Pollution-free heating tube device of vertical vacuum ion film plating machine

A heating tube, coating machine technology, applied in ion implantation coating, vacuum evaporation coating, sputtering coating and other directions, can solve the problem of secondary pollution, achieve compact equipment, solve secondary pollution problem, improve coating quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

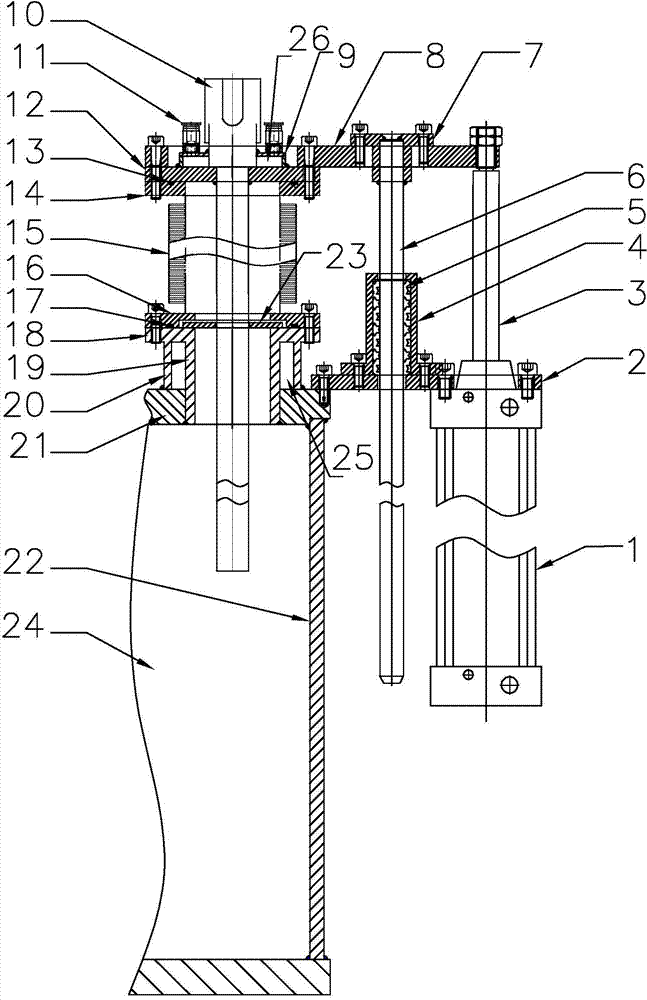

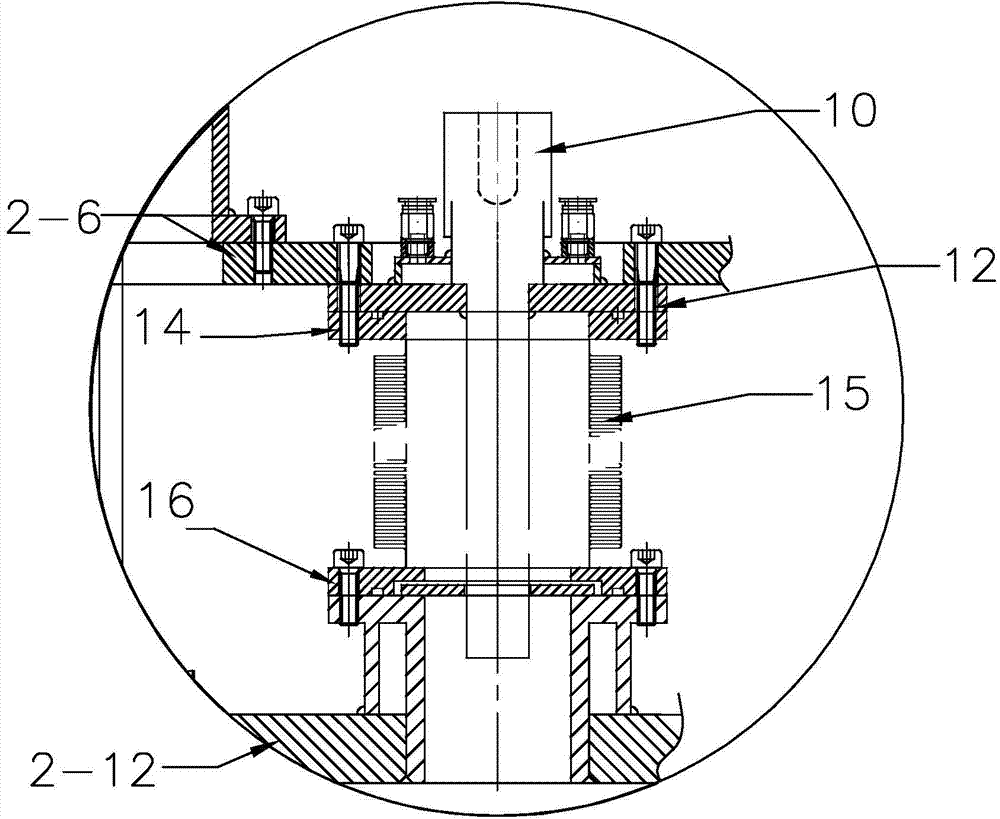

[0031] like figure 1 Shown is a pollution-free heating tube device for a vertical vacuum ion coating machine of the present invention, including a heating tube assembly, a bellows assembly, a bellows support seat assembly and a lifting mechanism. The heating tube assembly is composed of a special heating tube 10, a heating tube flange 12, a water cooling cover 9 at the end of the heating tube, and a water inlet and outlet nozzle 11. The upper end of the special heating tube 10 is the leading end of the wire, and the leading end is provided with an insulating joint. The position of the heating wire in the heating tube 10 is far from the leading end. When the heating tube 10 is lowered to the lowest position, the heating wire is located on the top plate 21 Slightly below, the