Brushless motor

一种无刷电动机、定子的技术,应用在电动组件、电气元件、机电装置等方向,能够解决对齐、难外部定子和磁极传感器位置、外部定子需要电绝缘性等问题,达到确保电绝缘性、提高位置精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

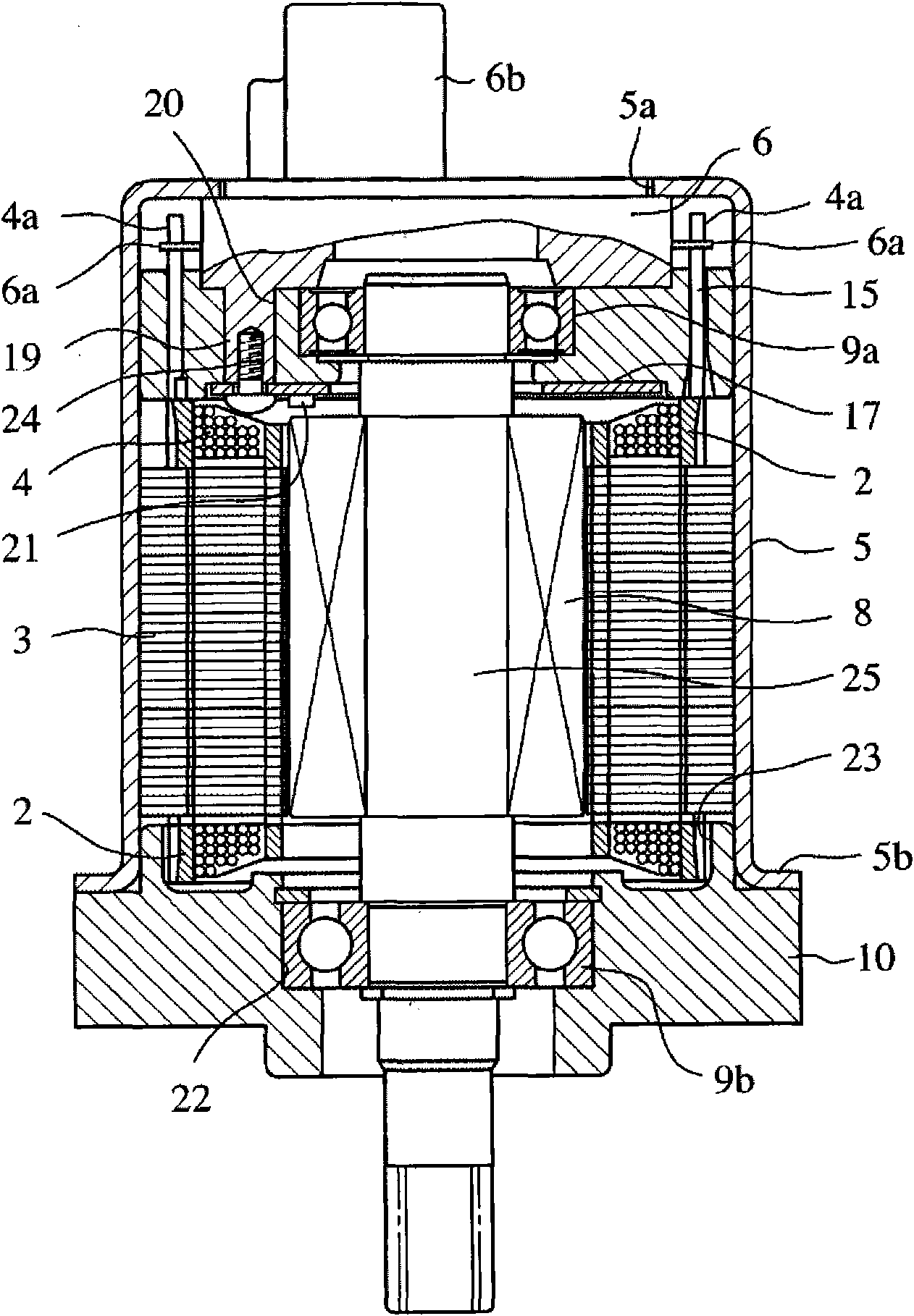

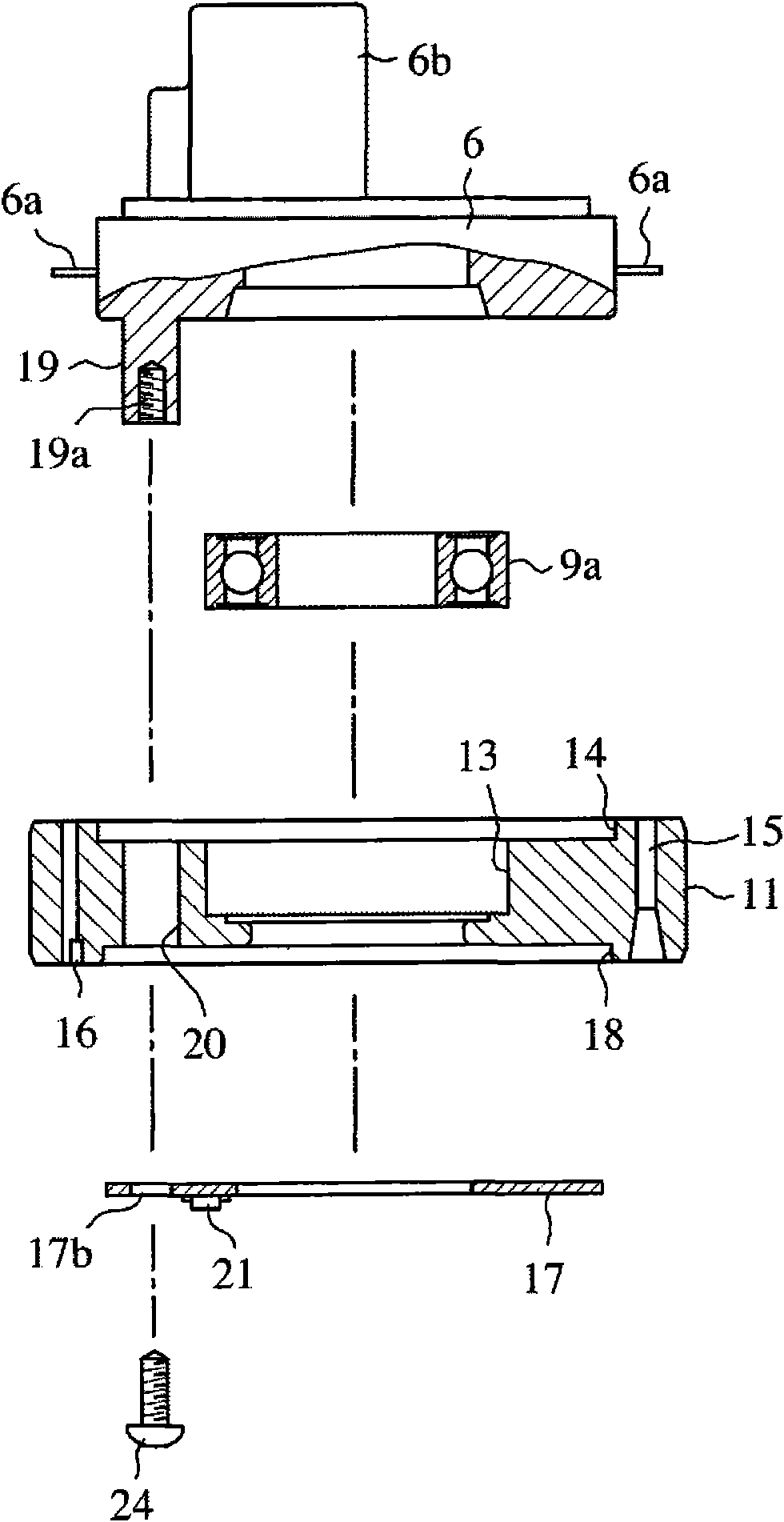

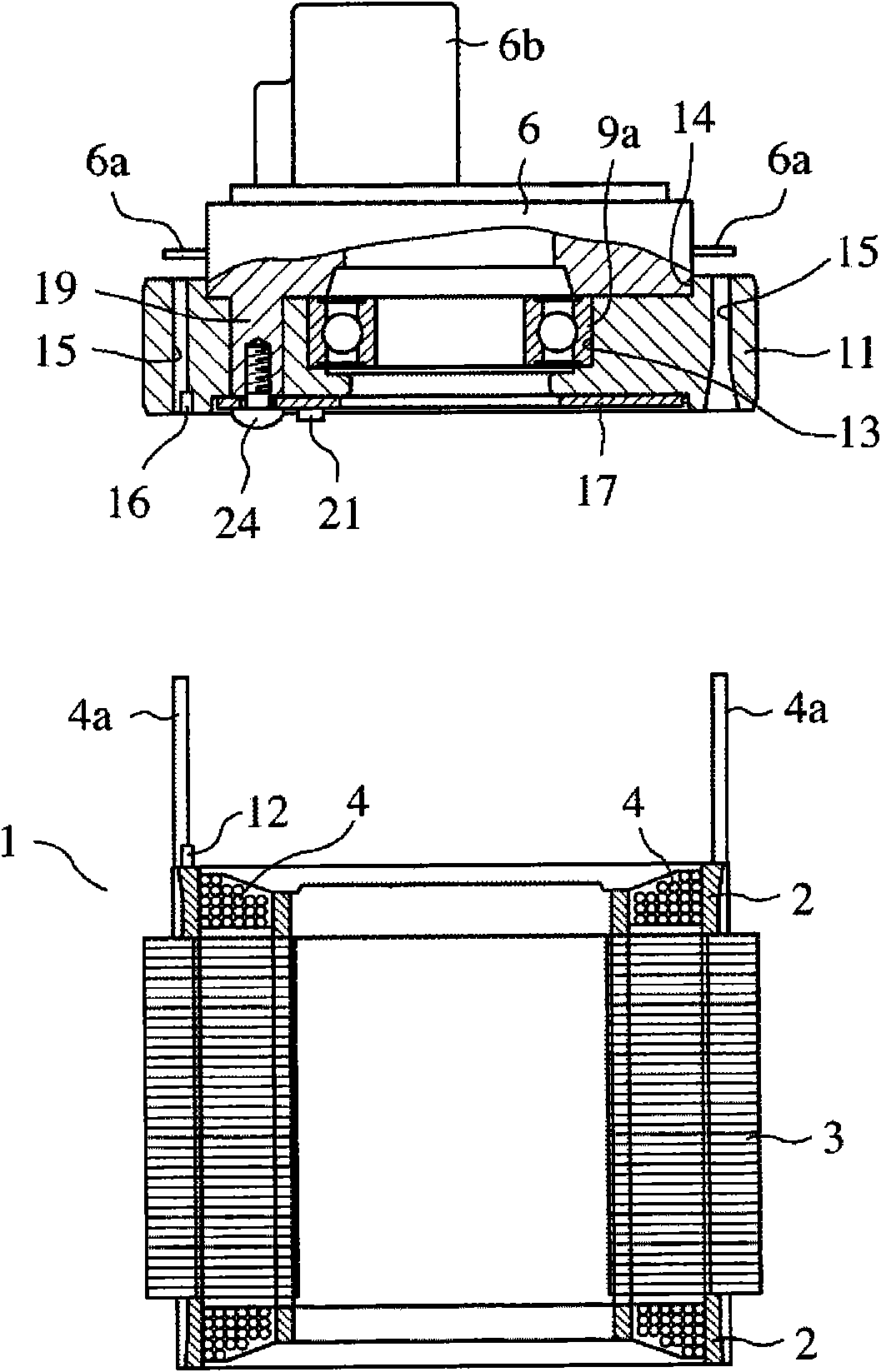

[0022] figure 1 is a longitudinal sectional view showing the brushless motor according to Embodiment 1 of the present invention; figure 2 is an exploded perspective view of components mounted on one end side of the outer stator; image 3 yes means figure 2 A longitudinal sectional view of the relationship between the assembly of the constituent parts and the external stator; Figure 4 is said to be figure 2 A longitudinal sectional view of a state in which the assembly of constituent parts and the external stator are assembled; Figure 5 is an enlarged view of the main part showing the relationship between the winding end passing through the through hole of the insulating plate and the bus bar terminal; Image 6 yes means Figure 4 A longitudinal sectional view of the relationship between the integrated structure and the outer shell; Figure 7 It is a longitudinal cross-sectional view showing the relationship between the outer stator and the case in which the inner ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com