Installation for spraying a multicomponent coating product

A multi-component and equipment technology, applied in spray devices, electrostatic spray devices, liquid supply devices, etc., can solve problems such as loss of coated products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

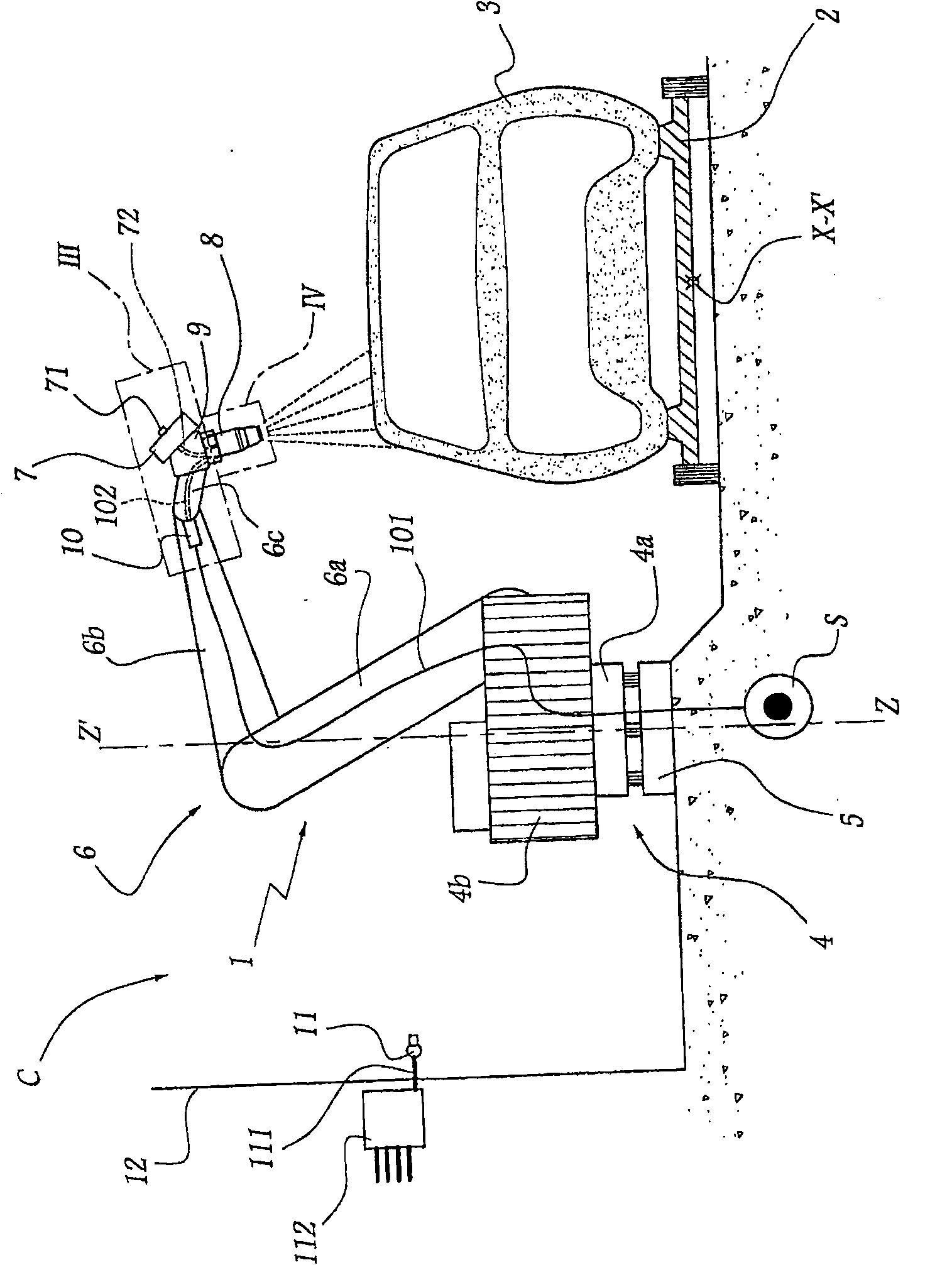

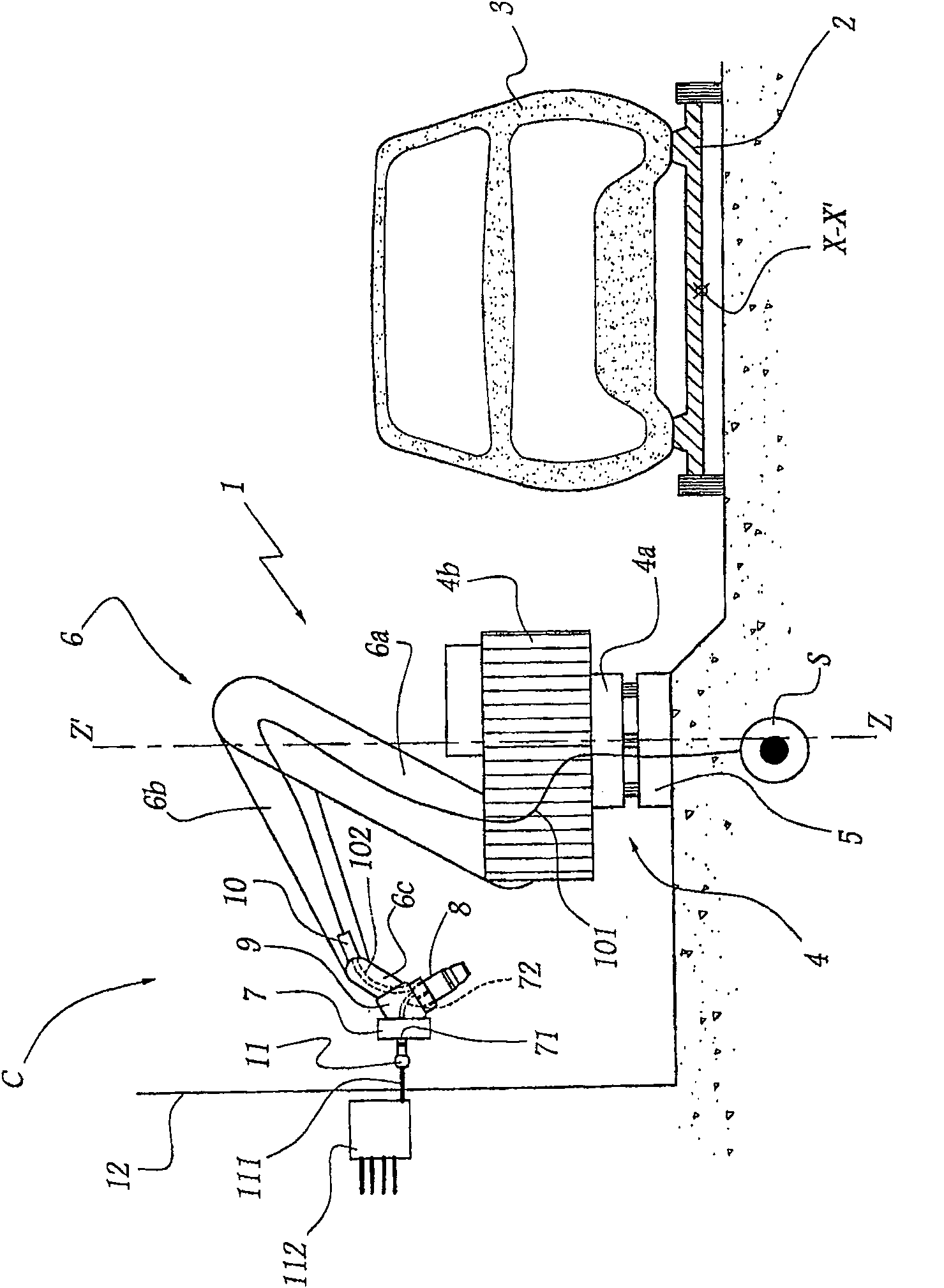

[0020] [20] in figure 1 with 2 In the shown installation, the robot 1 is located near a conveyor 2 that transports the object to be coated, for example a motor vehicle body 3 . The robot 1 is of the multi-axis type and comprises a base 4 movable on guides 5 extending parallel to the conveying direction X-X'. An arm 6 is supported by the base 4 and comprises several mutually hinged sections 6a, 6b, 6c. The base 4 consists of two parts 4a and 4b hinged to each other about a substantially vertical axis Z-Z'.

