Manufacturing method of light-induced discoloration prevention wooden floor

A manufacturing method and floor technology, which can be used in manufacturing tools, wood treatment, impregnating wood, etc., can solve the problems of limited interception effect of paint film, no protective effect, and unsatisfactory effect, and achieve good drug adsorption and absorption effect, prevent Good photochromic effect and long-lasting decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

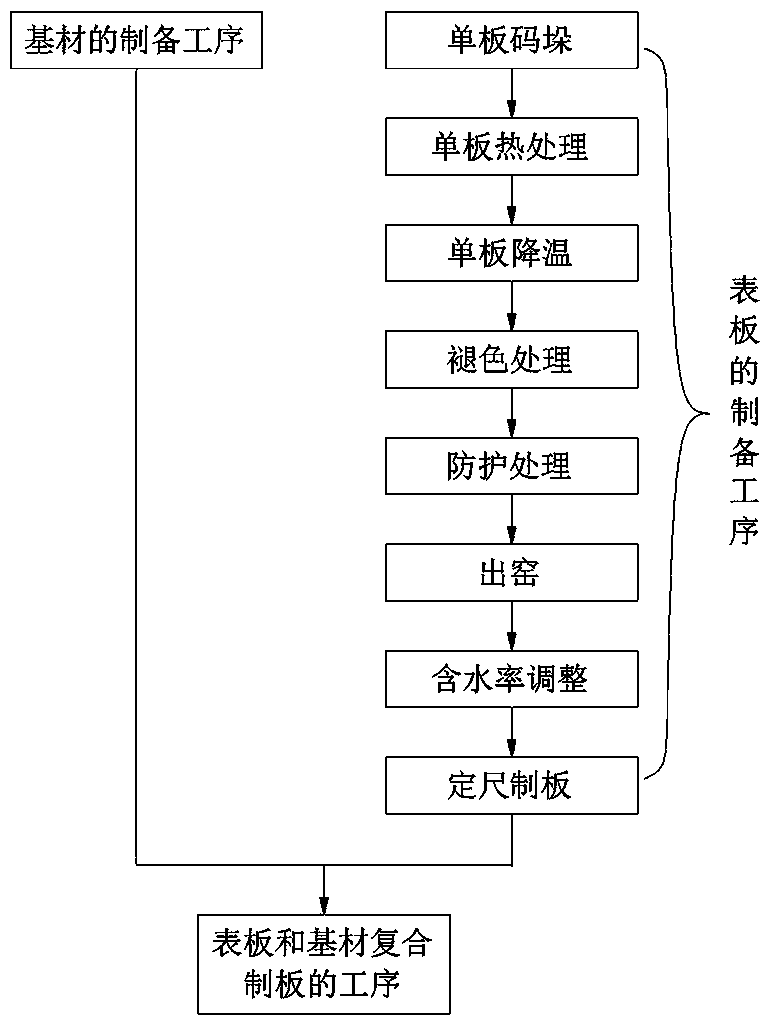

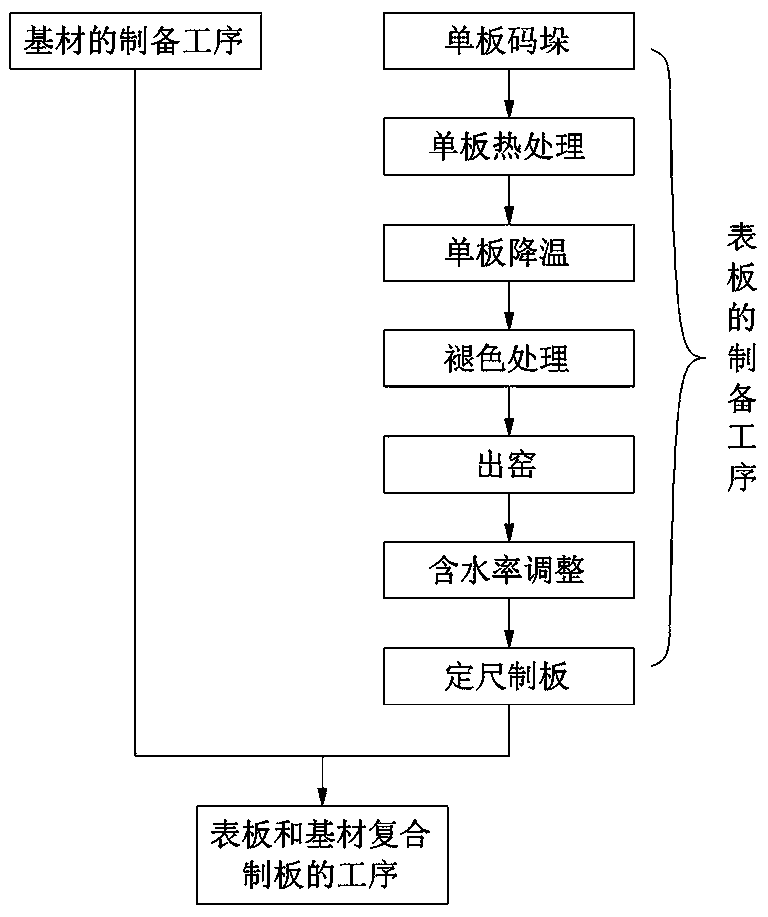

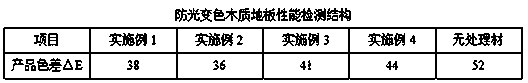

[0029] Embodiment 1: as figure 1 The manufacturing method of a light-resistant and discolored wooden floor includes the preparation process of the surface plate, the preparation process of the base material, and the process of composite board making of the surface plate and the base material.

[0030] In the technical solution, the base material adopts a multi-layer composite base material, so the preparation process of the base material includes the preparation process of the multi-layer composite base material.

[0031] The preparation process of the panel comprises the following steps:

[0032] (1) Palletizing of veneers, the spacing between veneer layers is 2.5mm, a horizontal airflow channel is provided between every 4 veneer layers, and the height of the horizontal airflow channel is 20mm; vertical airflow is provided between every 9 veneer rows Channel, the width of the vertical airflow channel is 100mm.

[0033] (2) Heat treatment of the veneer. The veneer is heat-tr...

Embodiment 2

[0041] Embodiment 2: as figure 1 The manufacturing method of a light-resistant and discolored wooden floor includes the preparation process of the surface plate, the preparation process of the base material, and the process of composite board making of the surface plate and the base material.

