Patents

Literature

31 results about "Epoxy nanocomposites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transparent epoxy nano composite material and its preparation method and use

InactiveCN101077923AOvercoming Light Scattering PhenomenonHigh light transmittanceOther chemical processesSilica particleUltraviolet

The present invention relates to one kind of transparent composite epoxy material and its preparation process and use. The transparent composite epoxy material has nanometer composite inorganic stuffing comprising nanometer silica particle serving as core, titania serving as shell coating the silica particle core and outer silica layer coating the titania shell. The transparent composite epoxy material possesses high transparency, excellent ultraviolet ray shielding effect, high ultraviolet ray tolerance, low heat expansion coefficient, high heat conductivity and other advantages, and is suitable for use in pacing LED and other light emitting semiconductor devices.

Owner:广东中科顺威新材料科技发展有限公司

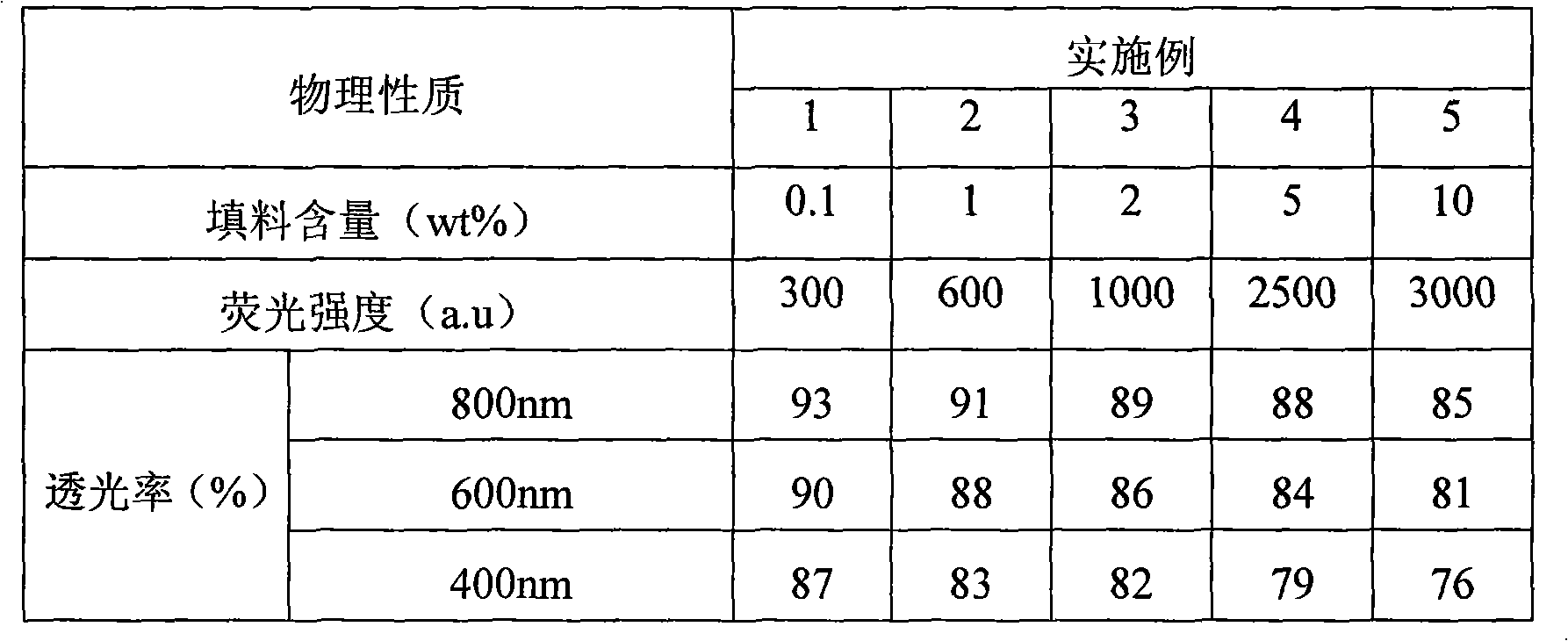

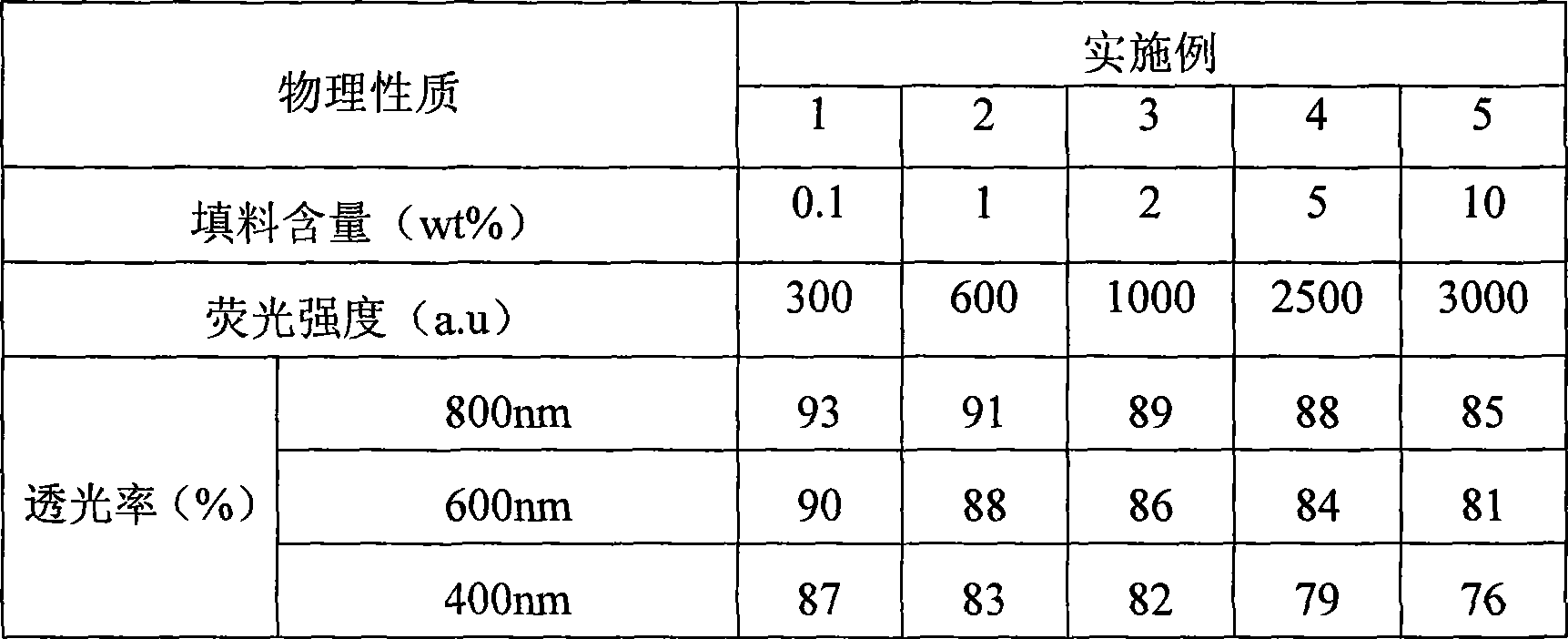

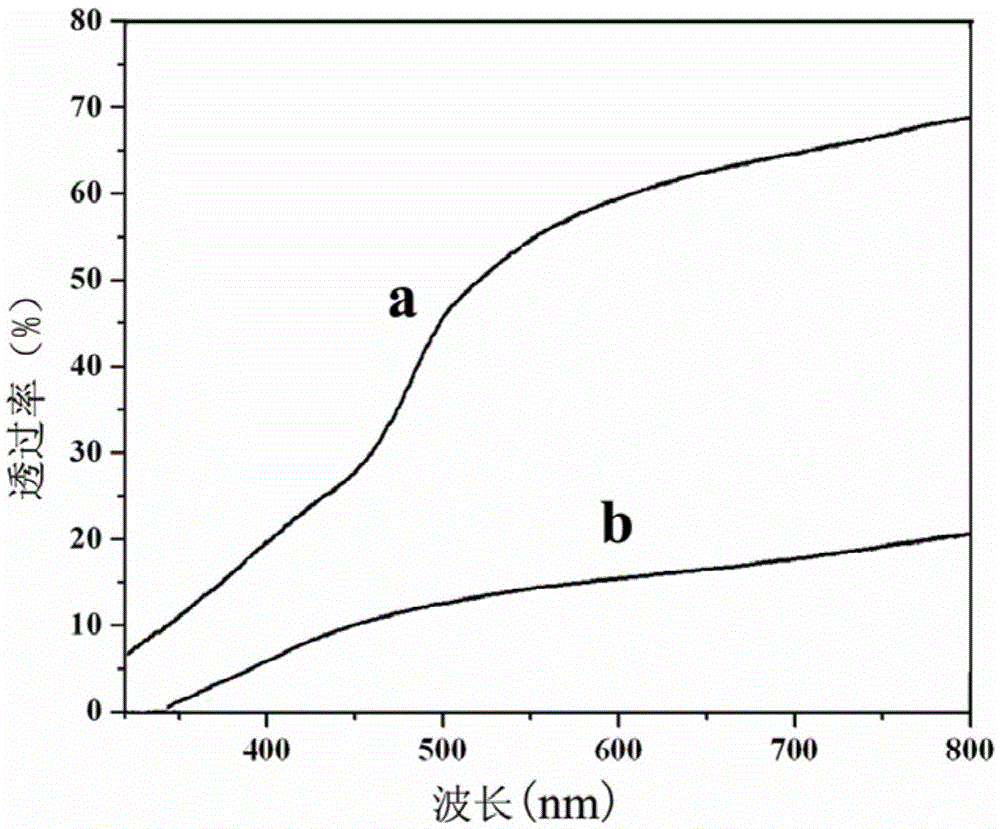

Photoluminescent transparent epoxy nanometer composite material, preparation method and application thereof

InactiveCN101338187APhotoluminescence achievedHigh light transmittanceLuminescent compositionsPhotoluminescenceHexahydrophthalic anhydride

The invention relates to a photoluminescence transparent epoxy nanometer composite material, a manufacturing method and the usage. The composite material comprises transparent epoxy resin matrix material and photoluminescence inorganic nanometer fillers uniformly dispersed in the epoxy resin matrix material; the transparent epoxy resin matrix material comprises epoxy resin and acid anhydrides epoxy curing agent. The epoxy resin is alicyclic epoxy resin, bisphenol A type epoxy resin or hydrogenated bisphenol A type epoxy resin. The acid anhydrides epoxy curing agent is methyl hexahydro-pthalic anhydride or hexahydrophthalic anhydride containing 1.0-5.0wt percent of curing accelerator. The curing accelerator is amine curing accelerator or imidazole curing accelerator. The composite material of the invention is provided with good transparency and photoluminescence, can be used for substituting the traditional sealing mode of phosphor adding packaging material and can be directly applied to the sealing of LED luminescence semiconductor devices, large outdoor neon lamps, etc.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

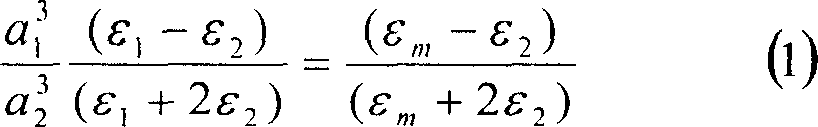

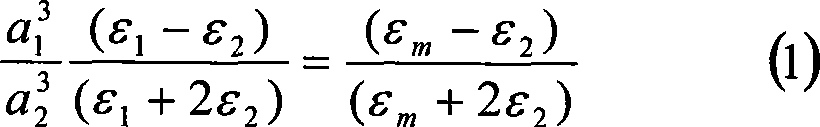

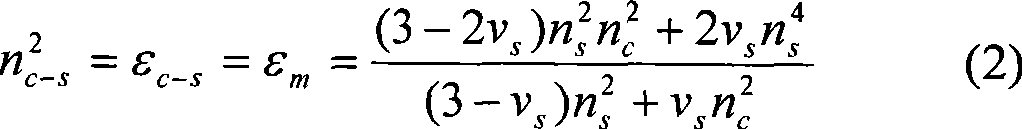

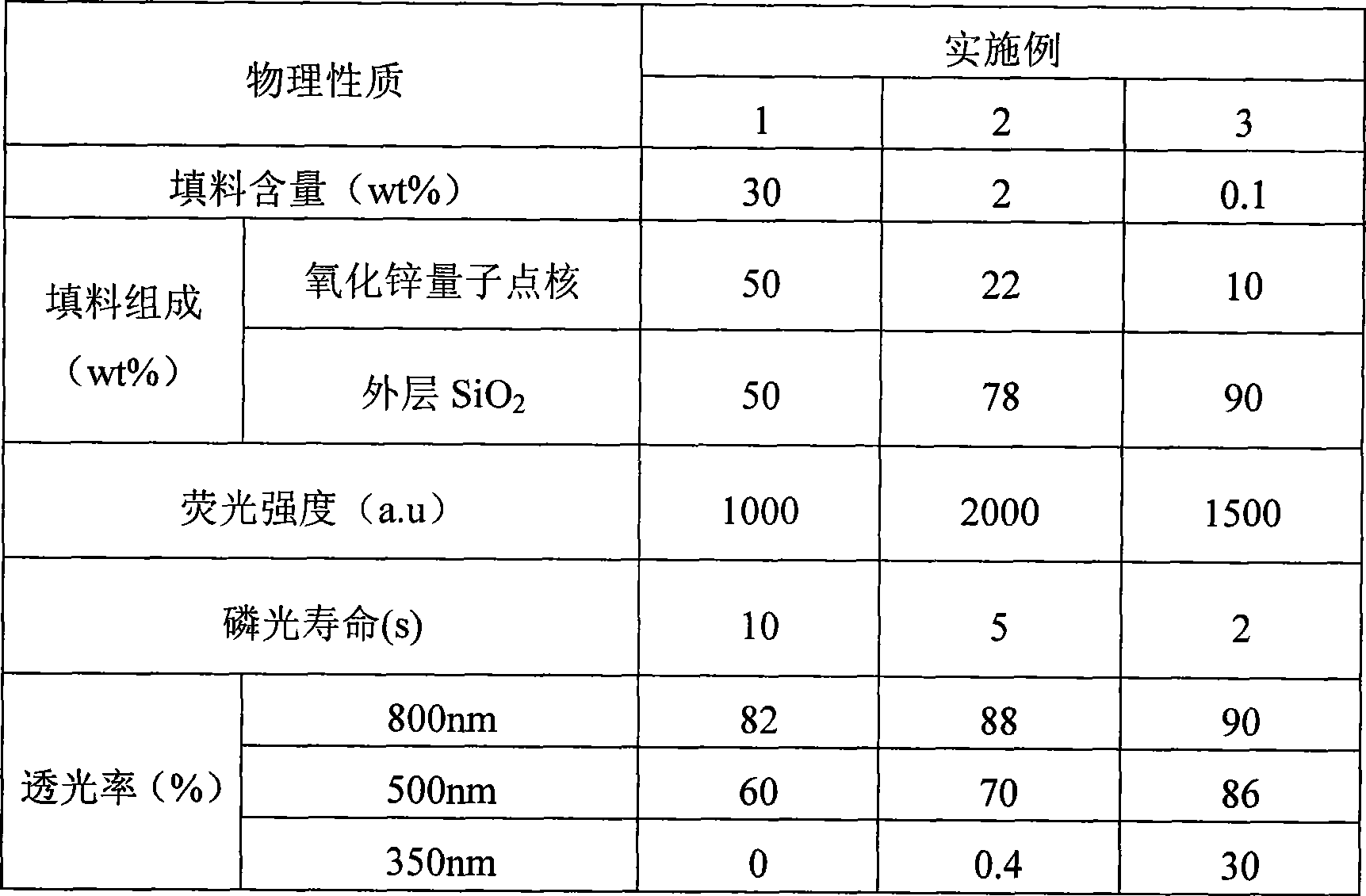

Transparent epoxy nanometer composite material, preparation method and application thereof

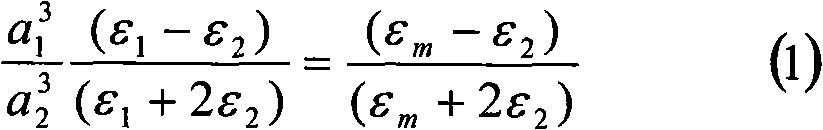

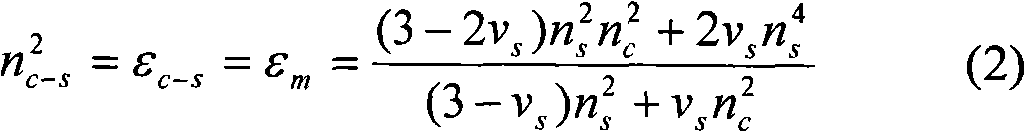

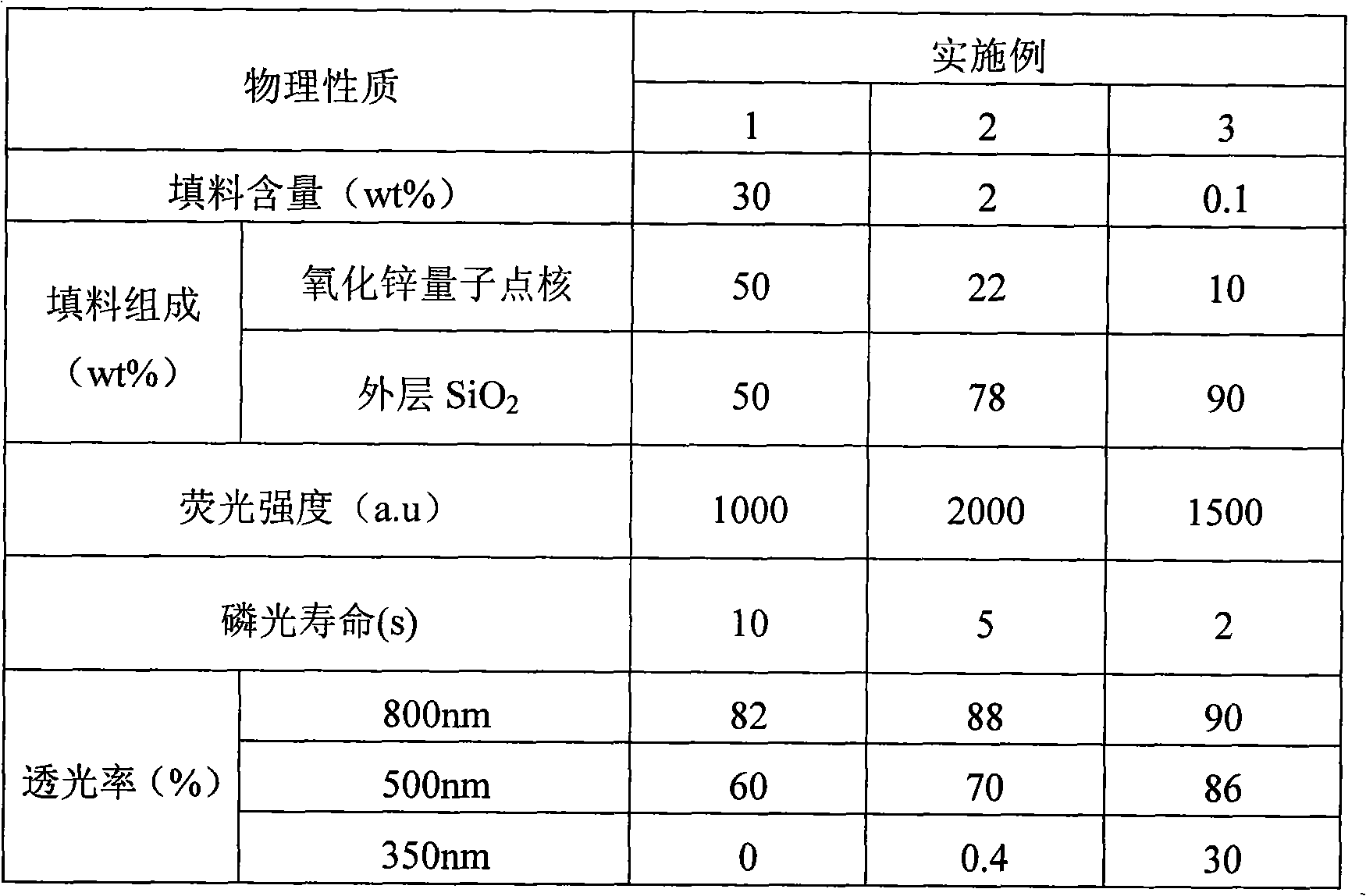

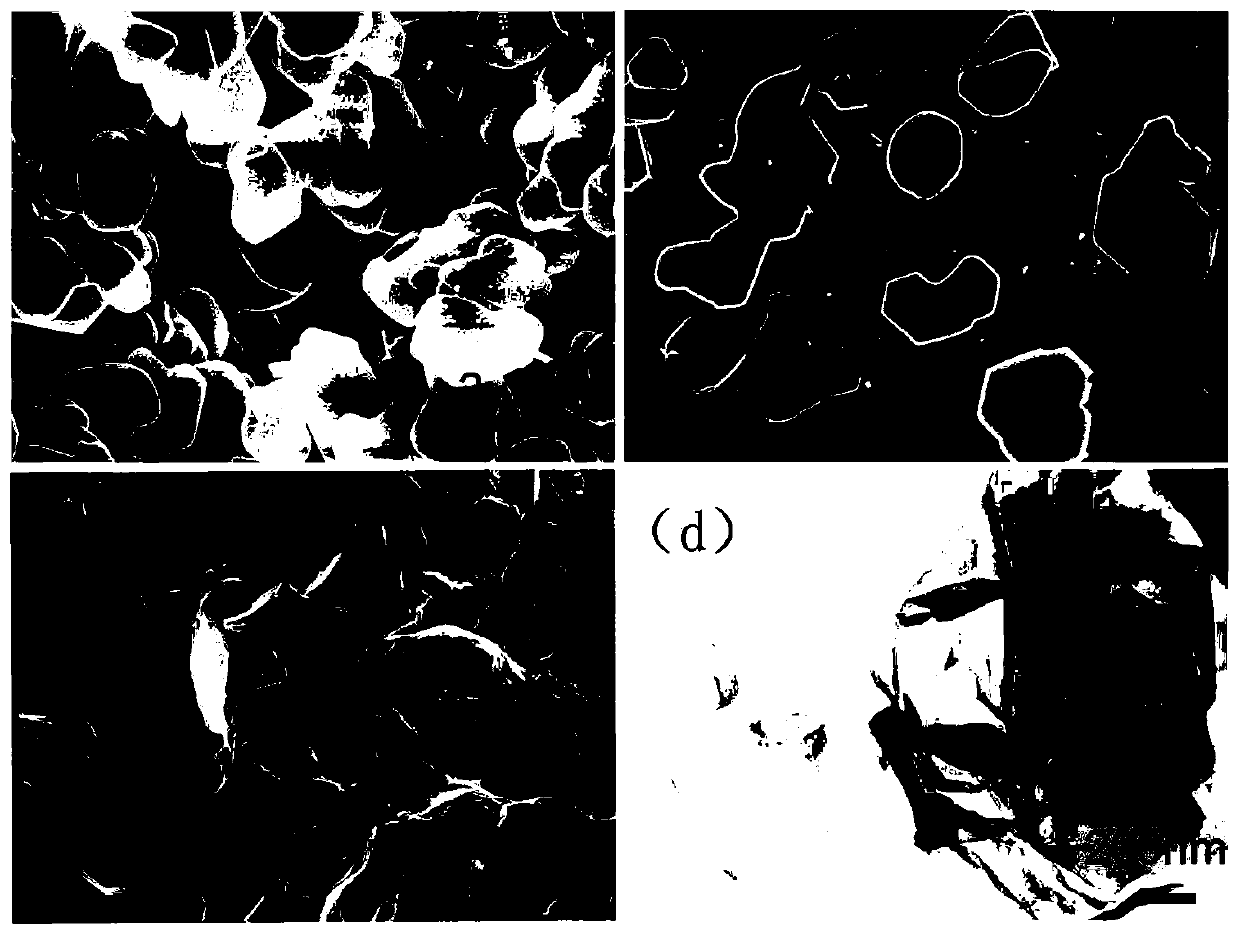

InactiveCN101338066AOvercoming Light Scattering PhenomenonHigh light transmittanceOther chemical processesResin matrixEpoxy nanocomposites

