Preparing method for fiberboard surface treating agent and application method of fiberboard surface treating agent

A technology of surface treatment agent and application method, applied in the direction of wood treatment, wood treatment details, chemical instruments and methods, etc., can solve the problems of wet flowers, impregnated paper not firmly pressed, bubbling, etc., to improve reactivity, reduce Effects of uncontrollability, increased stability and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

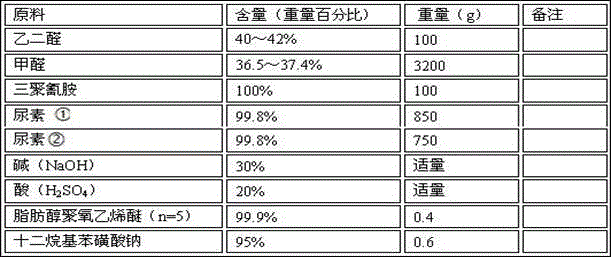

[0031] The raw material formula of table 1 embodiment

[0032]

[0033] 1) Synthesis of surface treatment agent:

[0034] (1) Add accurately measured glyoxal and formaldehyde into the reaction kettle equipped with mechanical stirring, temperature controller, and condensation reflux equipment, and control the reaction temperature at 35-40°C;

[0035] (2) Add dilute sulfuric acid to adjust pH=2.0~2.5;

[0036] (3) The addition of melamine and urea is completed within 25 to 30 minutes ;

[0037] (4) Heat up to 75°C and keep warm for 5 minutes;

[0038] (5) Add alkali to adjust pH=8.0~8.5; cool down

[0039] (6) When the temperature drops to 75°C, add urea , continue to cool down to 50 ~ 60 ℃;

[0040] (7) Slowly add surfactant and stir for 30 minutes. Continue to cool down to below 40°C;

[0041] (8) Adjust the pH=7.5~8.0, and discharge.

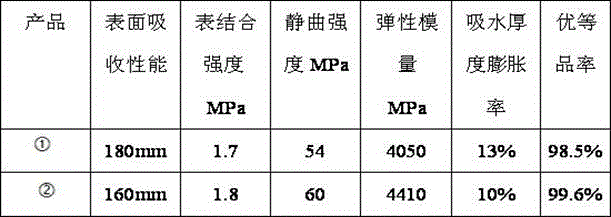

[0042] The quality index of gained surface treatment agent:

[0043] pH value: 7.8

[0044] Viscosity (25°C): 5~15mpa*s

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com