[0042] In the technical solution, the base material is a fiberboard base material, so the preparation process of the base material includes the preparation process of the fiberboard base material.

[0043] The preparation process of the panel comprises the following steps:

[0044] (1) Palletizing of veneers, the spacing between veneer layers is 3mm, horizontal airflow channels are provided between every 5 veneer layers, and the height of horizontal airflow channels is 25mm; vertical airflow channels are provided between every 10 veneer columns , the width of the vertical airflow channel is 200mm.

[0045] (2) Heat treatment of the veneer. The veneer is heat-treated in a heat treatmen...

Embodiment 3

[0053] Embodiment 3: as figure 1 The manufacturing method of a light-resistant and discolored wooden floor includes the preparation process of the surface plate, the preparation process of the base material, and the process of composite board making of the surface plate and the base material.

[0054] In the technical solution, the base material is a particle board base material, so the preparation process of the base material includes the preparation process of the particle board base material.

[0055] The preparation process of the panel comprises the following steps:

[0056] (1) Palletizing of veneers, the spacing between veneer layers is 3mm, horizontal airflow channels are provided between every 5 veneer layers, and the height of horizontal airflow channels is 25mm; vertical airflow channels are provided between every 10 veneer columns , the width of the vertical airflow channel is 150mm.

[0057] (2) Heat treatment of the veneer. The veneer is heat-treated at a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com