The invention relates to transparent epoxy nano composite material, and a preparation method and purposes thereof. The composite material comprises epoxy resin matrix material and composite nano inorganic filler which is evenly distributed in the epoxy resin matrix material; the composite nano inorganic filler consists of a zinc oxide quantum dot which is taken as a core and has grain size of 2nm to 10nm and a silicon dioxide outer layer which is taken as a shell and coated on the zinc oxide quantum dot; the epoxy resin matrix material consists of epoxy resin and epoxy curing agent; the epoxy resin is bisphenol-A epoxy resin or hydrogenated bisphenol-A epoxy resin; the epoxy curing agent is estolide curing agent which contains 1.0 weight percent to 5.0 weight percent of curing accelerator; the curing accelerator is amine curing accelerator or imidazole curing accelerator. The transparent epoxy nano composite material of the invention has excellent transparency, good fluorescence and phosphorescence effect compared with common pure transparent epoxy, and can replace traditional fluorescent powder. The invention is applicable in packaging LED and other luminescent semiconductor devices.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

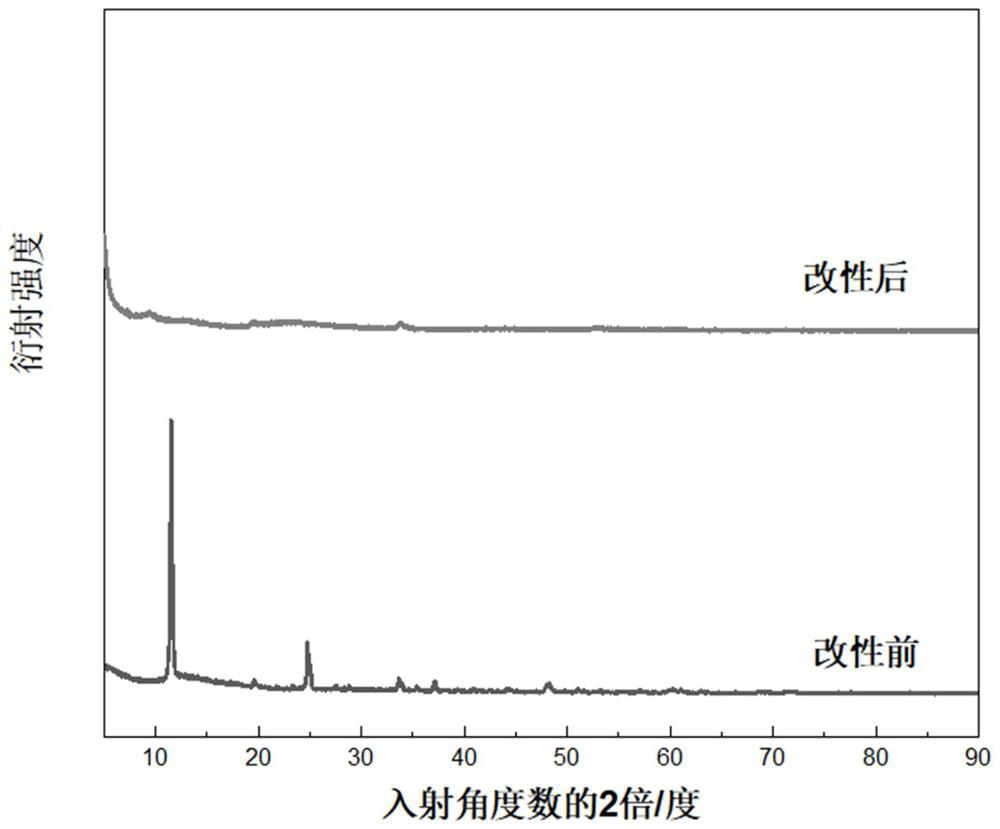

Modified zirconium phosphate-epoxy nanometer composite material and preparation method thereof

ActiveCN110591294AImprove mechanical propertiesImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxy nanocompositesSolvent

The invention discloses a modified zirconium phosphate-epoxy nanometer composite material and a preparation method thereof. The preparation method comprises the following steps: mixing an intercalation agent, a surfactant and a solvent, adding layered zirconium phosphate, oscillating uniformly and ultrasonically dispersing to obtain a single-layer zirconium phosphate solution after stripping; adopting a stripping agent to adjust the pH of the single-layer zirconium phosphate solution, centrifuging, washing and discarding supernatant liquid; adding zirconium phosphate and a modifier into the solvent, performing stirring reaction at the temperature of 80 to 100 DEG C for 12 to 24 hours, washing and drying to obtain modified zirconium phosphate; dispersing the zirconium phosphate with the solvent, mixing with an ethanol solution of a curing agent, adding epoxy resin and stirring uniformly to obtain the modified zirconium phosphate-epoxy nanometer composite material. Compared with the epoxy resin, the modified zirconium phosphate-epoxy nanometer composite material significantly improves the mechanical property and the anti-corrosion property.

