Patents

Literature

202 results about "Composite epoxy material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite epoxy materials (CEM) are a group of composite materials typically made from woven glass fabric surfaces and non-woven glass core combined with epoxy synthetic resin. They are typically used in printed circuit boards.

Multilayer wiring board and manufacture method thereof

InactiveUS7091589B2Improve electrical performanceBroaden your optionsInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringConductive materials

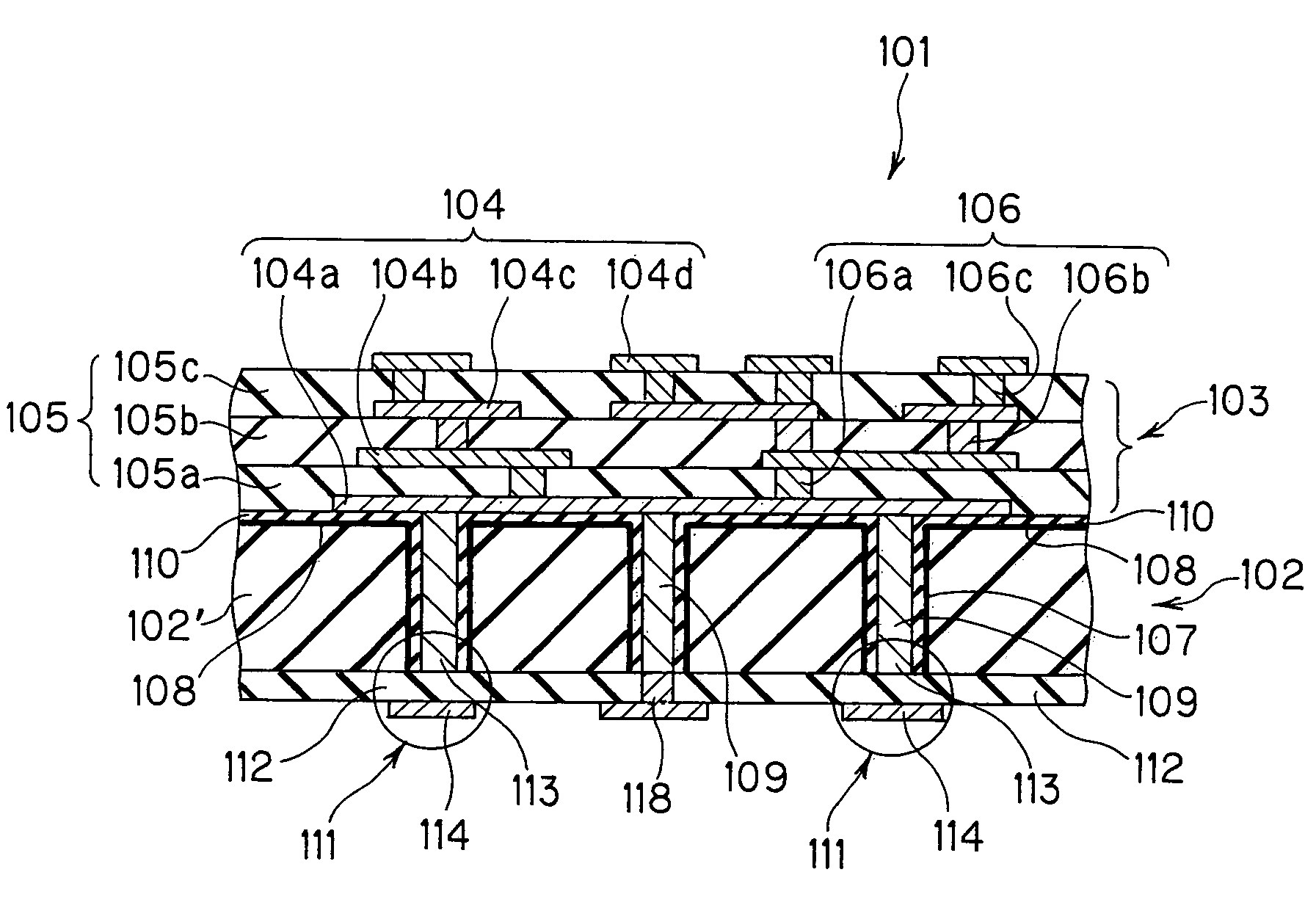

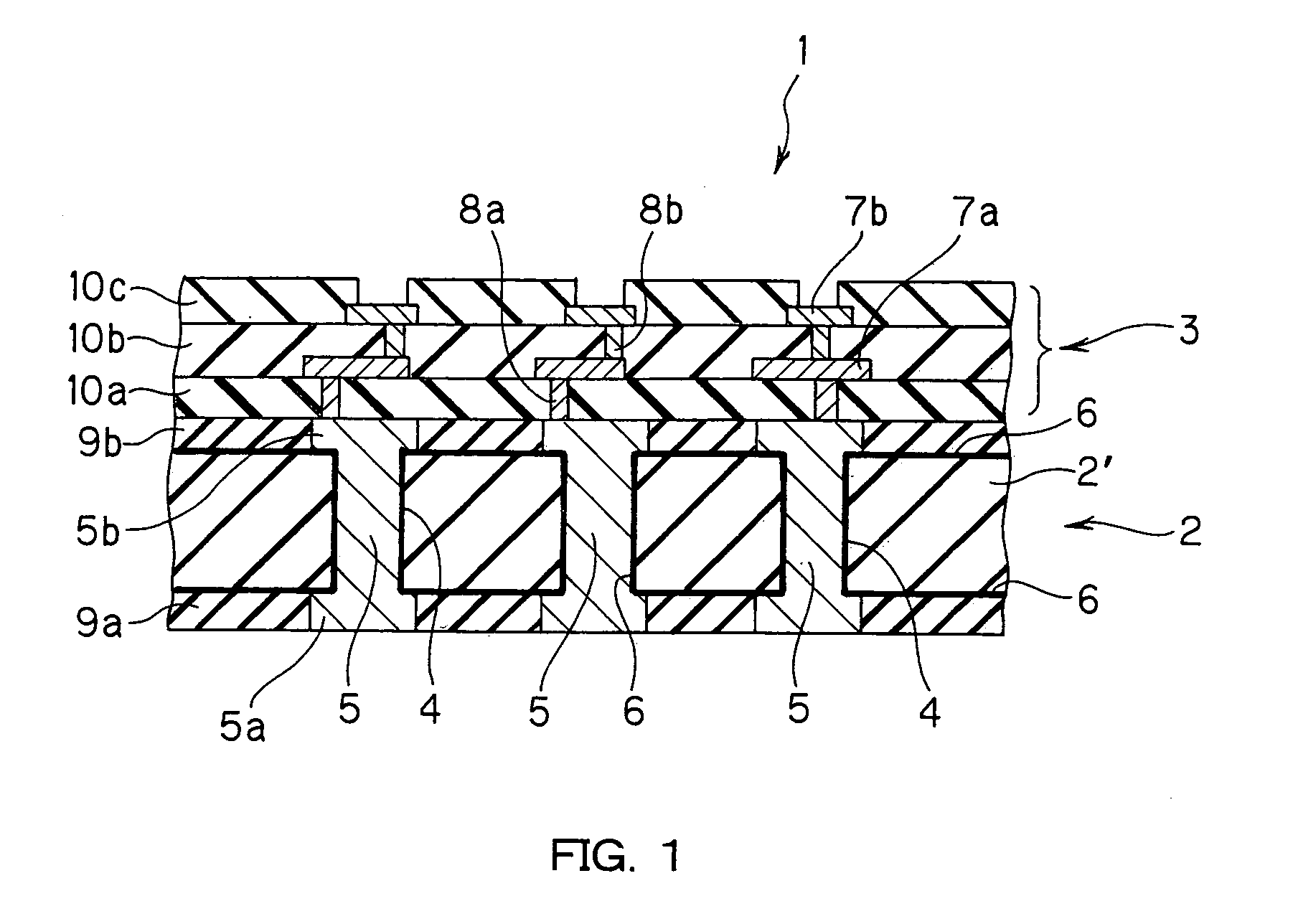

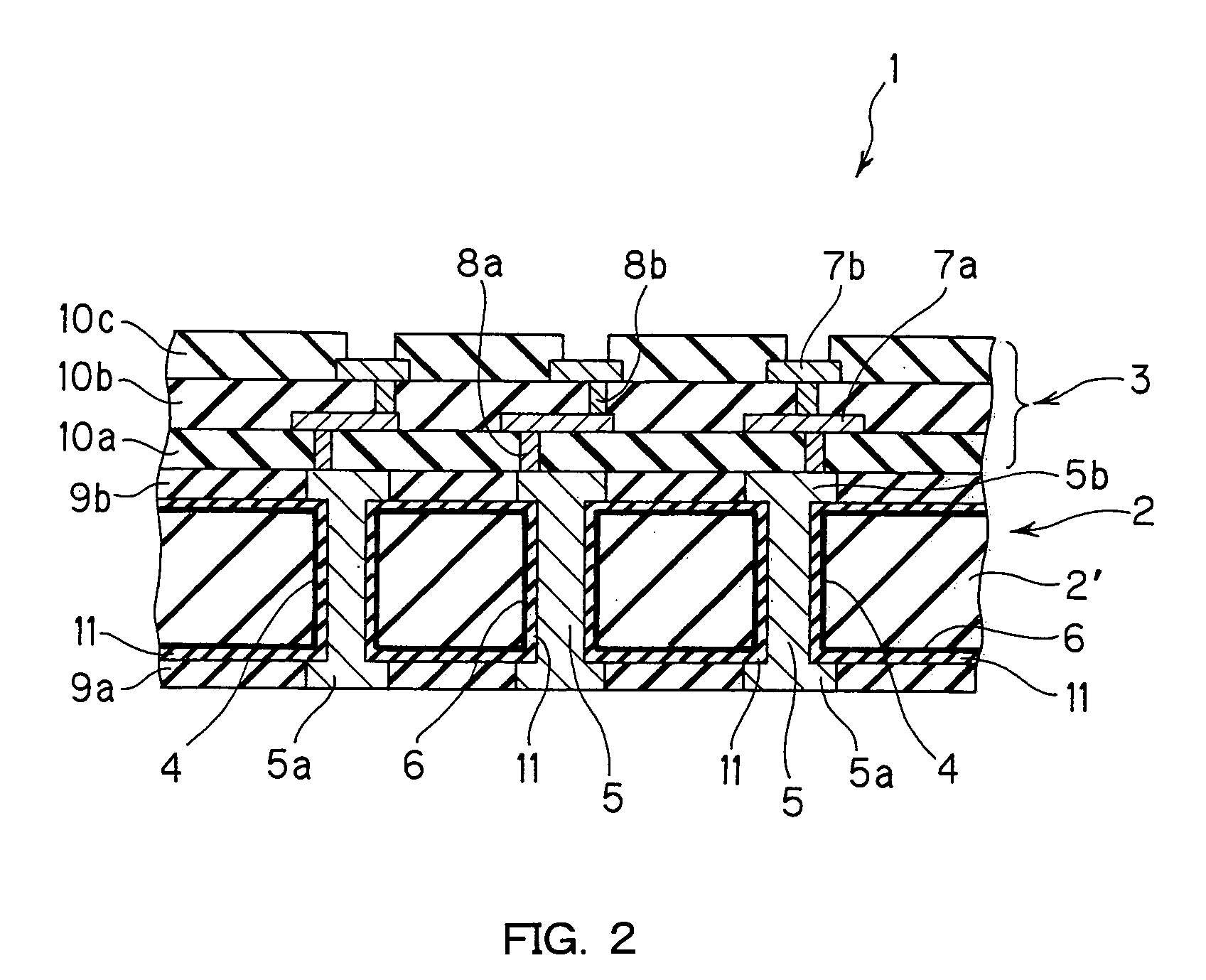

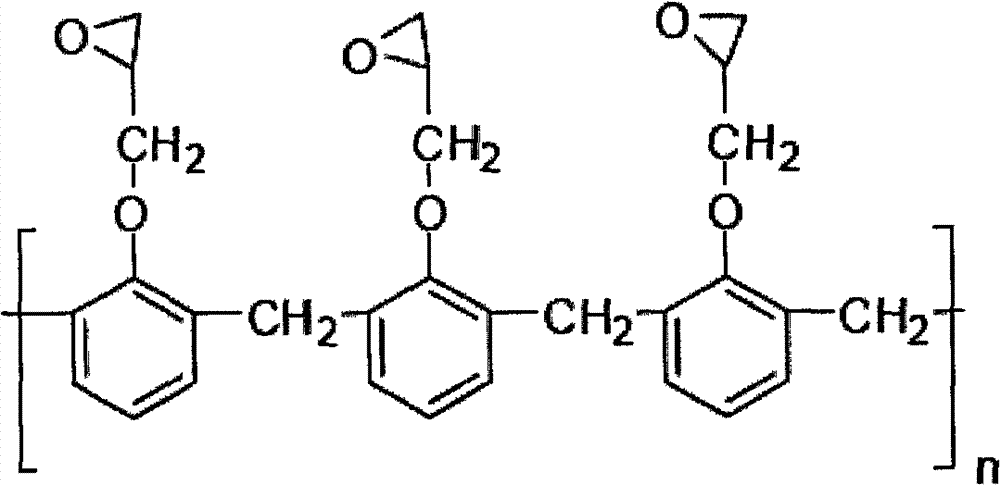

In a multilayer wiring board comprising a core board, and a wiring layer and an electrically insulating layer that are stacked on one surface of said core board, a thermal expansion coefficient of said core board in XY directions falls within a range of 2 to 20 ppm, a core member for said core board is a core member selected from silicon, ceramics, glass, a glass-epoxy composite, and metal, said core board is provided with a plurality of through holes that are made conductive between the front and the back by a conductive material, and a capacitor is provided on one surface of said core board, wherein said capacitor comprises an upper electrode being the conductive material in said through hole, and a lower electrode disposed so as to confront said upper electrode via a dielectric layer.

Owner:DAI NIPPON PRINTING CO LTD

Flame retardant epoxy prepreg composite material and its preparing method and its use

ActiveCN102731969AImprove toughnessImprove flame retardant performanceCabin furnitureEfficient propulsion technologiesTetrabromobisphenol AResin matrix

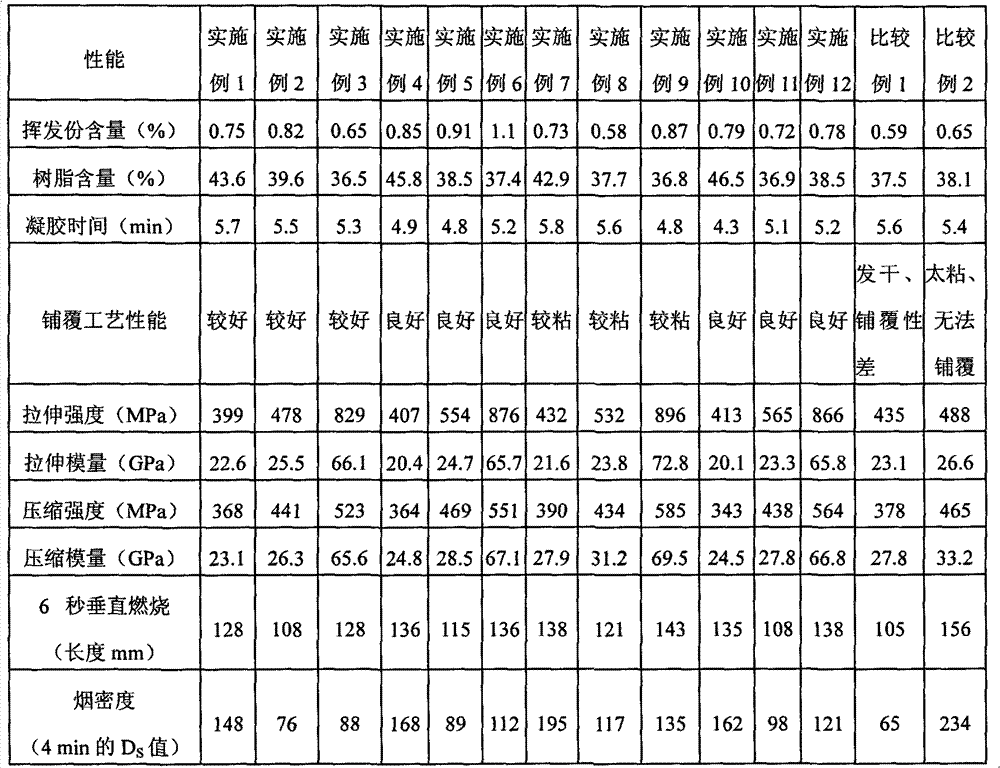

The present invention relates to a flame retardant epoxy prepreg composite material and its preparation method and its use, the composite material contains 20 to 70% of epoxy resin matrix and 30-80% of fiber reinforced materials; wherein the epoxy resin matrix comprises the following components by mass part: 100 parts of an F type epoxy resin, 10-50 parts of an E type epoxy resin, 5-40 parts of tetrabromobisphenol A, 5-20 parts of a curing agent, 1-10 parts of a curing accelerator, 5-25 parts of a toughening agent, 1-10 parts of antimonous oxide and 20-80 parts of an organic solvent. According to the invention, F46 type epoxy resin containing a rigid frame structure is taken as a main component, the flame retarding and toughening modification are carried out on the resin matrix by a combination technology, the epoxy composite material with high toughness, high flame retardancy and good overlaying manufacturability can be realized, the flue gas density is obviously decreased when the flame is carried out, and the epoxy prepreg composite material possesses important popularization and application prospects in the fields of large aircraft, ships, high-speed rails and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Method for preparing epoxy sheet mould plastic

The invention provides a method for preparing an epoxy sheet-like mold plastic, which comprises the following steps: thickening the mixed epoxide resin system with diisocyanate compound; strengthening the chopped strand; making the tectorial into non-stick hand and shear epoxy sheet-like mold plastic, that is, preparing the epoxide resin paste and the epoxy sheet-like mold plastic; ripening. The epoxy sheet-like mold plastic comprises the following parts: 100 quetient mixed epoxide resin, 4-10 quetient deflocculating agent, 15-80 quetient curing agent, 5-20 quetient thickener, 1-4 quetient internal releasing agent, 80-180 filler and 50-150 fiber, wherein the intermediate core material of the epoxy sheet-like mold plastic comprises fiber which is dipped epoxide resin paste, and the up-down surface is covered by PE thin film. The epoxy sheet-like mold plastic is provided with the good heat flow property, the short curing time, the long saving time and the corrosion resistant, which can be made high strength epoxide composite material part.