top plate 21 of the furnace body is located at the upper end of the surrounding board 22 of the furnace body of the coating chamber 24 . The heating pipe flange 12 is attached to the shoulder of the heatin...

Embodiment 2

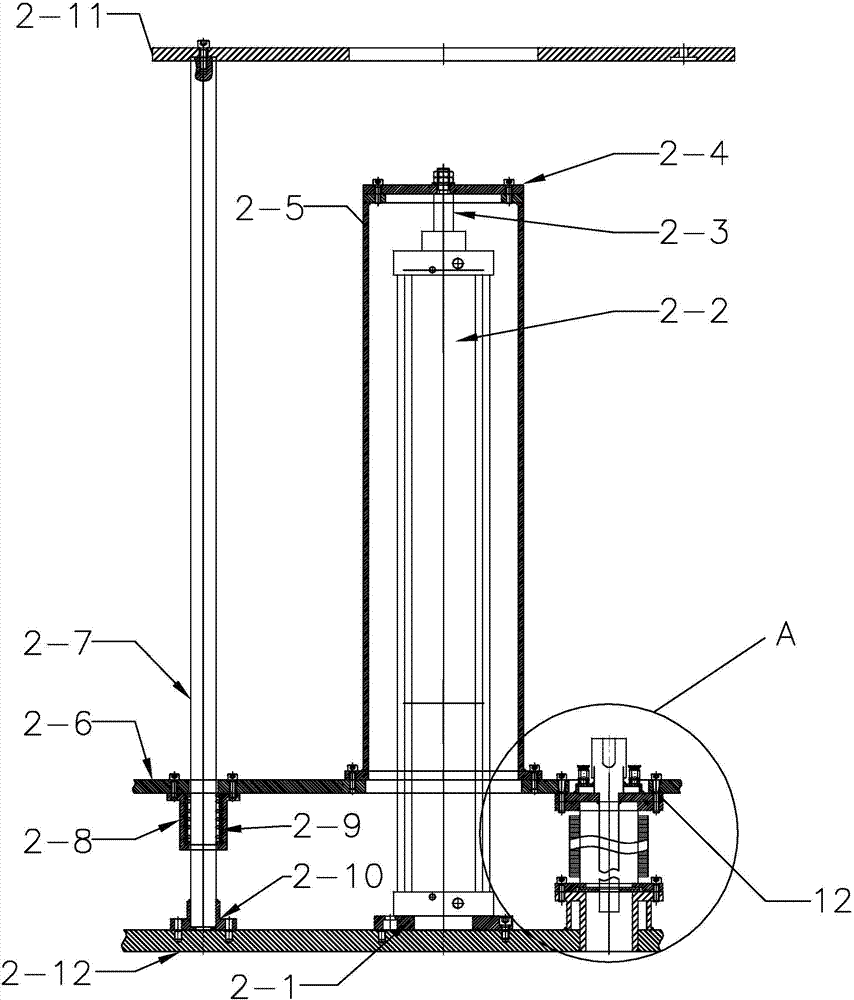

[0040] like figure 2 , 3 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment is applied to a plurality of heating tubes to rise and fall simultaneously, and only one lifting mechanism is equipped, and the lifting mechanism includes a lifting plate 2-6, a cylinder 2-2 and a cylinder cover , The cylinder cover is composed of a support cylinder 2-5 and a support cylinder flange 2-4 located at the upper port of the support cylinder 2-5. Cylinder 2-2 is installed on the furnace body top plate 2-12 of coating chamber by cylinder fixed base 2-1, and the piston rod 2-3 of cylinder 2-2 stretches out upwards. The cylinder cover is covered on the cylinder 2-2, and the piston rod 2-3 is connected and fixed with the support tube flange 2-4 top surface of the cylinder cover. The lifting plate 2-6 is set on the lower part of the cylinder 2-2, the lower port of the support cylinder 2-5 is fixed on the lifting plate 2-6, and several mounting holes for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com