Owner:SOUTH CHINA UNIV OF TECH

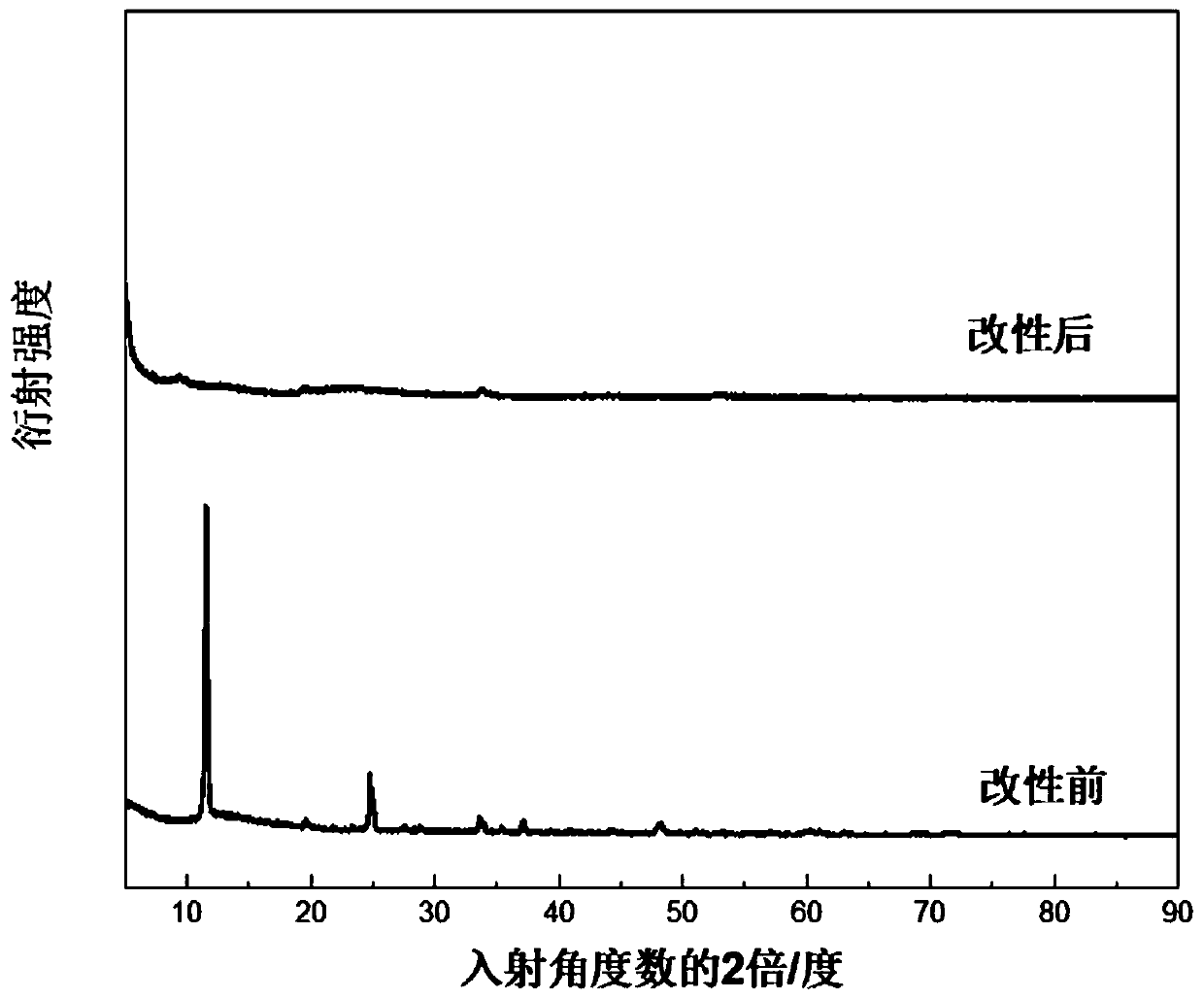

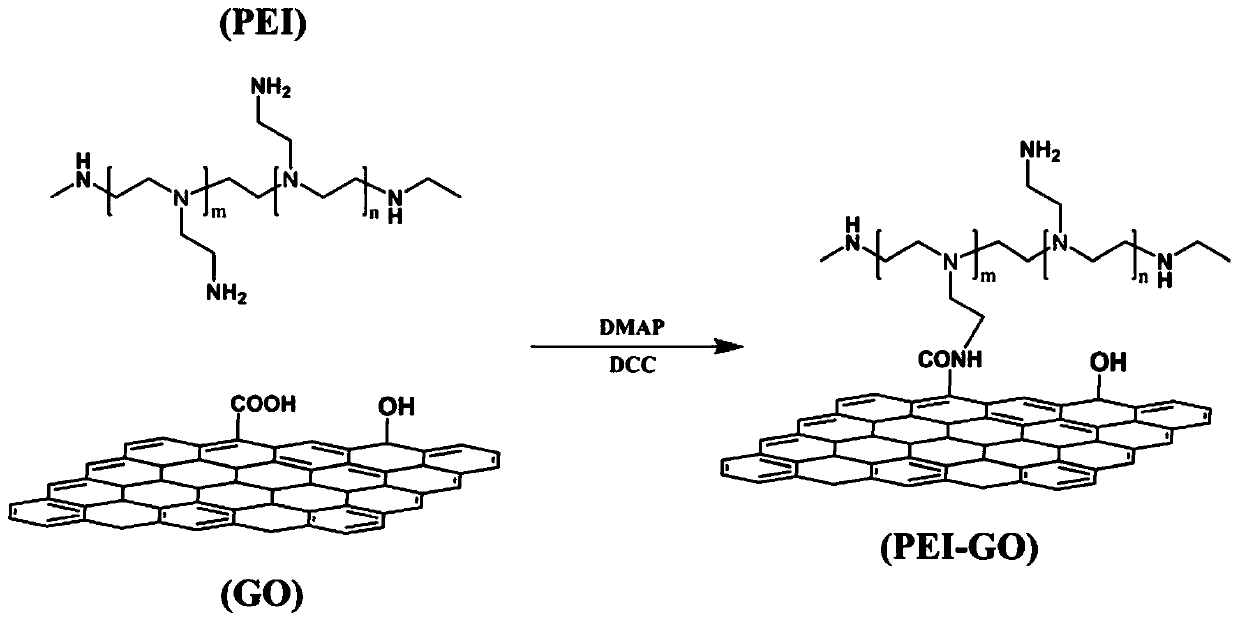

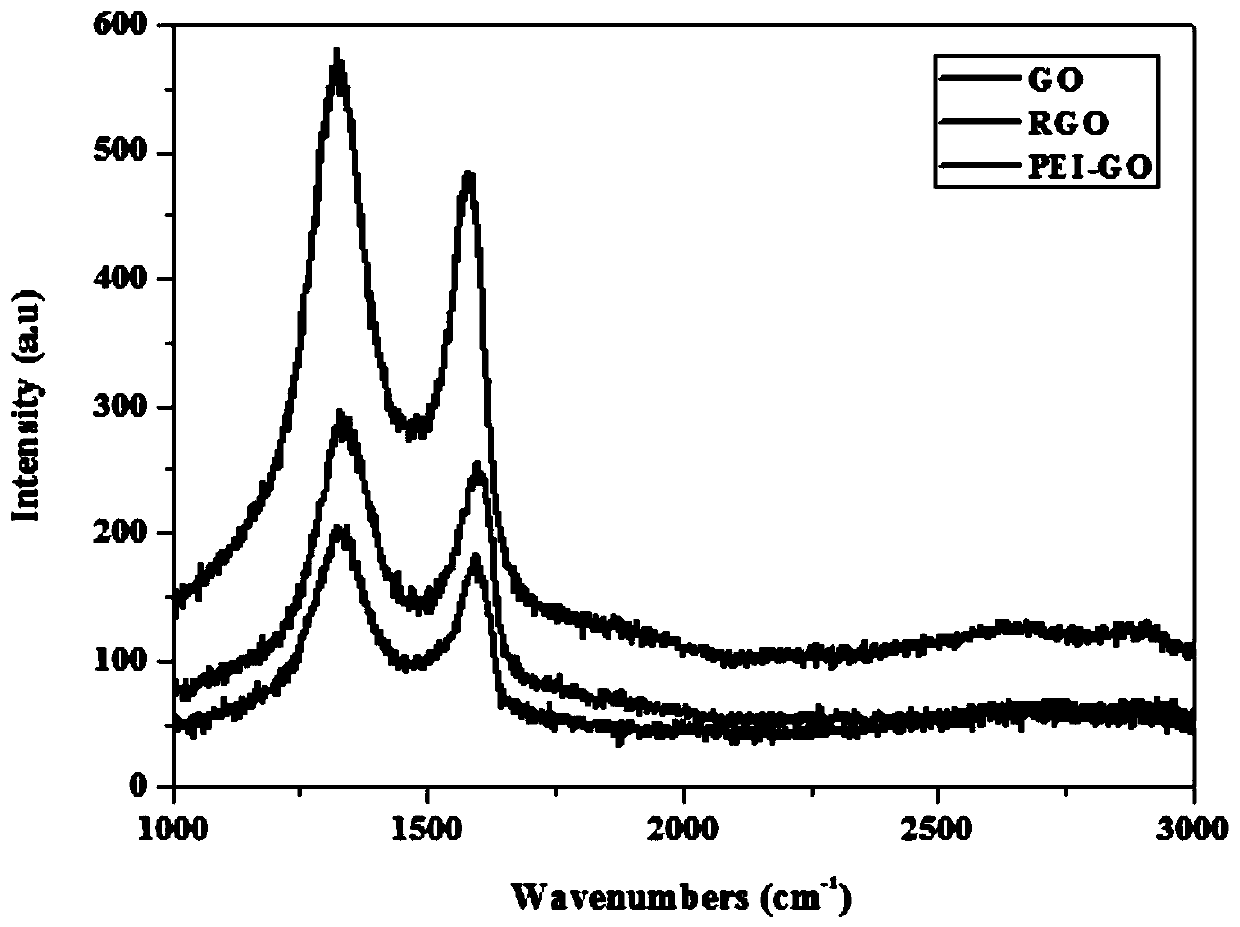

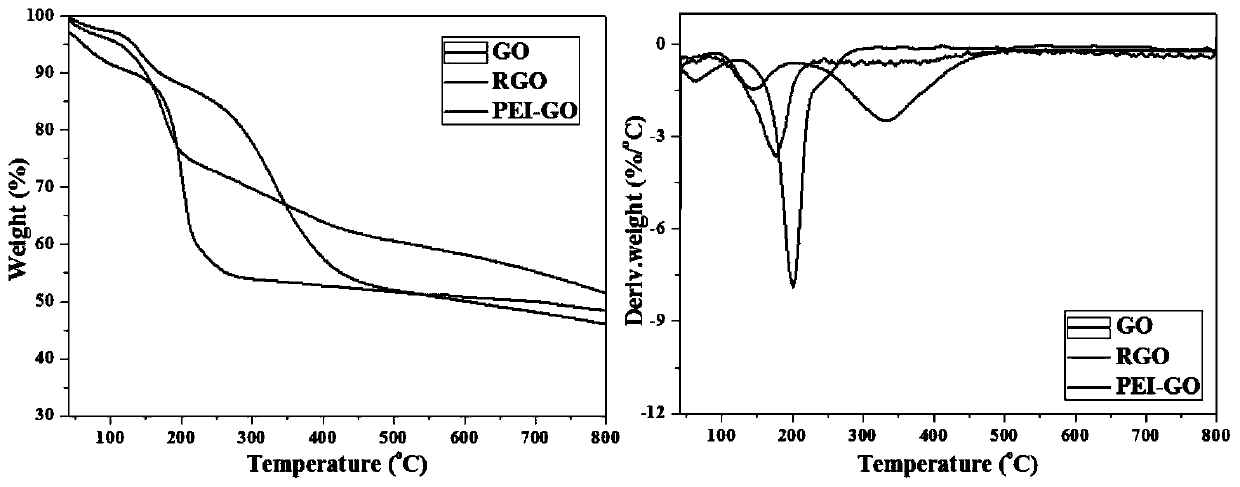

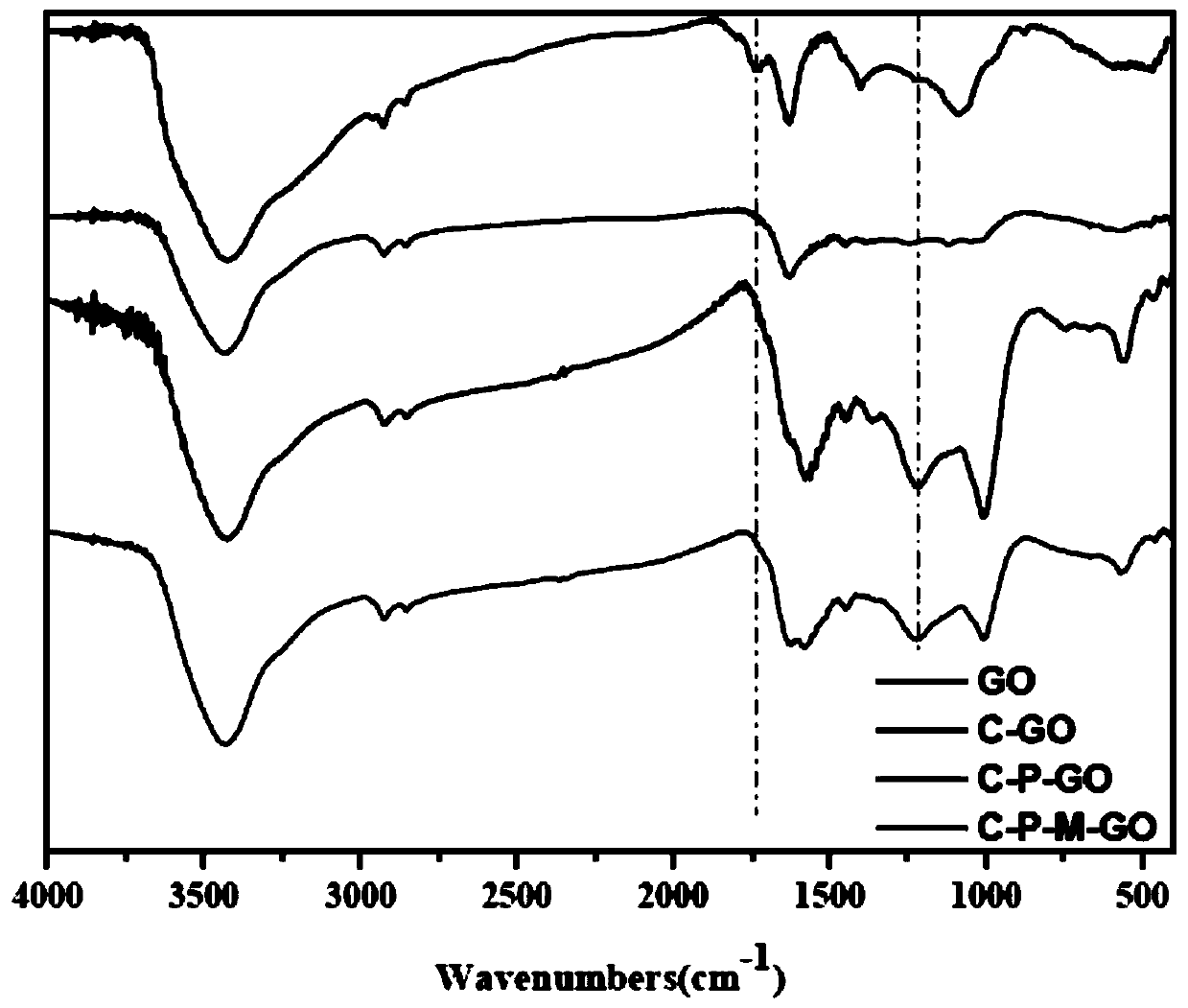

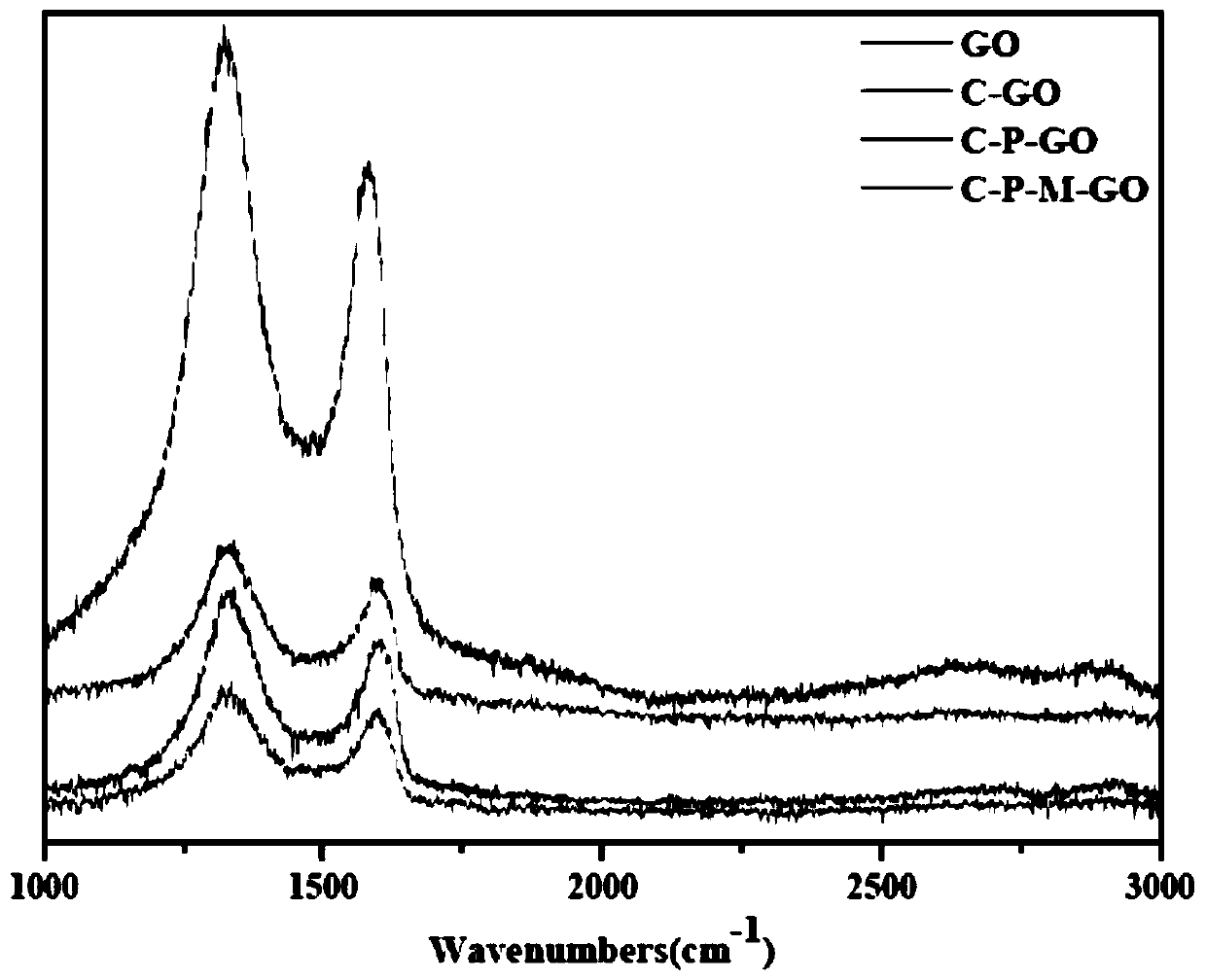

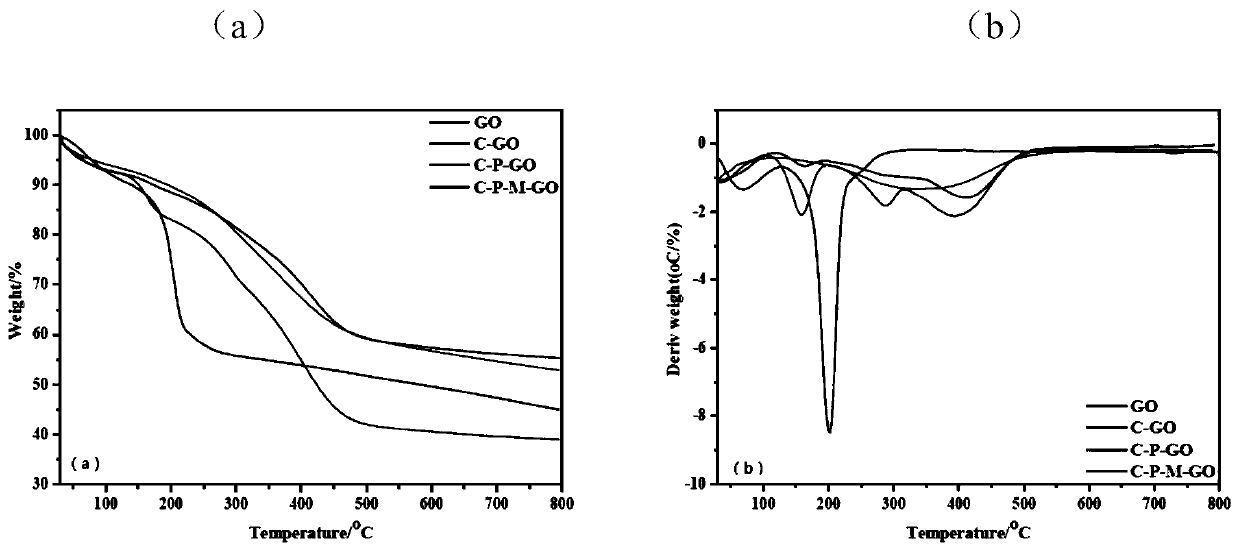

Polyethylenimine modified graphene oxide and epoxy nano composite material thereof

PendingCN109929141AImprove mechanical propertiesImproves toughness and tensile strengthPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsEpoxy nanocompositesMechanical property

The invention provides polyethyleneimine modified graphene oxide PEI-GO which is obtained by replacing-OH groups of carboxyl groups on the surface of graphene oxide with A groups. Polyethyleneimine modified graphene oxide / epoxy nano composite PEI-GO / EP is further prepared. The polyethyleneimine modified graphene oxide prepared by the method can greatly improve the mechanical properties of the epoxy nano composite material under a low addition dose, and has a good application prospect.

Owner:SICHUAN UNIV

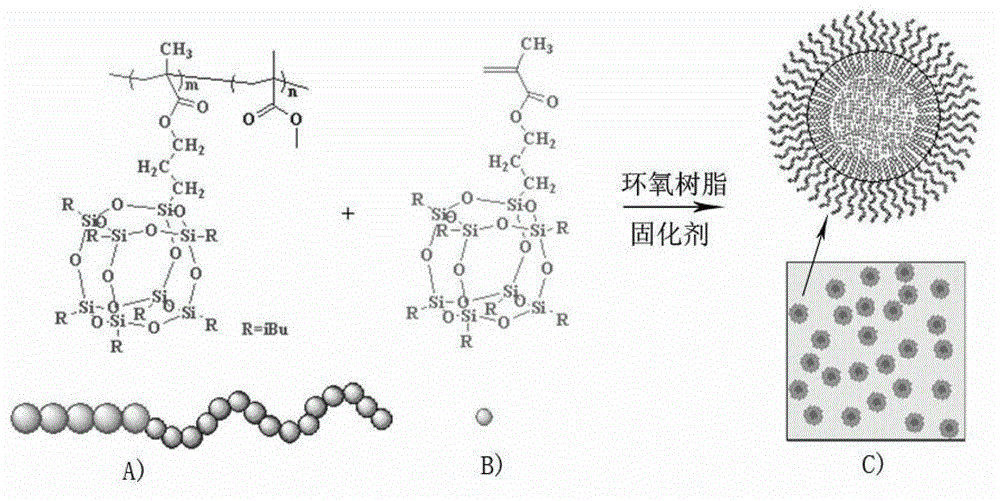

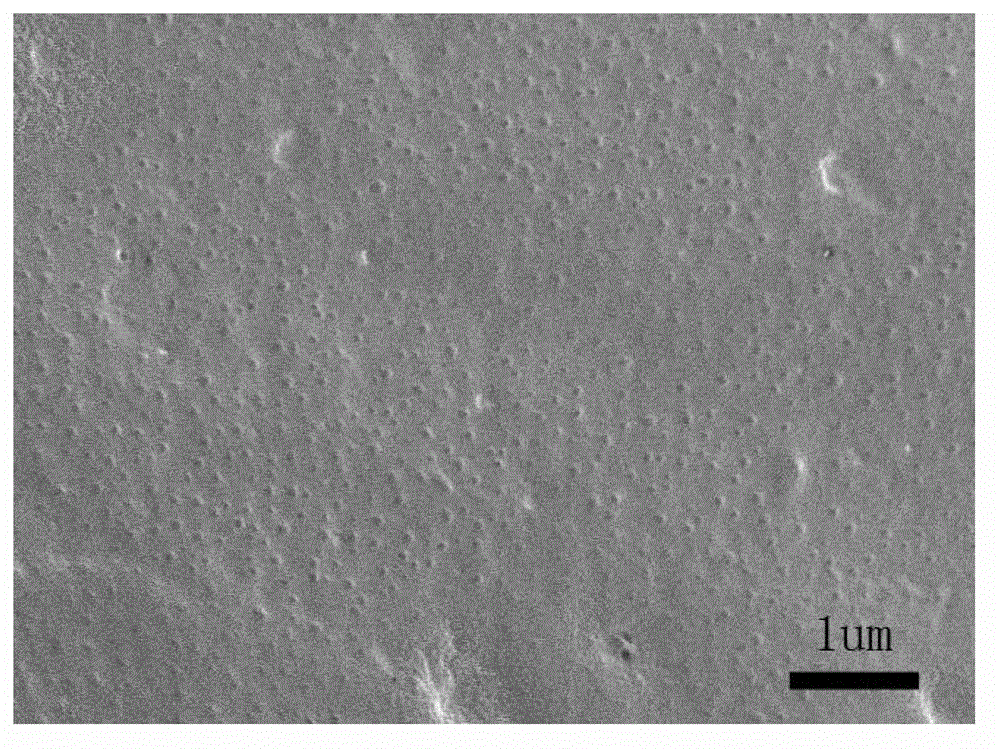

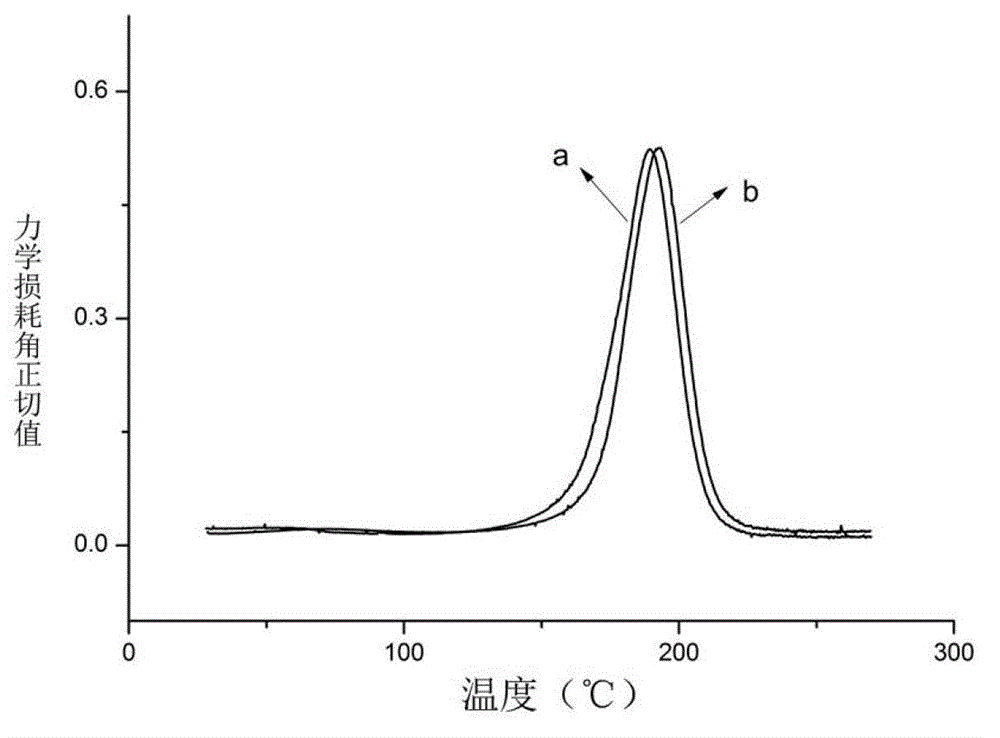

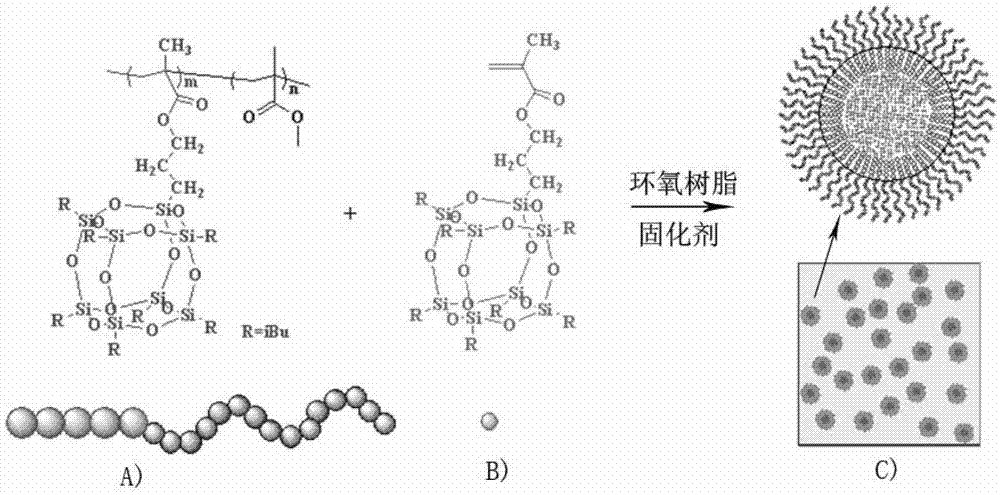

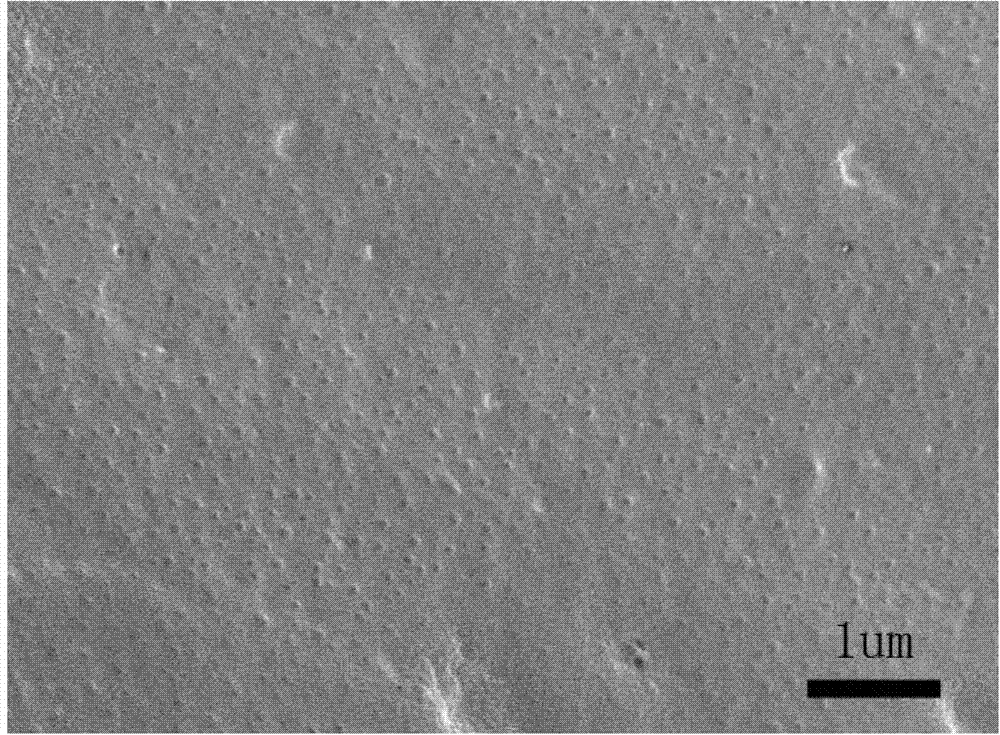

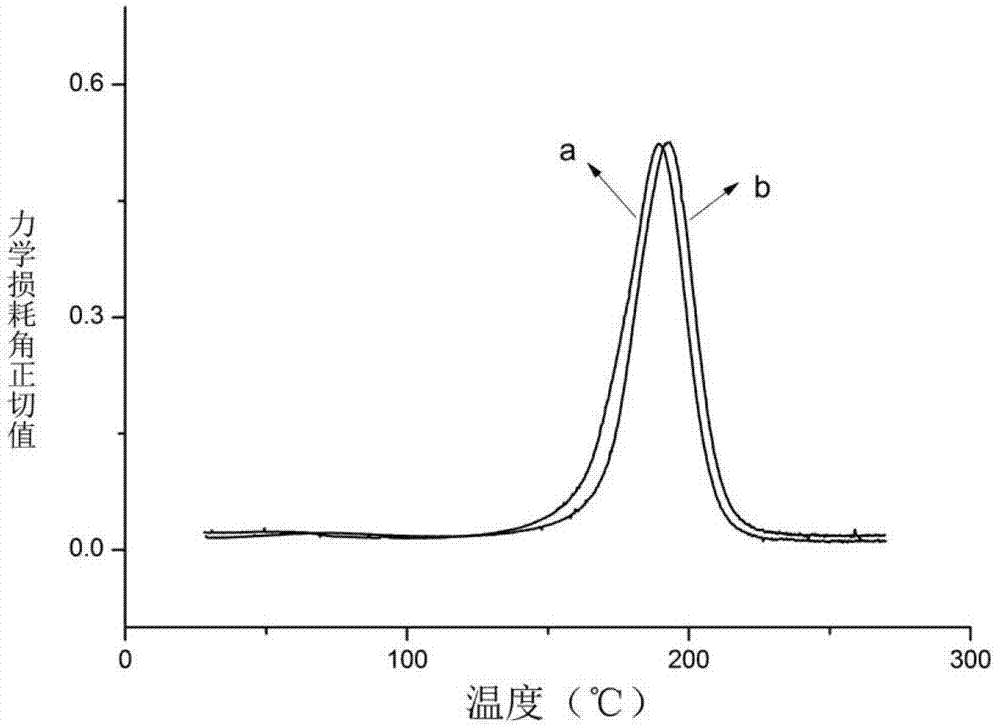

Epoxy nanocomposite with controllable phase structure and based on polyhedral oligomeric silsesquioxanes (POSS)

The invention discloses an epoxy nanocomposite based on polyhedral oligomeric silsesquioxanes (POSS) and a preparation method of the epoxy nanocomposite based on the POSS and relates to the epoxy nanocomposite with a controllable phase structure capable of improving effect and based on the POSS. The preparation method includes the following steps of allocating a POSS monomer, a chain transfer agent and an initiating agent in a solution according to the measuring amount through a reversible addition-fragmentation chain transfer (RAFT) method, conducting freeze thaw and degassing through liquid nitrogen, charging argon shield to enable the mixture to react, and obtaining PMAiBuPOSS; further allocating PMAiBuPOSS, Methl Methacrylate monomer (MMA) and an initiating agent in a solution, and obtaining POSS base block copolymer , namely, PMAiBuPOSS-b-PMMA, through the RAFT; conducting melt blending on the POSS monomer, epoxy resin, the prepared POSS base block copolymer to obtain blend precursor of the POSS and the epoxy, adding in a curing agent, fully stirring, dissolving the mixture the curing agent, pouring the blend into a die, conducting temperature programming and curing, and obtaining the nanocomposite with the controllable phase structure and based on the POSS.