Owner:SHANGHAI MANSDA INDAL

High temperature self-restoring fibre enhancement epoxy composite material and preparation method thereof

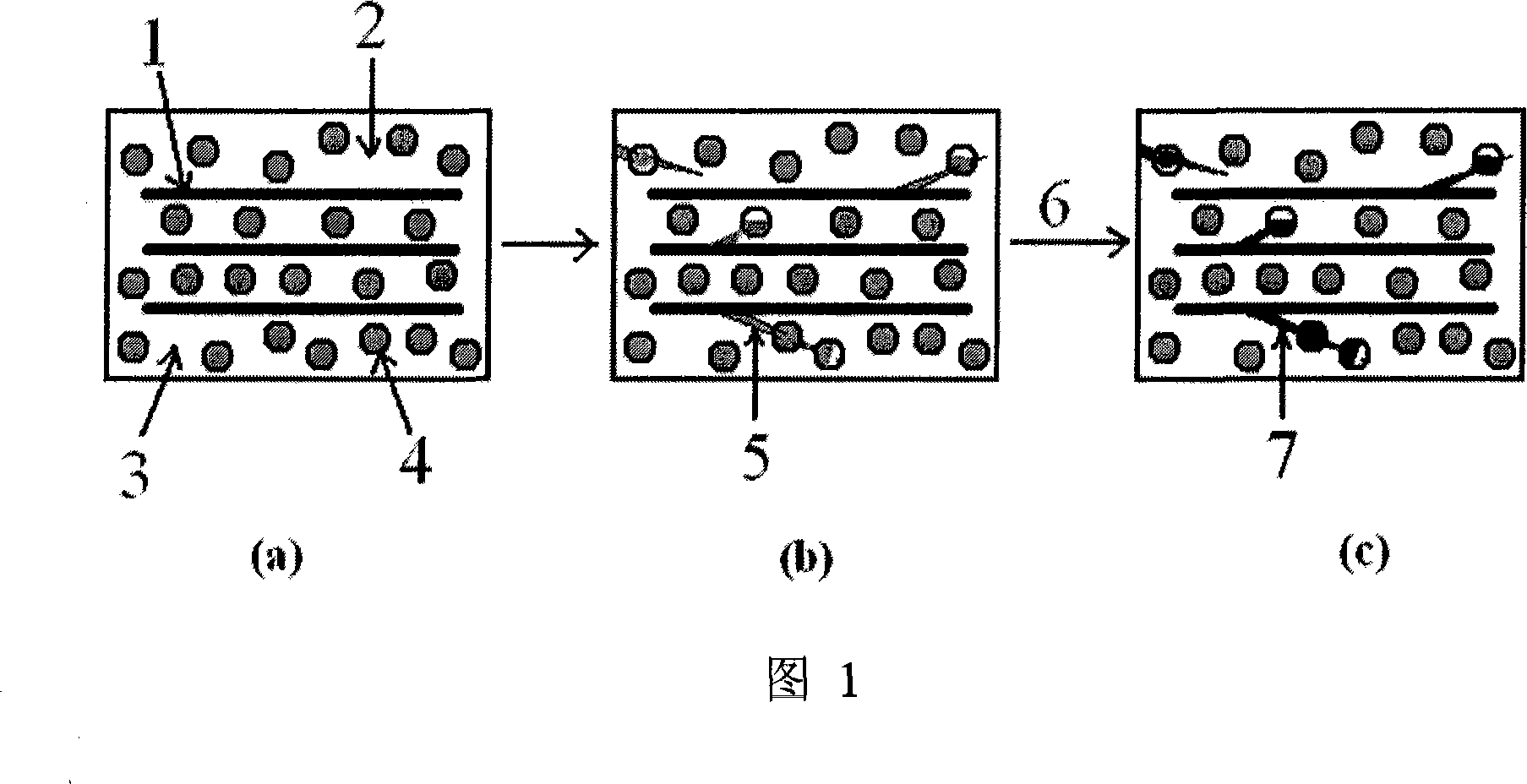

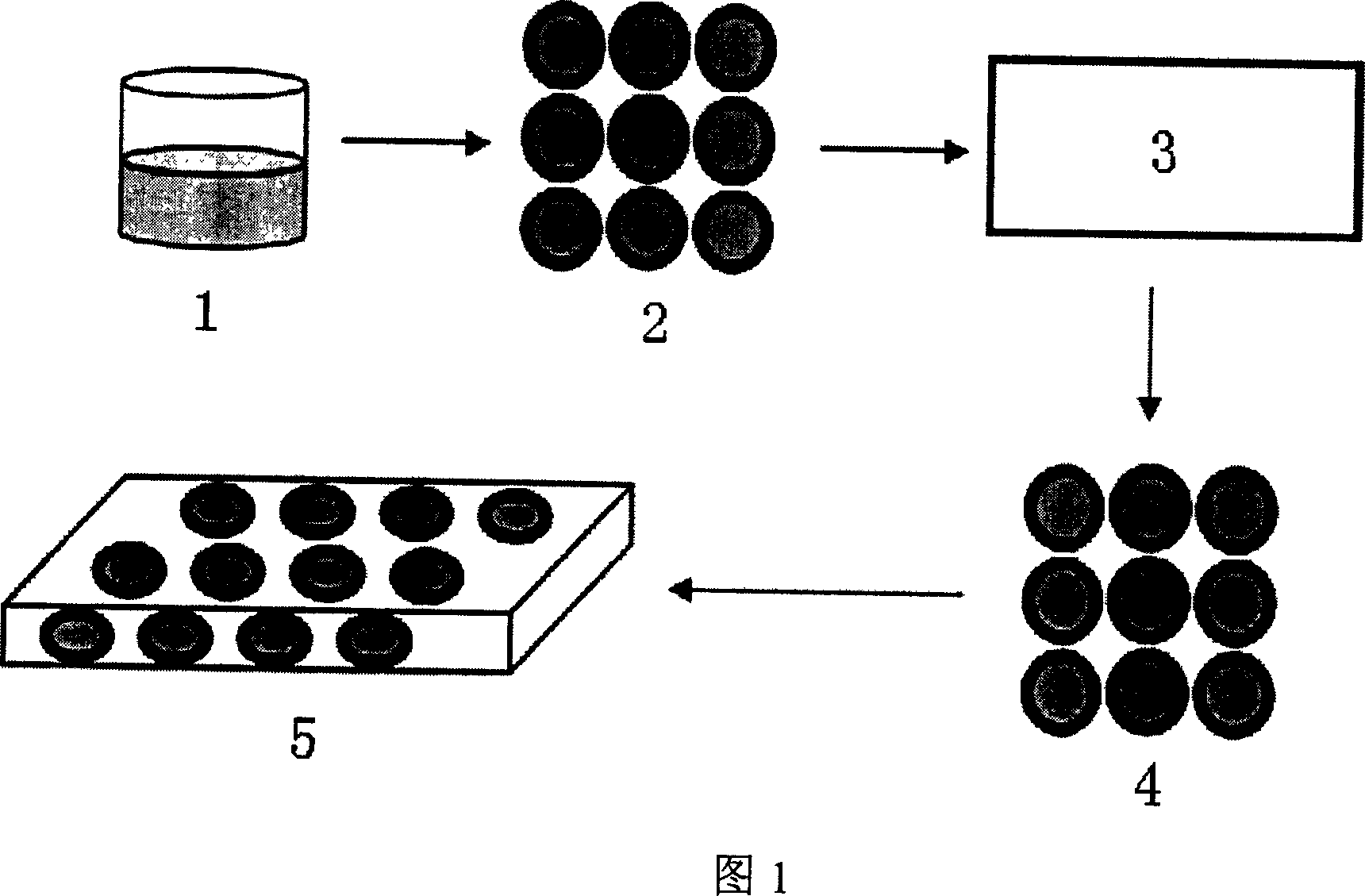

The invention discloses a high-temperature self-repair-type fiber-reinforcement epoxy composite material and a process for preparation, the process comprises adding microcapsule and accelerating agent which are evenly mixed into the basal body of epoxide resin, adding curing agent into the basal body of epoxide resin to evenly mix, infiltrating fiber-reinforcement reinforced materials with the mixture which is got, plying, finally, curing molding and getting high-temperature self-repair-type fiber-reinforcement epoxy composite material. When cracks are produced on the high-temperature self-repair-type fiber-reinforcement epoxy composite material of the invention because of forcing in the process of processing and employing, the cracks are extended to the built-in microcapsule, and the microcapsule wall is led to crack, liquid-state epoxide resin in the microcapsule is immediately released to fill into the cracks, the accelerating agent which is built in the basal body leads the liquid-state epoxide resin to be solidified under high temperature, thereby rebinding the cracks together, and the damage of the material is repaired, thereby keeping the mechanical properties of the epoxy composite material and prolonging the life span.

Owner:SUN YAT SEN UNIV

Fabrication of nanowire array composites for thermoelectric power generators and microcoolers

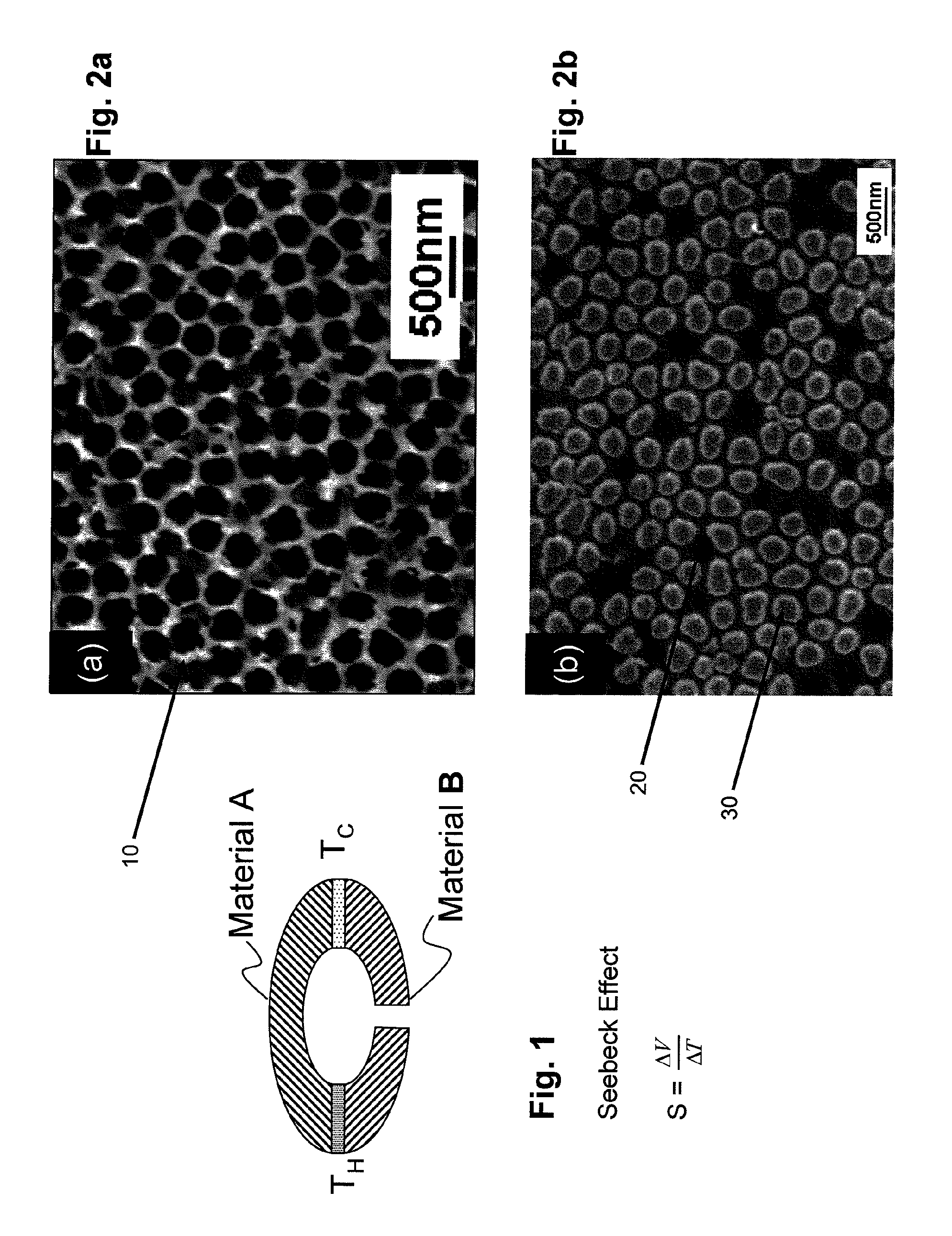

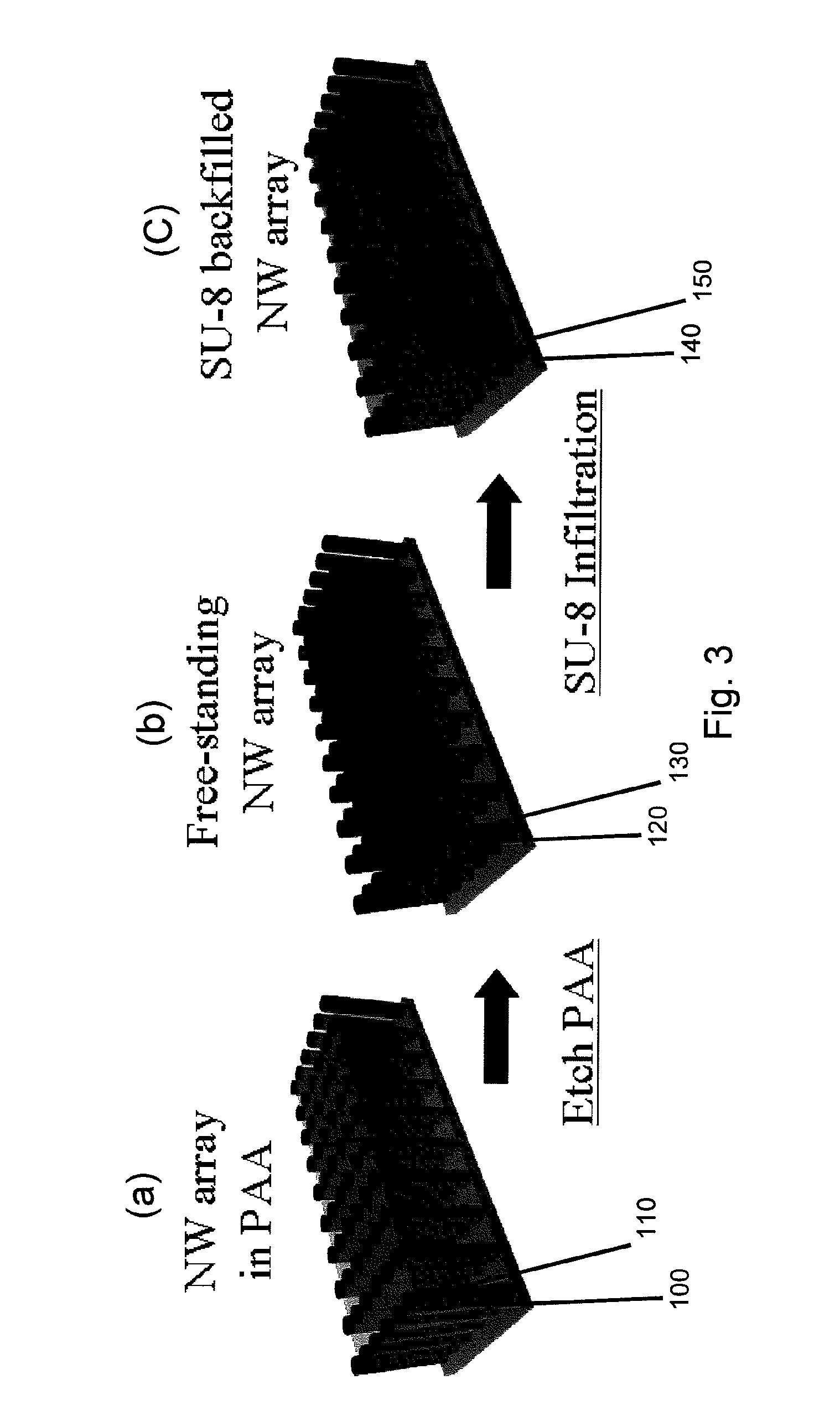

InactiveUS20090214848A1Low thermal conductivityAnodisationThermoelectric device manufacture/treatmentNanowire arrayMaximum temperature

Methods for fabricating a nanowire array epoxy composite with high structural integrity and low effective thermal conductivity to achieve a power conversion efficiency goal of approximately 20% and power density of about 104 W / m2 with a maximum temperature below about 380° C. Further, a method includes fabricating a self-supporting thick 3-D interconnected nanowire array with high structural integrity and low effective thermal conductivity to achieve a power conversion efficiency goal of 20% and power density of about 104 W / m2 with a maximum temperature of about 700° C., the nanowire array having substantially only air between nanowires.

