Wood antique finish technology for historic building

A technology for ancient buildings and wood, which is applied in the field of old wood for ancient buildings, can solve problems such as uncontrollability, reduced moth-proof performance, and old-fashioned damage, and achieves high erosion efficiency, excellent moth-proof performance and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

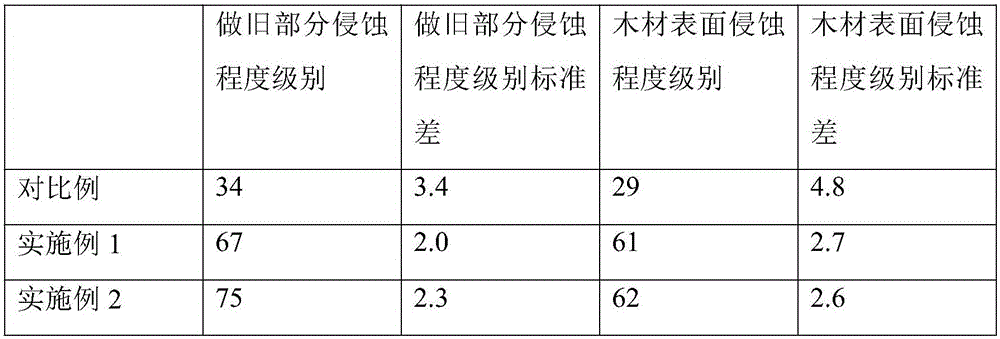

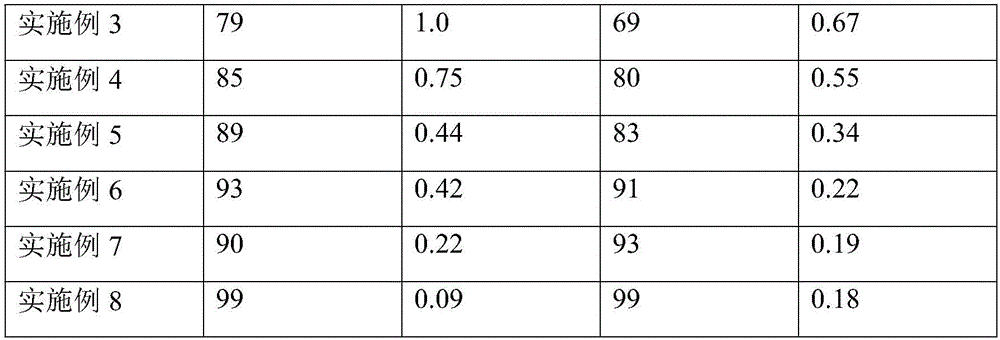

Examples

Embodiment 1

[0022] Embodiment 1: a kind of craft of old-fashioned wood used in ancient buildings is made according to the following steps,

[0023] S1, use clean water to fully clean the side and end of the wood, and dry it in the natural environment for 3 hours after cleaning;

[0024] S2, use circular and rectangular mold frames with a certain shape to stick to the wood surface, and use the mud with viscosity to adhere to the gap between the mold frame and the wood surface, and define the wood part surrounded by the mold frame as the old part. That is, according to the demand, the part needs to be aged; pour the melted liquid white wax into the wood mold frame, and use the scraper to scrape back and forth several times before stopping, and let it stand until the white wax is completely solidified and formed;

[0025] S3, smear preservative on the wood in step S2 except the remaining part of the old part, the preservative adopts the insecticide in the market, such as quaternary ammonium ...

Embodiment 2

[0029] Embodiment 2: A kind of process of making old wood for ancient buildings, and the difference with embodiment 1 is as follows, S3, on the wood in step S2 except the remaining part of the old part, smear preservative, preservative adopts market pesticides, such as quaternary ammonium salts, etc.; and wax the rest of the old part of the wood, using high melting point waxes such as polyethylene wax. All the other steps are the same as in Example 1.

Embodiment 3

[0030]Embodiment 3: A process for making old wood for ancient buildings, the difference from Embodiment 1 is as follows, S4, put the wood in step S3 into a high-temperature barrel, and treat the wood under the condition of 60°C to 70°C The old part of the wood is treated with white wax for 40-60 minutes, and finally the white wax is removed from the old part of the wood, and the wood surface can be exposed to the air; then the old part of the wood is coated with an attractant, and the old part of the wood is used Partially coated with fulvic acid, lignin. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com