Owner:XIAMEN UNIV

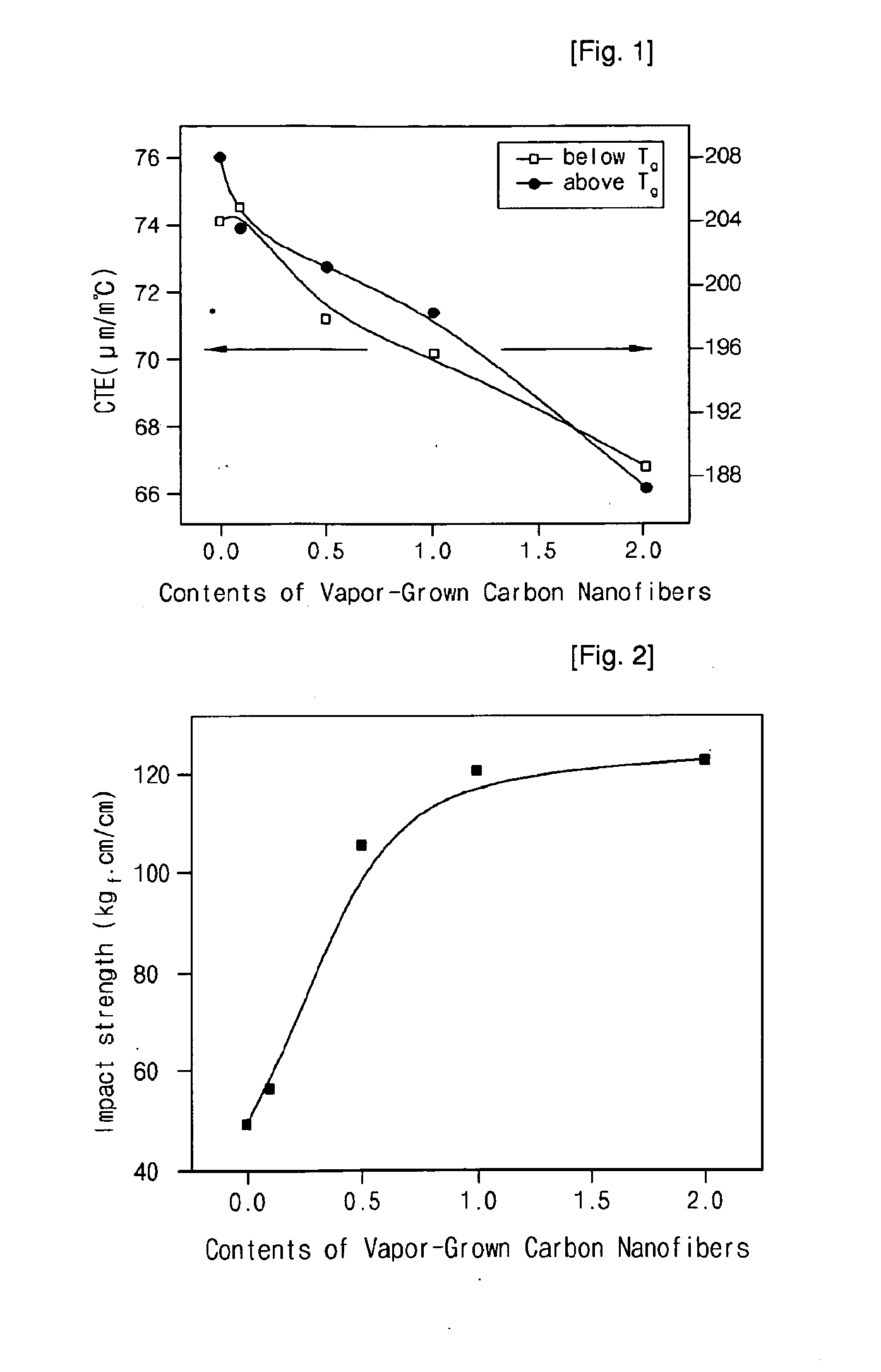

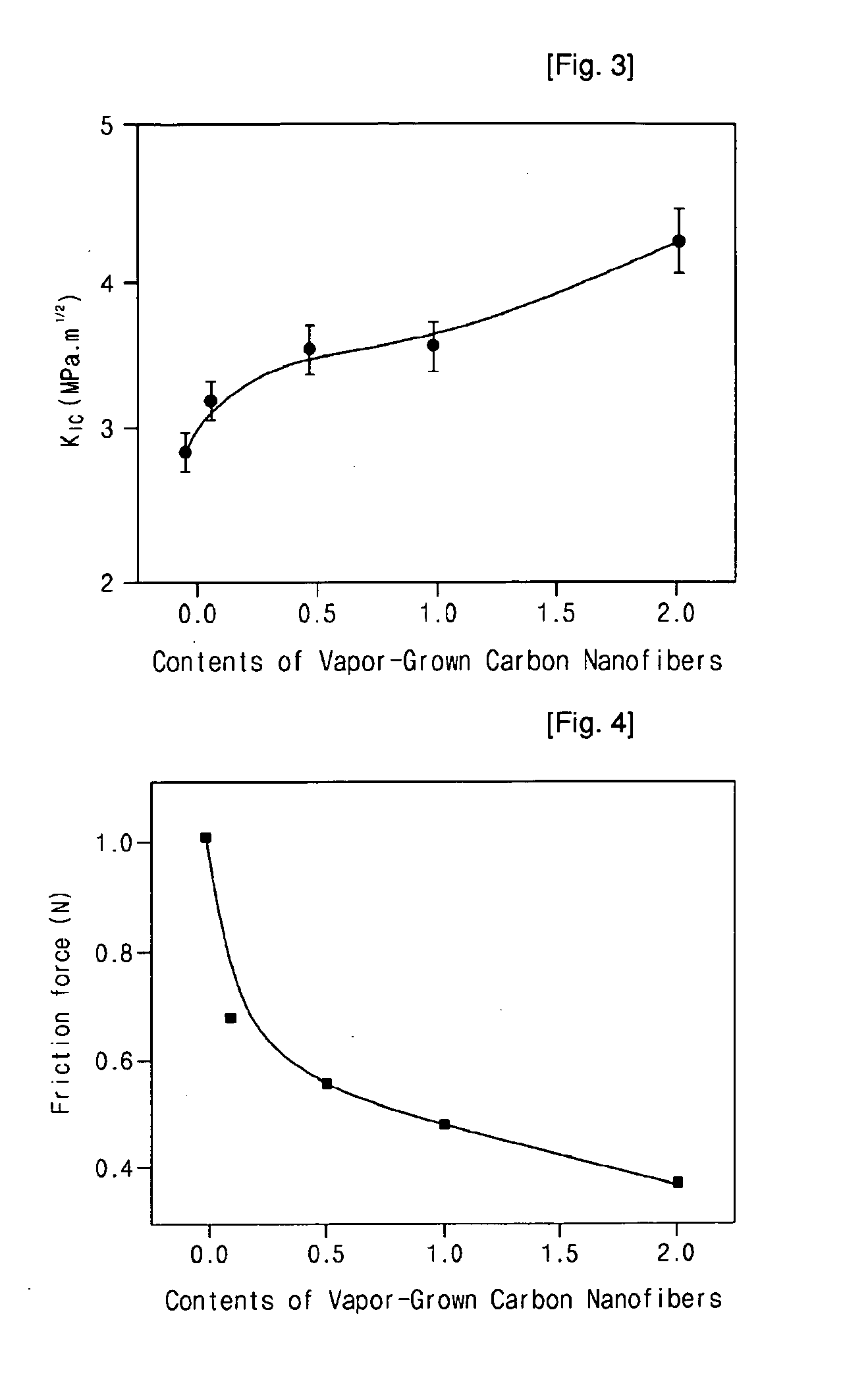

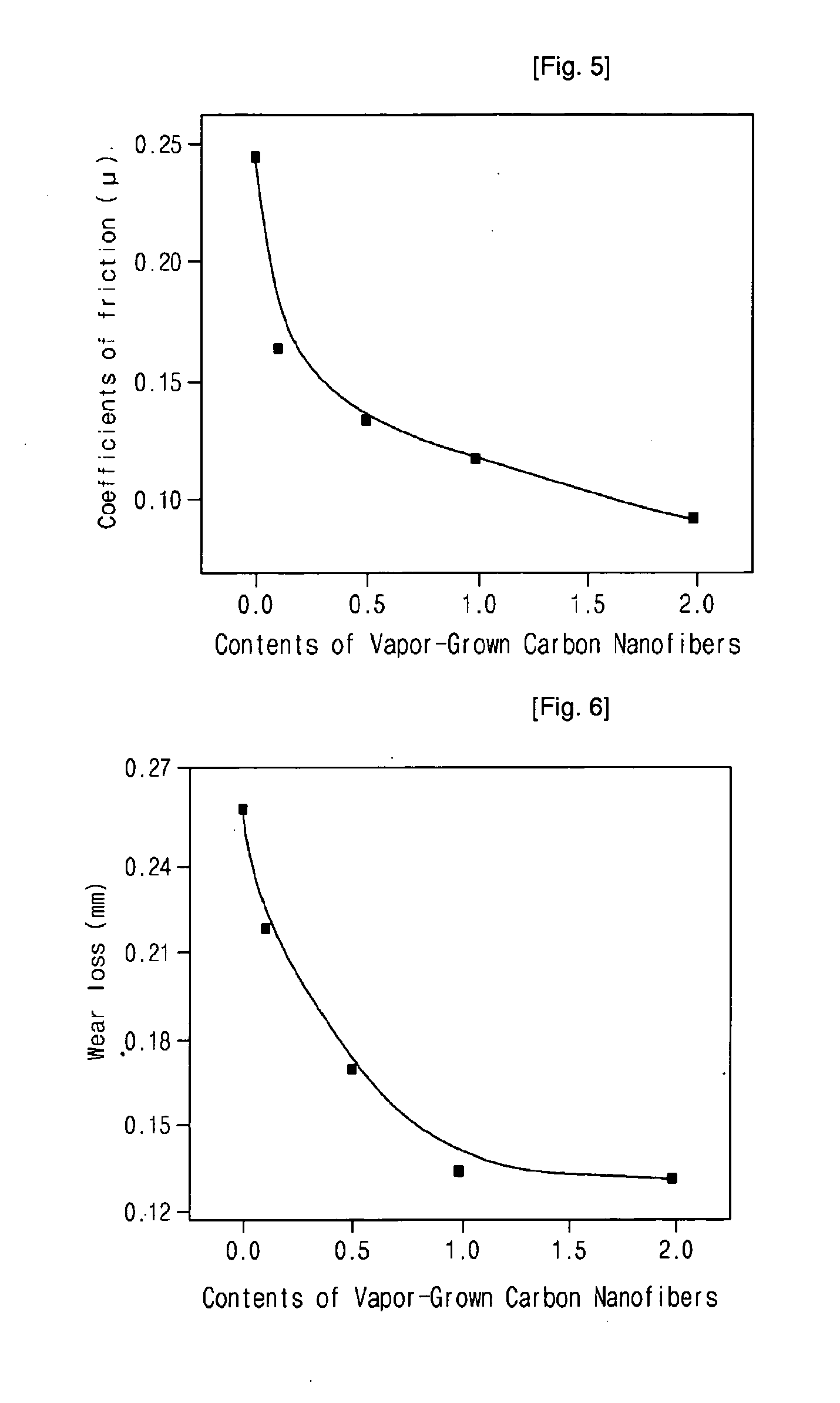

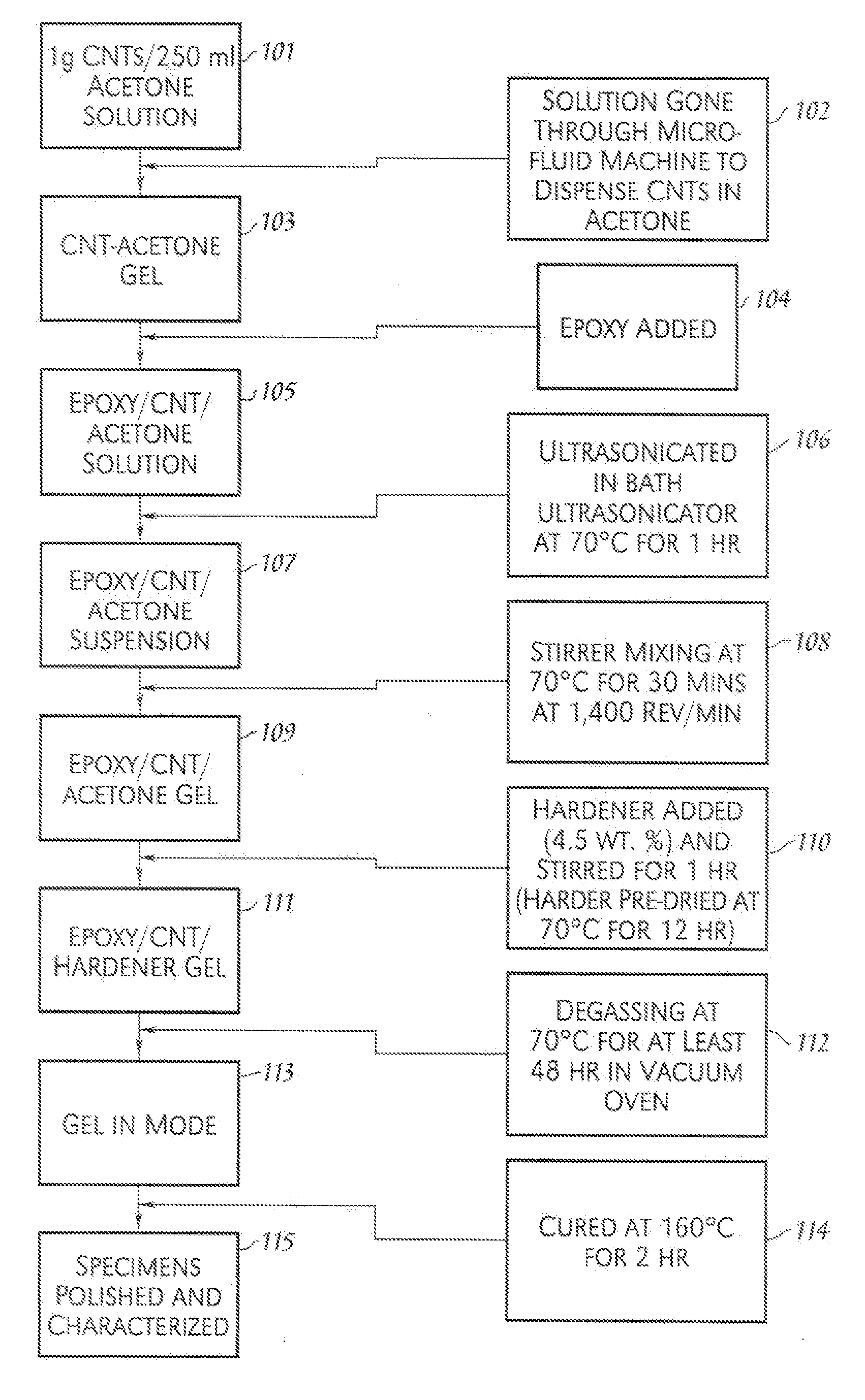

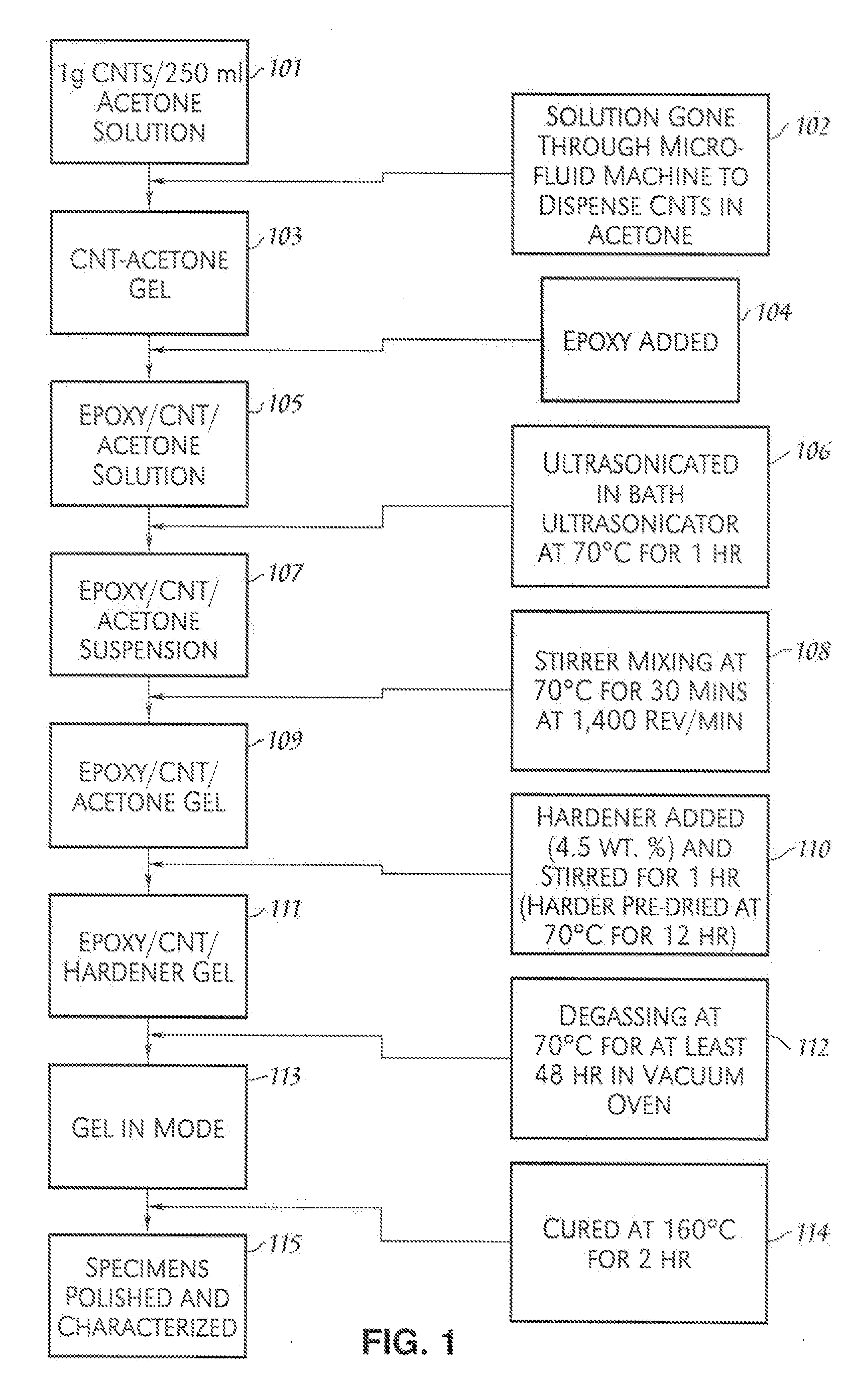

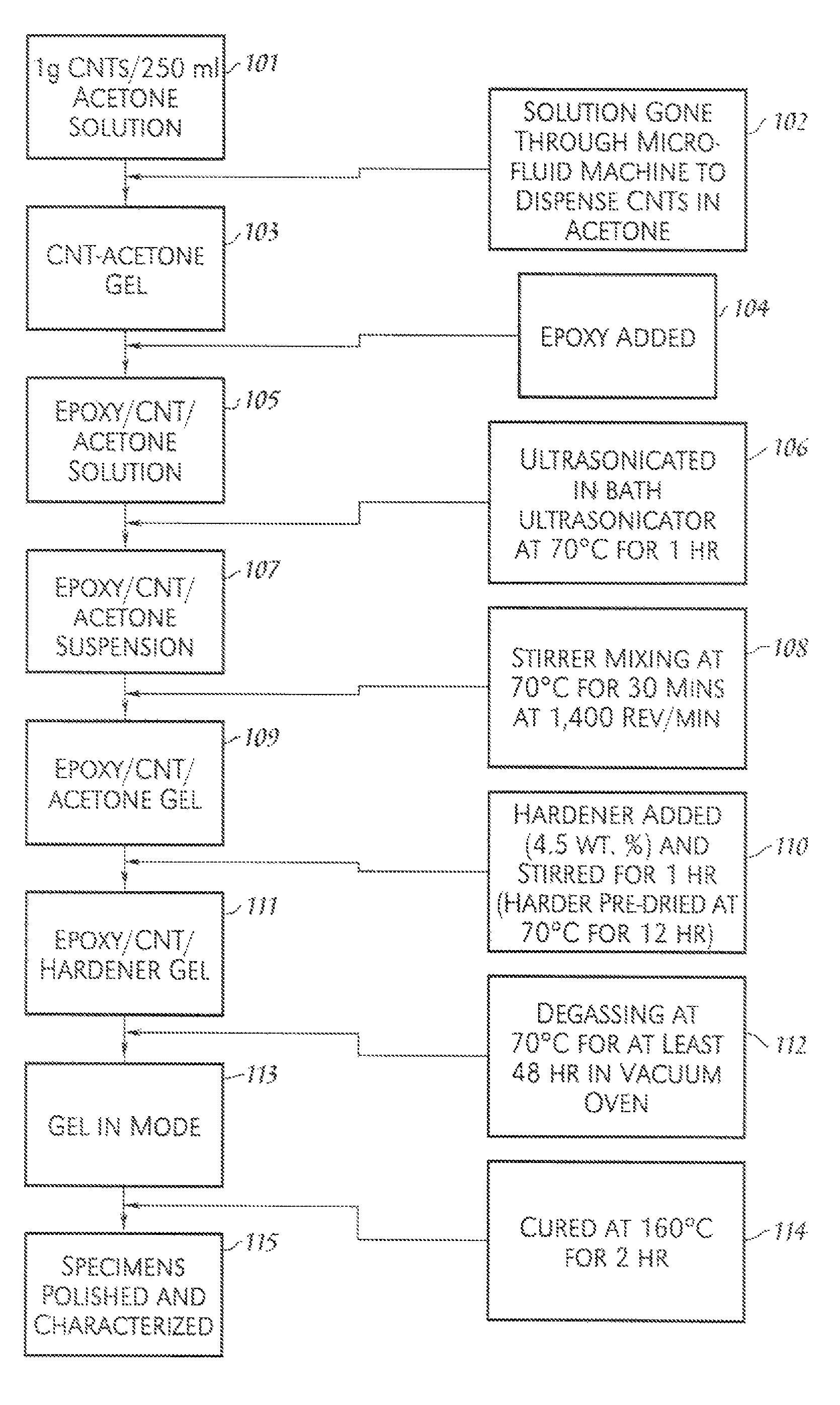

Method for manufacturing epoxy nanocomposite material containing vapor-grown carbon nanofibers and its products thereby

InactiveUS20100130646A1Good dispersionImprove thermal performancePrinted circuitsCost effectivenessRoom temperature

Disclosed is a method for producing an epoxy nanocomposite material containing vapor-grown carbon nanofibers and an epoxy nanocomposite material produced thereby. The method comprises physically mixing 0.1-5.0 parts by weight of vapor-grown carbon nanofibers as reinforcing materials with 100 parts by weight of an epoxy matrix resin to disperse the carbon nanofibers in the epoxy matrix resin, adding a curing agent to the mixture, and curing the mixture. According to the disclosed method, the vapor-grown carbon nanofibers are physically mixed with an epoxy matrix resin without using any solvent. Thus, the vapor-grown carbon nanofibers are sufficiently dispersed in the epoxy matrix resin compared to the case of using a solvent. Therefore, it is possible to produce an epoxy nanocomposite material having excellent mechanical strength and low friction / wear properties at room temperature and excellent thermal properties even at high temperature. Also, the vapor-grown carbon nanofibers are cost-effective and, at the same time, used in an amount smaller than the amount of carbon nanotubes used to improve the physical properties of epoxy resin in the prior art, thus effectively reducing the production cost of the nanocomposite material.

