Method for removing formaldehyde from artificial plate

A technology for removing formaldehyde and wood-based panels, used in wood treatment, wood heating, wood impregnation, etc., can solve problems such as high cost and incomplete removal, and achieve the effects of increasing content, improving hydrophilicity, and increasing acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

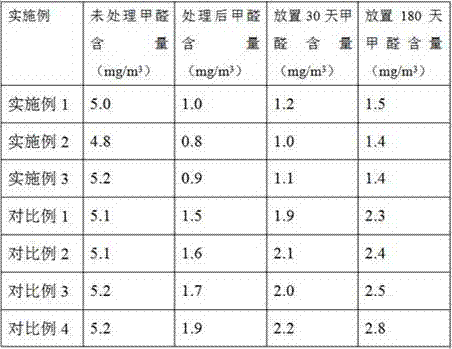

Examples

Embodiment 1

[0022] A method for removing formaldehyde from wood-based panels, comprising the following steps:

[0023] (1) Place the wood-based panel in a closed space, blow in nitrogen, spray solution A to a humidity of 30%, heat it to 60°C at a heating rate of 10°C / h, and keep it warm for 2 hours. Solution A is amino acid, ethylene glycol Mixed aqueous solution of amine tetraacetic acid, dodecyl glucoside, tea polyphenols, ammonium phosphate and 1,8-cineole, the concentration is 0.1g / L, amino acid, ethylenediaminetetraacetic acid, dodecyl glucoside , tea polyphenols, ammonium phosphate and 1,8-cineole in a mass ratio of 1:1:2:1:2:0.5.

[0024] (2) Dry to a humidity of 10% and keep warm for 1 hour;

[0025] (3) Vacuumize, cool down to 30°C, and keep warm for 2 hours;

[0026] (4) Spray solution B on the wood-based panel, heat up to 40°C at a heating rate of 10°C / h, keep it warm for 0.5 hours, then cool down to 25°C, and dry. Solution B is a mixed aqueous solution of epichlorohydrin mo...

Embodiment 2

[0028] A method for removing formaldehyde from wood-based panels, comprising the following steps:

[0029] (1) Place the wood-based panel in a closed space, ventilate nitrogen, spray solution A to a humidity of 60%, heat it to 70°C at a heating rate of 20°C / h, and keep it warm for 4 hours. Solution A is amino acid, ethylene glycol A mixed aqueous solution of amine tetraacetic acid, dodecyl glucoside, tea polyphenols, ammonium phosphate and 1,8-cineole, the concentration is 1g / L, amino acid, ethylenediaminetetraacetic acid, dodecyl glucoside, The mass ratio of tea polyphenols, ammonium phosphate and 1,8-cineole is 1:3:2:1:2:0.5.

[0030] (2) Dry to a humidity of 15% and keep warm for 2 hours;

[0031] (3) Vacuumize, cool down to 30°C, and keep warm for 5 hours;

[0032] (4) Spray solution B on the wood-based panel, heat up to 50°C at a heating rate of 15°C / h, keep it warm for 2 hours, then cool down to 30°C, and dry. Solution B is a mixed aqueous solution of epichlorohydrin ...

Embodiment 3

[0034] A method for removing formaldehyde from wood-based panels, comprising the following steps:

[0035] (1) Place the wood-based panel in a closed space, ventilate nitrogen, spray solution A to a humidity of 45%, heat to 65°C at a heating rate of 15°C / h, and keep warm for 3 hours. Solution A is amino acid, ethylene glycol Mixed aqueous solution of amine tetraacetic acid, dodecyl glucoside, tea polyphenols, ammonium phosphate and 1,8-cineole, the concentration is 0.5g / L, amino acid, ethylenediaminetetraacetic acid, dodecyl glucoside , tea polyphenols, ammonium phosphate and 1,8-cineole in a mass ratio of 1:2:2:1:2:0.5.

[0036] (2) Dry to a humidity of 125% and keep warm for 1.5 hours;

[0037] (3) Vacuumize, cool down to 30°C, and keep warm for 3 hours;

[0038] (4) Spray solution B on the wood-based panel, heat up to 45°C at a heating rate of 12°C / h, keep it warm for 1 hour, then cool down to 30°C, and dry. Solution B is a mixed aqueous solution of epichlorohydrin modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com