Treatment method for removing formaldehydes in board

A processing method and board technology, applied in wood processing, wood processing details, radiation/wave wood processing, etc., can solve problems such as slow processing speed, and achieve the effect of reducing time, fast drying, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

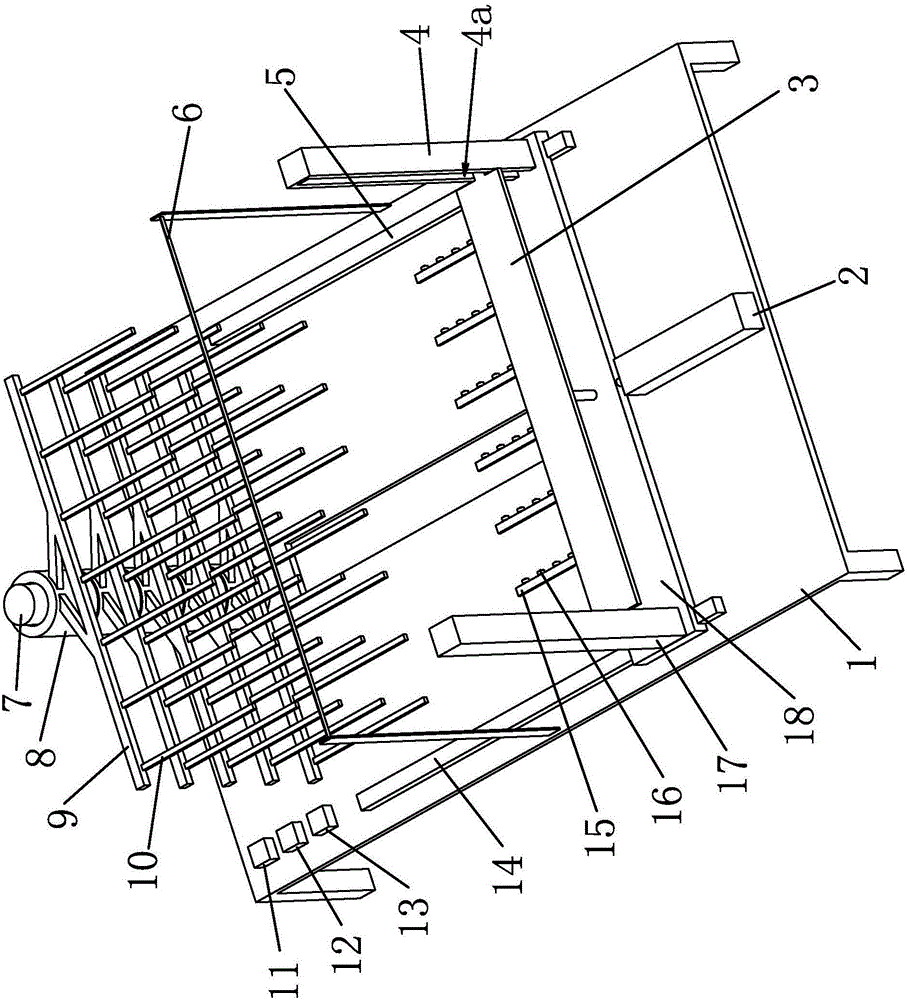

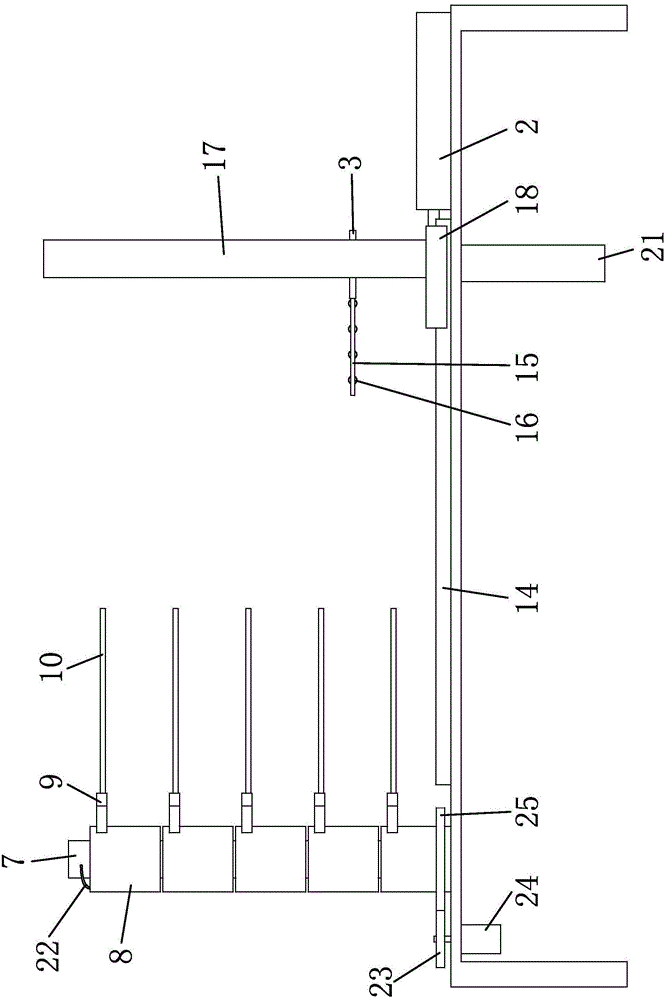

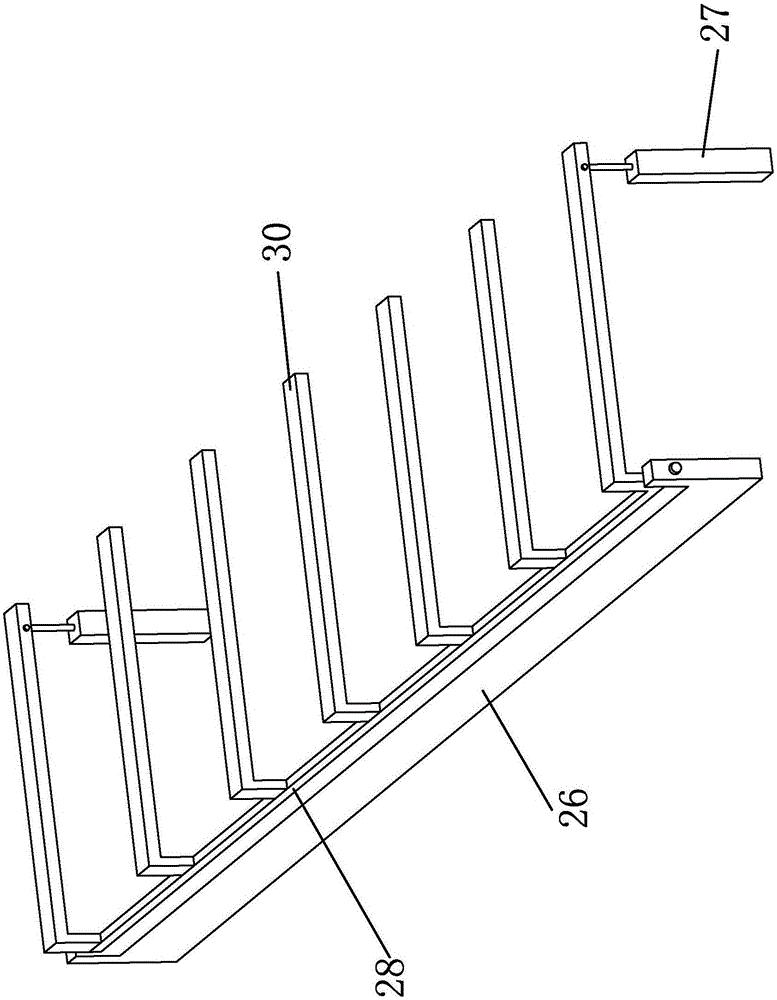

[0048] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0049] The processing method of formaldehyde in this removal board comprises the steps:

[0050] a. Prepare a formaldehyde scavenger. The formaldehyde scavenger is composed of the following parts by weight: 50-60 parts of plant extract, 6-10 parts of sodium bicarbonate, 1-4 parts of nano titanium dioxide, 6-9 parts of hydrogen peroxide, nano 2-6 parts of antibacterial agent, 1-3 parts of penetrating agent, 1-2 parts of antiseptic, 2-4 parts of surfactant and 30-40 parts of water; Composition: 55 parts of plant extract, 8 parts of sodium bicarbonate, 2 parts of nano titanium dioxide, 7 parts of hydrogen peroxide, 3 parts of nano antibacterial agent, 2 parts of penetrant, 1 part of preservative, 2 parts of surfactant and 35 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com