Glass fiber/carbon nanotube co-modified epoxy composite and preparation method thereof

A technology of carbon nanotubes and glass fibers, which is applied in the field of preparation of the above-mentioned glass fibers and carbon nanotubes co-modified epoxy composite materials, which can solve the problems of ineffective improvement of thermal conductivity, affecting the performance of composite materials, and difficulty in dispersion , to achieve the effect of improving the bonding strength of the interface, improving the thermal conductivity, and ensuring the electrical insulation of the busbar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

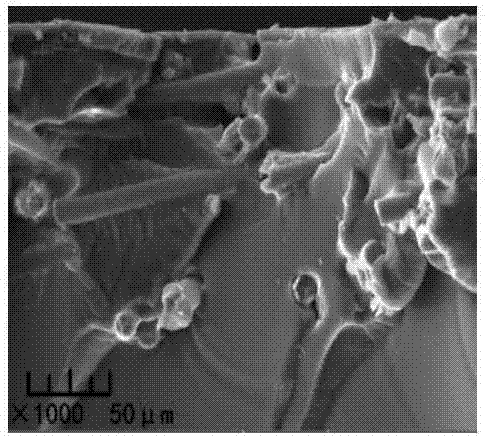

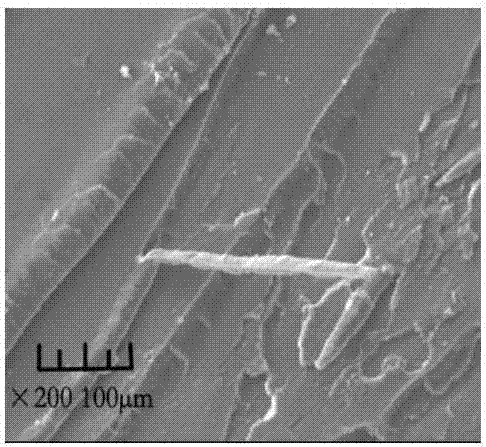

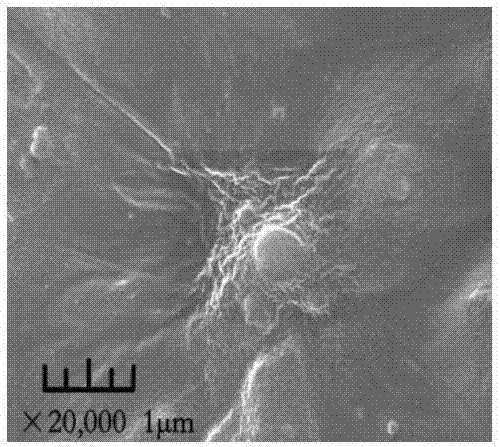

Image

Examples

Embodiment 1

[0048] Glass fiber, carbon nanotube co-modified epoxy composite material is composed of the following components: for every 100g of epoxy resin, add 0.2g of carbon nanotube, 10g of glass fiber, 80g of curing agent, 0.1g of accelerator and 20g of coupling agent .

[0049] The preparation method of the above-mentioned glass fiber and carbon nanotube co-modified epoxy composite material is specifically implemented according to the following steps:

[0050] Step 1, weigh the following components epoxy resin 100g, carbon nanotube 0.2g, glass fiber 10g, curing agent 80g, accelerator 0.1g and coupling agent 20g according to the mass ratio;

[0051] Step 2, carrying out surface acidification treatment to the carbon nanotubes weighed in step 1; specifically:

[0052] Step 2.1, the purity is 98wt% H 2 SO 4 With a purity of 68wt% HNO 3 Mix according to the volume ratio of 3:1 to obtain the mixed solution A;

[0053] In step 2.2, put the carbon nanotubes weighed in step 1 into the mi...

Embodiment 2

[0058] Glass fiber, carbon nanotube co-modified epoxy composite material is composed of the following components: for every 100g of epoxy resin, add 0.2g of carbon nanotube, 15g of glass fiber, 80g of curing agent, 0.1g of accelerator and 20g of coupling agent .

[0059] The preparation method of the above-mentioned glass fiber and carbon nanotube co-modified epoxy composite material is specifically implemented according to the following steps:

[0060] Step 1, weigh the following components epoxy resin 100g, carbon nanotube 0.2g, glass fiber 15g, curing agent 80g, accelerator 0.1g and coupling agent 20g according to the mass ratio;

[0061] Step 2, carrying out surface acidification treatment to the carbon nanotubes weighed in step 1; specifically:

[0062] Step 2.1, the purity is 98wt% H 2 SO 4 With a purity of 68wt% HNO 3 Mix according to the volume ratio of 3:1 to obtain the mixed solution A;

[0063] In step 2.2, put the carbon nanotubes weighed in step 1 into the mi...

Embodiment 3

[0068] The glass fiber and carbon nanotube co-modified epoxy composite material is composed of the following components: for every 100g of epoxy resin, add 0.2g of carbon nanotube, 15g of glass fiber, 80g of curing agent, 0.1g of accelerator and 20g of coupling agent.

[0069] The preparation method of the above-mentioned glass fiber and carbon nanotube co-modified epoxy composite material is specifically implemented according to the following steps:

[0070] Step 1, weigh the following components epoxy resin 100g, carbon nanotube 0.2g, glass fiber 20g, curing agent 80g, accelerator 0.1g and coupling agent 20g according to the mass ratio;

[0071] Step 2, carrying out surface acidification treatment to the carbon nanotubes weighed in step 1; specifically:

[0072] Step 2.1, the purity is 98wt% H 2 SO 4 With a purity of 68wt% HNO 3 Mix according to the volume ratio of 3:1 to obtain the mixed solution A;

[0073] In step 2.2, put the carbon nanotubes weighed in step 1 into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com