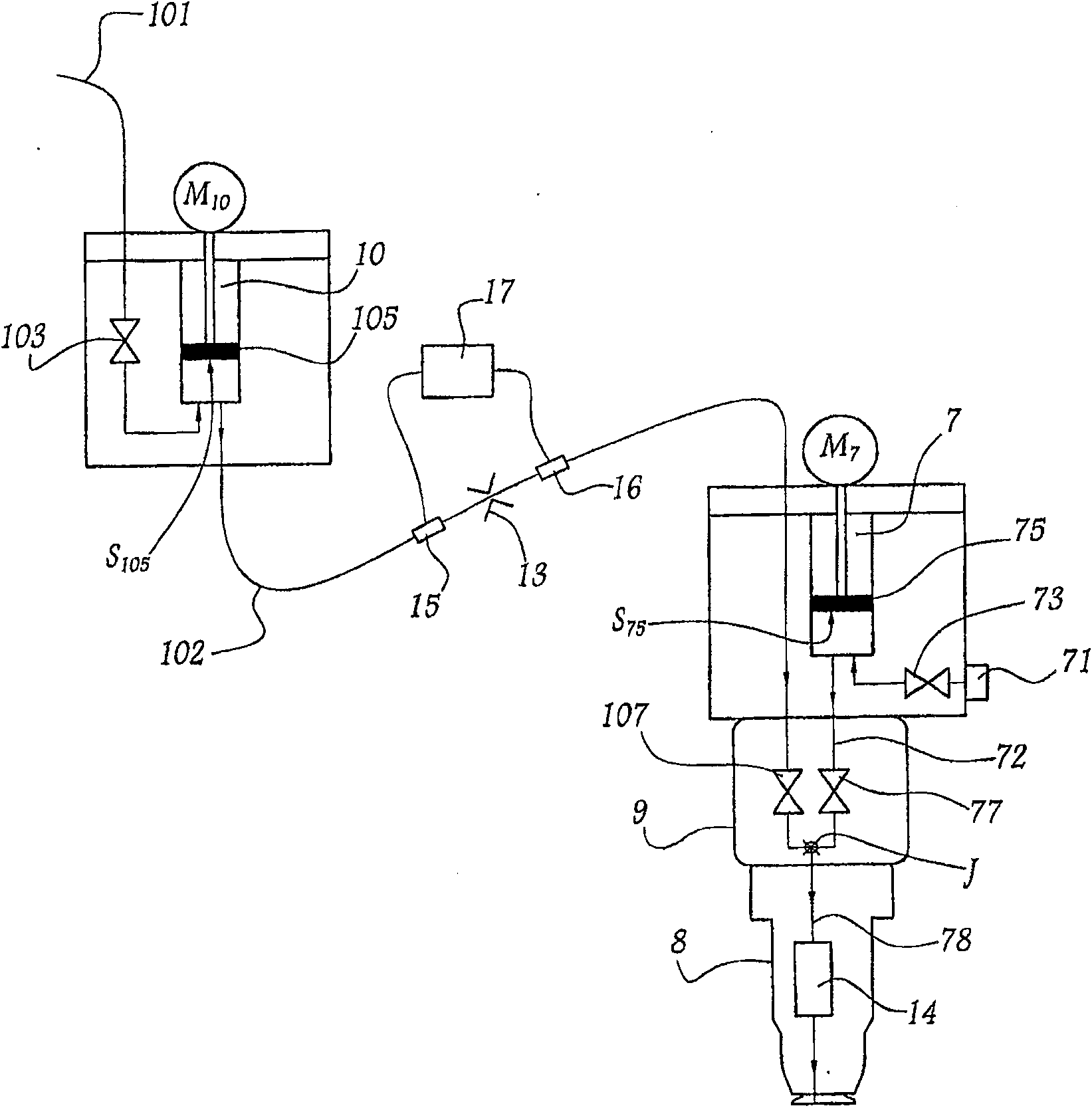

[0021] [21] Section 6c of arm 6 supports an assembly including reservoir 7, rotary injector 8, and carrier plate (platine) 9, and conduits connecting reservoir 7 and injector 8 are provided in carrier plate 9, and among these conduits one of the figure 1 with 2 Indicated by reference numeral 72 .

[0022] [22] The injector 8 is of the electrostatic type and is connected to an adjustable high voltage generator not shown. The generator is zeroed outside the injector 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com