Owner:KOREA RES INST OF CHEM TECH

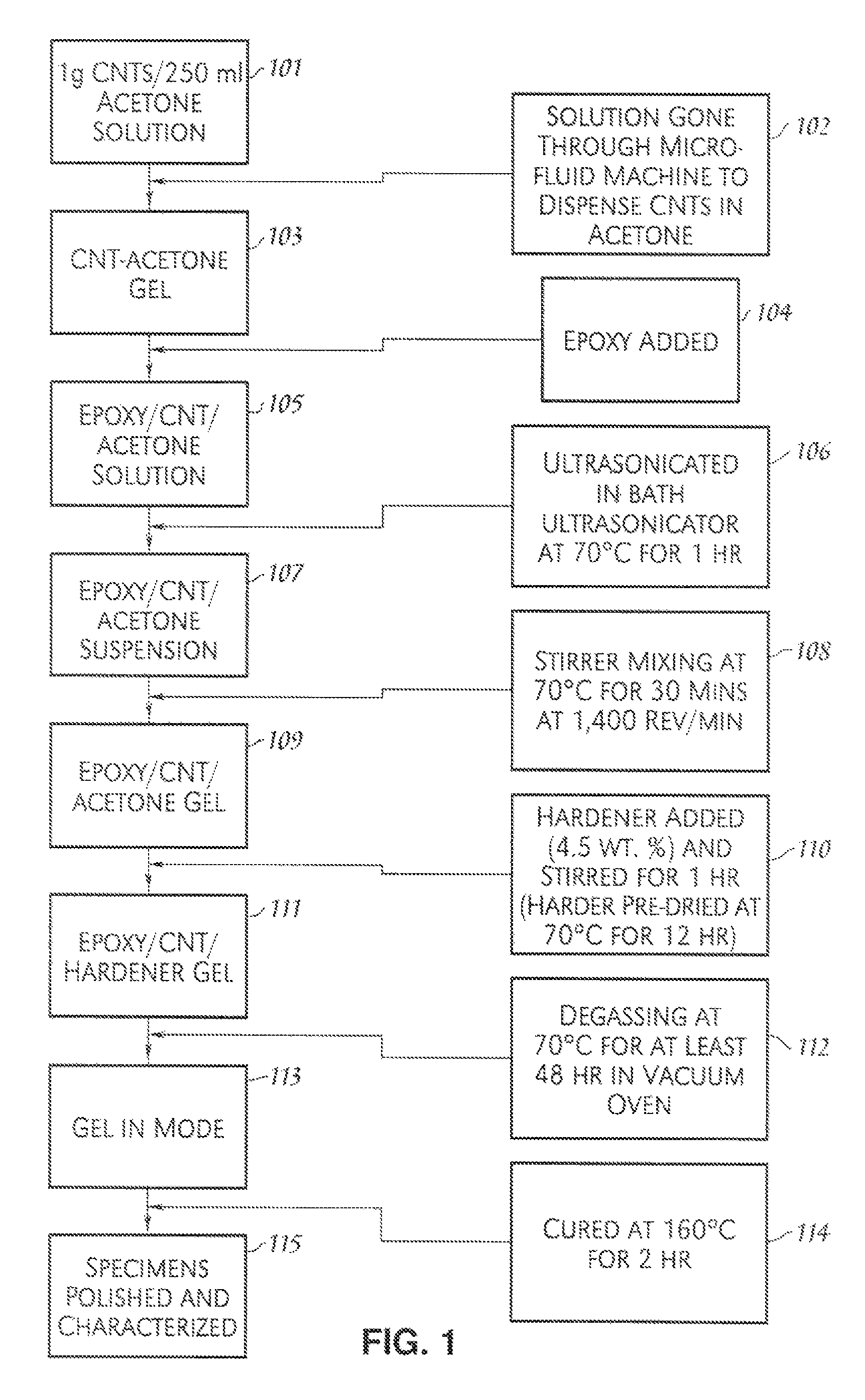

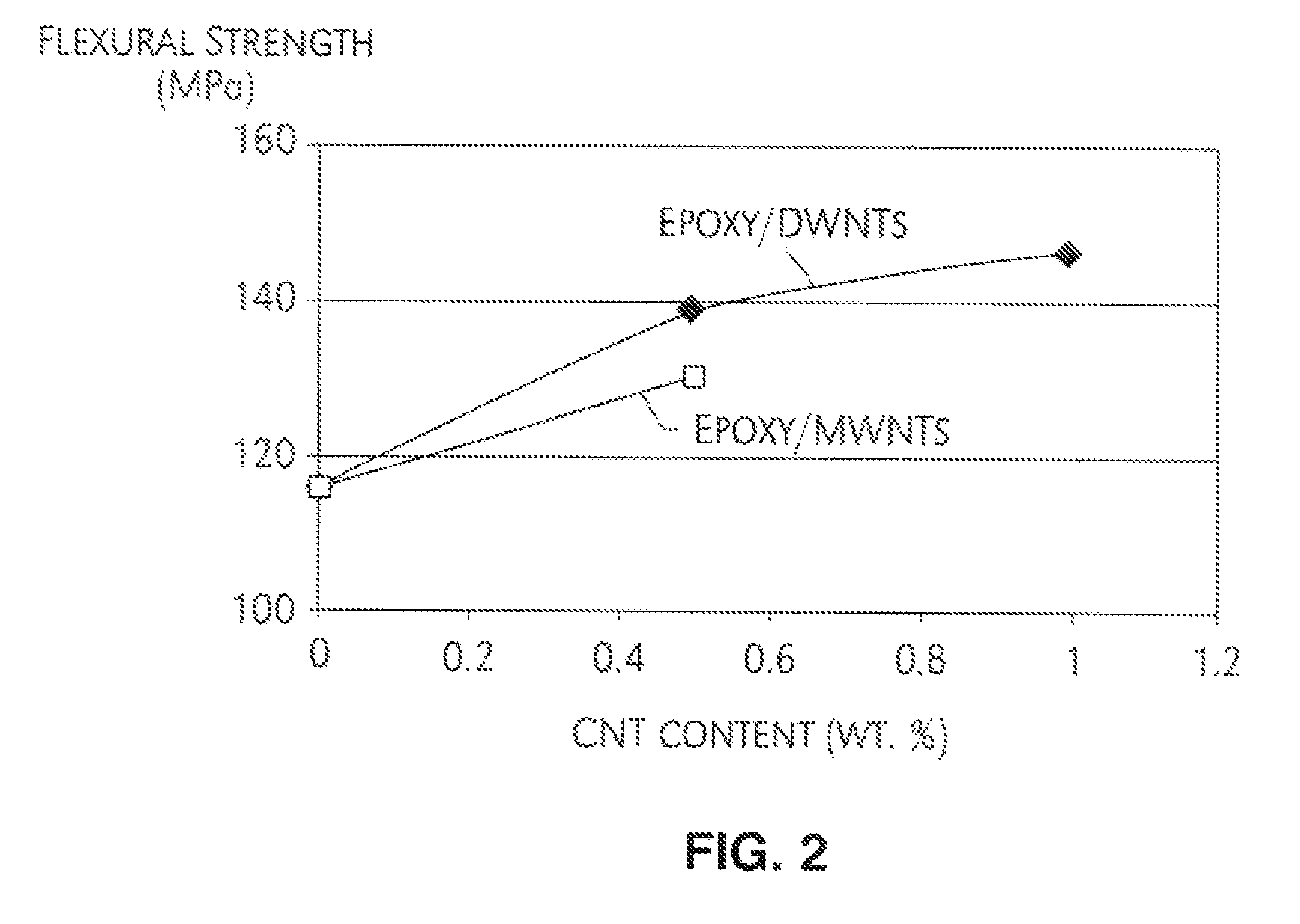

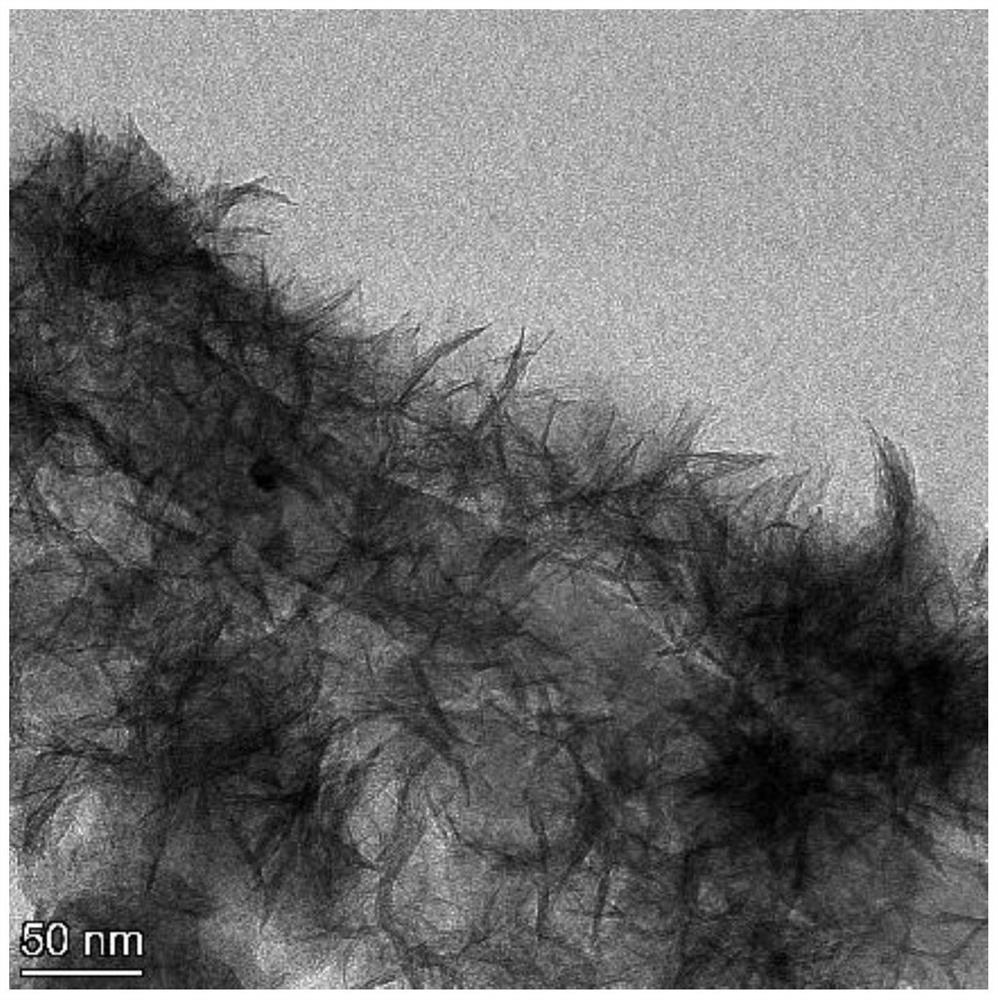

Carbon Nanotube-Reinforced Nanocomposites

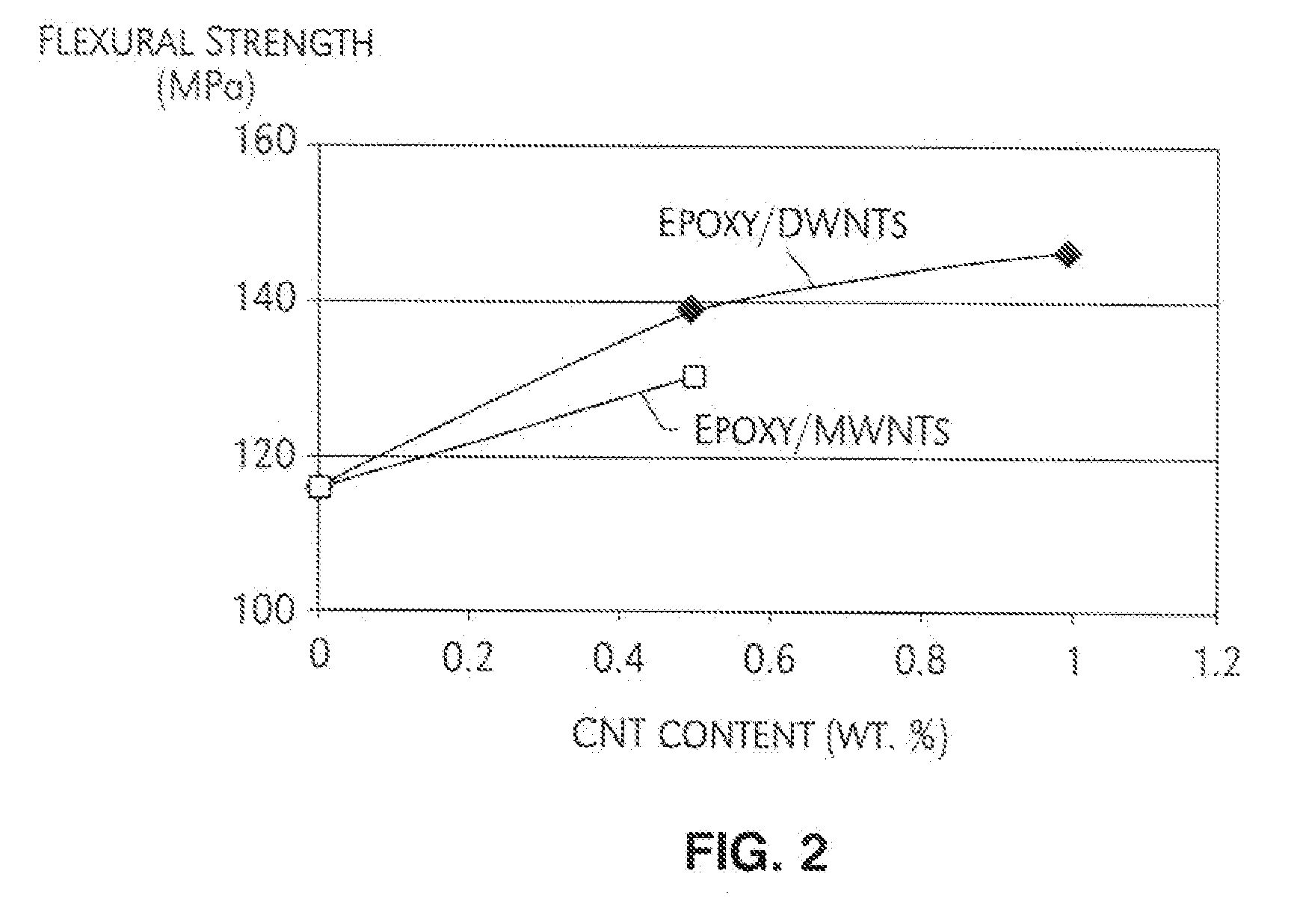

InactiveUS20080300357A1Individual molecule manipulationSynthetic resin layered productsFlexural modulusEpoxy nanocomposites

A combination of MWNTs (herein, MWNTs have more than 2 walls) and DWNTs significantly improves the mechanical properties of polymer nanocomposites. A small amount of DWNTs reinforcement (<1 wt. %) significantly improves the flexural strength of epoxy matrix nanocomposites. A same or similar amount of MWNTs reinforcement significantly improves the flexural modulus (stiffness) of epoxy matrix nanocomposites. Both flexural strength and flexural modulus of the MWNTs and DWNTs-coreinforced epoxy nanocomposites are further improved compared with same amount of either DWNTs or MWNTs-reinforced epoxy nanocomposites. In this epoxy / DWNTs / MWNTs nanocomposite system, SWNTs may also work instead of DWNTs. Besides epoxy, other thermoset polymers may also work.

