Weaving processing method for improving the service life of wicker products

A treatment method and technology for woven products, which are applied in wood treatment, wood heat treatment, pressurized wood treatment, etc., can solve the problems of restricted use and promotion, low service life, easy deformation of shapes, etc. Cracking rate, effect of alleviating stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

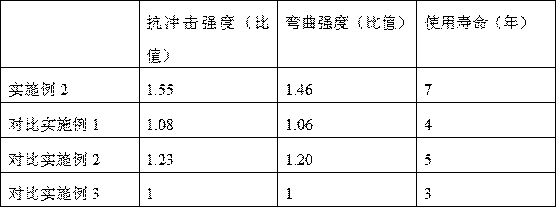

Examples

Embodiment 1

[0028] A weaving treatment method for improving the service life of willow products, comprising the following steps:

[0029] (1) Cleaning treatment:

[0030] Rinse the wicker material with clean water, remove the surface sludge and dust, and dry it for later use;

[0031] (2) Cooking and softening treatment:

[0032] Put the willow material treated in step (1) into boiling water for 20 minutes and take it out for later use;

[0033] (3) Steam explosion treatment:

[0034] Put the wicker raw material processed in step (2) into the steam explosion tank for steam explosion treatment, and take it out for later use after completion;

[0035] (4) Soaking treatment:

[0036] Put the willow material treated in step (3) into solution A for soaking treatment, during which the temperature of the modified solution is kept at 33°C by heating, and ultrasonic irradiation treatment is performed at the same time, and the willow material is taken out after 40 minutes for later use; Soluti...

Embodiment 2

[0047] A weaving treatment method for improving the service life of willow products, comprising the following steps:

[0048] (1) Cleaning treatment:

[0049] Rinse the wicker material with clean water, remove the surface sludge and dust, and dry it for later use;

[0050] (2) Cooking and softening treatment:

[0051] Put the willow material treated in step (1) into boiling water for 23 minutes and take it out for later use;

[0052] (3) Steam explosion treatment:

[0053] Put the wicker raw material processed in step (2) into the steam explosion tank for steam explosion treatment, and take it out for later use after completion;

[0054] (4) Soaking treatment:

[0055] Put the willow material treated in step (3) into the solution A for soaking treatment, during which the temperature of the modified solution is kept at 35°C by heating, and ultrasonic irradiation treatment is carried out at the same time, and the willow material is taken out after 42 minutes for later use; ...

Embodiment 3

[0066] A weaving treatment method for improving the service life of willow products, comprising the following steps:

[0067] (1) Cleaning treatment:

[0068] Rinse the wicker material with clean water, remove the surface sludge and dust, and dry it for later use;

[0069] (2) Cooking and softening treatment:

[0070] Put the wicker raw material processed in step (1) into boiling water for 25 minutes and take it out for later use;

[0071] (3) Steam explosion treatment:

[0072] Put the wicker raw material processed in step (2) into the steam explosion tank for steam explosion treatment, and take it out for later use after completion;

[0073] (4) Soaking treatment:

[0074] Put the willow material treated in step (3) into the solution A for soaking treatment, during which the temperature of the modified solution is kept at 37°C by heating, and ultrasonic irradiation treatment is performed at the same time, and the willow material is taken out after 45 minutes for later us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com