Modified flame-retardant oriented strand board and preparation method thereof

An oriented strand board and modified technology, applied in the field of wood science, can solve the problems of poor flame retardant stability, difficult flame retardant grade, poor flame retardant effect, etc., to avoid secondary processing equipment, good flame retardant effect, The effect of improving flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

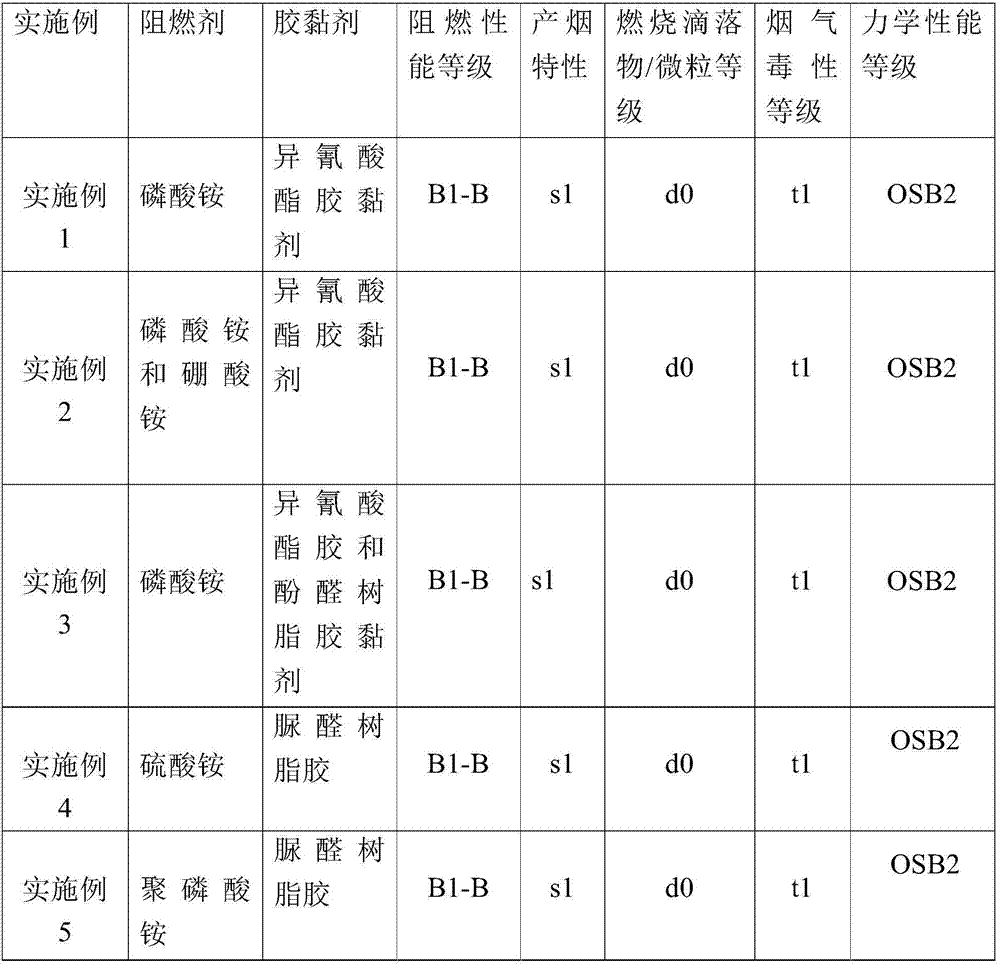

Examples

Embodiment 1

[0039] A modified flame-retardant oriented strand board, comprising the following raw materials in mass percentage:

[0040] Silica 4%;

[0041] Ammonium phosphate 15%;

[0042] Wood shavings 55%;

[0043] Adhesive 4%;

[0044] Paraffin 1%.

[0045] A preparation method of a modified flame-retardant oriented strand board adopts the above-mentioned raw material ratio, comprising the steps of:

[0046] The peeled logs are processed into wood flakes by the knife ring type long wood planer, and the wood flakes are sent to the flake dryer through a mechanical transporter for drying, so that the moisture content of the dried wood flakes is 3-7 %, the dried wood flakes are screened by a screening machine, and the qualified wood flakes are sent to the core and surface wood flake bins by the mechanical transporter, and the average length is about 80mm, the width is 25mm, and the thickness of the surface layer is 0.6mm. Wood chips and core wood chips with an average length of about...

Embodiment 2

[0049] A modified flame-retardant oriented strand board, comprising the following raw materials in mass percentage:

[0050] Silica 5%;

[0051] Ammonium phosphate and ammonium borate 20%;

[0052] Wood shavings 60%;

[0053] Isocyanate adhesive 4%;

[0054] Paraffin 3%.

[0055] Among them, the mass ratio of ammonium phosphate and ammonium borate is 1:1

[0056] A preparation method of a modified flame-retardant oriented strand board adopts the above-mentioned raw material ratio, comprising the steps of:

[0057] The peeled logs are processed into wood flakes by the knife ring type long wood planer, and the wood flakes are sent to the flake dryer through a mechanical transporter for drying, so that the moisture content of the dried wood flakes is 3-7 %, wherein, the shape of the wood planer is: about 60-150mm in length, 20-30mm in width, and 0.60-0.70mm in thickness. The dried wood flakes are screened by the screening machine, and the qualified wood flakes are sent to t...

Embodiment 3

[0060] The method is the same as in Example 1, only the type of adhesive is changed, and the "isocyanate adhesive" in Example 1 is changed to "isocyanate adhesive and phenolic resin adhesive, and the mass ratio of isocyanate adhesive and phenolic resin adhesive is 2:3" modified flame retardant oriented strand board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com