Owner:PURDUE RES FOUND INC

Process for Preparing Composites Using Epoxy Resin Formulations

Epoxy composites are prepared by separately preheating an epoxy resin and a hardener; mixing the preheated epoxy resin and preheated hardener to form a hot reaction mixture and curing the hot reaction mixture in the presence of a reinforcement until the mixture cures to form a composite having a polymer phase with a glass transition temperature of at least 150° C.

Owner:SHAFI ASJAD +3

Room-temperature self-repairing fiber-reinforced epoxy composite material and preparation method thereof

The invention discloses a room-temperature self-repairing fiber-reinforced epoxy composite material and a preparation method thereof. According to the method, a repairing agent is loaded in a capillary tube, and buried among fiber-reinforced epoxy composite material layers, and the repairing agent contains a certain amount of foaming agent. After being formed, the composite material is heated above the decomposition temperature of the foaming agent, so that the interior of the capillary tube produces positive pressure. When the material is damaged to cause the breakage of the capillary tube, the repairing agent can fast flow to a breakage surface and produce reaction under the promotion of pressure, thus rebinding cracks together and repairing the damage of the material. The material has the outstanding characteristics that the capillary tube can provide enough repairing agent, so that the material has higher repair efficiency; through the introduction of the foaming agent, the repairing agent in the capillary tube can be guaranteed to fast flow automatically when the material is damaged.

Owner:SUN YAT SEN UNIV

Method for manufacturing CEM (Composite Epoxy Material Grade)-3 copper-clad plate with high dielectric constant and low loss

ActiveCN103101252ASmall dielectric lossSimple processSynthetic resin layered productsLaminationDielectricFirming agent

The invention provides a method for manufacturing a CEM (Composite Epoxy Material Grade)-3 copper-clad plate with a high dielectric constant and low loss. The method for manufacturing the CEM-3 copper-clad plate with the high dielectric constant and the low loss comprises the following steps of: firstly, preparing epoxy resin liquid; carrying out surface treatment on composite fillers; preparing composite resin liquid; preparing a bonding sheet; and finally, pressing a lamination plate. The method provided by the invention uses bisphenol A epoxy resin with low cost, good manufacturability and good dielectric properties as main resin, and the problems of the cost and the manufacturability of a product can be solved; the high-dielectric fillers are partially composited by using a special curing agent, so that a curing article has a high dielectric constant, low loss, good thermal resistance, and high mechanical strength; and the CEM-3 copper-clad plate manufactured by the method disclosed by the invention has the advantages of simple process, low cost and good properties.

Owner:SHAANXI SHENGYI TECH

Molded epoxy resin sheet and its prepn process

InactiveCN101088754AExcellent mechanical propertiesImprove liquiditySynthetic resin layered productsLaminationOrganic acidFiber

The present invention discloses one kind of molded epoxy resin sheet comprising core of epoxy resin dipped fiber and facing layers of PE film. The molded epoxy resin sheet has the materials including epoxy resin 100 weight portions, diluent 4-20 weight portions, curing agent 15-80 weight portions, thickening agent 9-16 weight portions, organic acid 6-18 weight portions, internal demolding agent 1-4 weight portions, stuffing 80-180 weight portions, and fiber 50-150 weight portions. Its preparation process includes the steps of: preparing epoxy resin paste, forming molded epoxy resin sheet and curing molded epoxy resin sheet. The molded epoxy resin sheet has simple preparation, high strength, high corrosion resistance and high insulating property.

Owner:WUHAN UNIV OF TECH

Transparent epoxy nano composite material and its preparation method and use

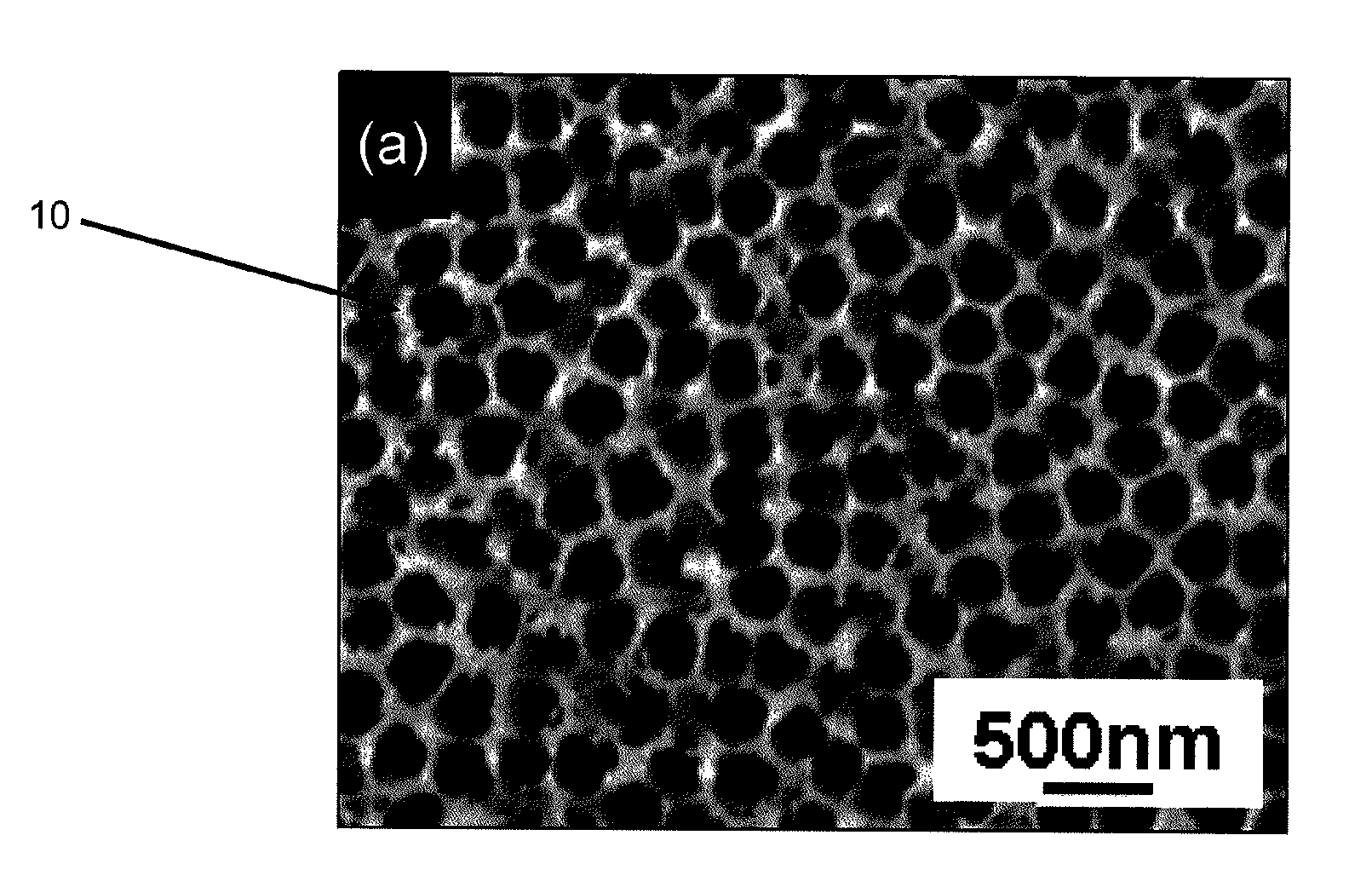

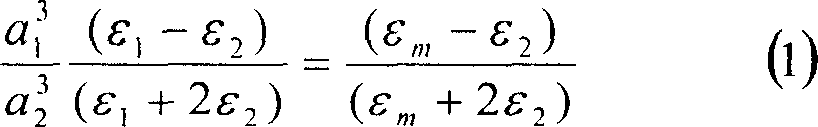

InactiveCN101077923AOvercoming Light Scattering PhenomenonHigh light transmittanceOther chemical processesSilica particleUltraviolet

The present invention relates to one kind of transparent composite epoxy material and its preparation process and use. The transparent composite epoxy material has nanometer composite inorganic stuffing comprising nanometer silica particle serving as core, titania serving as shell coating the silica particle core and outer silica layer coating the titania shell. The transparent composite epoxy material possesses high transparency, excellent ultraviolet ray shielding effect, high ultraviolet ray tolerance, low heat expansion coefficient, high heat conductivity and other advantages, and is suitable for use in pacing LED and other light emitting semiconductor devices.

Owner:广东中科顺威新材料科技发展有限公司

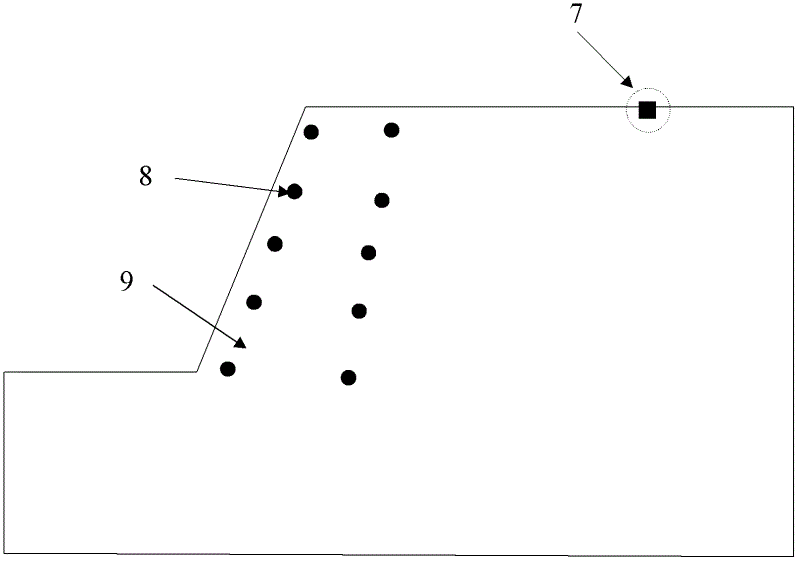

Magnetic label and method for monitoring and positioning

InactiveCN102622636AIgnore the impactSave powerUsing electrical meansRecord carriers used with machinesMagnetic field gradientWhole body

The invention discloses a magnetic label and method for monitoring and positioning, and belongs to the technical field of measurement. The invention is characterized in that the magnetic label comprises a magnetic coil, a director, an RF (Radio Frequency) communication controller, an antenna, a power supply and an epoxy compound sealing material, wherein the magnetic coil, the RF communication controller, the antenna and the power supply are located in the middle of the director, and the whole body is sealed with the epoxy compound sealing material; the magnetic torque of the magnetic coil keeps constant through the director, and the unknown number of the magnetic label is only a position parameter; and the magnetic field excited by the magnetic label is measured by a magnetic gradiometer, the position of the magnetic label is obtained through a magnetic field gradient tensor sum optimization algorithm, and the monitoring and positioning of the magnetic label are realized. The invention has the effects and benefits as follows: the monitoring and positioning in environments such as an underwater part, sludge, a soil layer deep part and the like are realized; and the magnetic label has the advantages of simplicity in operation, high test accuracy and stable performance, can be used for deformation monitoring of rock soil structures of side slopes, embankments and the like, and also can be widely applied to washing monitoring of huge engineering structures of reservoir dams, river levees and the like.

