Anti-corrosion and anti-mildew treatment process for plate production and manufacturing

A technology for anti-corrosion, mildew-proof, and board production. It is used in manufacturing tools, wood processing, and wood processing details. It can solve problems such as operator injury, anti-corrosion splash, and anti-corrosion layer pits, so as to improve the degree of fit and improve the smoothness. degree, the effect of improving the molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways that are predetermined and covered by the claims.

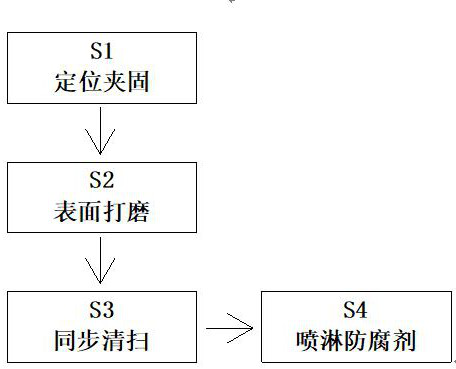

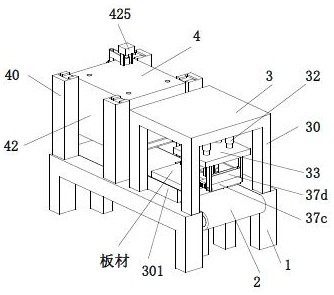

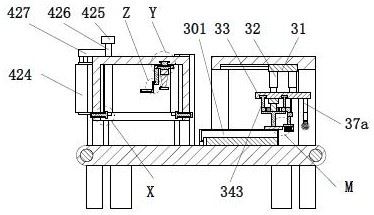

[0042] Such as Figure 1 to Figure 13 As shown, an anti-corrosion and anti-mildew treatment process for plate production uses a anti-corrosion and anti-mold treatment device for plate production. And spraying mechanism 4, when using the above-mentioned board manufacturing anti-corrosion and mildew-proof treatment device to carry out board manufacturing anti-corrosion and mildew-proof treatment, the specific treatment process is as follows:

[0043] S1. Positioning and clamping: place the plate between the fixed block 20 manually, and then manually push the moving plate 22 inward, and the moving plate 22 and the fixed block 20 cooperate with each other to clamp the plate. Then the plate is transported to the working area of the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com