Plasma sealing structure for discharge chamber of annular magnetic steel ring cutting field ion thruster

A technology of ion thruster and sealing structure, which is applied in the direction of using plasma, thrust reverser, machine/engine, etc., to reduce the pollution rate, realize sealing, and realize the effect of electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

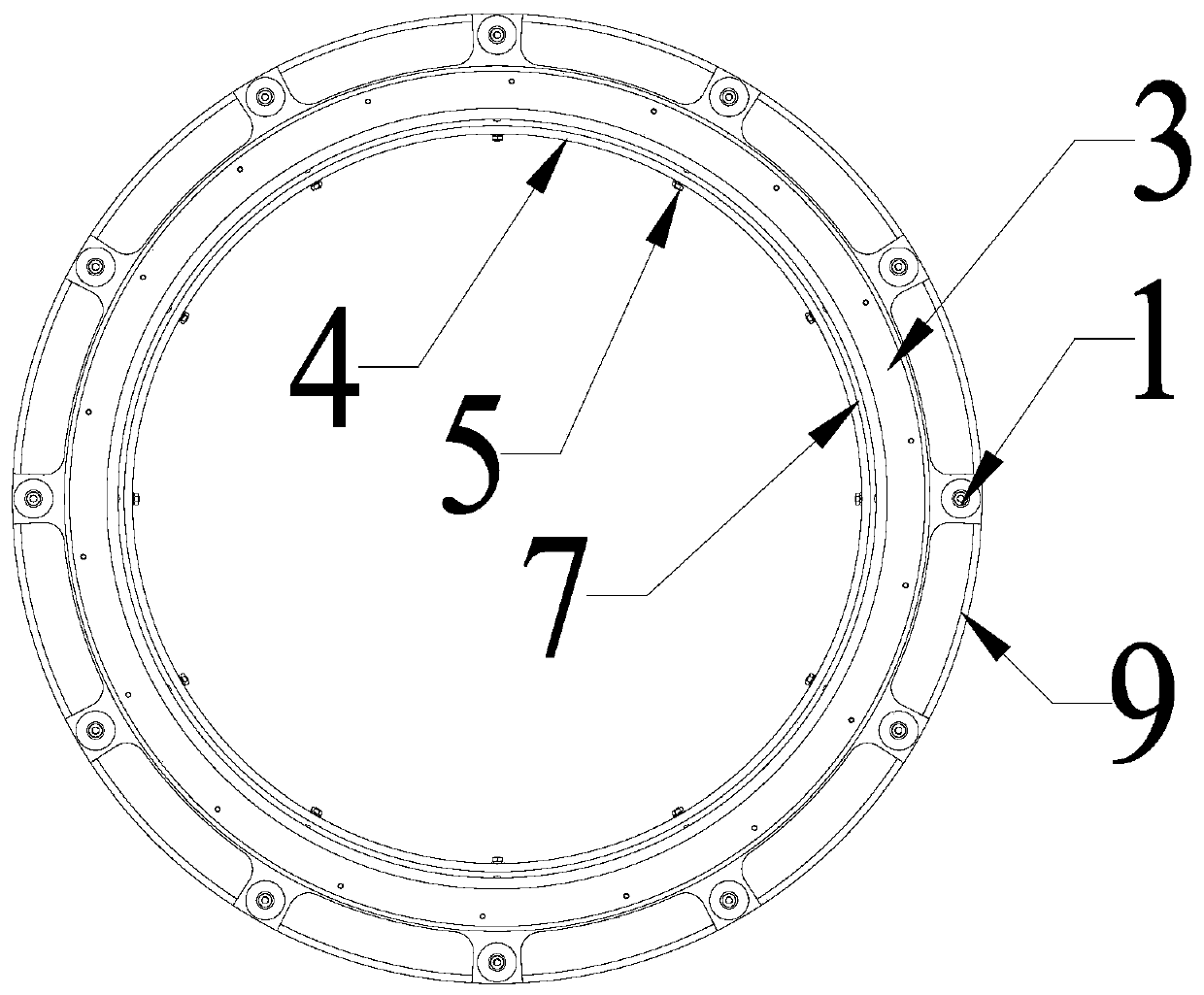

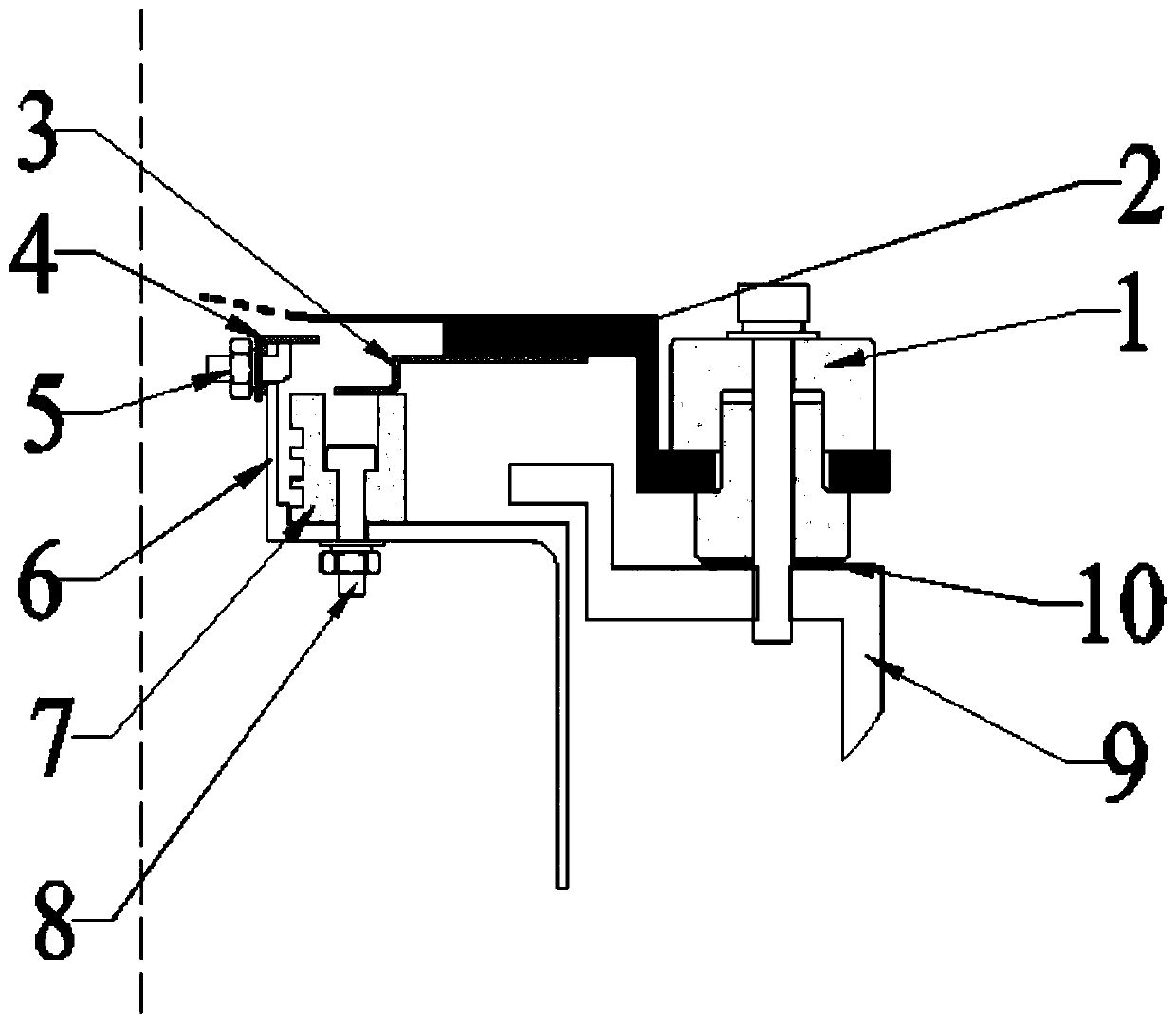

[0023] This embodiment provides a plasma sealing structure in the discharge chamber of the annular magnetic steel annular tangential field ion thruster, such as figure 1 As shown, the sealing structure includes a ceramic ring 7, a shielding cover 4, a Z-shaped sealing ring 3 and a sealing gap adjustment pad 10, which are installed on an ion thruster, and the ion thruster includes a grid assembly 2, an anode 6, and a ceramic support assembly 1 and support ring 9. The anode 6 is a stepped cylinder structure, including a large-diameter cylinder and a small-diameter cylinder, and the axial section is convex; the ceramic support assembly 1 is fixed on the support ring 9, and the ceramic support assembly 1 is used to fix the grid assembly 2 .

[0024] like figure 2 As shown, the shielding cover 4 is a metal ring with a cylindrical protrusion, and the axial se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com