Owner:DALIAN UNIV OF TECH

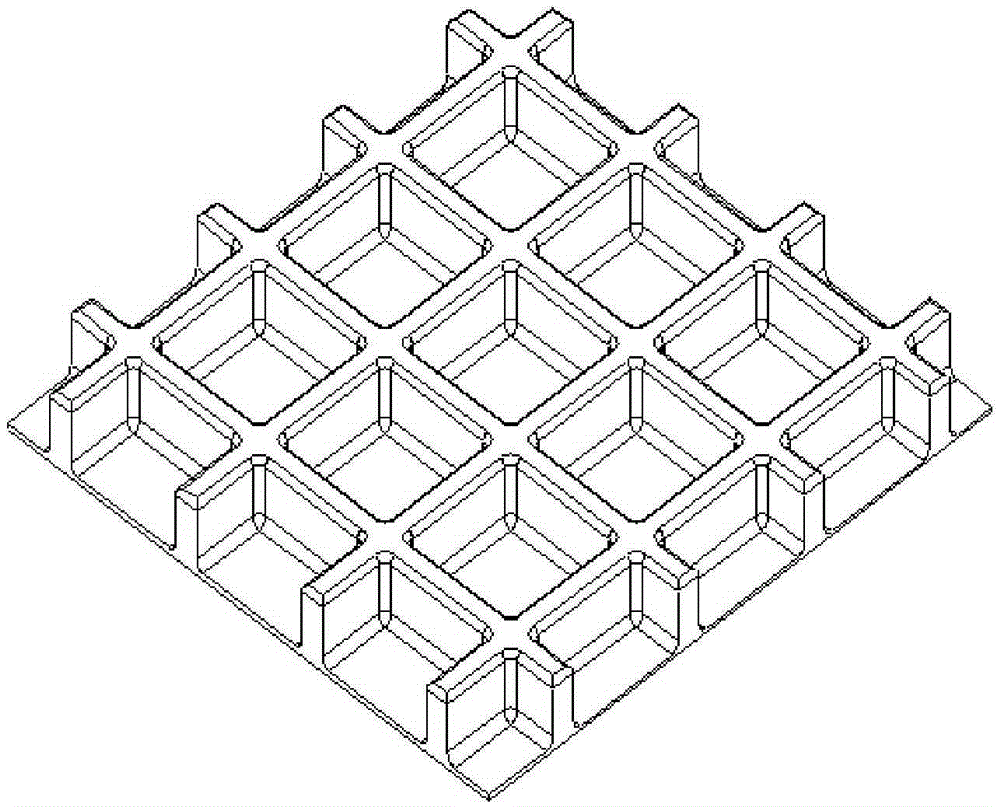

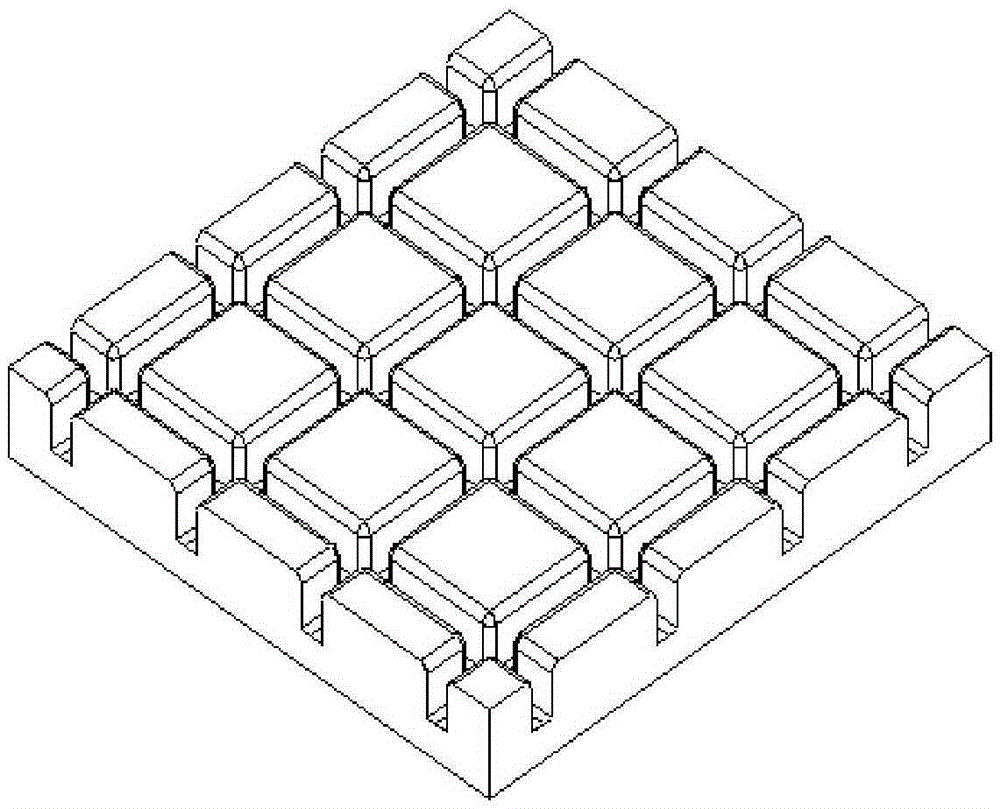

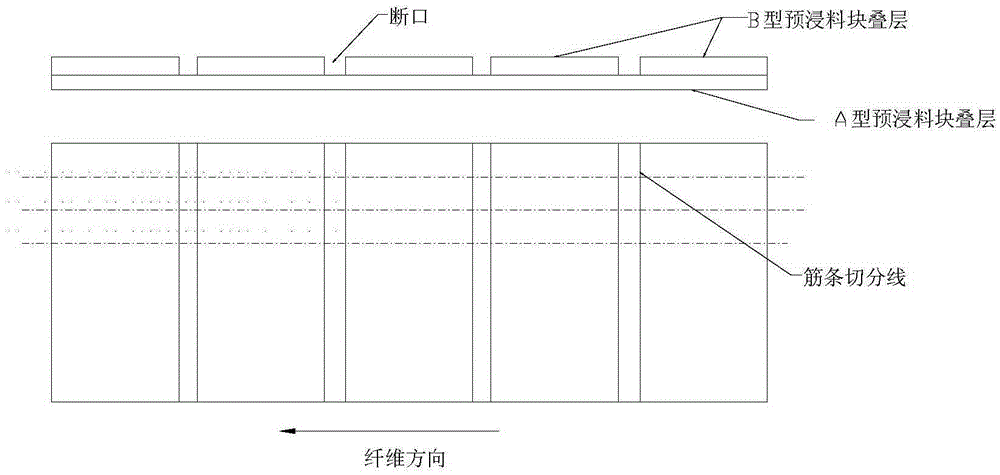

Carbon fiber/high tenacity epoxy composite material grid fillet molding method

The invention relates to a carbon fiber / high tenacity epoxy composite material grid fillet molding method, and belongs to the technical field of grid ribbing structure composite material molding. The cross section of a grid fillet prepared with the molding method is large, the common depth-to-width ratio is 1-3, the depth ranges from 15 mm to 20 mm, and the carbon fiber / high tenacity epoxy composite material grid fillet molding method In particular, the invention relates to a T800 carbon fiber / epoxy hot melting method prepreg grid fillet skin class structure molding method. The carbon fiber / high tenacity epoxy hot melting pre-soaking silk material system which is low in flue containing amount and high in filter size content is adopted in the method, large-section size fillet molding technical researches are developed, adaptation improvements are carried out on the pre-soaking silk paving process, the glue absorbing curving process, the skin interface interlayer bonding process and the like are achieved, and application to grid fillet standard structure pieces is achieved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

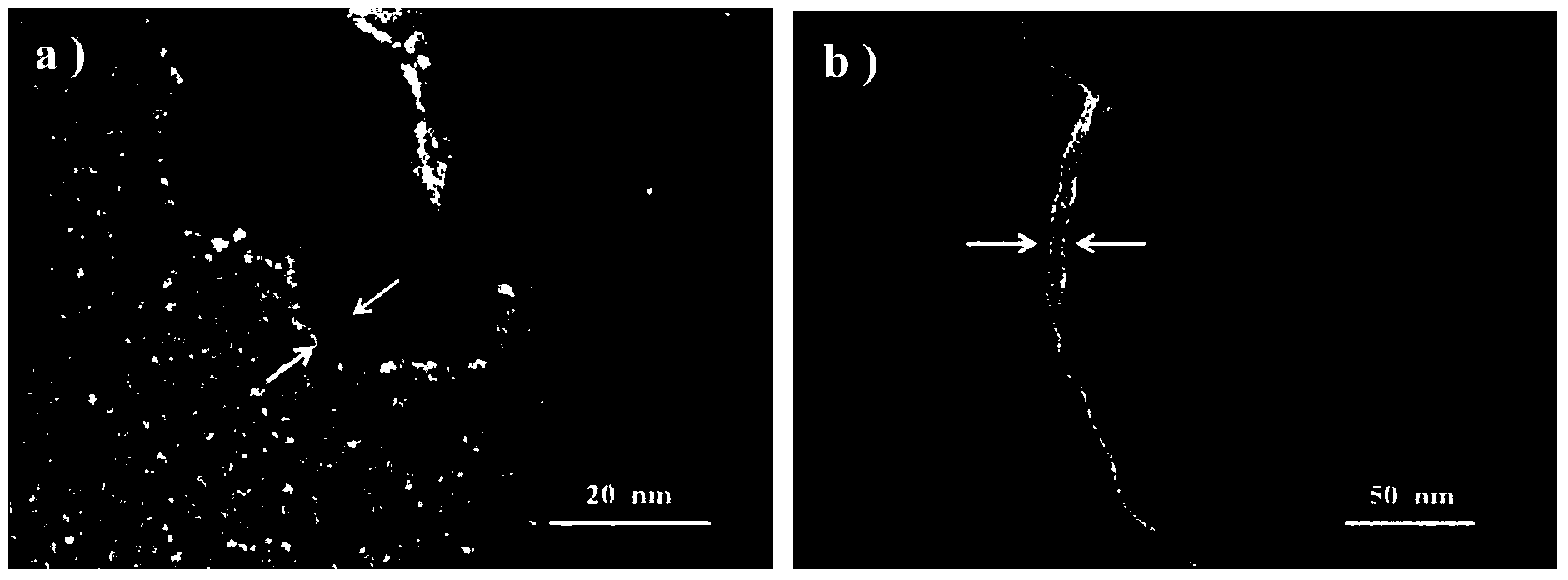

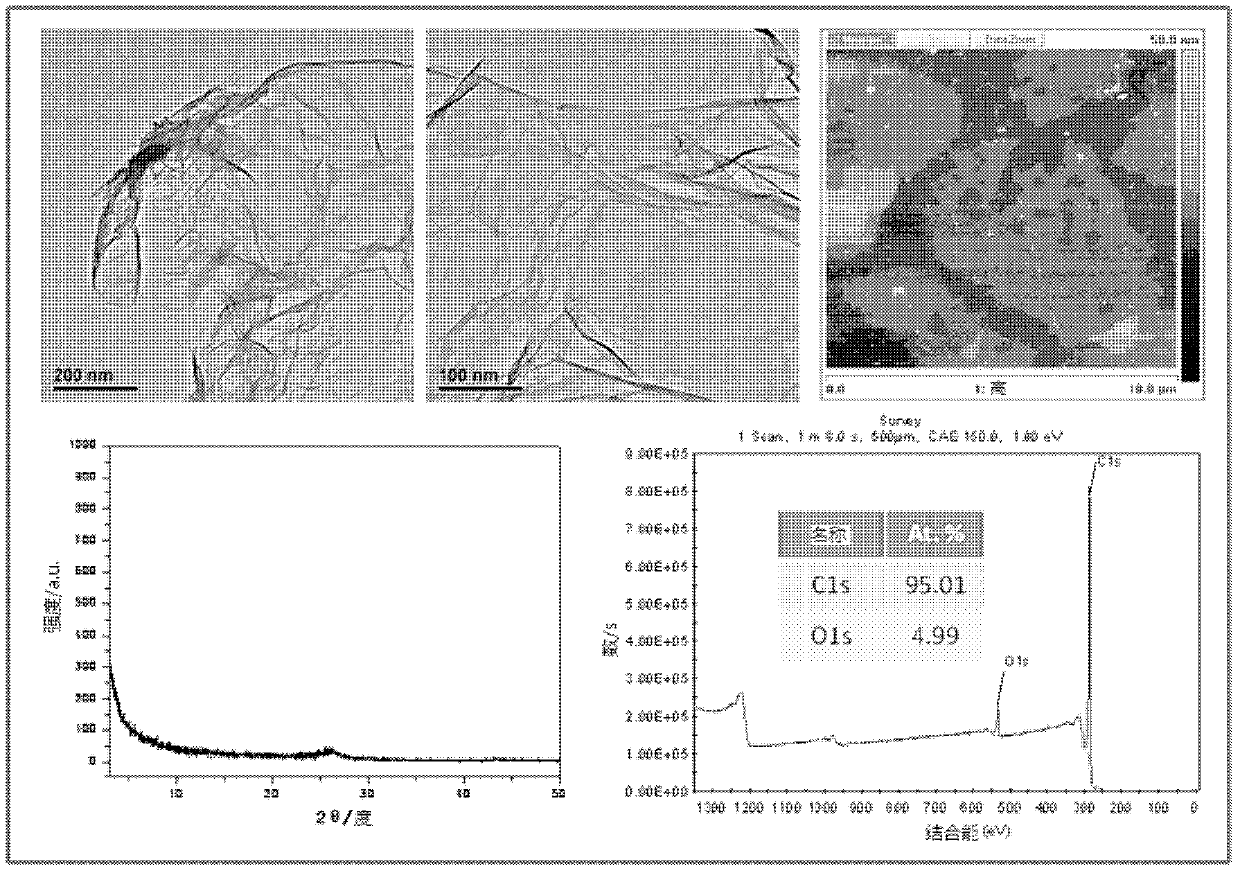

Preparation method of acrylic polymer grafted carbon fiber multi-scale reinforcement

InactiveCN103275282AThe surface is inertSmall specific surface areaPhysical treatmentInterlaminar shearResin matrix

The invention discloses a preparation method of an acrylic polymer grafted carbon fiber multi-scale reinforcement, relating to a carbon fiber reinforcement and a preparation method thereof. The preparation method comprises the following steps of: 1) performing oxidation treatment on a carbon fiber surface; 2) grafting a silane coupling agent to the carbon fiber surface after the oxidation treatment; 3) obtaining chain transfer agent grafted carbon fiber through a reaction between the carbon fiber surface grafted silane coupling agent and a chain transfer agent; and 4) initiating acrylic monomer grafting polymerization on the surface of the chain transfer agent grafted carbon fiber to finally obtain an acrylic polymer grafted carbon fiber multi-scale reinforcement. The method disclosed by the invention has the advantages that the roughness of the carbon fiber surface can be greatly improved, a great quantity of active functional groups can be introduced, the reaction activity of the carbon fiber surface is improved, the wettability and cohesiveness between the carbon fiber and a resin matrix are improved, and the interlaminar shear strength of an epoxy composite material is enhanced by 40-50%.

Owner:NANCHANG HANGKONG UNIVERSITY

Surface treatment method of aramid fiber III

The invention provides a surface treatment method of aramid fiber III, comprising preparation of surface treating agent, surface treatment, drying and the like. The method can improve the flexibility of the aramid fiber III, perfects hand feeling, reduces strength loss caused by factors such as bending and the like in the subsequent operation process, and more importantly improves the surface polarity of the aramid fiber III, thus improving the interface adhesive property of aramid fiber III / epoxy composite material, and further enhancing the interlaminar shear strength of the aramid fiber III / epoxy composite material, wherein the interlaminar shear strength reaches 45-55Mpa. Furthermore, the method is simple and safe in operation, and solvent can be recovered, so that on-line continuous treatment can be easily realized; and the performance of the aramid fiber III is not attenuated, and the aramid fiber III / epoxy resin prepared by aramid fiber which is placed for a longer time has the shear strength being the same as that of the aramid fiber III / epoxy resin treated just now.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

