High-heat-conductivity low-viscosity epoxy resin composite, and preparation method and application thereof

A technology of epoxy resin and composite material, which is applied to epoxy resin composite material with high thermal conductivity and low viscosity and its preparation, and the field of epoxy resin composite material, which can solve the problem that the processing flow performance is difficult to meet the actual application requirements and reduce the effective filling volume. , reduce the viscosity of composite materials, etc., to achieve the effect of reducing the effective filling volume, good processability, and increasing filling density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

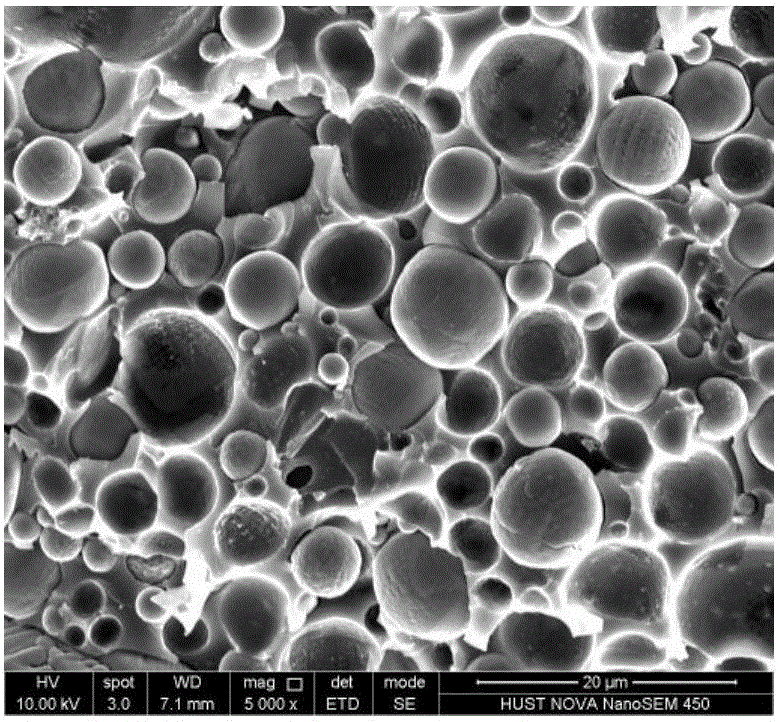

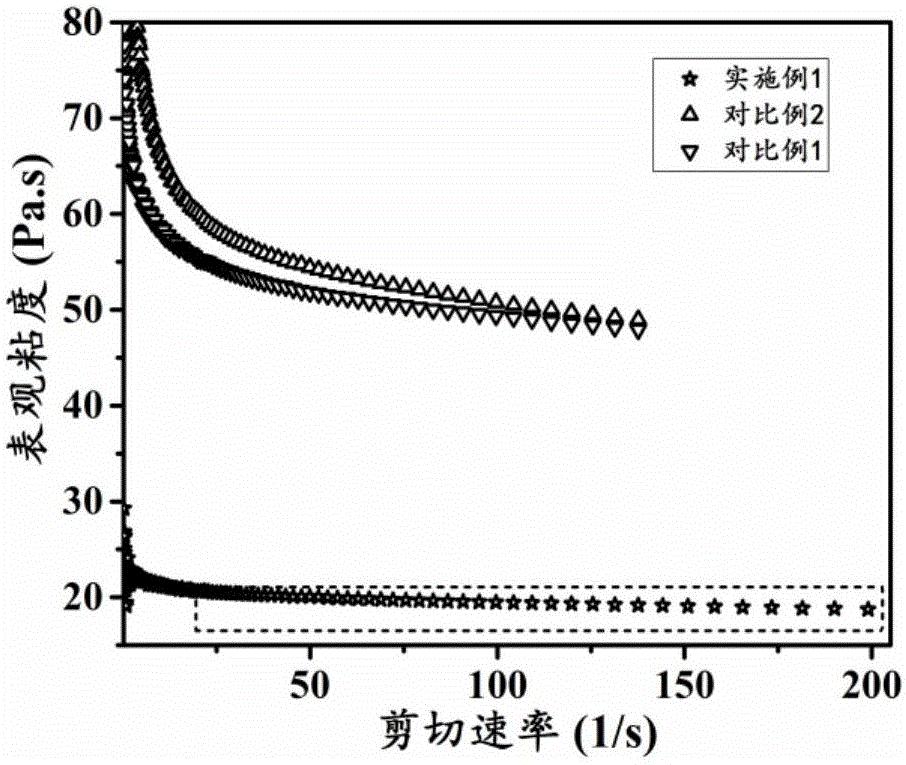

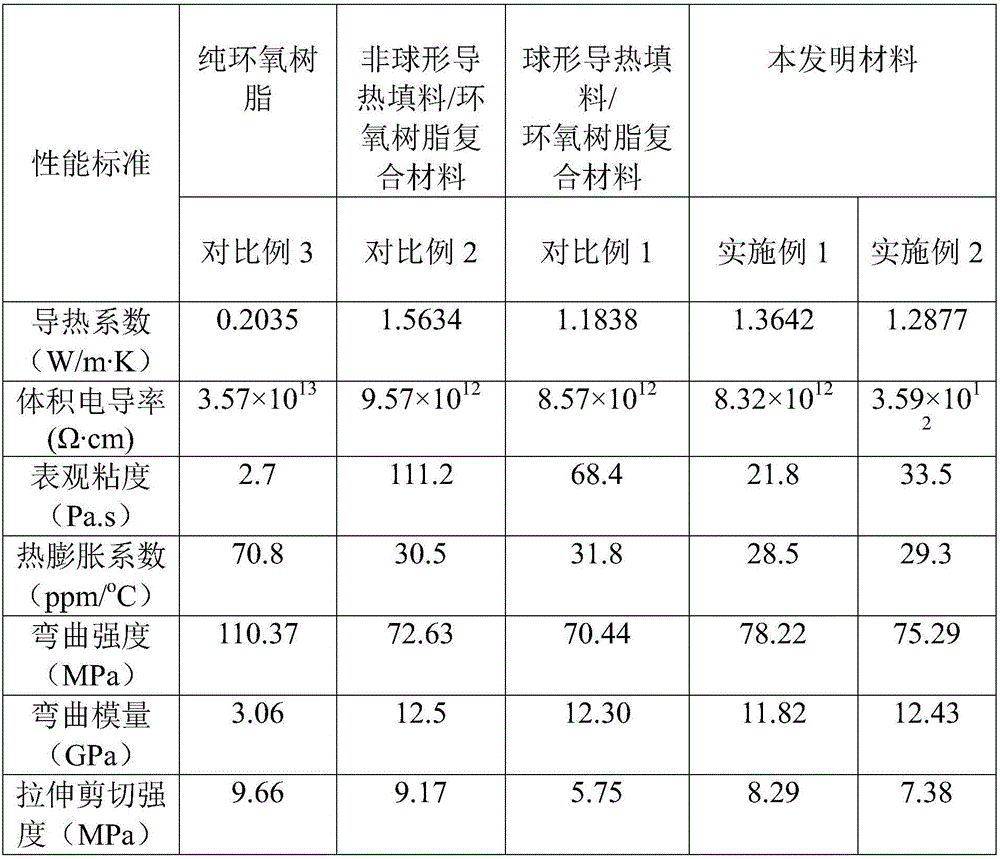

[0030] A high thermal conductivity low viscosity epoxy resin composite material, comprising 40 parts by volume of the first spherical thermally conductive filler, 10 parts of the second spherical thermally conductive filler and 50 parts of epoxy resin, the first spherical thermally conductive filler The median particle diameter is 30 μm, and the median particle diameter of the second spherical thermally conductive filler is 5 μm.

[0031] The first spherical thermally conductive filler and the second spherical alumina filler are alumina spherical thermally conductive fillers, and the ratio of the median particle size is 6:1.

[0032] Described high thermal conductivity low viscosity epoxy resin composite material, its preparation method, comprises the following steps:

[0033] (1) The spherical thermally conductive filler (the first spherical thermally conductive material and the second spherical thermally conductive material) is vacuum-dried at 120°C for 2 hours, and after co...

Embodiment 2

