Transparent epoxy nano composite material and its preparation method and use

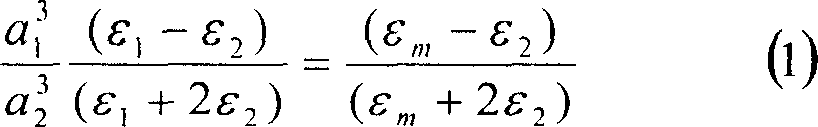

A nano-composite material and nano-composite particle technology are applied in the field of transparent epoxy nano-composite materials and their preparation, which can solve the problems of decreased transmittance in the visible light region, increased viscosity of mixtures, and increased specific surface area of fillers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

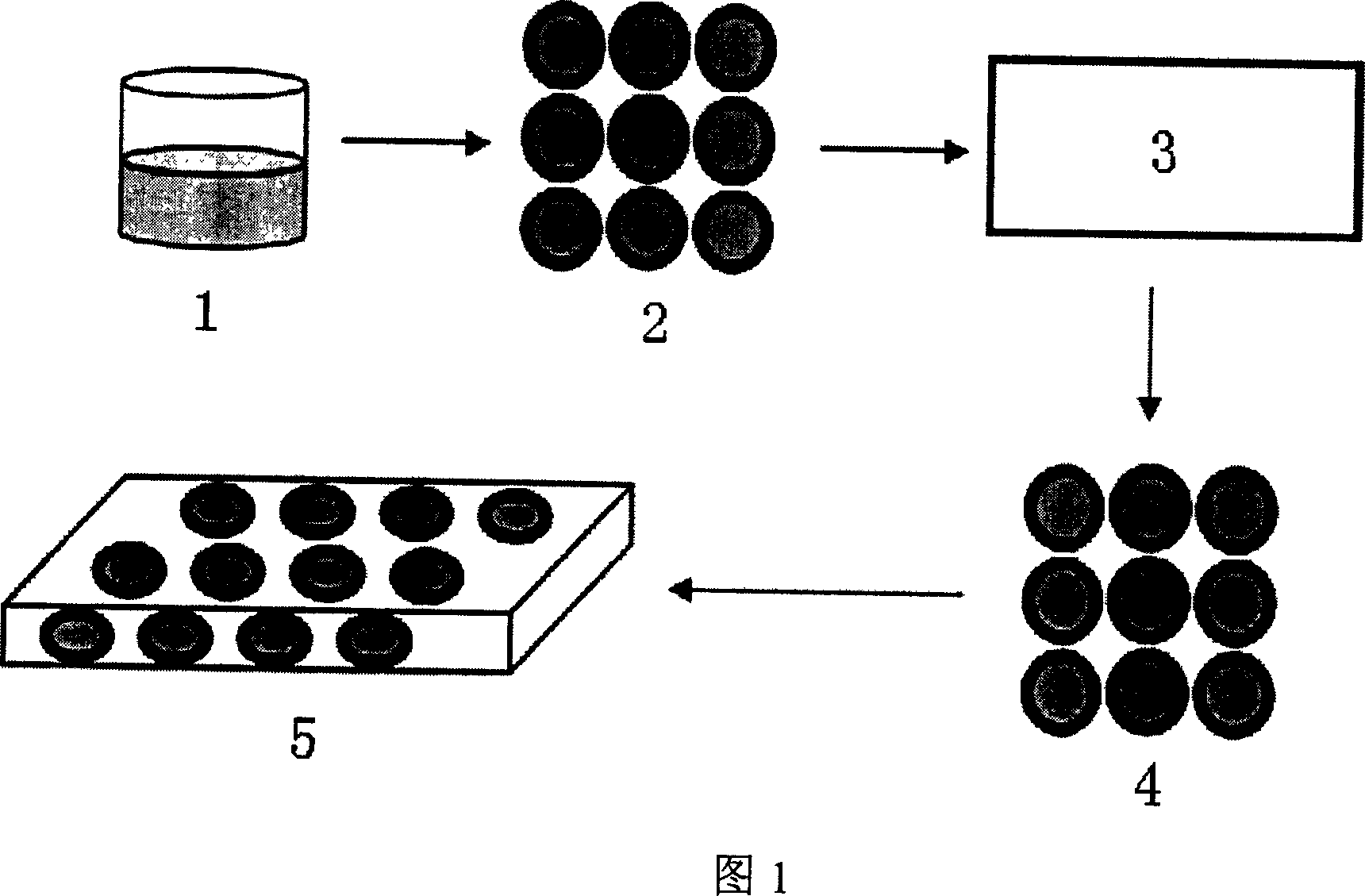

Method used

Image

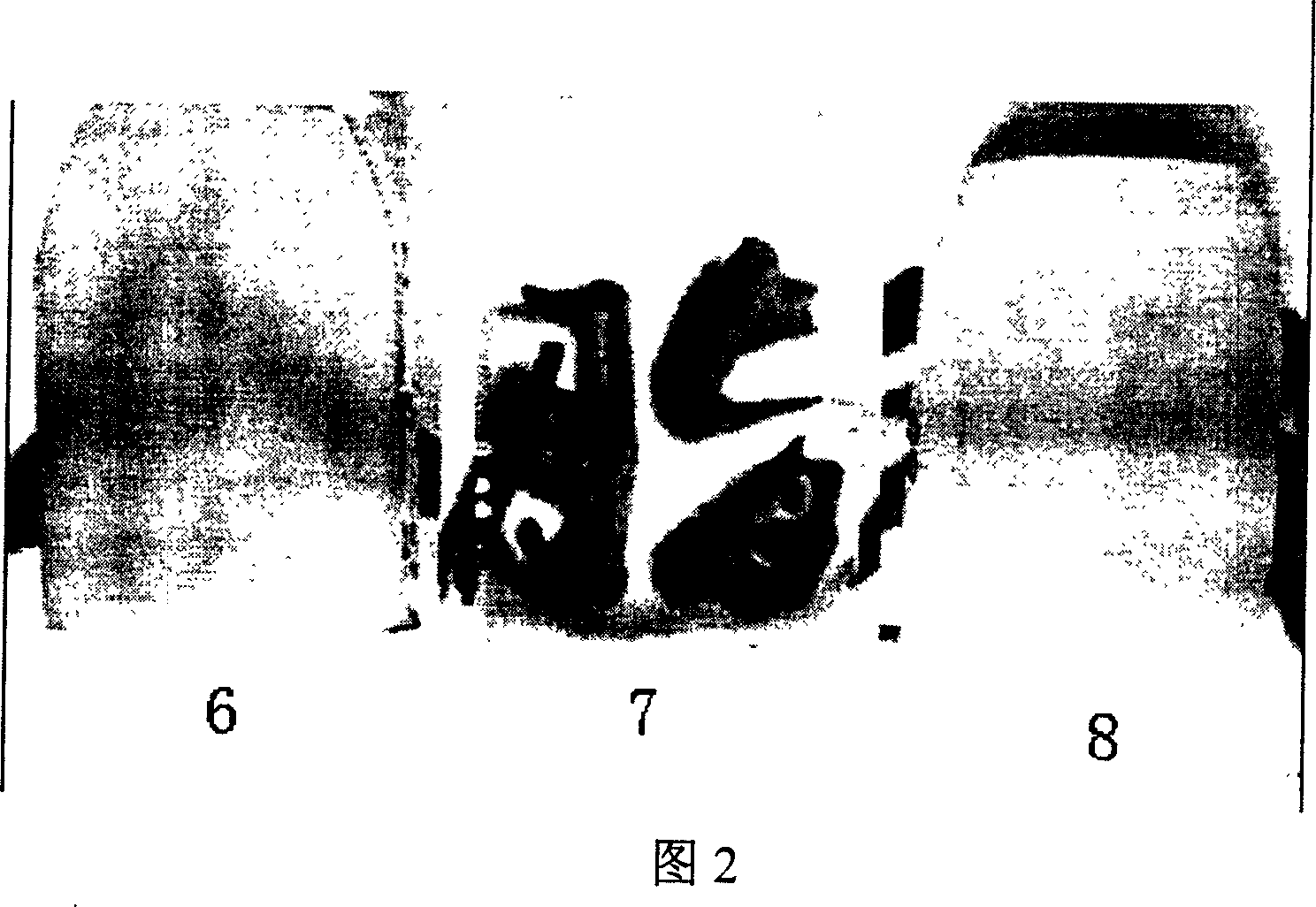

Examples

Embodiment 1

[0049] Ultrasonic disperse 5 g of spherical silica particles with a particle size of 10 nm in 1 L of methanol solution, and then add 3.6 g (0.2 mol) of H 2 O makes the concentration of water in the solution 0.2mol / L. While stirring, add 6.43g (0.0189mol) butyl titanate (TBOT) to the above solution within 1h, and add 1.36g (0.0756mol) H at the same time 2 O, keep the concentration of water in the solution at 0.2 mol / L, continue to stir the solution for 2 hours to complete the hydrolysis reaction of butyl titanate, and form composite nanoparticles (S-T) coated with titanium dioxide and silicon dioxide.