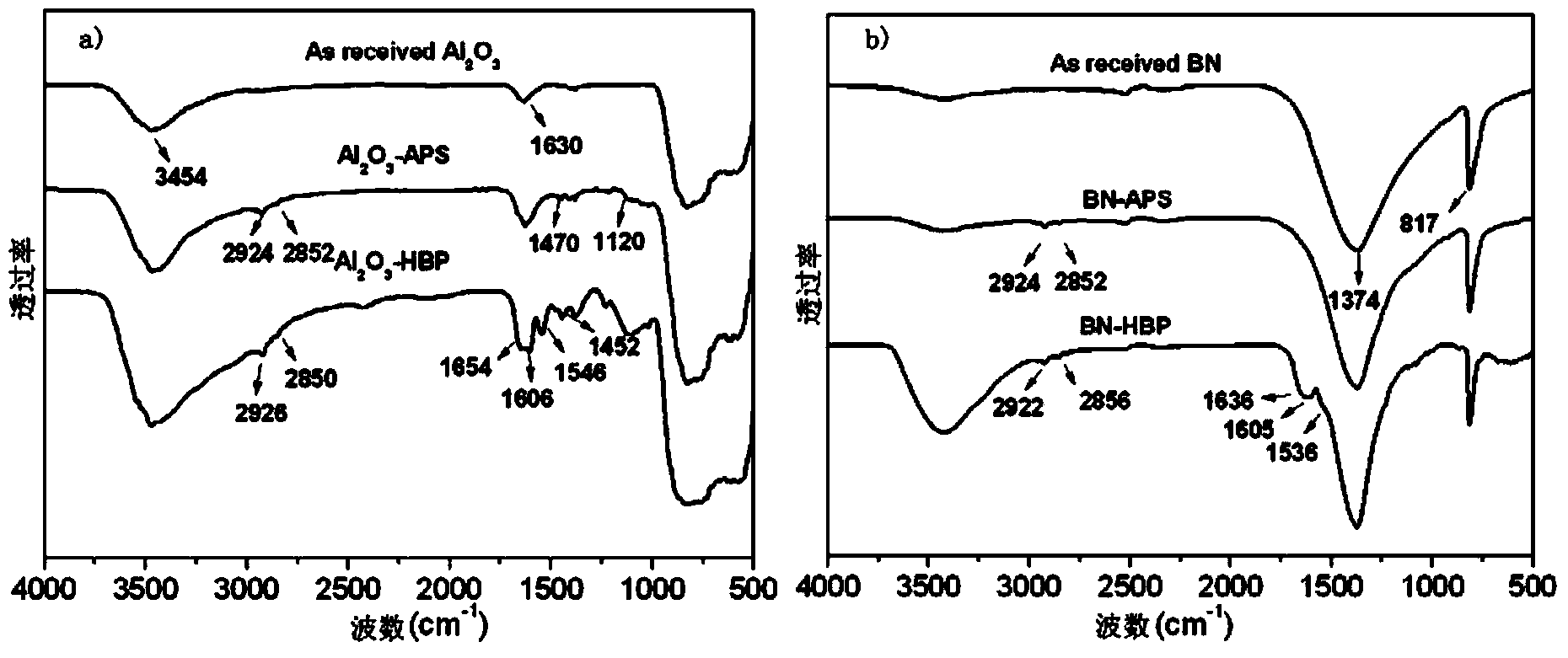

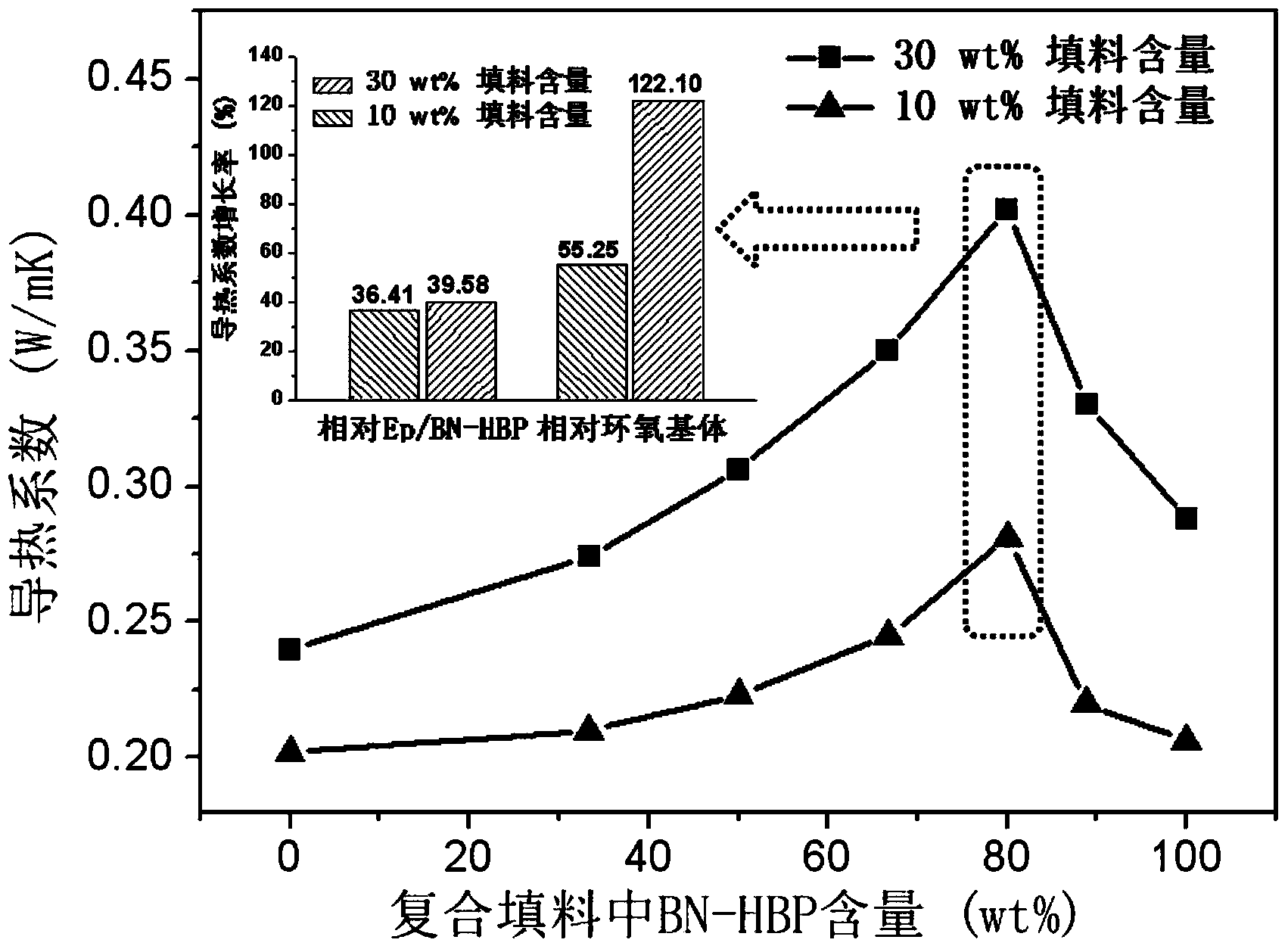

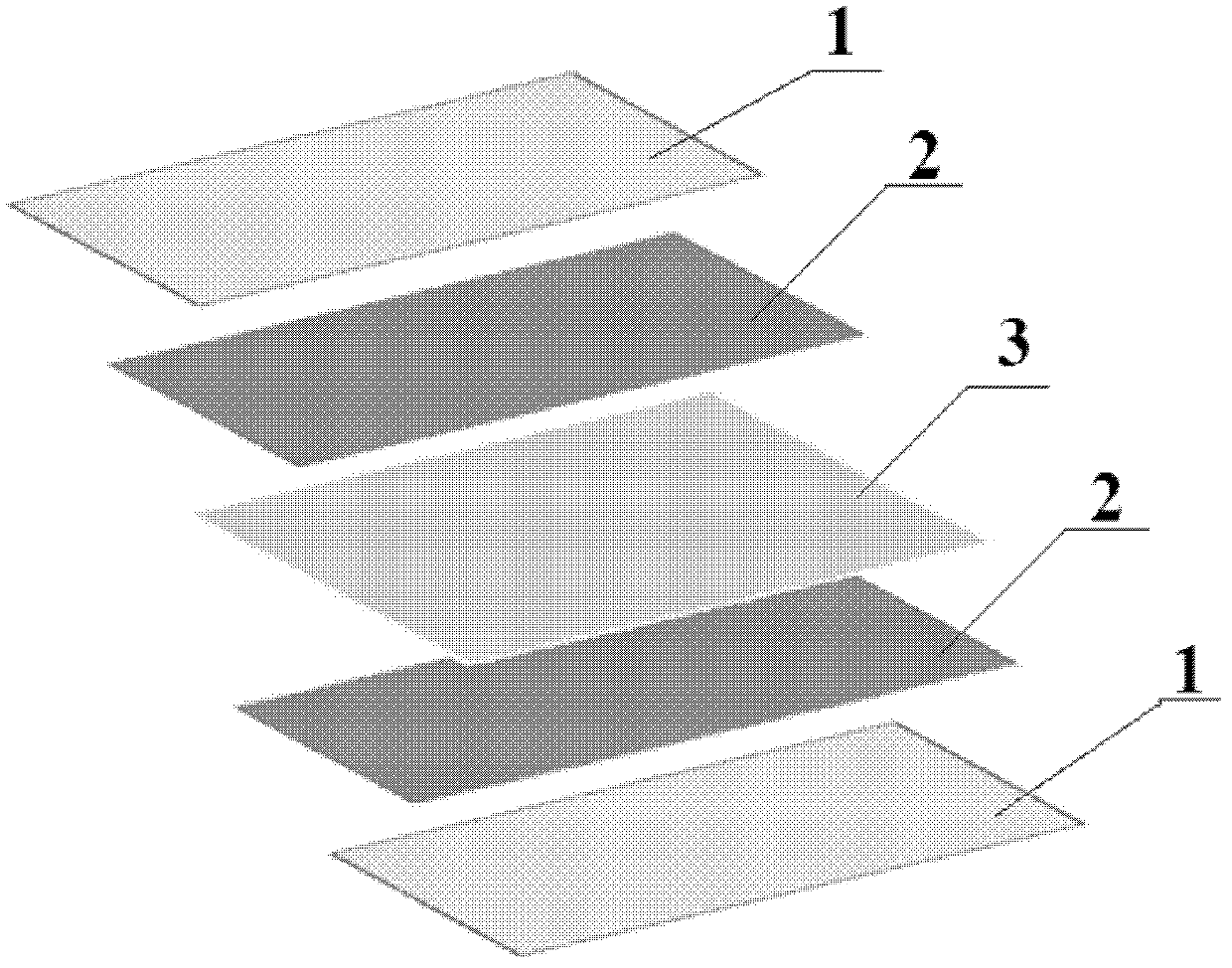

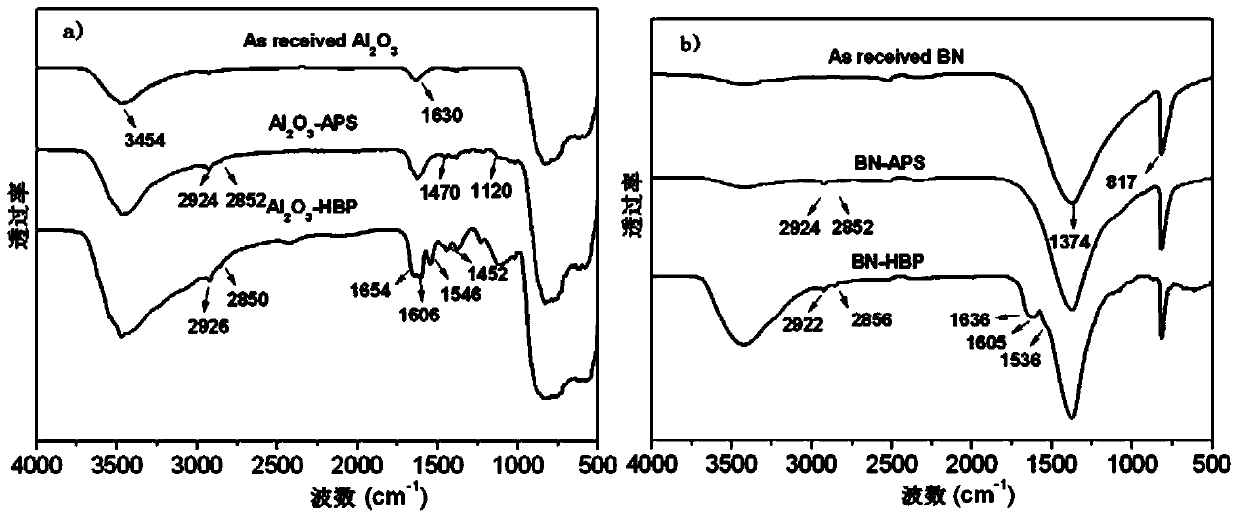

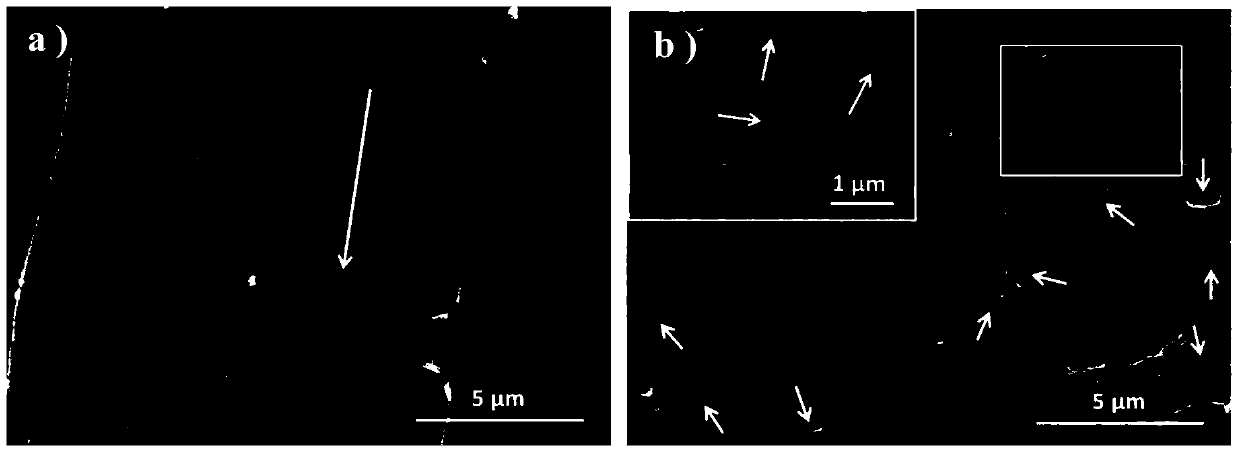

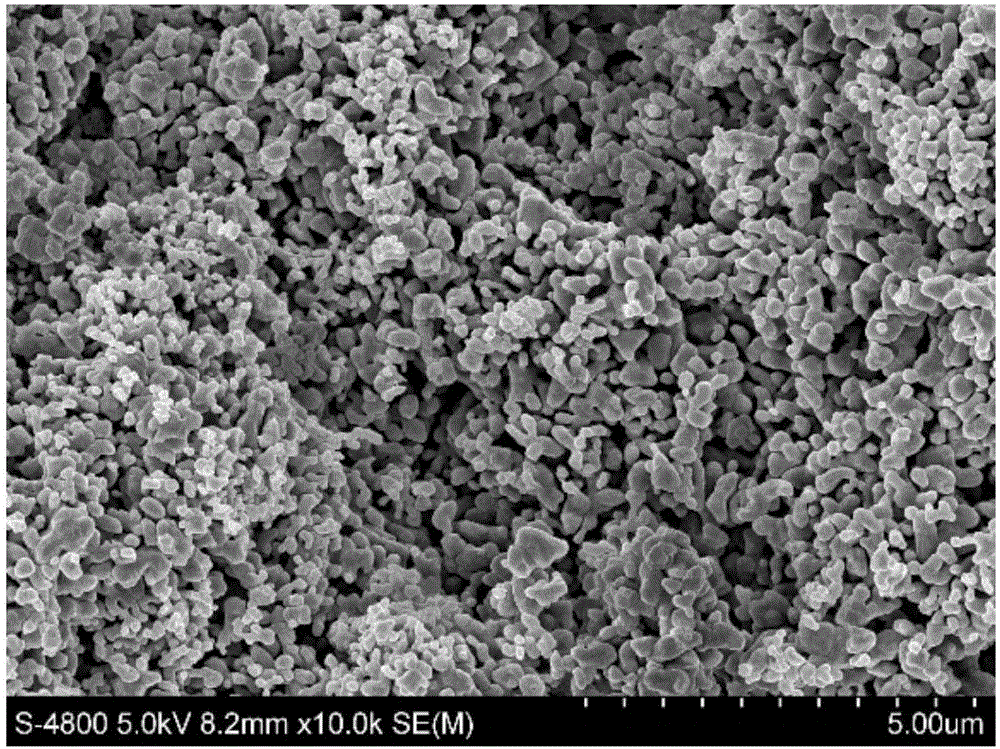

Preparation method of epoxy composite material with low packing content, high thermal conductivity and ternary nano/micro structure

The invention relates to a preparation method of an epoxy composite material with low packing content, high thermal conductivity and a ternary nano / micro structure. The preparation method comprises the following steps of modifying through a silane coupling agent gamma-APS (Aminopropyltriethoxysilane), and introducing amino groups on the surfaces of Al2O3 and h-BN; grafting hyperbranched aromatic polyamide (HBP) on the surface of initially modified packing by taking grafted amino groups as an active site to obtain modified packing Al2O3-HBP and BN-HBP; sufficiently mixing the two kinds of modified packing and an epoxy resin matrix according to a certain proportion and content; preparing the epoxy composite material with the ternary nano / micro structure by using a two step-by-step heating and curing methods. The heat conducting property of the epoxy composite material provided by the invention has a remarkable synergistic effect, the heat conductivity coefficient of a system can be regulated through changing the proportion of the packing, the epoxy composite material has a high heat conductivity coefficient under low packing content, the favorable mechanical and processing performances of the composite material of a polymer are kept, and the cost is greatly reduced.

Owner:SHANGHAI JIAO TONG UNIV

Epoxy composite material and preparation method thereof

The invention provides an epoxy composite material and a preparation method thereof. The method comprises the following steps: (1) mixing trace of conductive nano fillers with one part of epoxy resin; grinding a mixture obtained by agitating and mixing to obtain a master batch; (2) mixing the master batch obtained in the step (1) with the other part of the epoxy resin and a curing agent; then removing air bubbles; (3) carrying out curing and molding on materials obtained by removing the air bubbles, wherein the conditions of agitating and mixing in the step (1) enable the dynamic viscosity of the mixture obtained by agitating and mixing to be 5-18Pa*s at 60 DEG C. An epoxy composite material thin film prepared by using the method disclosed by the invention has high disruptive strength and a relatively good dielectric property.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Epoxy resin curing agent, method for preparing same and application thereof

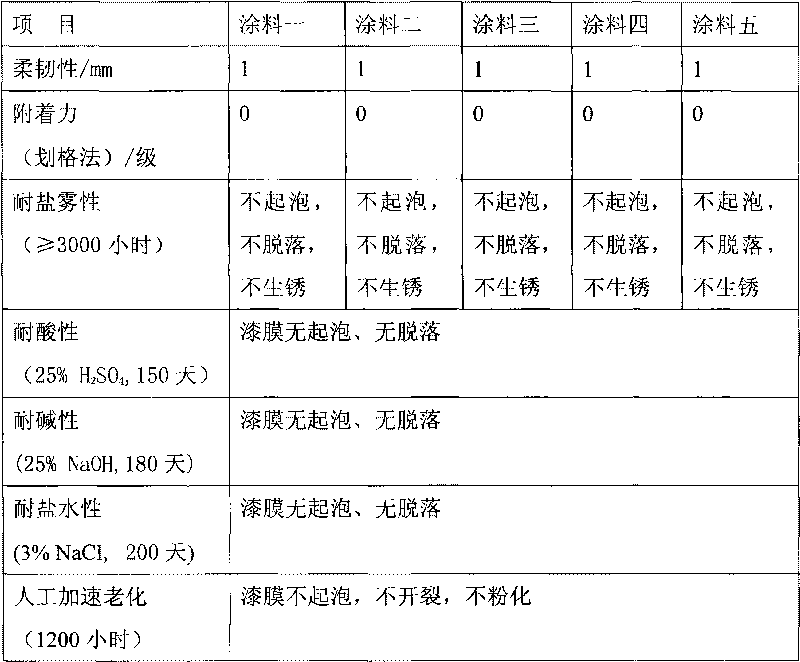

The invention belongs to the technical field of epoxy resin materials, and in particular relates to an epoxy resin curing agent, a method for preparing the same and application thereof. The preparation method is characterized by: adding water into ethanol solution of organic alkoxy silane monomers, and preparing oligosiloxane through hydrolytic condensation; performing chemical grafting reaction on the oligosiloxane and alkylphenol (the carbon number n of the alkyl group is 1 to 30), and adding polybasic amine for chemical reaction or physical mixing to prepare the novel epoxy resin curing agent. In the method, the curing agent is prepared by adding the alkylphenol and the oligosiloxane, the synthetic process is simple, the reaction conditions are mild, the compatibility between the curing agent and the epoxy resin is good, and the impact resistance, the weathering resistance, the strong acid-alkali resistance, the salt-fog resistance and the like of the epoxy system are improved. Thecuring agent can be applied in various fields of heavy corrosion resistant coatings, epoxy coatings, epoxy adhesives, epoxy composite materials, epoxy electrical packaging materials and the like.