[0038] An epoxy resin composite material with high thermal conductivity and low viscosity, including 25 parts by volume of the first spherical thermally conductive filler, 25 parts by volume of the second spherical thermally conductive filler and 50 parts of epoxy resin, the middle of the first spherical thermally conductive filler The median particle diameter is 30 μm, and the median particle diameter of the second spherical thermal conductive filler is 5 μm.

[0039] The first spherical thermally conductive filler and the second spherical alumina filler are alumina spherical thermally conductive fillers, and the ratio of median particle size is 6:1.

[0040] Described high thermal conductivity low viscosity epoxy resin composite material, its preparation method, comprises the following steps:

[0041] (1) Vacuum-dry the spherical thermally conductive filler at 120°C for 2 hours, and after cooling to room temperature, add epoxy resin, curing agent and spherical thermally cond...

Embodiment 3

[0046] An epoxy resin composite material with high thermal conductivity and low viscosity, comprising 60 parts by volume of the first spherical thermally conductive filler, 5 parts of the second spherical thermally conductive filler, and 35 parts of epoxy resin, the middle of the first spherical thermally conductive filler The median particle diameter is 50 μm, and the median particle diameter of the second spherical thermally conductive filler is 5 μm.

[0047] The first spherical thermally conductive filler and the second spherical alumina filler are aluminum nitride spherical thermally conductive fillers, and the ratio of median particle size is 10:1.

[0048] Described high thermal conductivity low viscosity epoxy resin composite material, its preparation method, comprises the following steps:

[0049] (1) Vacuum-dry the spherical heat-conducting filler at 80°C for 12 hours, and after cooling to room temperature, add epoxy resin, curing agent and spherical heat-conducting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com