Wood material with formaldehyde removal function and preparation method thereof

A formaldehyde purification and wood material technology, applied in the field of air purification, can solve the problems of high dependence on light intensity, easy to be oxidized, easy to be inactivated, etc., to enhance the ability to remove formaldehyde, promote efficient reaction, and fast adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation of wooden floor with formaldehyde purification function.

[0038]1) Add 2g of polyvinylpyrrolidone, 1g of polyacrylamide and 3g of water-based polyurethane into 500g of deionized water, and dissolve with mechanical stirring at 85°C to obtain solution A;

[0039] 2) Mix 1g of titanium dioxide, 1g of tin dioxide, 1g of silicon dioxide, 2g of magnesium oxide, 1g of activated carbon, 1g of calcium chloride, 1g of sodium carbonate and 4g of 1,2-dimethylaminoethanol to obtain mixture B;

[0040] 3) Add the mixture B obtained in step 2) to the solution A obtained in step 1), and disperse evenly by means of mechanical stirring to obtain mixture C, which is filtered through a 200-mesh filter to obtain a formaldehyde scavenger;

[0041] 4) Use a rotary cutter to cut the pine wood into a uniform single-layer sheet with a thickness of 1mm, and use a dryer to dry the single-layer sheet at a drying temperature of 150°C until the moisture content reaches below 1...

Embodiment 2

[0046] Example 2: Preparation of a wooden decorative board with formaldehyde purification function.

[0047] 1) Add 10g of polyvinylpyrrolidone, 4.5g of polymethacrylic acid and 10g of water-based polyurethane into 800g of absolute ethanol, and dissolve with magnetic stirring at 60°C to obtain solution A;

[0048] 2) Mix 7g of titanium dioxide, 7g of tin dioxide, 7g of silicon dioxide, 6g of magnesium oxide, 13g of activated carbon, 9g of calcium chloride, 13g of sodium sulfite and 42g of 1,2,2-triphenyl-1,2-diaminoethanol , to obtain mixture B;

[0049] 3) Add the mixture B obtained in step 2) to the solution A obtained in step 1), and disperse evenly by means of magnetic stirring to obtain mixture C, which is filtered through a 300-mesh filter to obtain a formaldehyde scavenger;

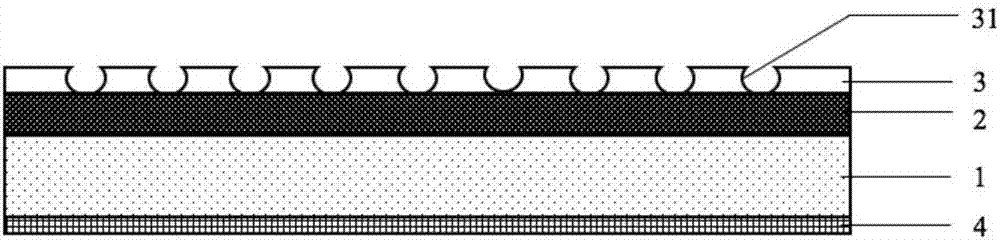

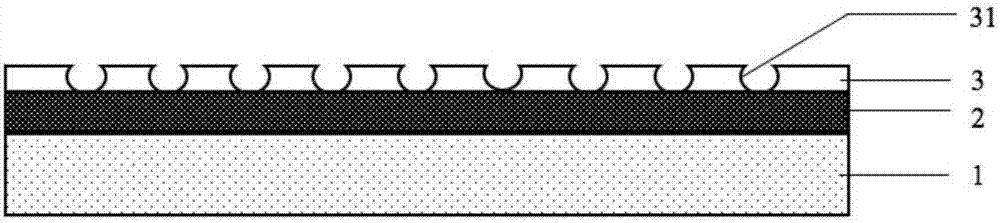

[0050] 4) Get the high-density wood fiber board as the base layer 1 (thickness is 1cm); brush the formaldehyde scavenger obtained in step 3) on its upper surface as the formaldehyde purification l...

Embodiment 3

[0052] Example 3: Preparation of wooden louvers with formaldehyde purification function.

[0053] 1) Add 6g of polyvinylpyrrolidone, 4g of carboxymethyl cellulose and 6g of water-based polyurethane into 600g of deionized water, and dissolve with mechanical stirring at 70°C to obtain solution A;

[0054] 2) 4g of titanium dioxide, 4g of tin dioxide, 4g of silicon dioxide, 4g of magnesium oxide, 6g of activated carbon, 4g of calcium chloride, 6g of sodium acetate and 20g of 1,2-diphenylaminoethanol were mixed to obtain mixture B;

[0055] 3) Add the mixture B obtained in step 2) to the solution A obtained in step 1), and disperse evenly by means of ultrasonic vibration to obtain mixture C, which is filtered through a 200-mesh filter to obtain a formaldehyde scavenger;

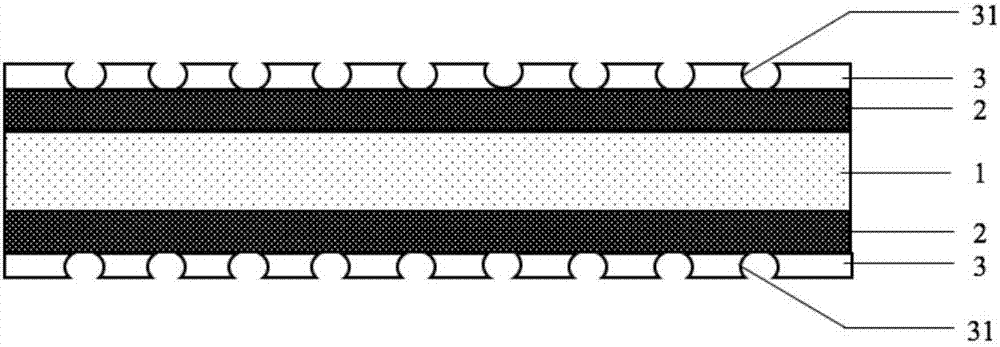

[0056] 4) Take medium-density wood fiberboard as the base layer 1 (thickness is 1cm); brush the formaldehyde scavenger obtained in step 3) on its upper and lower surfaces respectively, as formaldehyde purificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com