Owner:FUDAN UNIV

Preparing method of aramid fiber/epoxy composite material, and MXene modification treating liquid

InactiveCN103992490AImprove mechanical propertiesImprove the bonding strength of the interfaceFibre typesPre treatmentMechanical property

The invention relates to a preparing method of an aramid fiber / epoxy composite material, and an MXene modification treating liquid. The method includes: (1) dipping aramid fiber into an acetone solution for 1-2 h; (2) dipping the aramid fiber into a nitric acid solution for 0.5-1 h to perform surface pretreatment; (3) washing the dipped aramid fiber with deionized water, filtering and drying; (4) dipping the aramid fiber into the MXene modification treating liquid, filtering and drying; and (5) preparing the aramid fiber and epoxy resin into a fiber plate, and curing and forming the composite material plate by utilization of a mould pressing curing method. The MXene modification treating liquid comprises following components by weight: 0.1-5 parts of an MXene compound, 15-25 parts of acetone, 46-68 parts of deionized water, 1-10 parts of isocyanate, 1-3 parts of urea and 1-2 parts of nitric acid. The MXene compound is adopted as a connecting bond, thus improving the interface toughness performance of the aramid fiber / epoxy composite material and improving the overall mechanical properties of the composite material.

Owner:HARBIN ENG UNIV

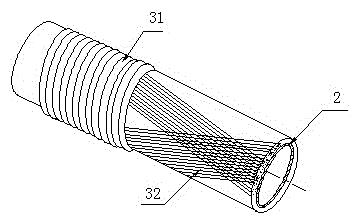

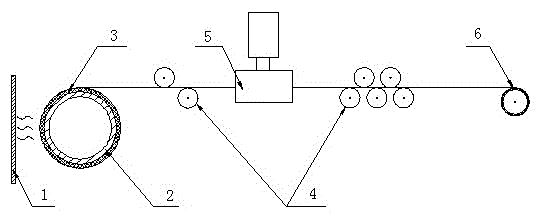

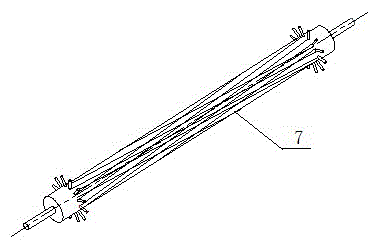

Dry-method winding formation method for carbon fiber composite transmission axle tube

The invention provides a dry-method winding formation method for a carbon fiber composite transmission axle tube. Pollutants on a mould are cleaned up through acetone, and the mould is heated after the whole mould is evenly coated with release agents; prepreg of a proper width is wound on the mould according to a certain line form at a proper winding speed under proper winding tension, so that a composite layer is formed; heating is stopped, and after the mould is cooled to a certain temperature, a layer of silica film or polythylene terephthalate (PET) film is wound on the surface of the composite layer; after surface treatment is finished, temperature rises to 180 DEG C at the temperature rising speed not higher than 3 DEG C / min and is kept for a period of time, and finally the mould is cooled to the room temperature, released and cut, so that the transmission axle tube is obtained. The carbon fiber or epoxy composite transmission axle tube manufactured through dry-method winding formation method has high specific strength and specific stiffness and good humidity resistance, the thermogravimetric analysis (Tg) is 220 DEG C, and good compactness, uniformity and size accuracy are also realized.

Owner:HENGSHEN

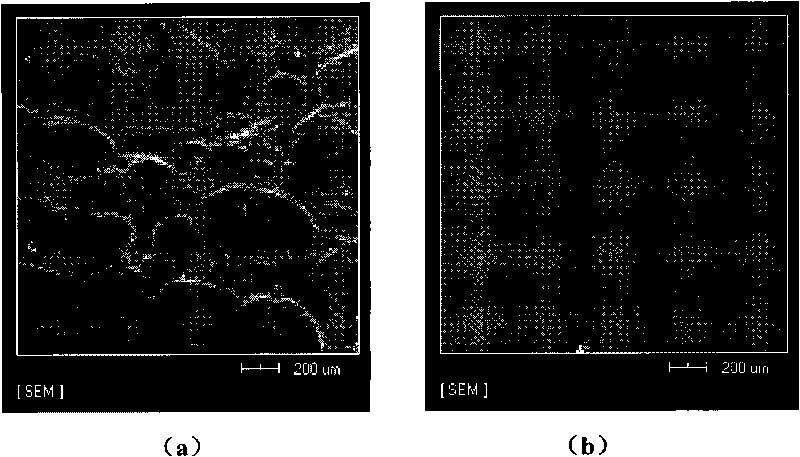

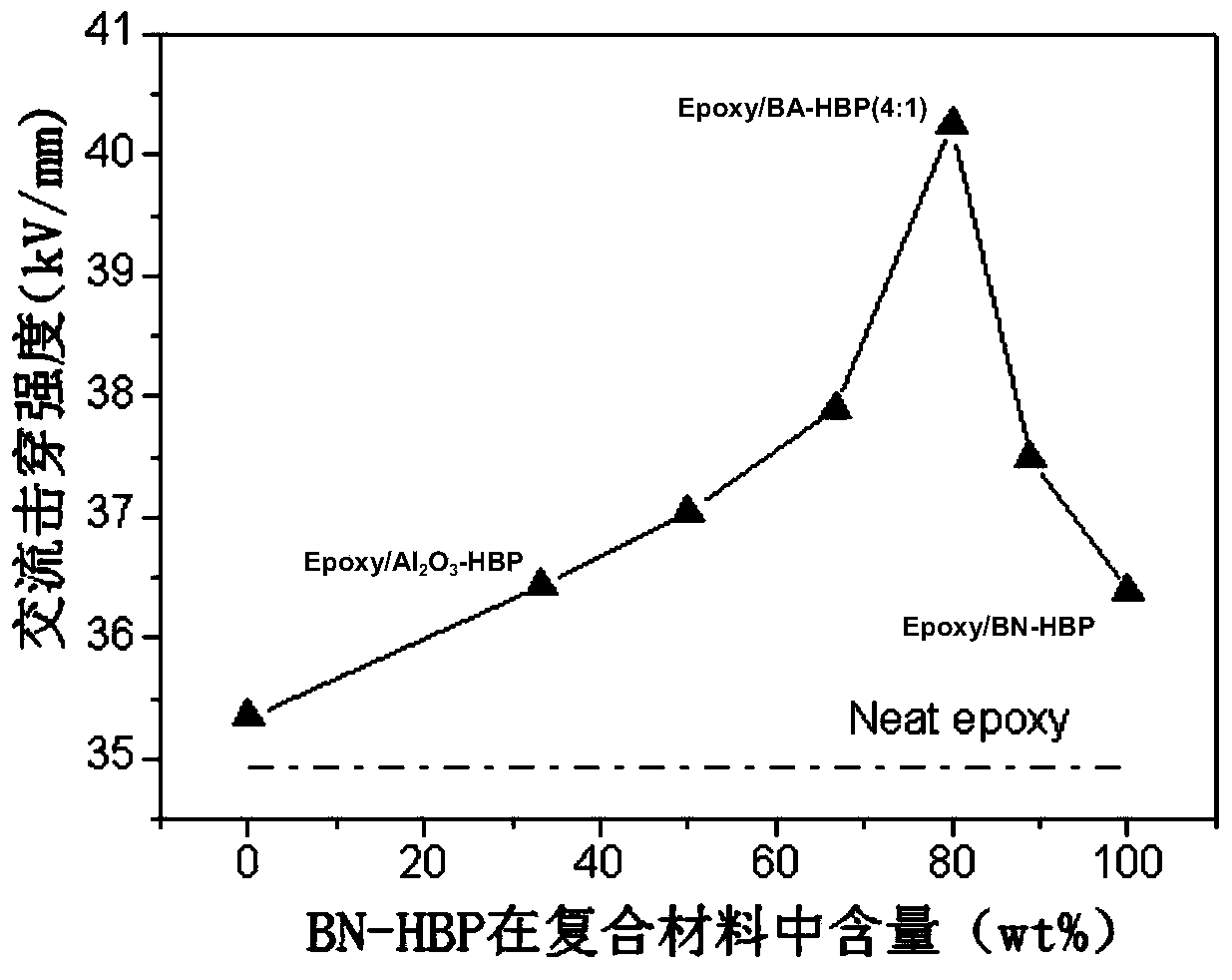

Preparation method of modified compound filler filled breakdown-resisting epoxy composite

The invention relates to a preparation method of a modified compound filler filled breakdown-resisting epoxy composite. The preparation method comprises the following steps: through the modification of a silane coupling agent gamma-APS, amino groups are introduced on the surfaces of Al2O3 and h-BN; hyperwheworries branched polymers (HBP) are grafted on the surfaces of the primarily modified fillers through taking the grafted amino groups as active sites to obtain a modified filler Al2O3-HBP and a modified filler BN-HBP; the two modified fillers are fully mixed with an epoxy resin matrix in different proportions; the epoxy composite is prepared through a two-step stepped heating and curing method. The alternating-current breakdown strength of the prepared epoxy composite shows the obvious cooperative behavior, the system breakdown strength can be regulated through changing the proportion of the fillers; when the BN-HBP accounts for 80 wt% of the compound filler, the performance of the BN-HBP is optimized, only 10 wt% of compound filler is added, and the alternating current strength of the epoxy composite can be improved by 15.7% as compared with that of the epoxy matrix.

Owner:SHANGHAI JIAO TONG UNIV

Process for the preparation of carbon fiber-carbon nanotubes reinforced hybrid polymer composites for high strength structural applications

ActiveUS20180112046A1Light weightIncrease loadMaterial nanotechnologyCarbon fibresPolymer scienceMultiwalled carbon

The present invention relates to the development of carbon fiber carbon nanotubes reinforced polymer composites for high strength structural applications. It is very difficult to incorporate higher amount of carbon fiber >60 vol % in any of the polymer matrix. Beyond this loading the mechanical properties of these composite starts deteriorate. Therefore, further improvement in the mechanical properties is not possible. Herein, a novel method is developed to fabricate the hybrid carbon fiber epoxy composites reinforced with multiwalled carbon nanotubes. The flexural strength of the hybrid composites (˜45 vol % CF+CNT) was achieved more than 600 MPa which is more than 35% over pure carbon fiber / epoxy composites (˜50 vol % CF). These high strength hybrid composites can be used in wind mill blades, turbine blades, sport industries, automobile and airframe.

Owner:COUNCIL OF SCI & IND RES

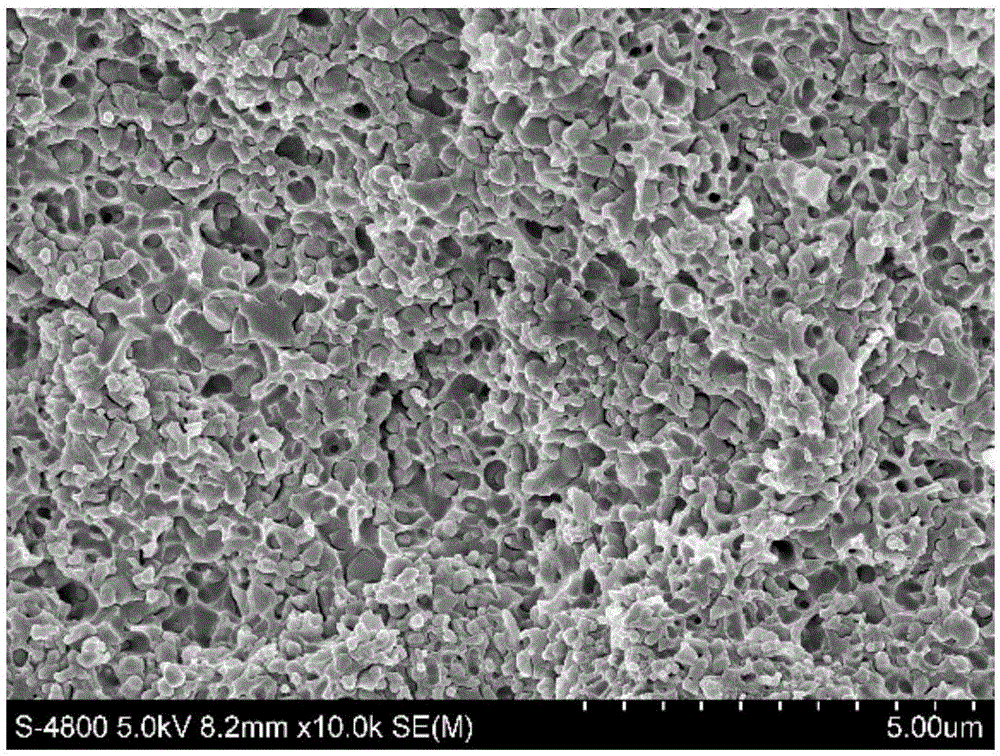

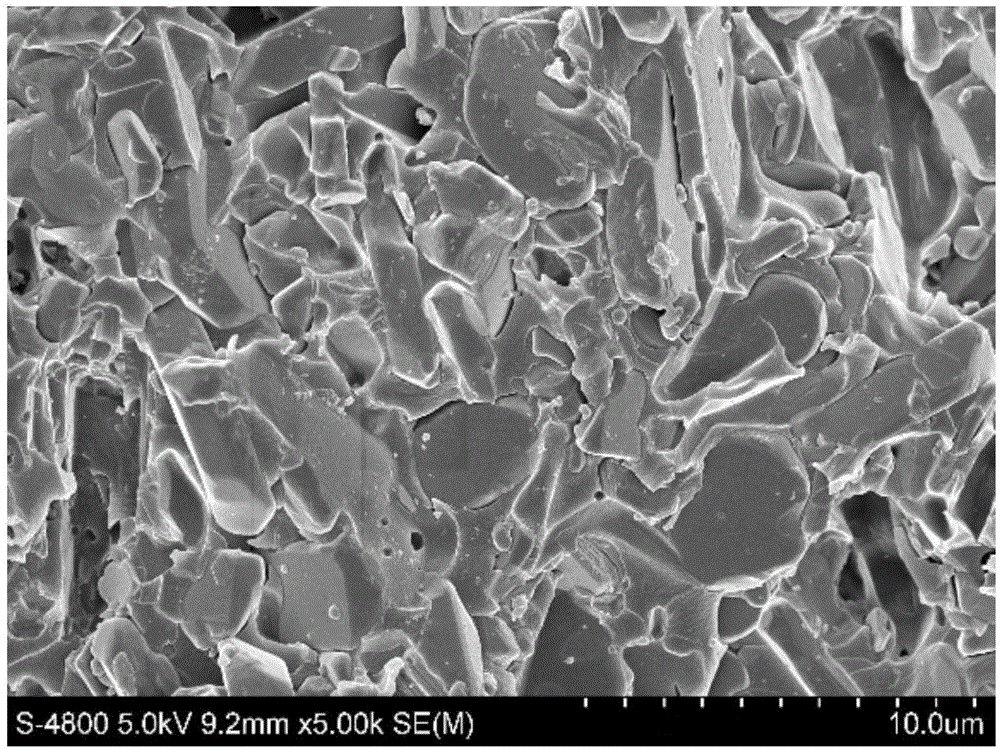

Preparation method of bicontinuous-phase alumina/epoxy resin composite material

InactiveCN106633652AImprove high and low temperature mechanical propertiesImprove thermal conductivityCeramicwarePorosityMechanical property

The invention relates to a preparation method of a bicontinuous-phase alumina / epoxy resin composite material, belonging to the technical field of composite materials. The method comprises the following steps: carrying out compression molding on Al2O3 powder with different particle sizes under different pressures, and sintering at different temperatures under normal pressure for holding time to obtain the porous Al2O3 ceramic with adjustable porosity and pore size; and after carrying out surface modification, standing the preheated porous Al2O3 ceramic in a mixed solution composed of an epoxy resin, an accelerator and a curing agent for some time, and carrying out solidifying formation to obtain the bicontinuous-phase alumina / epoxy resin composite material. The porosity of the porous alumina ceramic is regulated by controlling the content of the foaming agent and the volume density of the green compact, thereby regulating the volume percent of the alumina reinforcement phase in the composite material. The alumina phase in the composite material is a continuous phase, can greatly enhance the high / low-temperature mechanical properties, thermal conductivity and high-temperature creep resistance of the alumina / epoxy composite material, and provides a new idea for researching and developing high-performance epoxy resin composite materials.