Owner:NANO

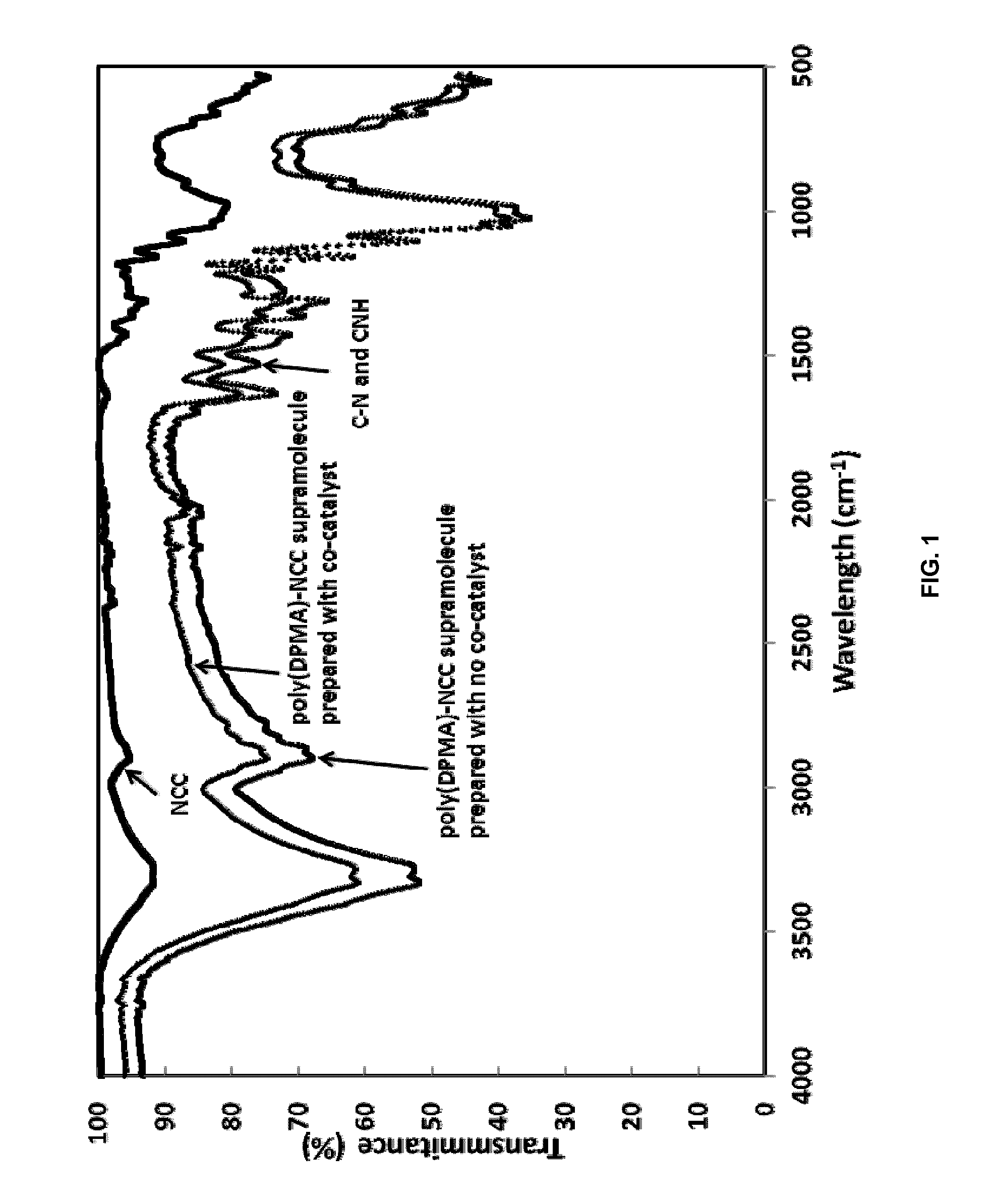

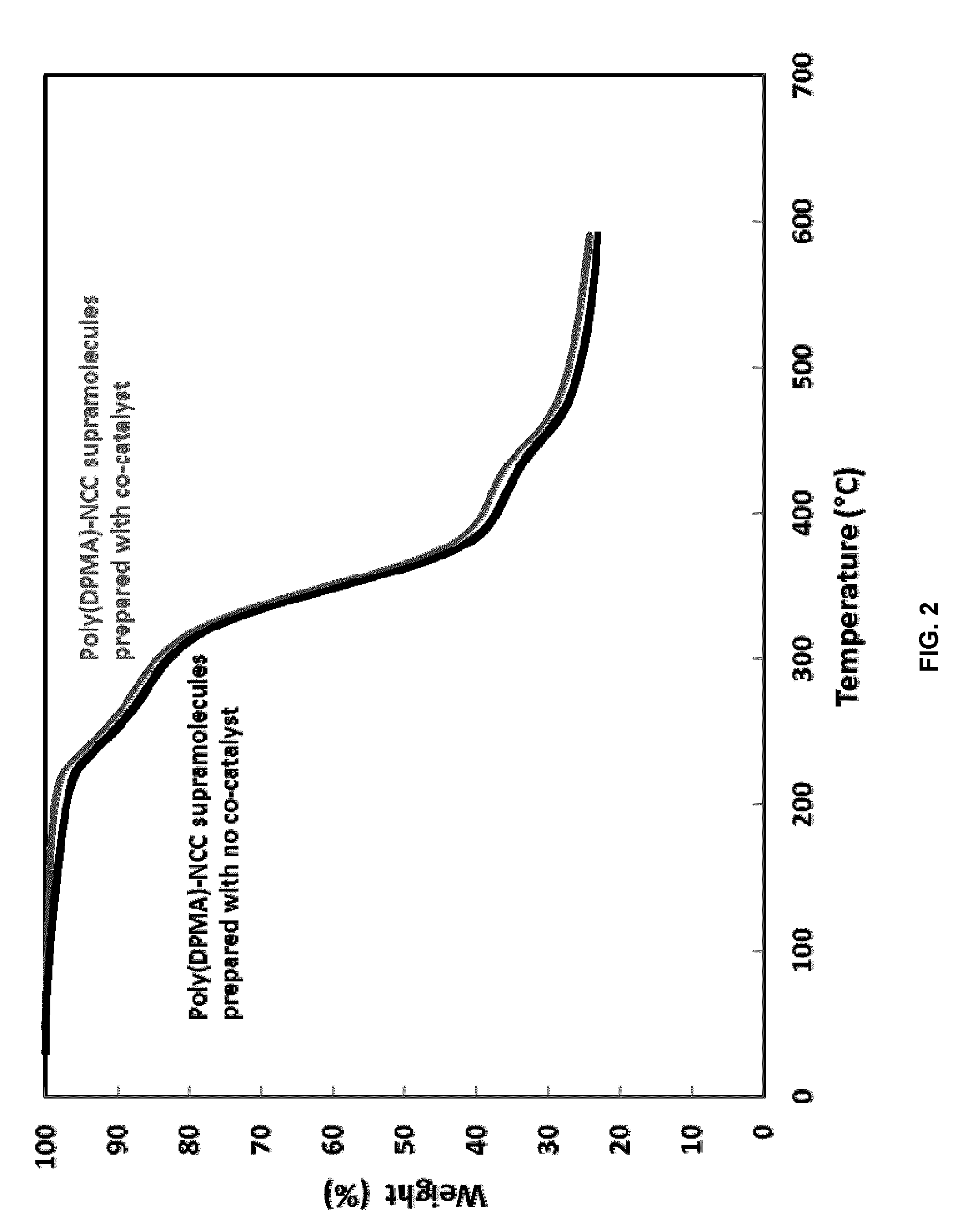

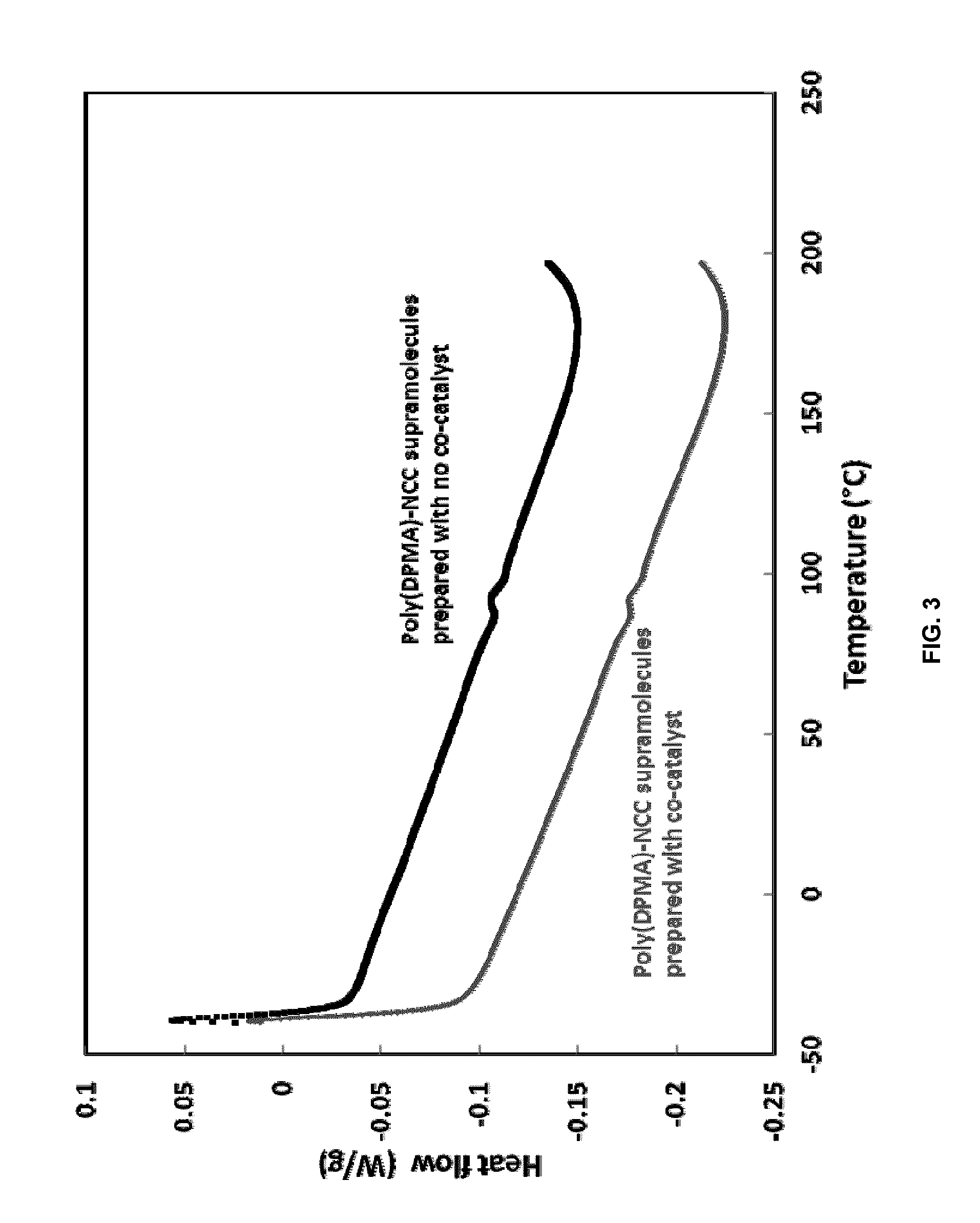

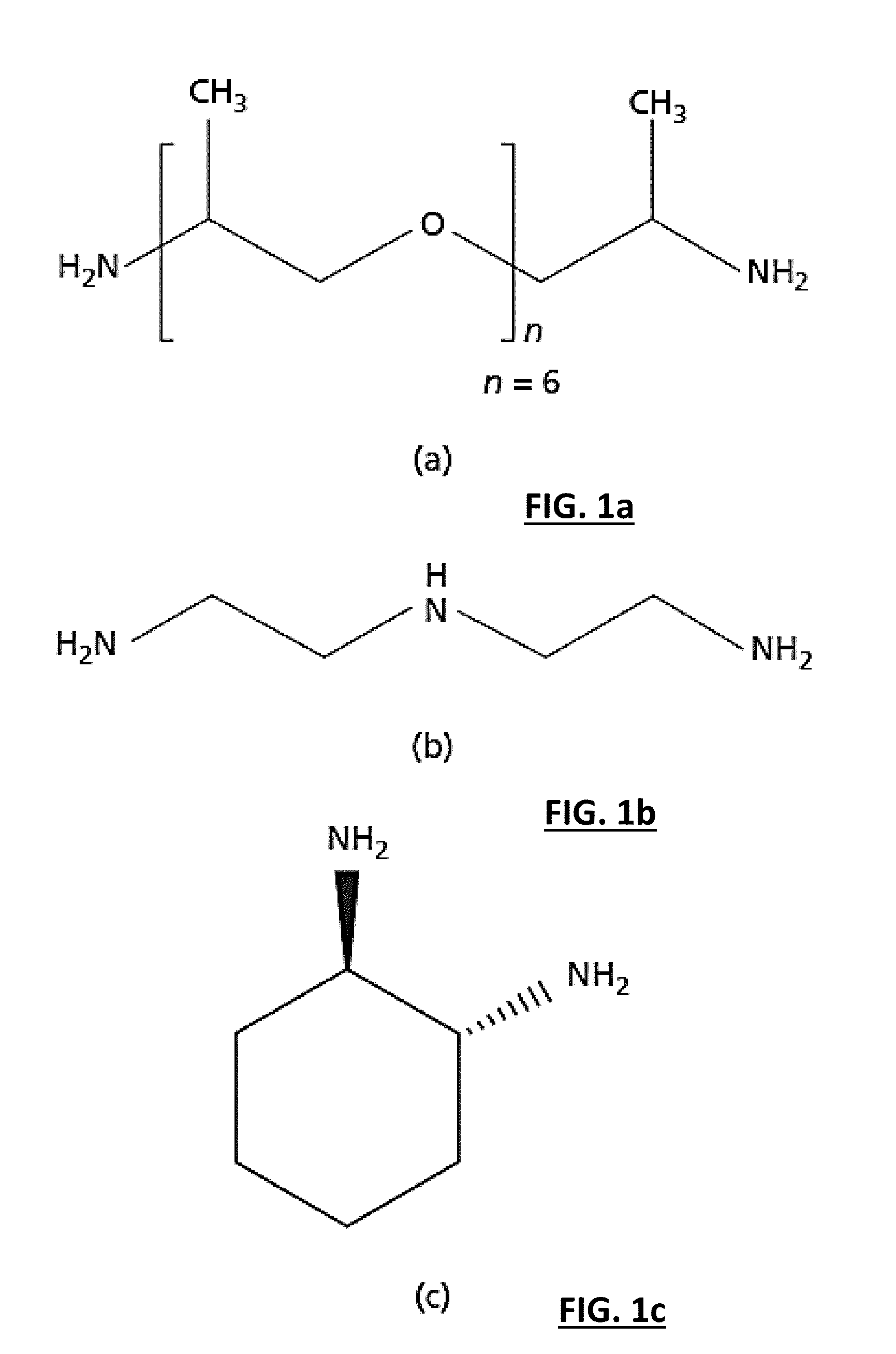

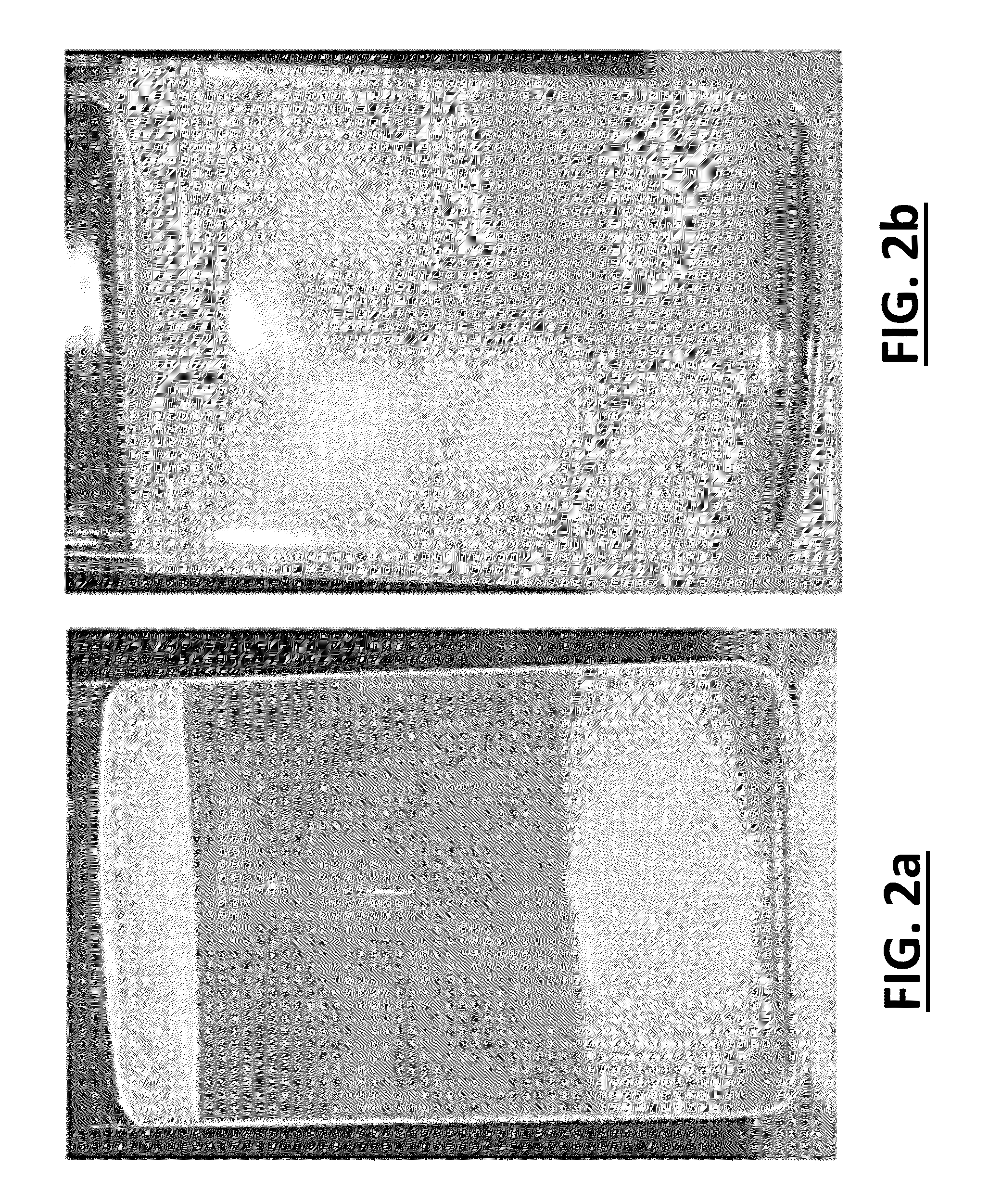

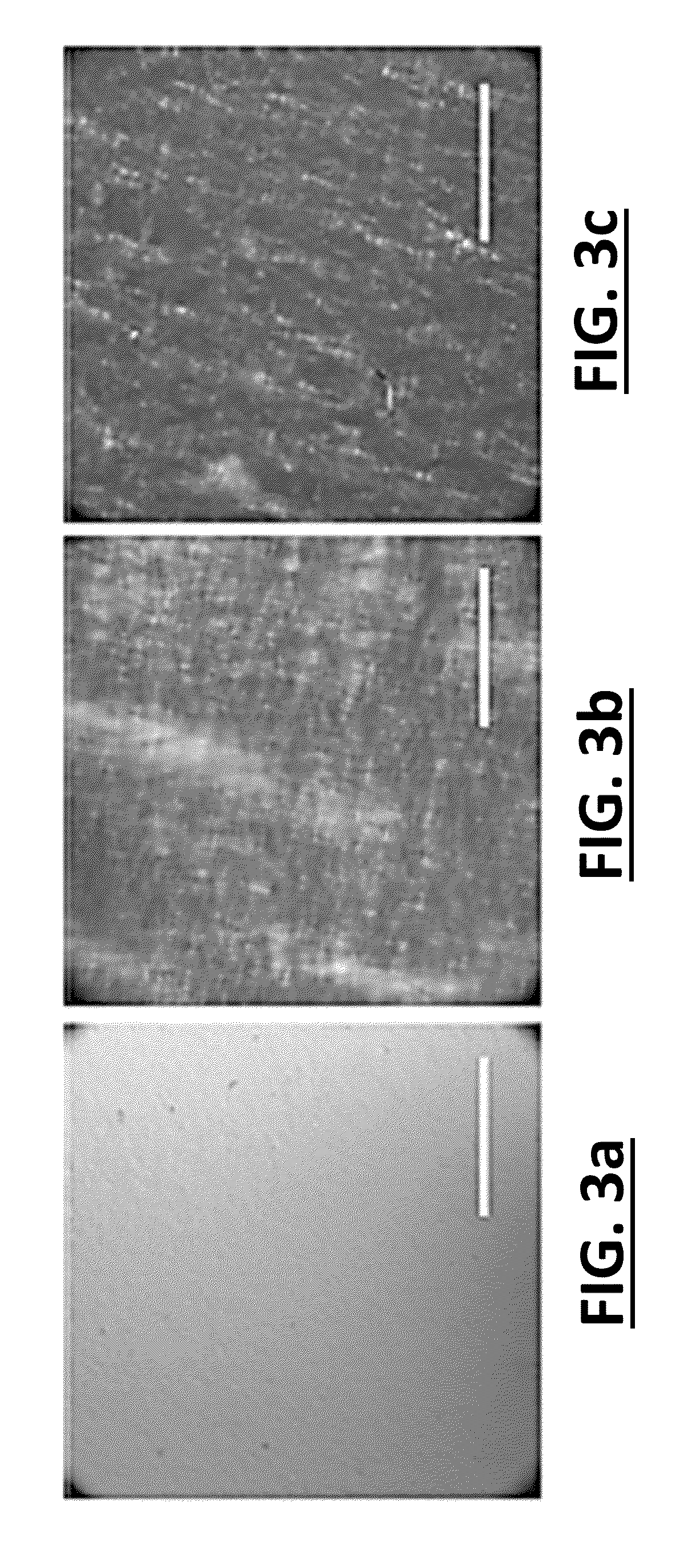

Ncc as a functional scaffold for amine-cured epoxy nanocomposite materials of tunable properties

The disclosure relates to a novel process for functionalizing NCC, a method for producing amine-cured epoxy-based nanocomposites through the use of said functionalized NCC, and nanocomposites thereof. The process for functionalizating NCC comprises providing a mixture of NCC and one or more monomers. The mixture is suitable for free radical polymerization and the monomer is cross-linkable with epoxy and is aqueous soluble. The polymerization takes place in the presence of a free radical initiator and oxygen is purged from the mixture and the initiator solution. The epoxy-based nanocomposite is produced by mixing the funtionalized NCC with an amine-curable epoxy resin and a hardener, in a solvent, and allowing the mixture to cure.

Owner:CELLUFORCE

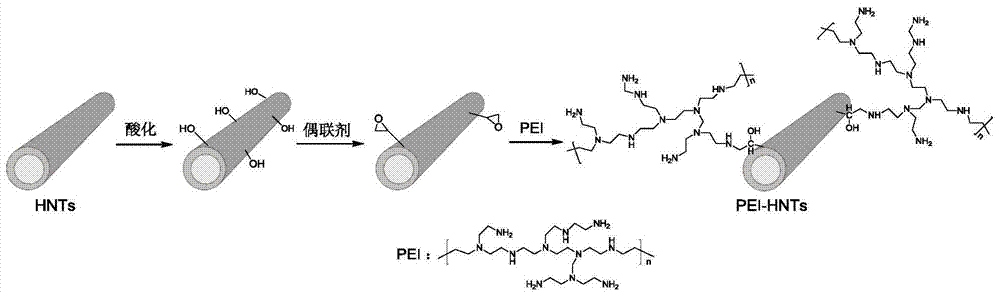

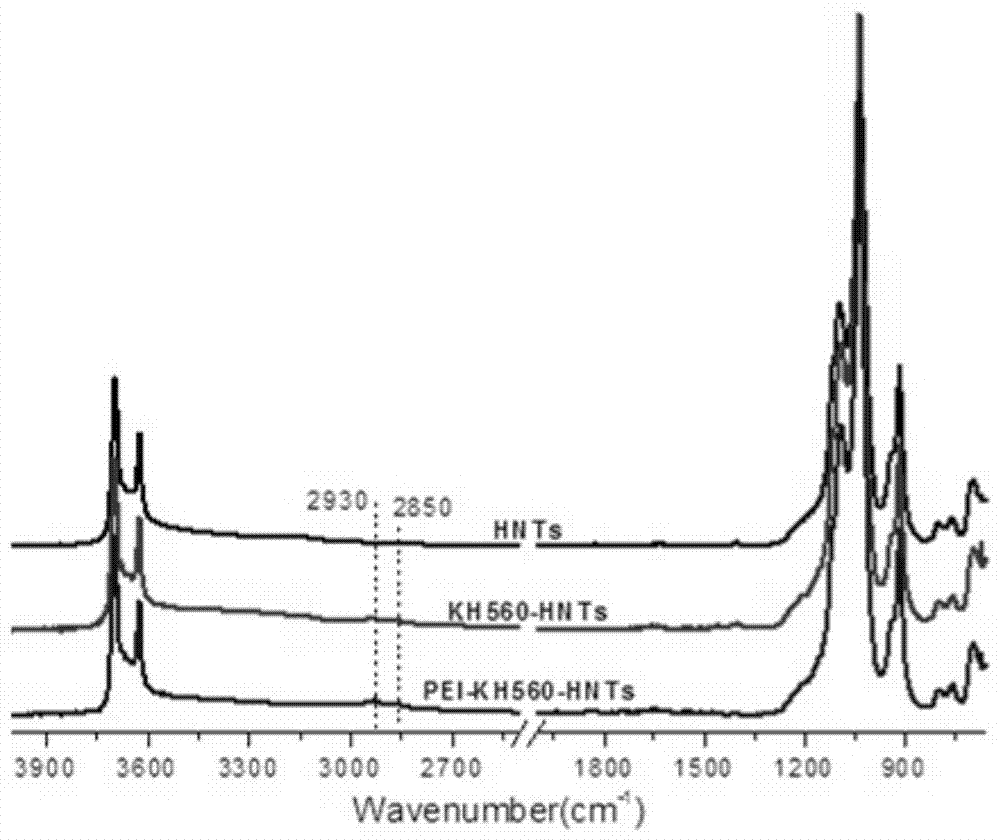

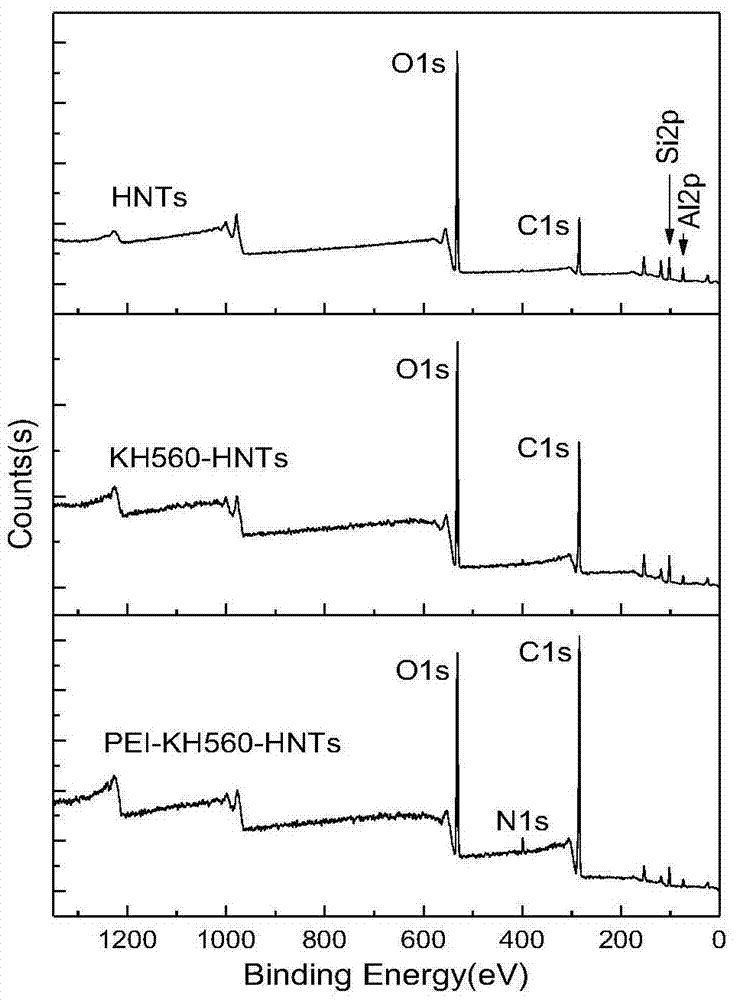

A kind of halloysite nanotube/epoxy resin nanocomposite material

The invention relates to the field of nanocomposite materials, in particular to a halloysite nanotube / epoxy resin nanocomposite material. The halloysite nanotubes of the present invention are branched polyethyleneimine grafted halloysite nanotubes, and the weight ratio of the branched polyethyleneimine grafted halloysite nanotubes to epoxy resin is 0.2~ 20:100; preferably 0.5-5:100; the present invention grafts hyperbranched polyethyleneimine onto epoxidized HNTs, and the branched structure has abundant amino groups, so that halloysite nanotubes and epoxy resin matrix Stronger chemical bonds or hydrogen bonds are formed between them to enhance the interfacial interaction. The modified halloysite nanotube prepared by the invention can effectively improve the impact resistance of the epoxy resin, reduce the brittle fracture of the epoxy resin, and has broad application prospects in the fields of automobiles, electronics, functional materials, aerospace and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

