtained in the step 4 is heated to 30-45 DEG C through electromagnetic waves, and 10000-50000 negative oxygen ions per cubic centimeter are released. Through the preparation method, the wood capable of releasing the negative oxygen ions can be obtained, inaddition, the wood has the formaldehyde removal function, and the good air exchange function is achieved.

Owner:安瑞康养生科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com