Owner:STATE GRID CORP OF CHINA +2

Preparation method of rare earth modified fanglun fiber/epoxy composite material

A RE modified aramid fibre / epoxy composite is prepared through pretreating the surface of aramid fibres, using RE modifier to modify the surface of aramid fibres, mixing epoxy resin with solidifying agent, soaking the aramid fibres in the mixture, winding on plate die, infrared baking, cutting the soaked fabric, laminating, and thermal die pressing. Its advantages are high mechanical performance and low cost.

Owner:SHANGHAI JIAO TONG UNIV

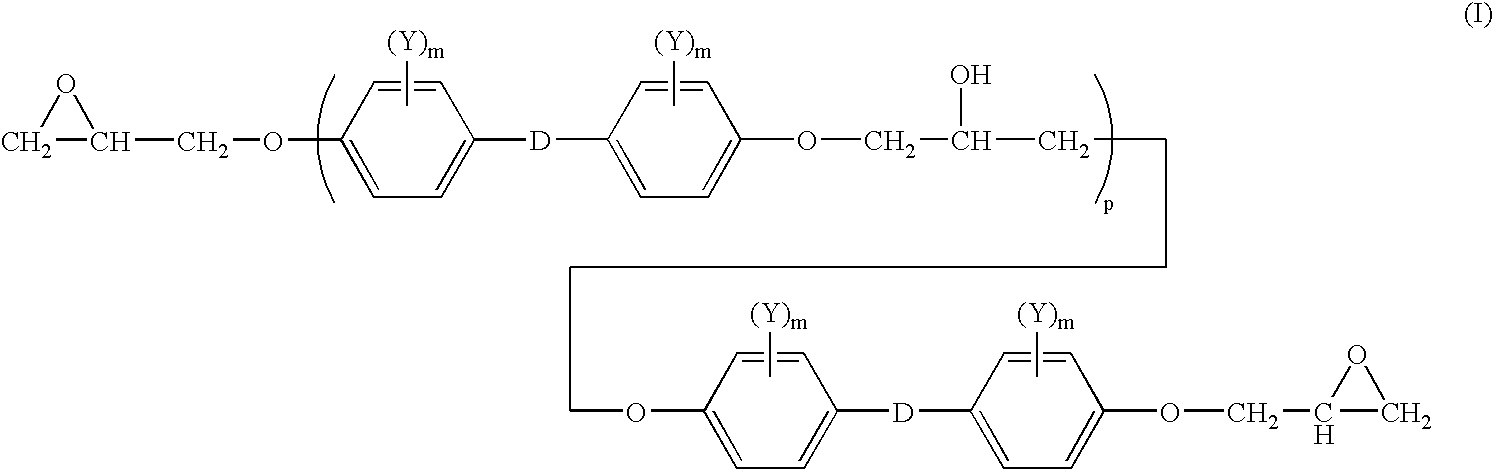

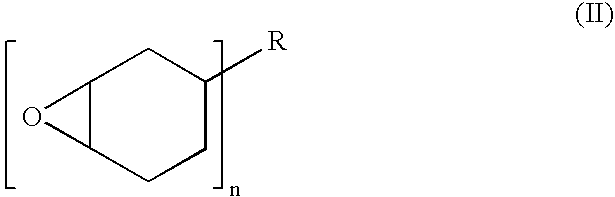

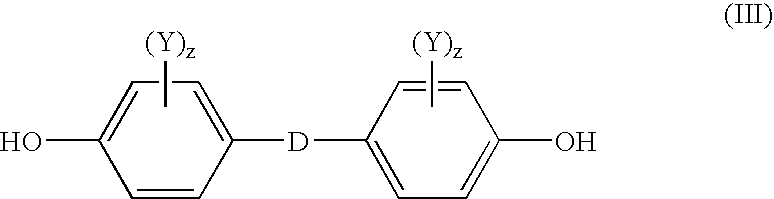

Process for preparing cured epoxy composites

ActiveCN104159968AHigh glass transition temperatureHigh densityPretreated surfacesModifications by conduction heat transferThermal expansionVolumetric Mass Density

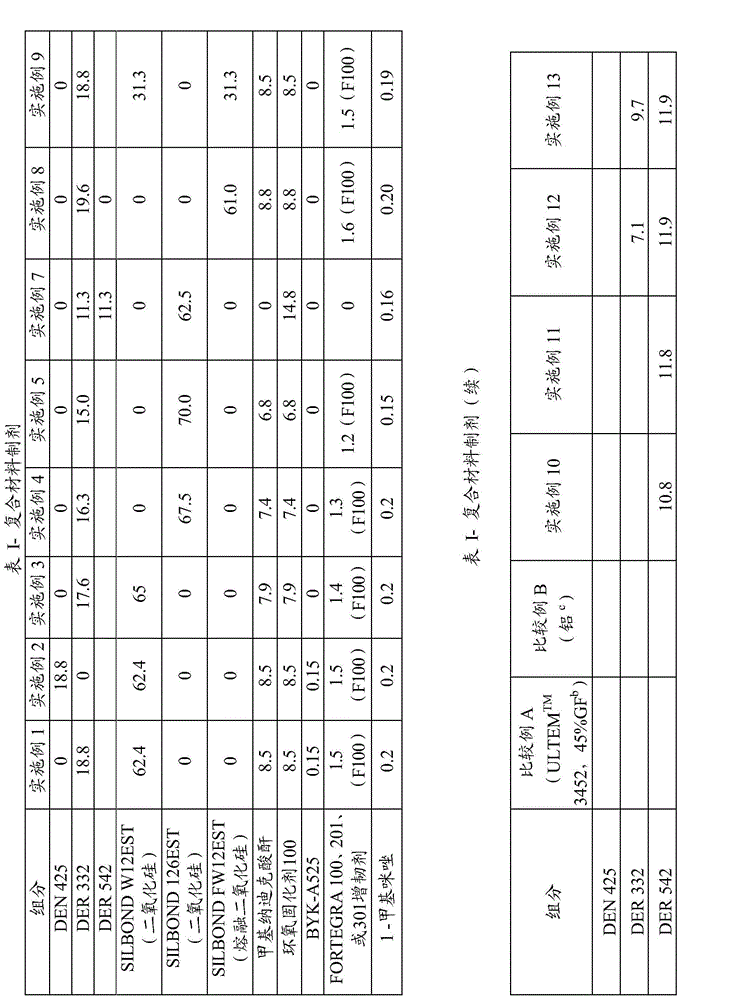

A process for preparing a cured composite material useful for radio frequency filter applications comprising the steps of: (a) providing a curable thermoset epoxy resin composition comprising (i) at least one epoxy resin; (ii) at least one toughening agent; (iii) at least one hardener; and (iv) at least one filler; (b) curing the curable thermoset epoxy resin composition of step (a) to form a cured composite; wherein the curable thermoset epoxy resin composition upon curing provides a cured composite product with a balance of properties comprising Tg, coefficient of thermal expansion, tensile strength, thermal conductivity; and having a density of less than 2.7 g / cc; and (c) coating at least a portion of the surface of the cured composite of step (b) with an electrically conductive metal layer to form a metalized coating on at least a portion of the surface of the cured composite. The cured composite material may be useful as a radio frequency cavity filter body housing for radio frequency filter applications.

Owner:DOW GLOBAL TECH LLC +1

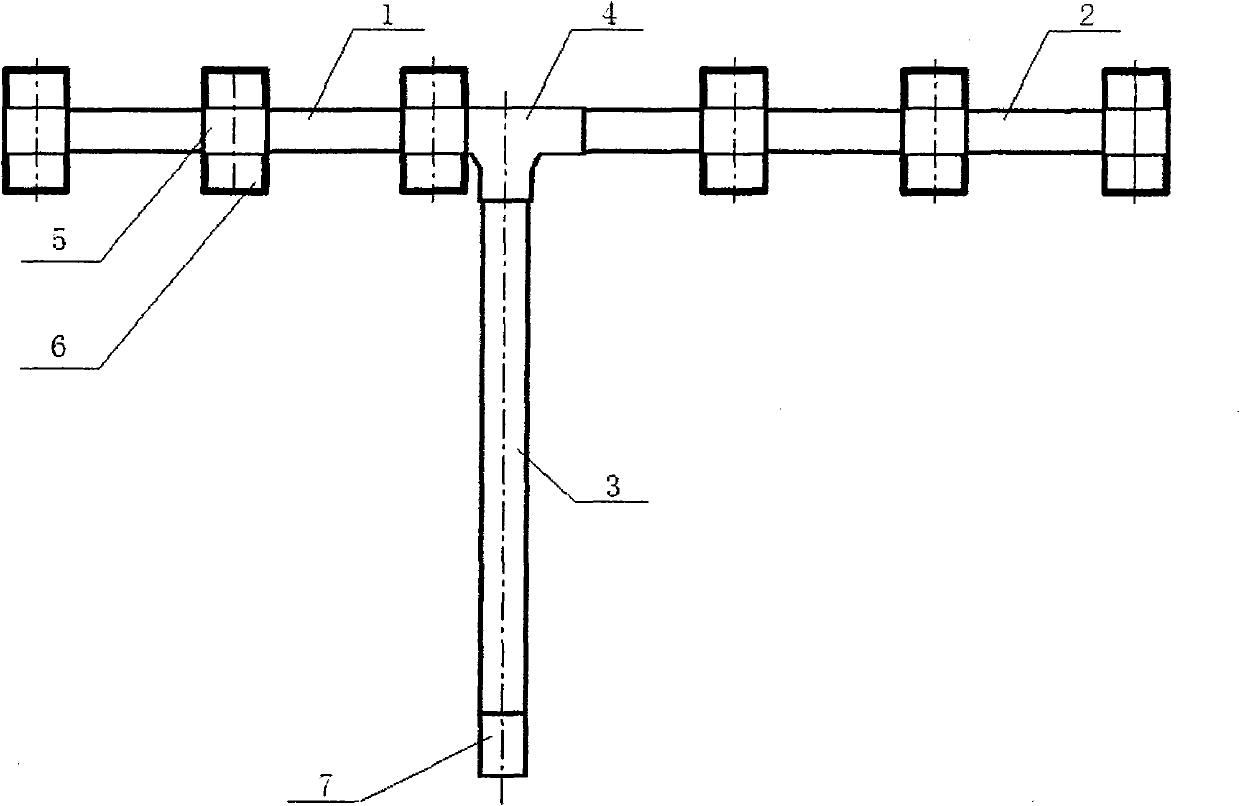

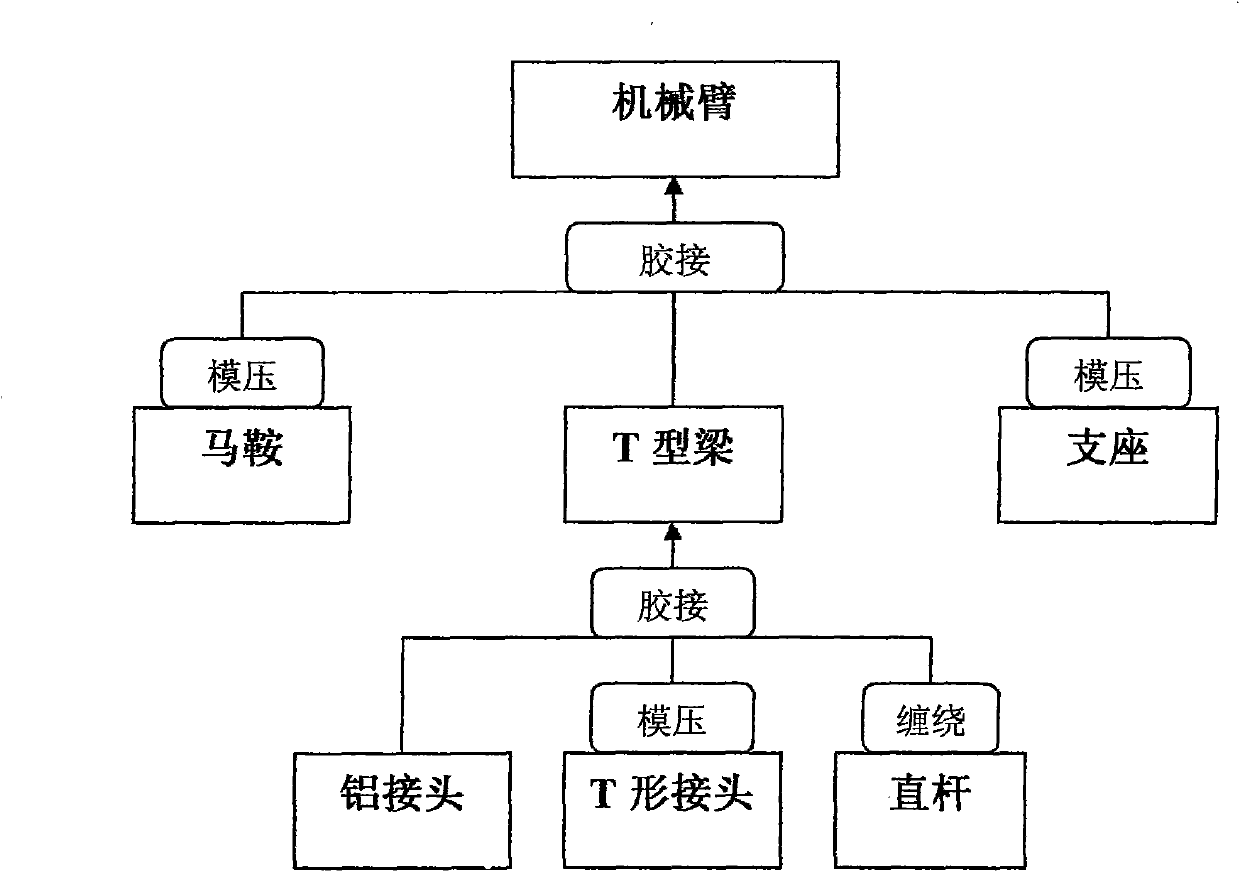

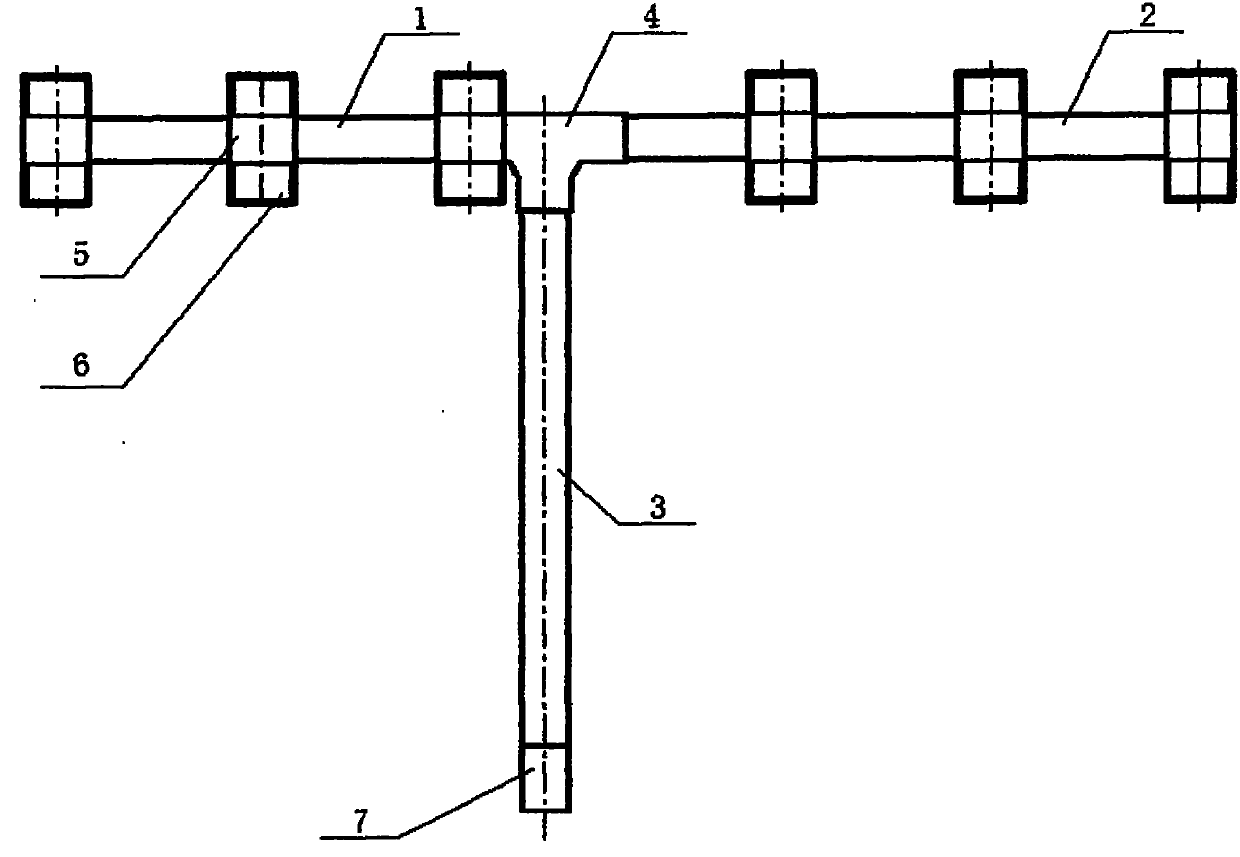

Composite material mechanical arm and manufacture method thereof

InactiveCN102085655AReduce weightSolve the problem of manual unloading difficultiesProgramme-controlled manipulatorFiberCarbon fibers

