Heavy metal agricultural soil remediation method

A technology of soil remediation and soil remediation agent, which is applied in the field of heavy metal agricultural soil remediation, can solve the problems of lack of research on the simultaneous existence of multiple heavy metals, and achieve the effect of reducing the content of heavy metals, improving the structure, and remediating excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

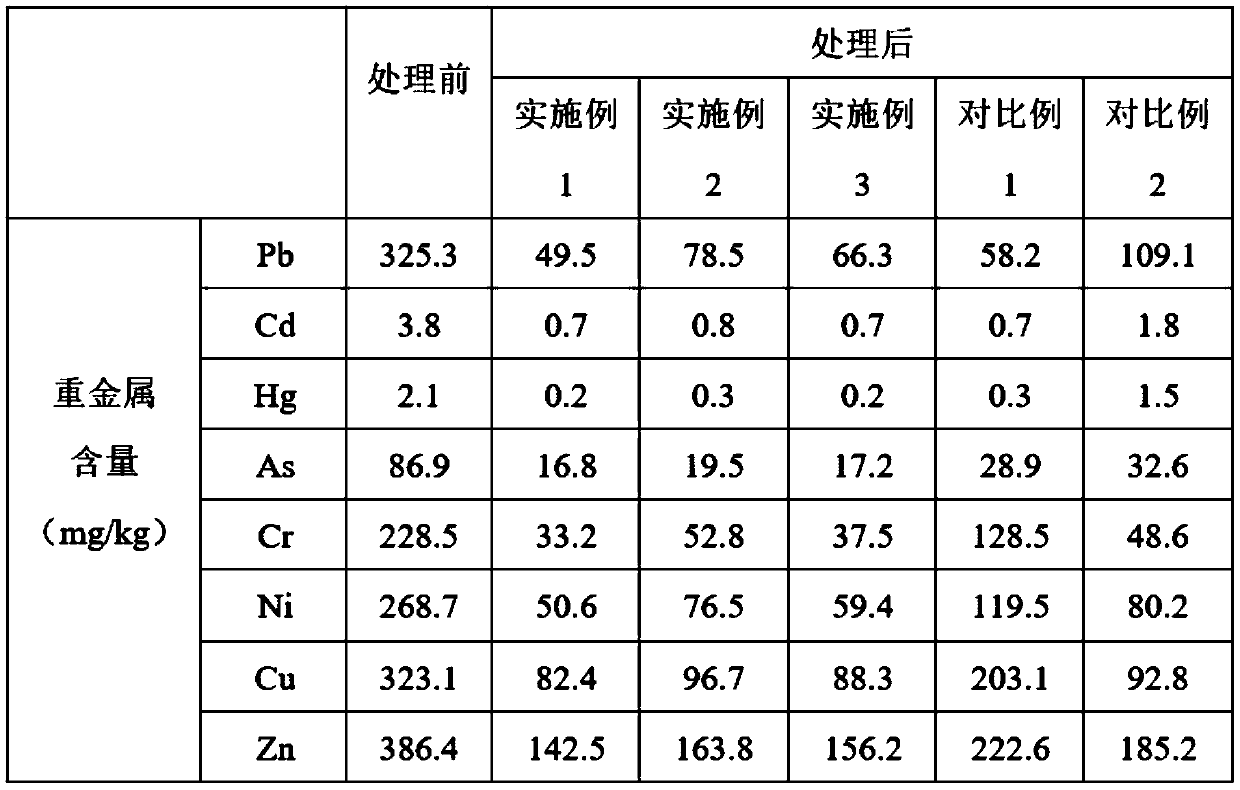

Examples

Embodiment 1

[0041] A method for remediating heavy metal agricultural soil, the method comprising:

[0042] (1) preparing a soil remediation agent, the soil remediation agent is calculated according to parts by weight, including: 45 parts of biochar; 10 parts of bentonite; 8 parts of curing agent;

[0043] (2) mix the soil remediation agent with the soil polluted by heavy metals according to the weight ratio of 1:15, and obtain the contaminated soil containing the soil remediation agent;

[0044] (3) Spray water mist to the contaminated soil containing the soil remediation agent to make the water content reach 30% to 50%, and then leave it at room temperature for 6 days to obtain the improved soil;

[0045] Among them, the curing agent includes the first curing agent and the second curing agent; biochar is made of straw and / or manure as raw material, and after vacuum pyrolysis at 200-300°C for 1-2 hours, it is ground to a particle size of 2-200°C. 3mm particles.

[0046] The preparation ...

Embodiment 2

[0063] A method for remediating heavy metal agricultural soil, the method comprising:

[0064] (1) preparing a soil remediation agent, the soil remediation agent is calculated according to parts by weight, including: 35 parts of biochar; 8 parts of bentonite; 5 parts of curing agent;

[0065] (2) mix the soil remediation agent with the soil polluted by heavy metals according to the weight ratio of 1:10, and obtain the contaminated soil containing the soil remediation agent;

[0066] (3) Spray water mist to the polluted soil containing the soil remediation agent, so that the water content reaches 30% to 50%, and then leave it at room temperature for 5 days to obtain the improved soil;

[0067] Among them, the curing agent includes the first curing agent and the second curing agent; biochar is made of straw and / or manure as raw material, and after vacuum pyrolysis at 200-300°C for 1-2 hours, it is ground to a particle size of 2-200°C. 3mm particles.

[0068] The preparation me...

Embodiment 3

[0085] A method for remediating heavy metal agricultural soil, the method comprising:

[0086] (1) Prepare a soil remediation agent, the soil remediation agent is calculated according to parts by weight, including: 50 parts of biochar; 20 parts of bentonite; 10 parts of curing agent;

[0087] (2) mix the soil remediation agent with the soil polluted by heavy metals according to the weight ratio of 1:20, and obtain the contaminated soil containing the soil remediation agent;

[0088] (3) Spray water mist to the polluted soil containing the soil remediation agent, so that the water content reaches 30% to 50%, and then leave it at room temperature for 7 days to obtain the improved soil;

[0089] Among them, the curing agent includes the first curing agent and the second curing agent; biochar is made of straw and / or manure as raw material, and after vacuum pyrolysis at 200-300°C for 1-2 hours, it is ground to a particle size of 2-200°C. 3mm particles.

[0090] The preparation me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com