Wood conditioning method

A wood and drying kiln technology, applied in the direction of wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of excessive equilibrium moisture content, long treatment time, and reduced wood moisture content, and achieve high grain-oriented tensile strength, Improved volume stability and faster heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

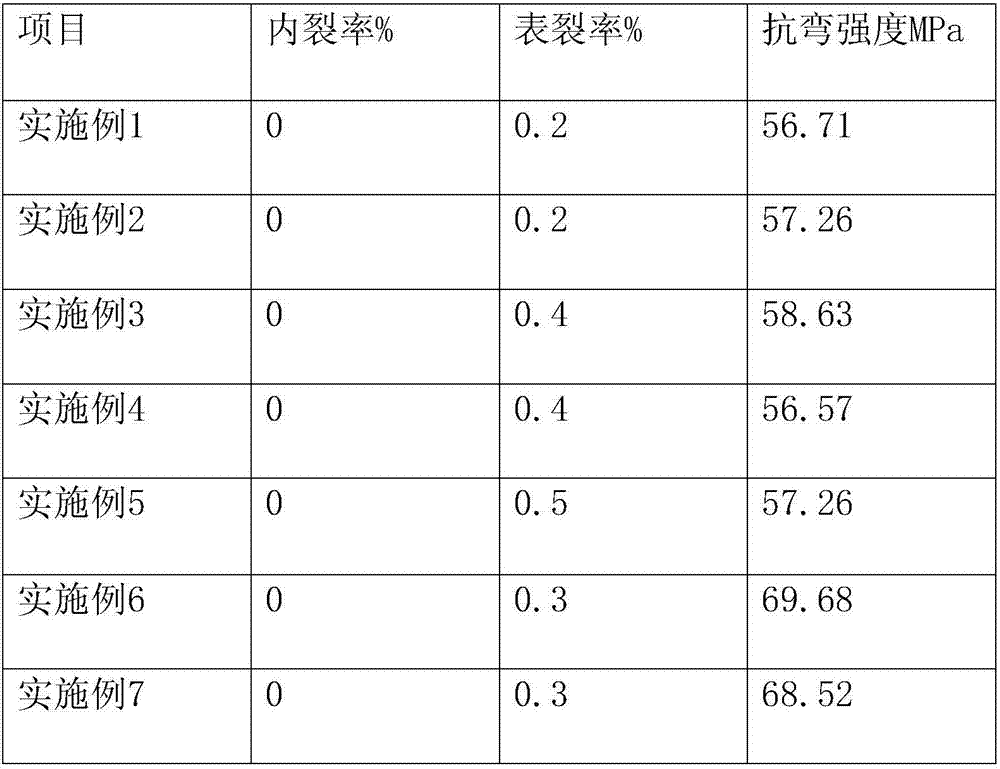

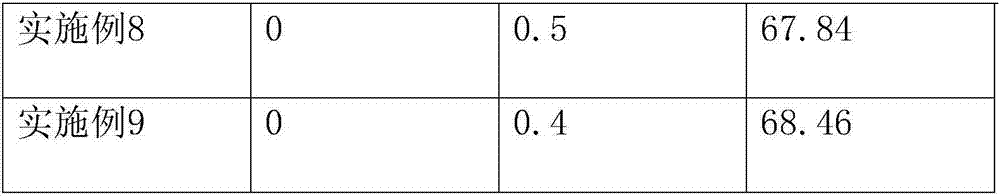

Examples

Embodiment 1

[0023] A method for maintaining the health of wood, comprising the following specific steps:

[0024] Step 1. Impregnation treatment: put the wood in a sealed tank, evacuate the inside of the tank to a negative pressure of 0.06MPa, and keep it for 10 minutes. Under this negative pressure, fill the sealed tank with a 5% aqueous solution of ammonium bicarbonate , then raise the pressure in the tank to 1MPa, keep it for 1h, let the ammonium bicarbonate solution penetrate into the micropores inside the wood, remove the pressure, and discharge the remaining ammonium bicarbonate solution, and then vacuumize the tank to 0.06MPa negative pressure state , keep for 2 hours, release the pressure, discharge the residual ammonium bicarbonate aqueous solution, and take out the wood;

[0025] Step 2, the first heating and humidification treatment: put the wood in the drying kiln, pass steam into the drying kiln, make the relative humidity in the drying kiln greater than 98%, heat the drying ...

Embodiment 2

[0033] A method for maintaining the health of wood, comprising the following specific steps:

[0034]Step 1. Impregnation treatment: put the wood in a sealed tank, evacuate the inside of the tank to a negative pressure of 0.08MPa, and keep it for 20 minutes. Under this negative pressure, fill the sealed tank with an aqueous solution of 8% ammonium bicarbonate. Then raise the pressure inside the tank to 2MPa and keep it for 2 hours, so that the aqueous ammonium bicarbonate solution penetrates into the micropores inside the wood, remove the pressure, and discharge the remaining aqueous ammonium bicarbonate solution, and then vacuumize the inside of the tank to a negative pressure state of 0.08MPa. Keep for 3 hours, release the pressure, discharge the residual ammonium bicarbonate aqueous solution, and take out the wood;

[0035] Step 2, the first heating and humidification treatment: put the wood in the drying kiln, pass steam into the drying kiln, make the relative humidity in ...

Embodiment 3

[0043] A method for maintaining the health of wood, comprising the following specific steps:

[0044] Step 1. Impregnation treatment: put the wood in a sealed tank, evacuate the inside of the tank to a negative pressure of 0.1 MPa, and keep it for 30 minutes. Under this negative pressure, fill the sealed tank with a 10% ammonium bicarbonate aqueous solution. Then raise the pressure inside the tank to 2MPa and keep it for 2 hours, so that the aqueous ammonium bicarbonate solution penetrates into the micropores inside the wood, remove the pressure, and discharge the remaining aqueous ammonium bicarbonate solution, and then vacuumize the inside of the tank to a negative pressure of 0.1MPa. Keep for 3 hours, release the pressure, discharge the residual ammonium bicarbonate aqueous solution, and take out the wood;

[0045] Step 2, the first heating and humidification treatment: put the wood in the drying kiln, pass steam into the drying kiln, make the relative humidity in the dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com