Construction method of typical softwood superhydrophobic surface

A technology of super-hydrophobic surface and coniferous wood, which is applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of high cost of preparation method, complicated operation of preparation method, etc., and achieves low price, simple and easy spraying process, convenient and convenient. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

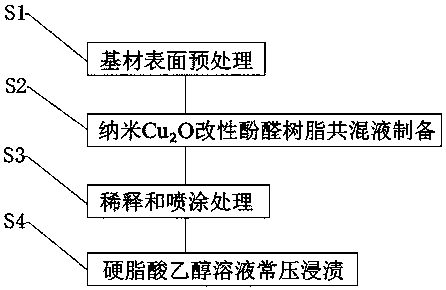

[0046] Masson pine is a typical coniferous material. Therefore, in this embodiment, the cross-section of masson pine is selected as the substrate, and the cross-section of masson pine is used as the spraying surface. The construction method of the typical softwood superhydrophobic surface that this embodiment provides, such as figure 1 shown, including the following steps:

[0047] Step S1, substrate surface pretreatment: Process the masson pine into a wooden block of length × width × height = 25mm × 20mm × 8mm, use 120 mesh sandpaper for sanding treatment, and blow it with an air compressor with an exhaust pressure of 0.7Mpa Sweep for 15 seconds, then wash twice with distilled water and twice with 75% medical alcohol to remove dust and impurities on the surface of the substrate, and finally dry it in an oven at 102°C for 6 hours, and store it for spraying;

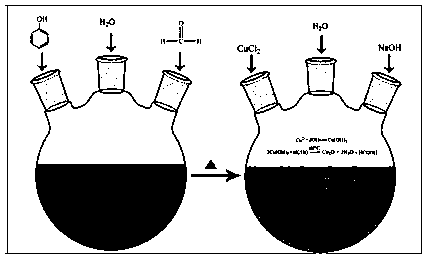

[0048] Step S2, Nano-Cu 2 Preparation of O-modified phenolic resin blend solution (the preparation principle is as fo...

Embodiment 2

[0060] The specific implementation steps of this embodiment and Example 1 are all the same, and the difference is: 0.55 g of surfactant added in step S2 (wherein, the content of sodium hexametaphosphate is 20%, the content of silane coupling agent KH550 20%, the content of polyvinylpyrrolidone is 60%), the concentration is 7% polyvinyl alcohol aqueous solution 50g; Nano Cu in step S3 2 The number of sprayed layers of the O-modified phenolic resin blended diluent is 8 layers; the stearic acid ethanol solution in step S4 is soaked for 3 hours at normal pressure. The static contact angle of water on the cross-section of the modified masson pine obtained in Example 2 is 151.5° (the test water drop is 4 μL), and the super-hydrophobic surface property is obtained. The treatment results are as follows: Figure 7 shown.

Embodiment 3

[0062] The specific implementation steps of this embodiment are the same as those of Example 1, except that: 0.5 g of surfactant added in step S2 (wherein, the content of sodium hexametaphosphate is 20%, and the content of silane coupling agent KH550 is 20%, the content of polyvinylpyrrolidone is 60%), the concentration is 50g of polyvinyl alcohol aqueous solution of 7.5%; Nano Cu in step S3 2 The number of sprayed layers of the O-modified phenolic resin blended diluent is 4 layers; the stearic acid ethanol solution in step S4 is soaked for 1 h at normal pressure. The static water contact angle of the cross-section of the modified masson pine obtained in Example 3 is 151° (the test water drop is 4 μL), and the superhydrophobic surface performance is obtained. The treatment results are as follows: Figure 8 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com