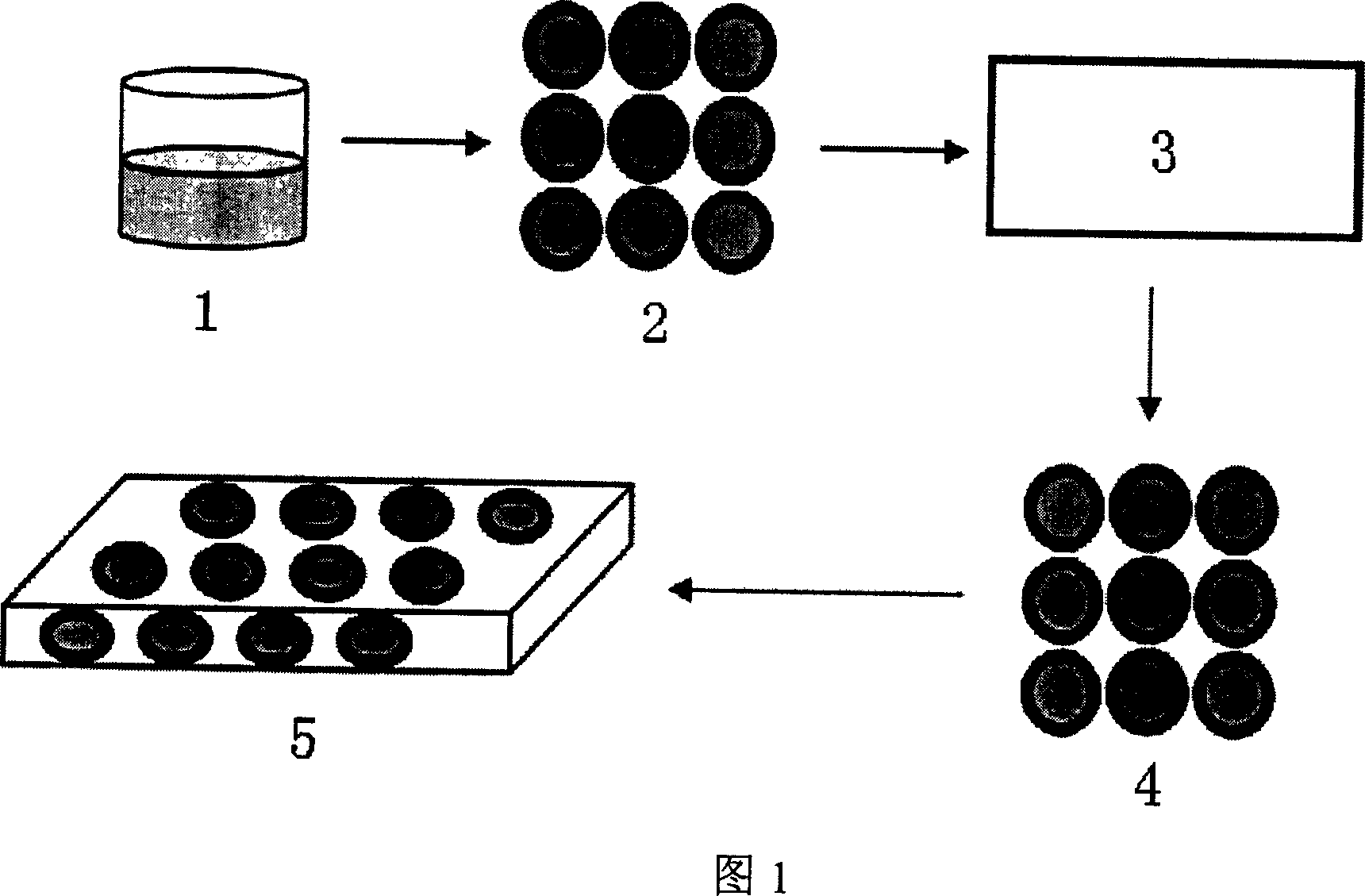

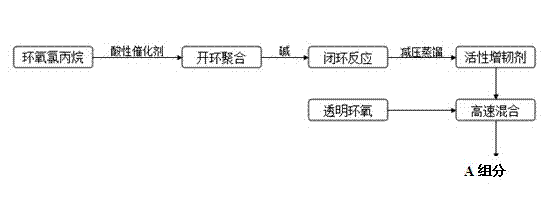

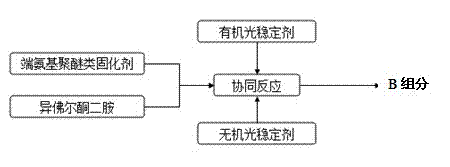

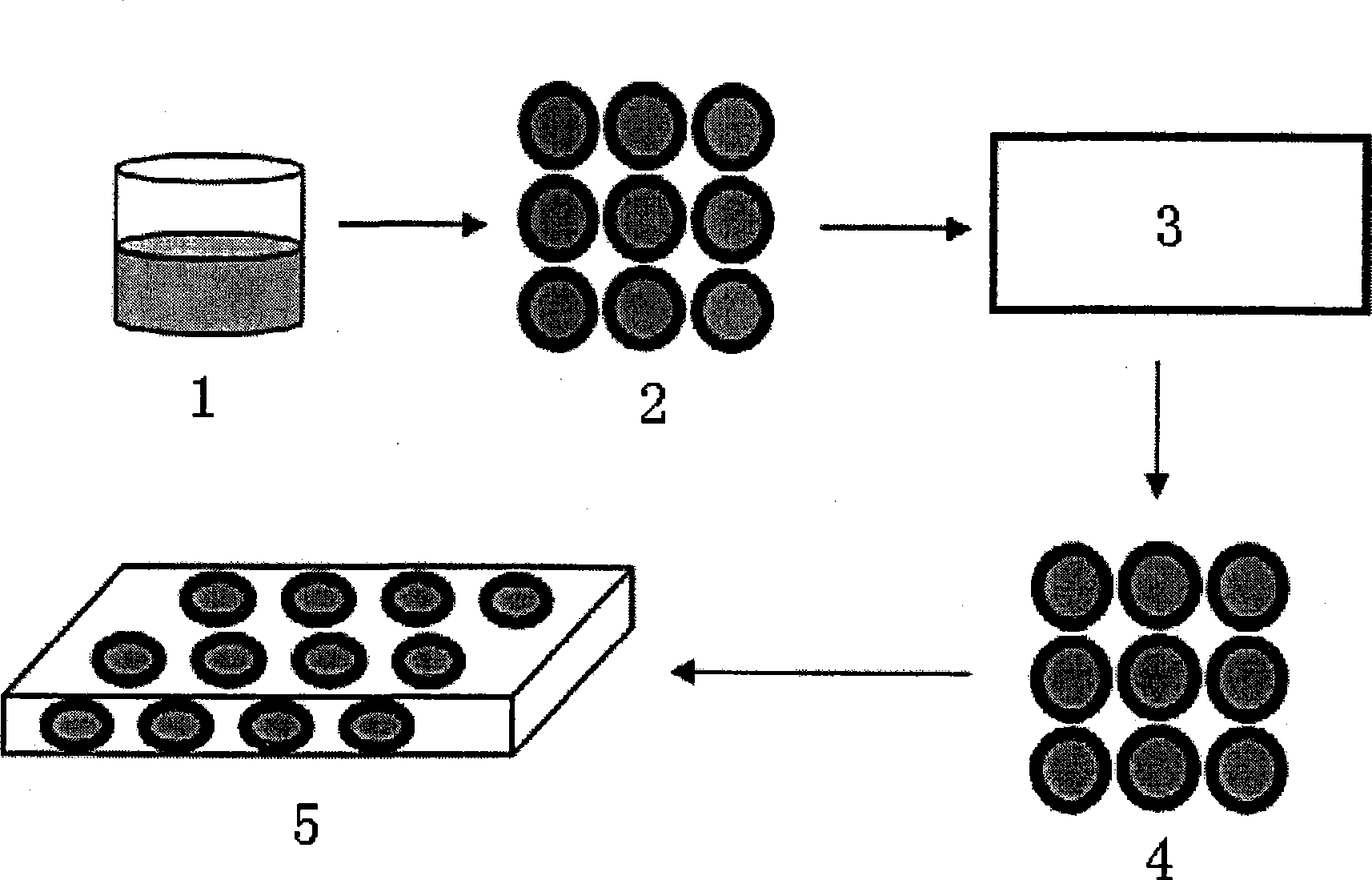

Preparation process of transparent epoxy nanocomposite material for encapsulating high-power LED (light-emitting diode)

InactiveCN102675823AHigh content of primary aminesImprove toughnessSemiconductor devicesLithium hydroxideUltraviolet

The invention discloses a preparation process of a transparent epoxy nanocomposite material for encapsulating a high-power LED (light-emitting diode). The process comprises the following steps that epichlorohydrin is used as a raw material, an acid catalyst is added to carry out ring opening polymerization reaction, alkali is added to carry out closure reaction, and extraction and other processes are carried out to obtain a flexibilizer; amine terminated polyether curing agent and isophorone diamine are mixed, and ortho-hydroxy diphenyl ketone, benzotriazole ultraviolet vapor, hindered amine light stabilizer are added to carry out concerted reaction with nano SiO2 to obtain the required curing agent; ethanol and zinc acetate are mixed and distilled to obtain residual fractions; the residual fractions are mixed with an ethanol solution of lithium hydrate to obtain an ethanol solution of ZnO-QD, and tetraethoxysilane and ammonia water are added for centrifugation and drying to obtain ZnO-QD / SiO2; and the components are mixed and then mechanically dispersed, vacuumized, defoamed, poured and cured to obtain a ZnO-QD / SiO2 / epoxy encapsulating material.