[0050] Add water and ammonia water to the above solution, so that the concentration of water and ammonia water in the solution reaches 2mol / L and 0.05mol / L respectively. After stirring evenly, add 0.23g (0.0011mol) tetraethyl orthosilicate (TEOS) within 1h to coat the surface of the S-T composite nanoparticles with silicon dioxide. After continuing to stir for 2 hours, centrif...

Embodiment 2

[0053] Ultrasonic disperse 10 g of spherical silica particles with a particle size of 100 nm in 1 L of ethanol solution, and then add 5.4 g (0.3 mol) of H 2 O makes the concentration of water in the solution 0.3mol / L. Under the condition of stirring, 16.16g (0.0475mol) butyl titanate (TBOT) was added to the above solution within 5h, and 3.42g (0.19mol) H 2 O, keep the concentration of water in the solution at 0.3 mol / L, continue to stir the solution for 5 hours to complete the hydrolysis reaction of butyl titanate, and form composite nanoparticles (S-T) coated with titanium dioxide and silicon dioxide.

[0054] Add water and ammonia water to the above solution, so that the concentration of water and ammonia water in the solution reaches 5mol / L and 0.1mol / L respectively. After stirring evenly, 0.98g (0.0047mol) TEOS was added within 2h to coat the surface of the S-T composite nanoparticles with silica. After continuing to stir for 5 hours, centrifuge to obtain a white precipi...

Embodiment 3

[0057] Ultrasonically disperse 20 g of spherical silica particles with a particle size of 1000 nm in 1 L of ethylene glycol solution, and then add 7.2 g (0.4 mol) of H 2 O makes the concentration of water in the solution 0.4mol / L. While stirring, add 41.17g (0.121mol) butyl titanate (TBOT) to the above solution within 10h, and add 8.71g (0.484mol) H at the same time 2 O, keep the concentration of water in the solution at 0.4 mol / L, continue to stir the solution for 10 h to complete the hydrolysis reaction of butyl titanate, and form composite nanoparticles (S-T) coated with titanium dioxide and silicon dioxide.

[0058] Add water and ammoniacal liquor to above-mentioned solution, make the concentration of water and ammoniacal liquor in the solution reach 10mol / L and 0.2mol / L respectively. After stirring evenly, 5.43g (0.026mol) TEOS was added within 5h to coat the surface of the S-T composite nanoparticles with silica. After continuing to stir for 10 h, centrifuge to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com