Comprehensive reaction kettle used for wood modification

A wood modification, comprehensive technology, applied in the field of wood modification production equipment, can solve the problems of short residence time, affecting reaction efficiency, short contact time, etc., and achieve the goal of increasing residence time, improving reaction efficiency and high utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

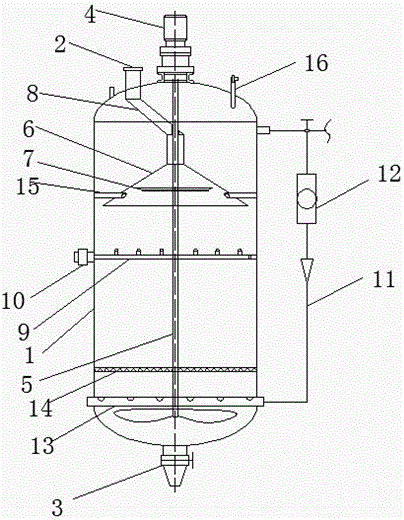

[0014] Embodiment 1: as figure 1 A comprehensive reactor for wood modification is shown, the comprehensive reactor is a sealed cylindrical shell 1, the top of the shell 1 is provided with a stirring motor 4, and the inside of the shell 1 is provided with Stirring shaft 5, the bottom of the housing 1 is provided with a discharge port 3, the top of the housing 1 is provided with a solid feed port 2 and a gas feed port 16, and the middle part of the housing 1 is provided with a liquid feed port 10, the said The upper part of the housing 1 is provided with a conical material distributor 6, the material distributor 6 is set on the stirring shaft 5, and the material distributor 6 is fixedly installed on the inner wall of the housing 1 through a fixed rod 15. The stirring shaft 5 inside the distributor 6 is provided with a material distribution round table 7, the top of the material distributor 6 is connected to the solid feeding port 2 through a material introduction pipe 8, and an ...

Embodiment 2

[0015] Embodiment 2: as figure 1 As shown, the housing 1 above the material distributor 6 of the present invention is provided with a gas return pipeline 11, and the bottom of the housing 1 is provided with an annular gas injection pipeline 13, and the gas return pipeline 11 passes through the air pump 12 Connected to the gas injection pipeline 13; through the combination of the gas return pipeline 11 and the gas injection pipeline 13, it is convenient to reintroduce the unreacted gas above the shell 1 into the reaction system below the shell 1, and react again , high gas medium utilization.

Embodiment 3

[0016] Embodiment 3: as figure 1 As shown, the air injection pipeline 13 of the present invention is evenly distributed with a plurality of horizontally injected airflow nozzles; through the horizontally injected airflow nozzles, it is convenient to inject the gas medium into the liquid reaction liquid below the housing 1, so as to improve the flow rate of the gas in the liquid after the backflow. The residence time in the reaction liquid, when it diffuses upwards, is in contact with the solid medium in the liquid reaction liquid, facilitating the simultaneous reaction of the three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com