The invention discloses a composite material mechanical arm which comprises a T-shaped beam, wherein a saddle (6) is arranged on the T-shaped beam, an installing support (5) is arranged on the saddle, and the beam, the saddle and the installing support are made of carbon fiber / epoxy composite materials. Due to the adoption of the mechanical arm disclosed by the invention, the weight of the traditional mechanical arm is lightened, the rigidity of the mechanical arm can be improved and the flexibility is reduced; especially, when the mechanical arm rapidly rotates, the transmission precision of the mechanical arm can be greatly improved and the use requirement for high-precision transmission is met due to good damping resistance of the composite materials and small vibration of the mechanical arm. The composite material mechanical arm can be used as a transmission arm of an automatic transmission robot in a car assembling line.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

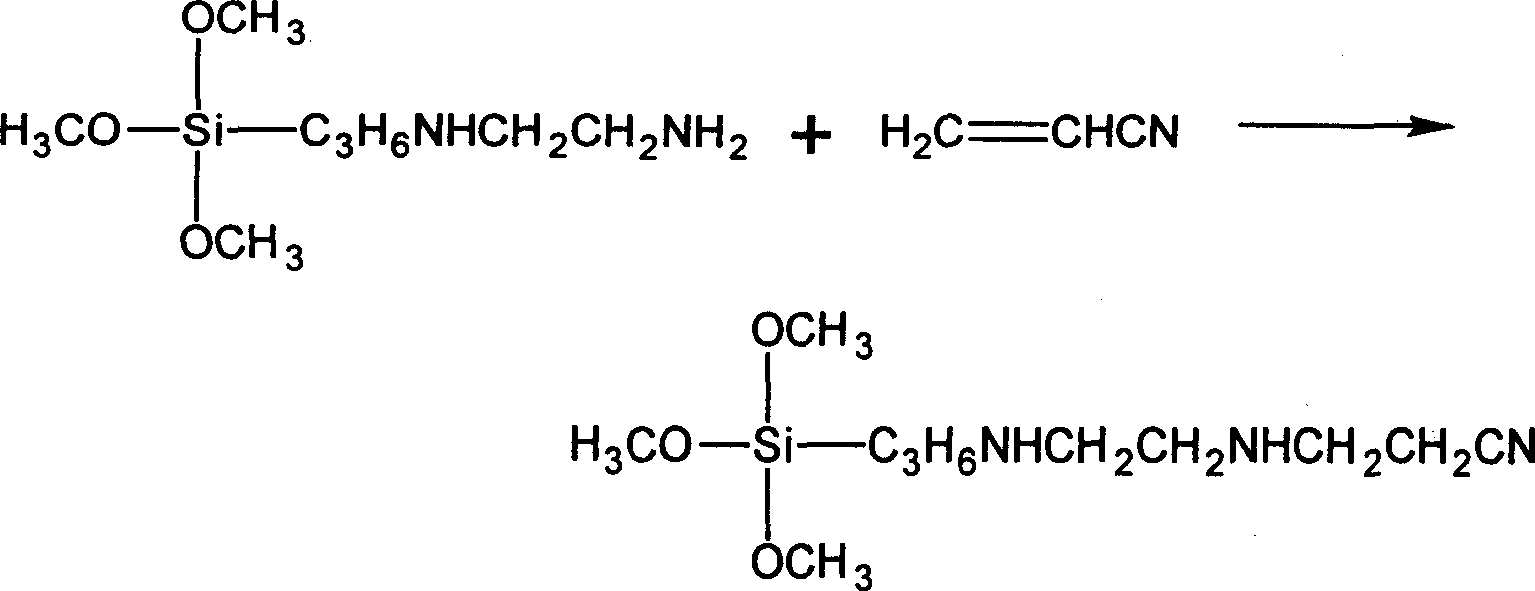

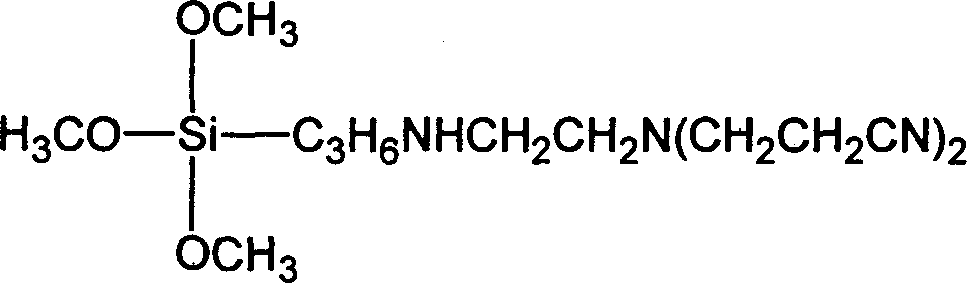

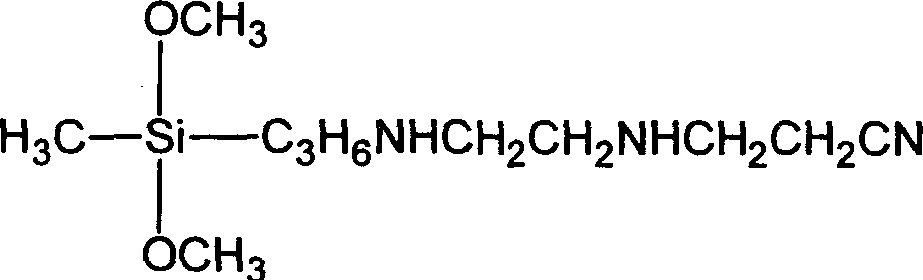

Silicomethane coupling agent containing cyanide and secondary amino and its preparation process and application thereof

InactiveCN1793207AHigh bonding strengthGood storage stabilityAldehyde/ketone condensation polymer adhesivesEpoxy resin adhesivesCyanideSilanes

The invention discloses a method to make silane coupler that contains cyan and secondary amino group. The molecular structure is (R1O)3-xSiR2xR3NHR4NHy(C2H4CN)z that is made up from the reaction of 1-2mol acrylonitrile and 1mol amino silane that has the molecular of (R1O)3-xSiR2xR3NHR4NH2. Comparing to traditional amino silane coupler, it has good restoring stability could be make into other coupler. The mechanical property and strength of bond to the base material would be greatly improved.

Owner:ZHEJIANG UNIV

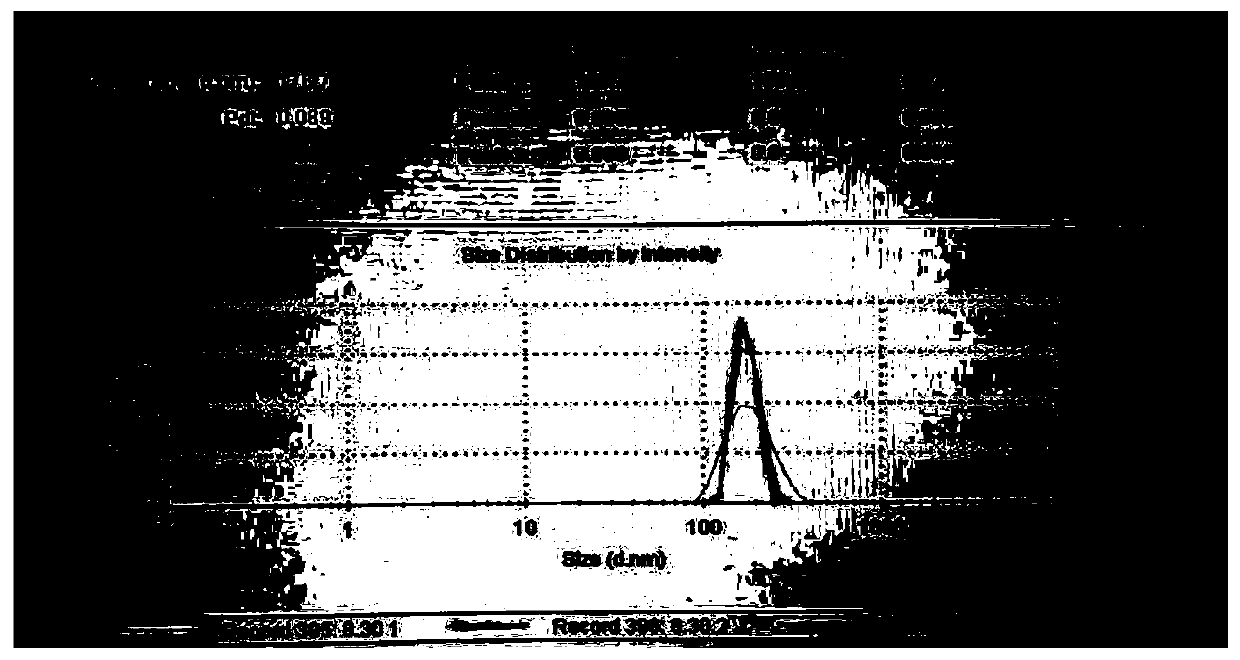

Water-based-epoxy sizing agent and preparing method thereof

The invention discloses a water-based-epoxy sizing agent and a preparing method thereof. The water-based-epoxy sizing agent is prepared from, by weight, 100 parts of epoxy resin, 10-30 parts of a hyperbranched emulsifying agent, 1-5 parts of an auxiliary emulsifying agent, 1-5 parts of a dispersing agent and 100-300 parts of deionized water. A hyperbranched structure of a modified epoxy emulsifying agent has a large quantity of holes, the holes are added into the epoxy resin, the viscosity of a system can be reduced, and the grain size of emulsion can be decreased in the phase transformation process to improve wetting of the sizing agent to the surface of a carbon fiber. According to the water-based-epoxy sizing agent and the preparing method thereof, the solvent problem caused by the large viscosity in a traditional emulsification epoxy process is solved, the grain size of the sizing agent prepared with the method is 200 nm or below, the sizing agent can be evenly spread on the surface of the carbon fiber, and the carbon simultaneously has good bundling and splitting properties accordingly. The interlaminar shear strength of an epoxy composite material prepared from the carbon fiber sized through the sizing agent can be 70 MPa or above.

Owner:BEIJING UNIV OF CHEM TECH

Heat resistant epoxide resin and preparation method thereof

InactiveCN101565535AImprove heat resistanceThe mechanical strength of the interface increasesFiberCarbon fibers

The invention discloses a heat resistant epoxide resin and a preparation method thereof, relating to an epoxide resin and a preparation method thereof, and solving the problem that the existing method for improving the heat resistance of the epoxide resin easily results in low shearing strength of a composite material. The heat resistant epoxide resin is prepared by kieselguhr, epoxide resin and a curing agent. The method comprises the following steps of: 1. conducting ultrasonic treatment to prepare suspending liquid; 2. stirring the epoxide resin, adding the suspending liquid, raising and keeping temperature; and 3. adding the curing agent, conducting heating and solidifying, and then obtaining the heat resistant epoxide resin. The heat resistant epoxide resin has good heat resistance and interface adhesion property and the thermal degradation temperature of the heat resistant epoxide resin is improved by over 60 DEG C compared with epoxide resin E51. The interface mechanical strength of carbon fiber enhanced epoxide composite material is increased by over 17.0 percent. The method has simple technique and low cost.

Owner:HARBIN INST OF TECH

Filler reaction type epoxy composite material as well as preparation method and application thereof

ActiveCN105273361AAvoid the disadvantages of slow curing and difficult curingFast water blockingSolventAccelerant

The invention belongs to the technical field of a water blocking material and discloses a filler reaction type epoxy composite material as well as a preparation method and application thereof. The composite material is prepared from a component A and a component B, wherein the component A is prepared from the following components in parts by weight: 10 to 70 parts of epoxy resin, 5 to 40 parts of an activating type reactive solvent, 0 to 30 parts of an enhanced type reactive solvent, 10 to 65 parts of reactive fillers, 0 to 5 parts of an interface enhancing agent and 0 to 5 parts of an interface activating agent; the component B is prepared from the following components in parts by weight: 5 to 85 parts of a function curing agent, 0 to 40 parts of a curing regulating agent, 5 to 85 parts of a double-function curing agent and 0 to 30 parts of a curing accelerant. With the adoption of the composite material, the effect of rapidly blocking water can be realized, and the disadvantages that the curing speed of the epoxy material in water is slow and the epoxy material is difficult to cure are avoided; the composite material has high mechanical strength, good durability and low-temperature resistance; the filler reaction type epoxy composite material has rapid curing speed, high mechanical strength and low construction cost.

Owner:SOUTH CHINA UNIV OF TECH

High-thermal-conductivity strong-insulation epoxy composite material for solid-state transformer under low doping amount and preparation method thereof

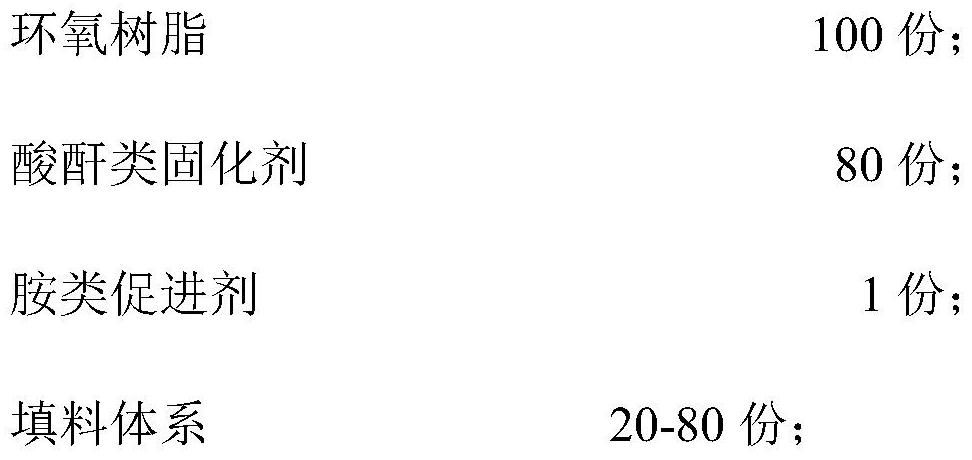

The invention discloses a high-thermal-conductivity strong-insulation epoxy composite material for a solid-state transformer under a low doping amount and a preparation method thereof. The preparationmethod comprises the following steps: 1) preparing core-shell structure BN@SiO2 micron particles, and carrying out coupling agent surface modification and ball-milling treatment on nano BN; 2) preparing 100 parts of epoxy resin, 80 parts of a curing agent, 1 part of an accelerant and 20-80 parts of a micro-nano filler system, wherein nano BN accounts for 1-5wt% of the specific gravity of the filler system; (3) mixing the components in the step (2), and carrying out dispersion and defoaming treatment by virtue of an autoroatation and revolution stirrer; and 4) pouring the mixture obtained in the step 3) into a mold, and heating and curing the mixture in a drying box. Through a micro-nano co-doping technology, micron particles adopt a core-shell structure, the surfaces of the nano particlesare modified, and the epoxy-based composite material with excellent electrical and thermal properties can be obtained under the selected co-doping ratio; in addition, the preparation method is simplein step, low in filler doping amount, low in cost and suitable for industrial production.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com