Method for preventing deformation and cracking of pines

An anti-cracking, pine wood technology, applied in wood treatment, impregnated wood, wood impregnation, etc., can solve the problems of rapid response to atmospheric temperature, harm to human health, difficult natural air drying, etc., to achieve stable water content, avoid high temperature drying, and absorb water The effect of reduced capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

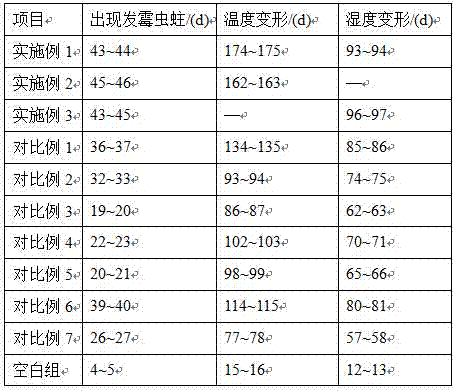

Examples

Embodiment 1

[0020] A method for preventing deformation and cracking of pine, comprising the following steps:

[0021] (1) Arrangement: cut off the felled pine wood according to the required length, retain the pine bark, increase the protective effect of the pine bark, inhibit the color change in the process of pine wood treatment, and facilitate the unified bleaching treatment in the later stage to obtain pine wood sections;

[0022] (2) Freezing: Put the pine wood section in the treatment room, adjust the temperature to 11°C and let it stand for 6 hours, then lower the temperature to 2°C and let it stand for 15 hours, then lower the temperature to -7°C, let it stand for 26 hours, continue Lower the temperature to -32°C, keep it warm for 50 hours, reduce the moisture in the pine wood in a low temperature environment, increase the gaps between the pine fibers, improve the tolerance of the pine wood to temperature and humidity, and reduce the impact of environmental changes on the pine wood....

Embodiment 2

[0034] A method for preventing deformation and cracking of pine, comprising the following steps:

[0035] (1) Arrangement: cut off the felled pine wood according to the required length, retain the pine bark, increase the protective effect of the pine bark, inhibit the color change in the process of pine wood treatment, and facilitate the unified bleaching treatment in the later stage to obtain pine wood sections;

[0036] (2) Freezing: Put the pine wood section in the treatment room, adjust the temperature to 12°C and let it stand for 7 hours, then lower the temperature to 3°C and let it stand for 16 hours, then lower the temperature to -6°C, let it stand for 27 hours, continue Lower the temperature to -31°C, keep it warm for 55 hours, reduce the moisture in the pine wood in a low temperature environment, increase the gaps between the pine fibers, improve the tolerance of the pine wood to temperature and humidity, and reduce the impact of environmental changes on the pine wood....

Embodiment 3

[0048] A method for preventing deformation and cracking of pine, comprising the following steps:

[0049] (1) Arrangement: cut off the felled pine wood according to the required length, retain the pine bark, increase the protective effect of the pine bark, inhibit the color change in the process of pine wood treatment, and facilitate the unified bleaching treatment in the later stage to obtain pine wood sections;

[0050] (2) Freezing: Put the pine wood section in the treatment room, adjust the temperature to 13°C and let it stand for 8 hours, then lower the temperature to 4°C and let it stand for 17 hours, then lower the temperature to -5°C, let it stand for 28 hours, continue Lower the temperature to -30°C, keep it warm for 60 hours, reduce the moisture in the pine wood in a low temperature environment, increase the gaps between the pine fibers, improve the tolerance of the pine wood to temperature and humidity, and reduce the impact of environmental changes on the pine wood....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com