Owner:唐来江

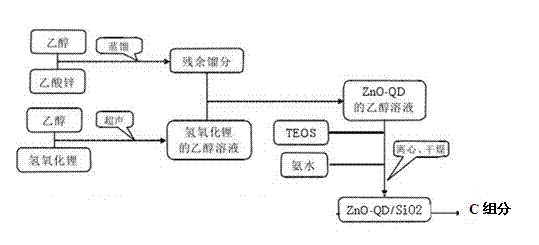

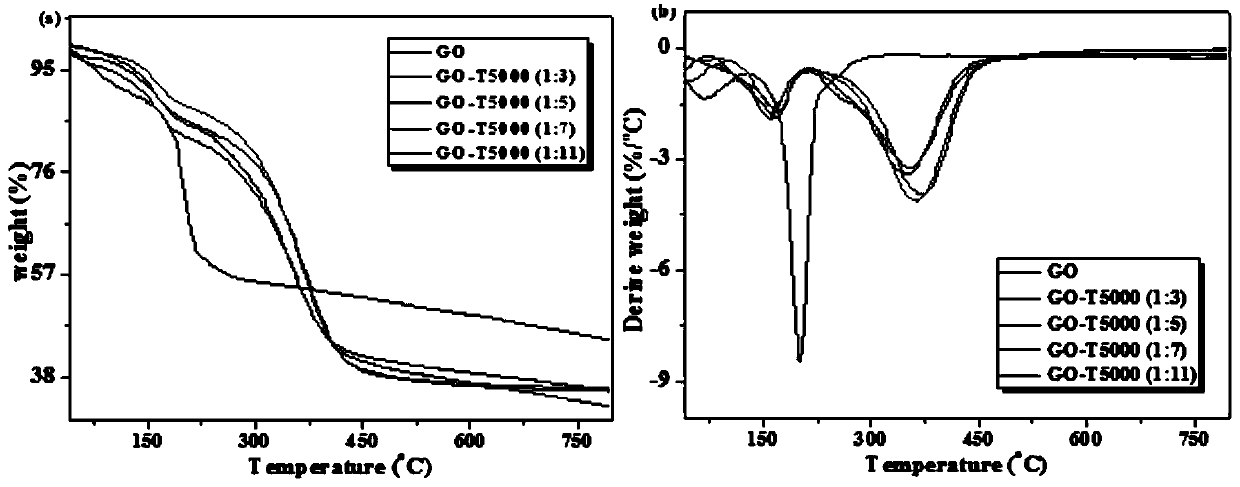

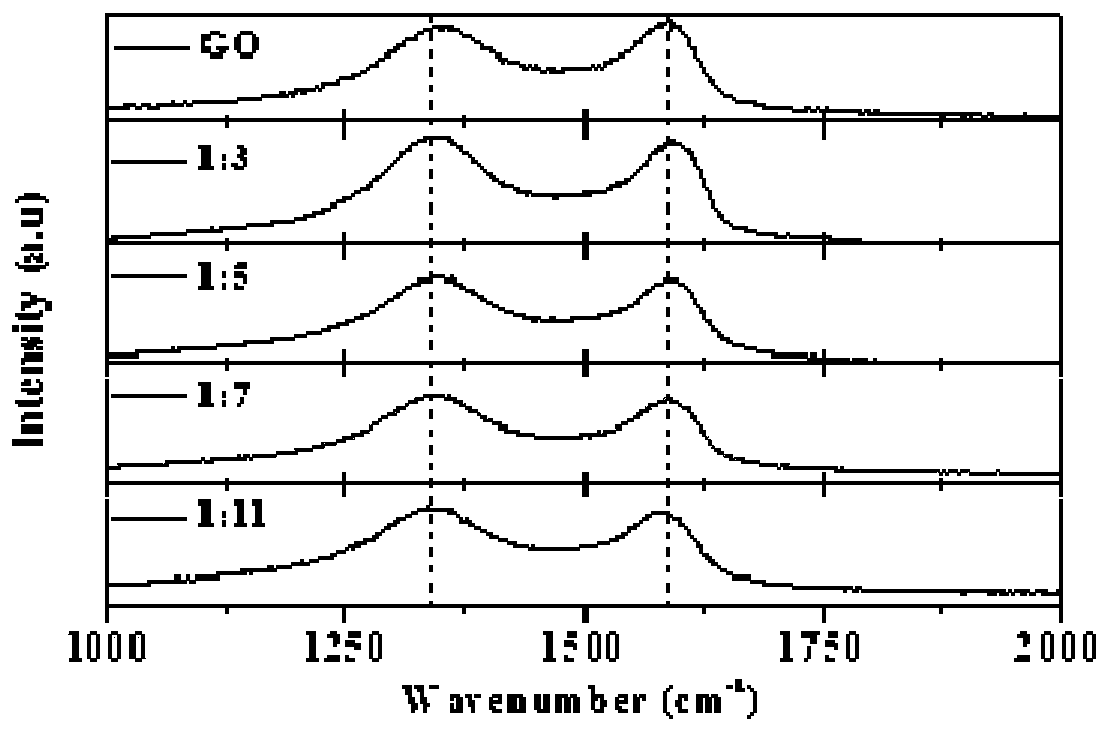

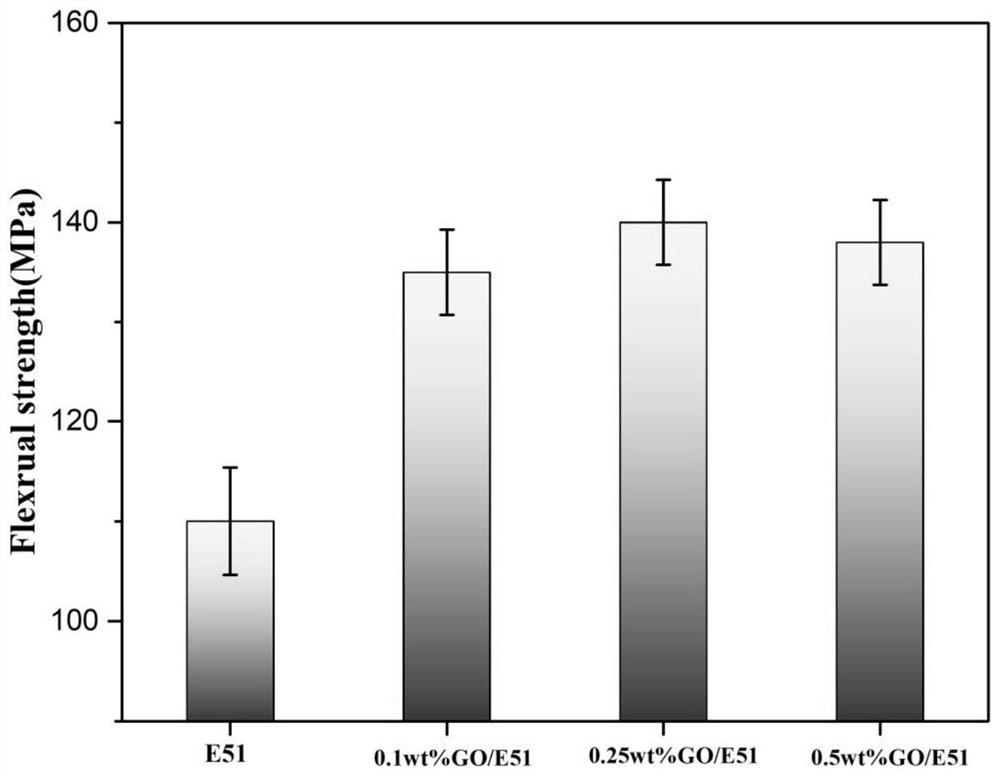

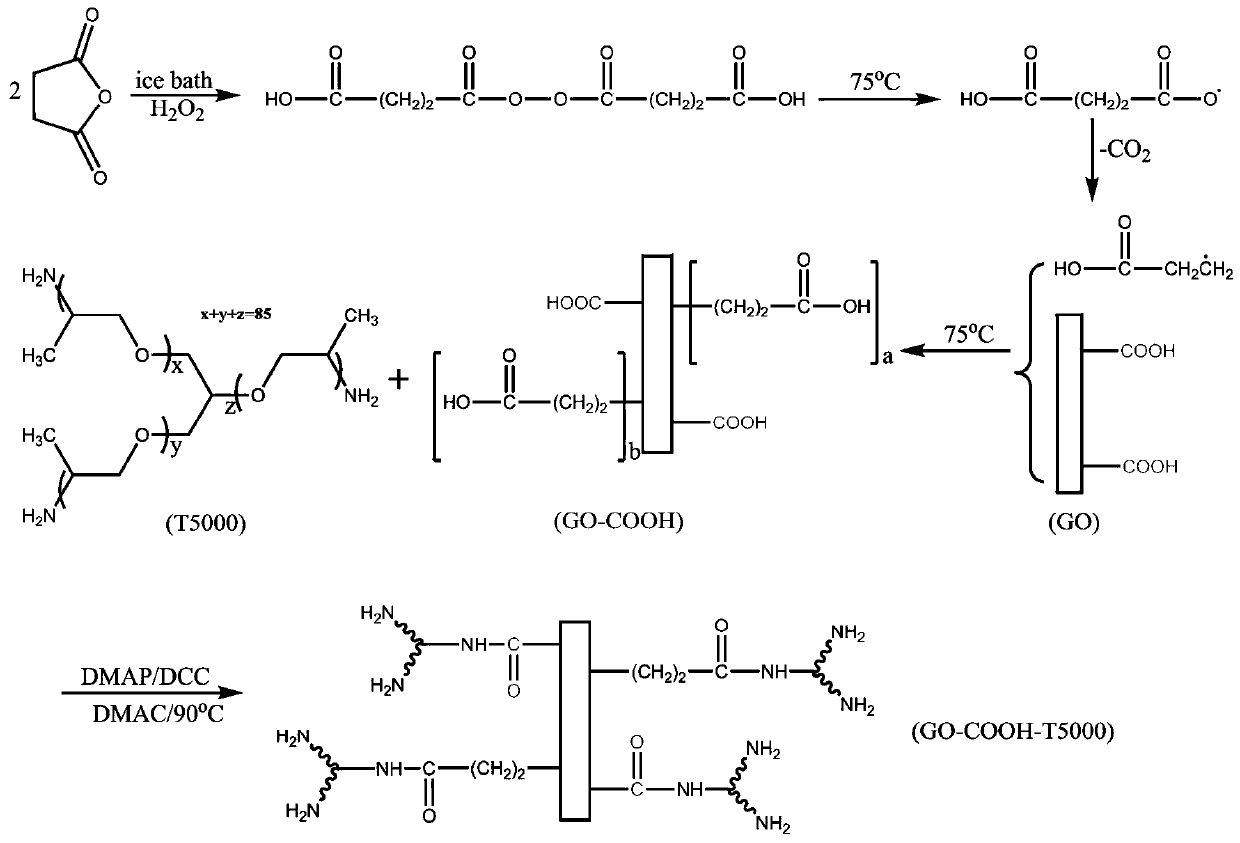

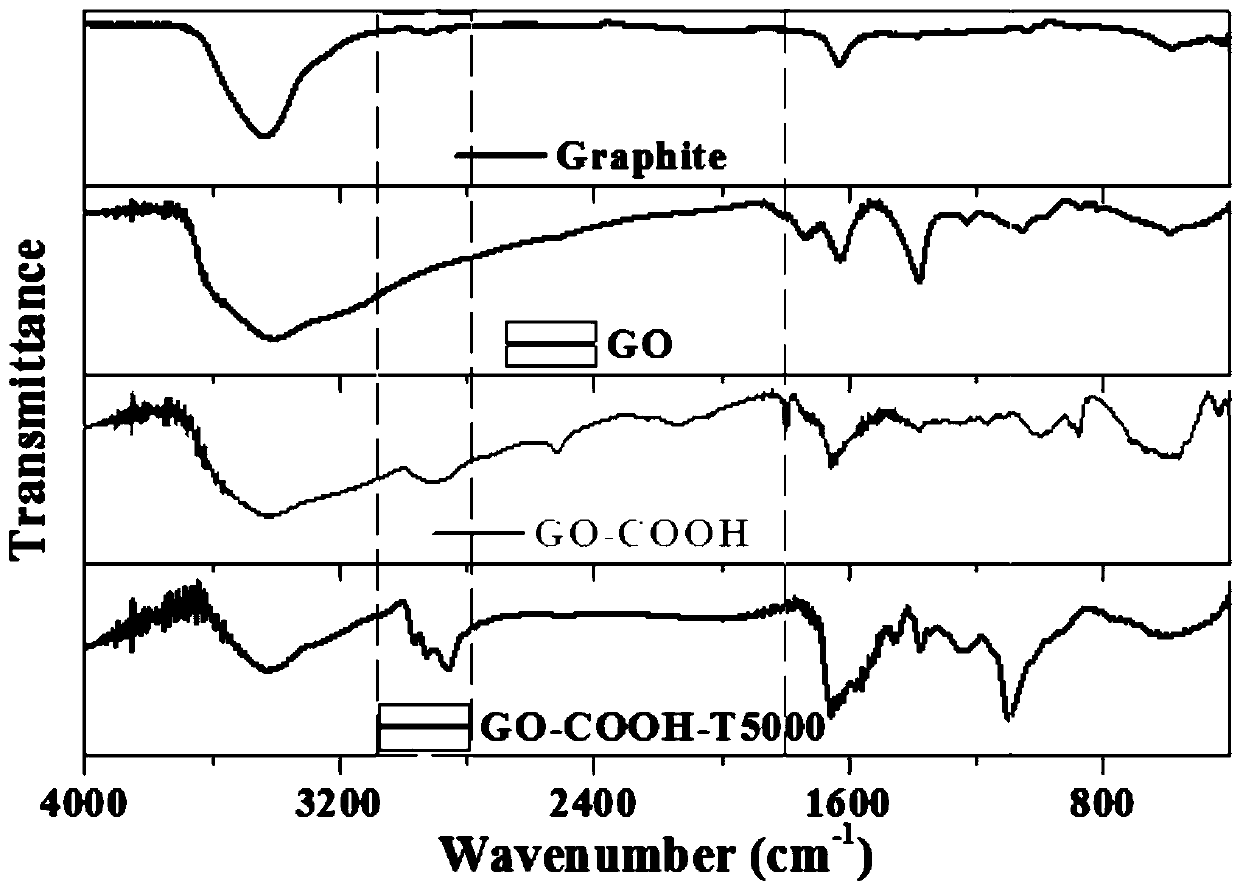

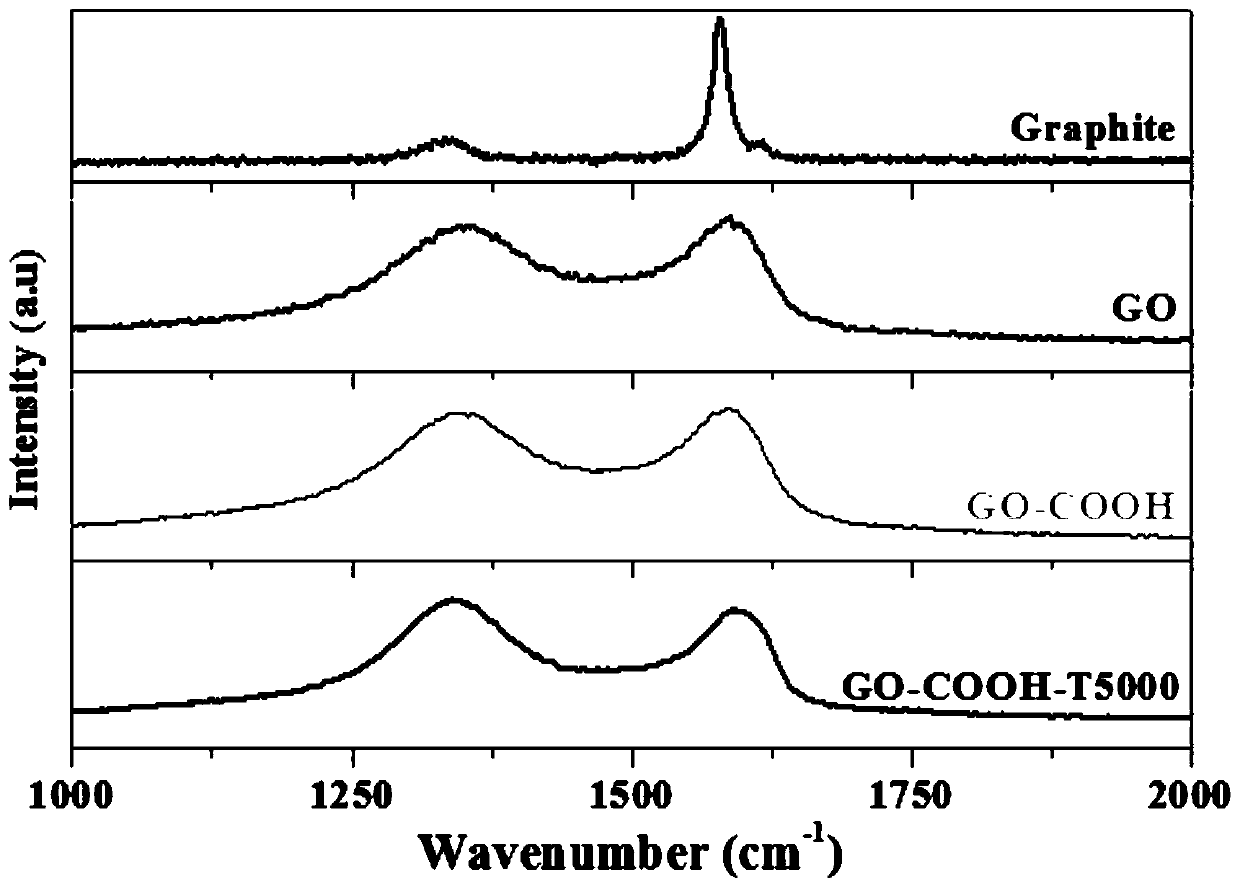

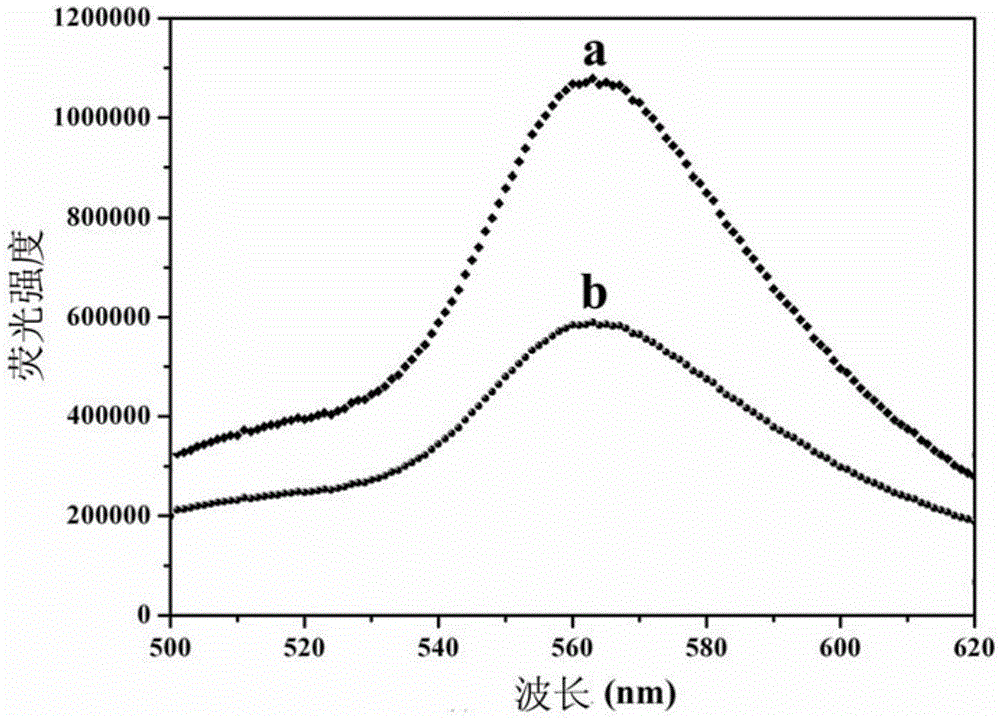

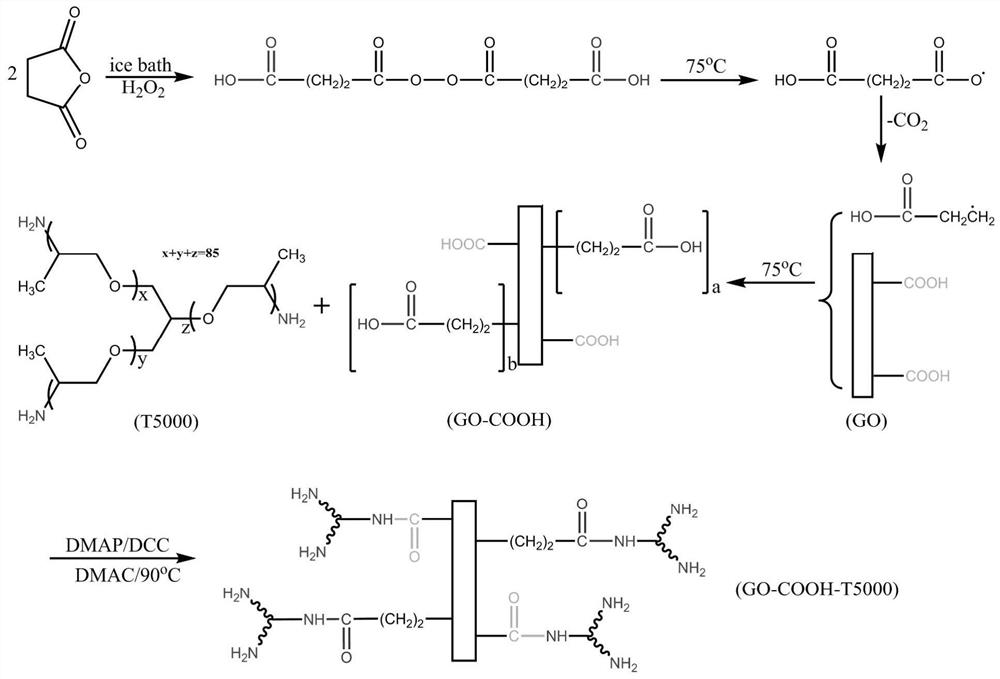

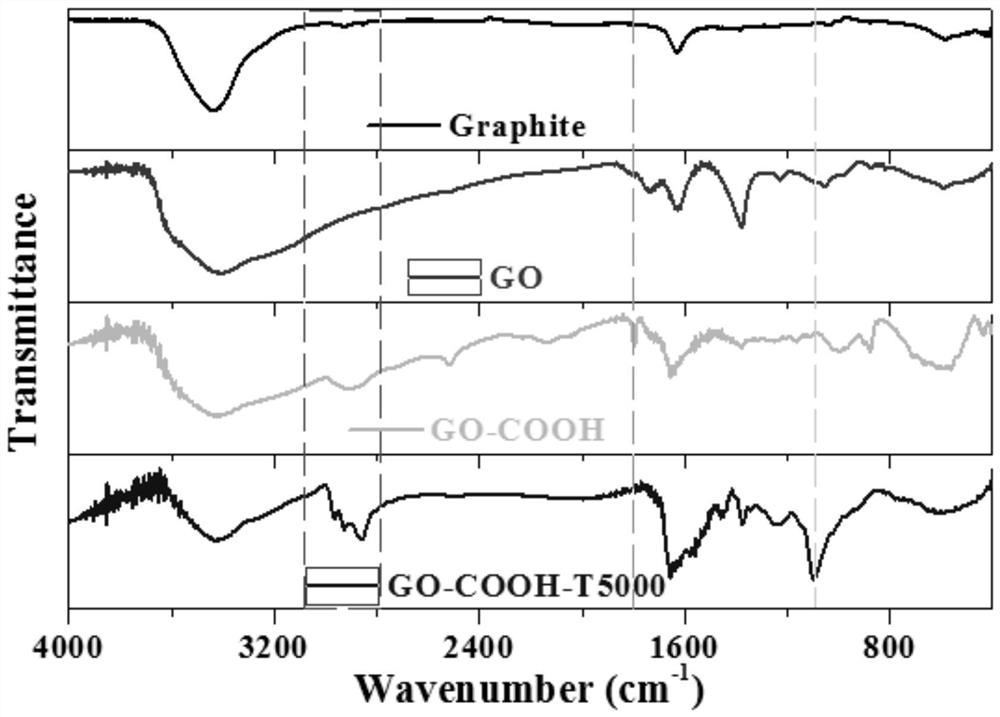

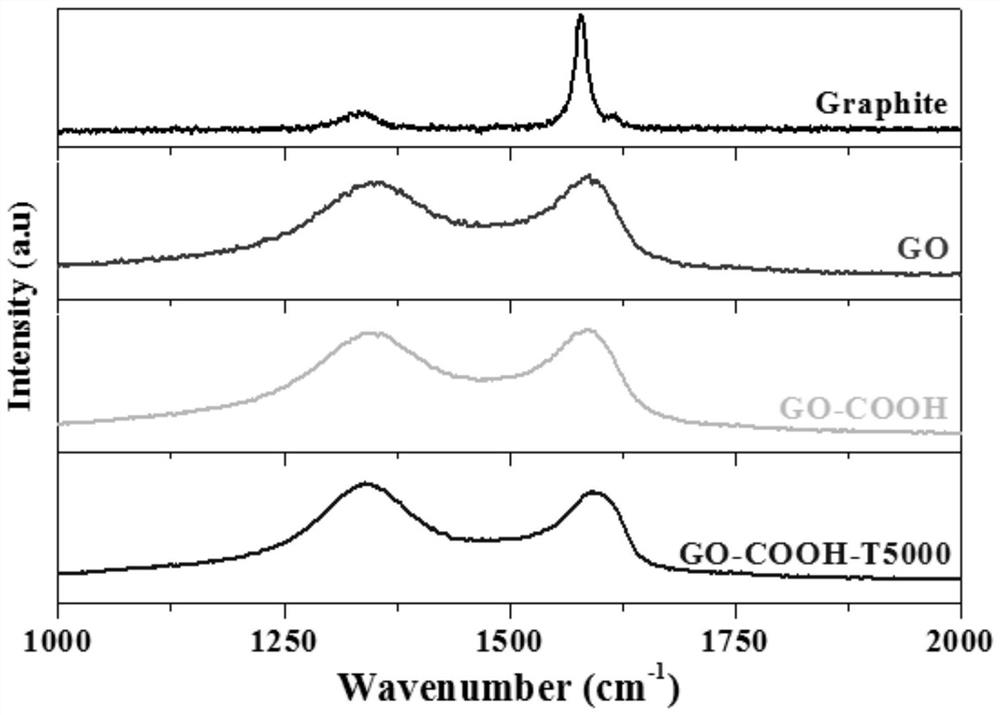

Polyetheramine-modified graphene oxide and epoxy composite nano-material thereof

The present invention provides a polyaminopolyetheramine-modified graphene oxide. The polyaminopolyetheramine-modified graphene oxide is obtained by substituting -OH groups in carboxyl groups on the surface of graphene oxide with A groups. A polyaminopolyetheramine-modified graphene oxide / TDE-85 epoxy composite nano-material system is further prepared. The polyaminopolyetheramine-modified grapheneoxide can effectively improve the mechanical properties of epoxy resin; and the composite material has optimum mechanical properties with a graft amount especially at a ratio of m(GO):n(T5000) of 1:7, and has a good application prospect.

Owner:SICHUAN UNIV

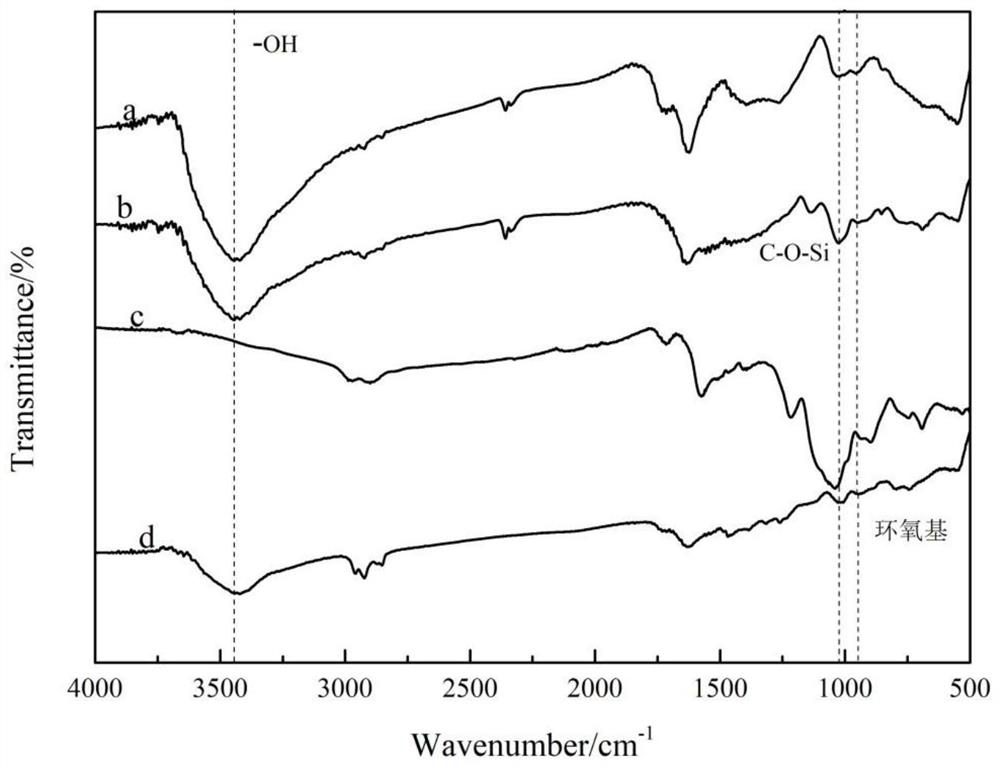

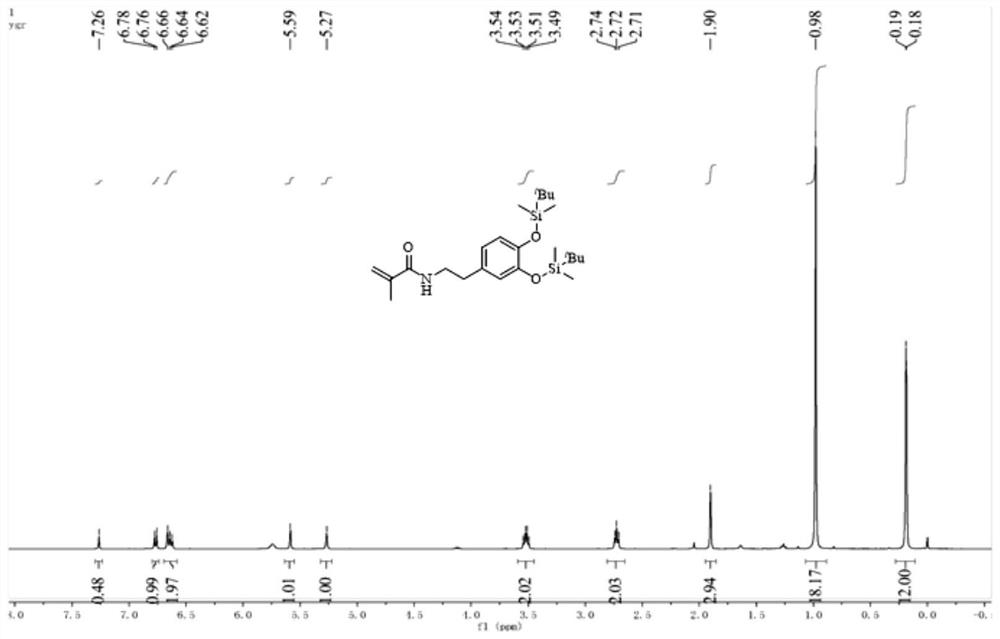

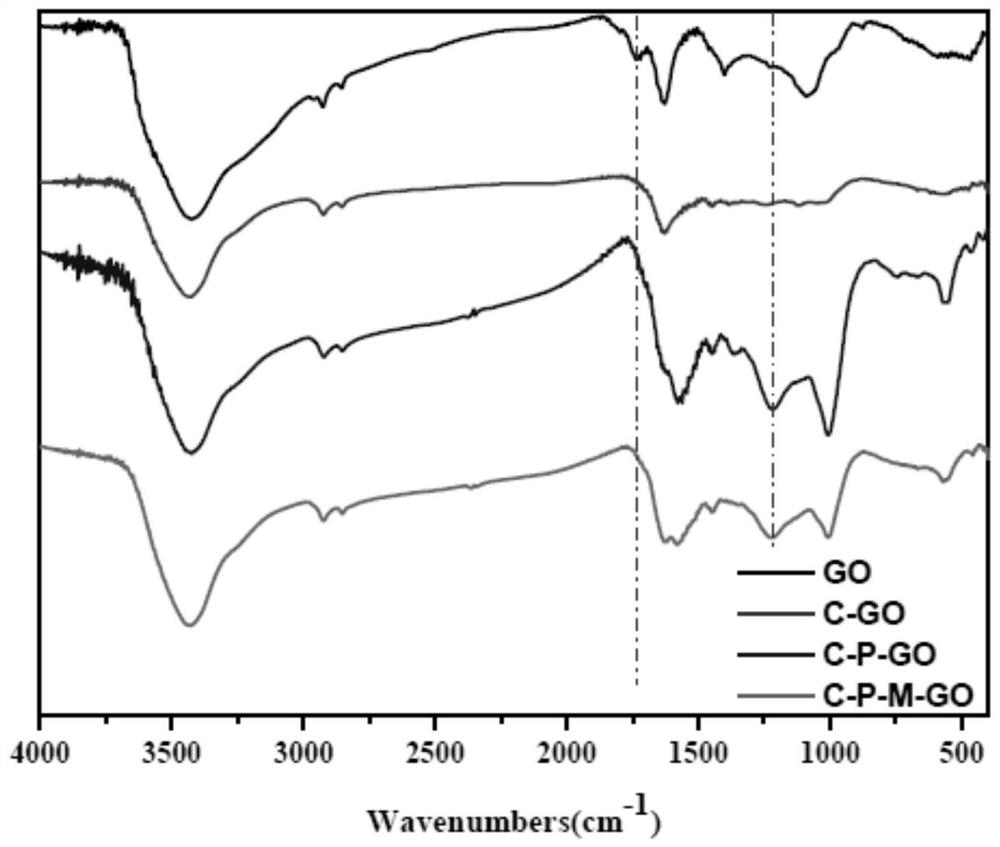

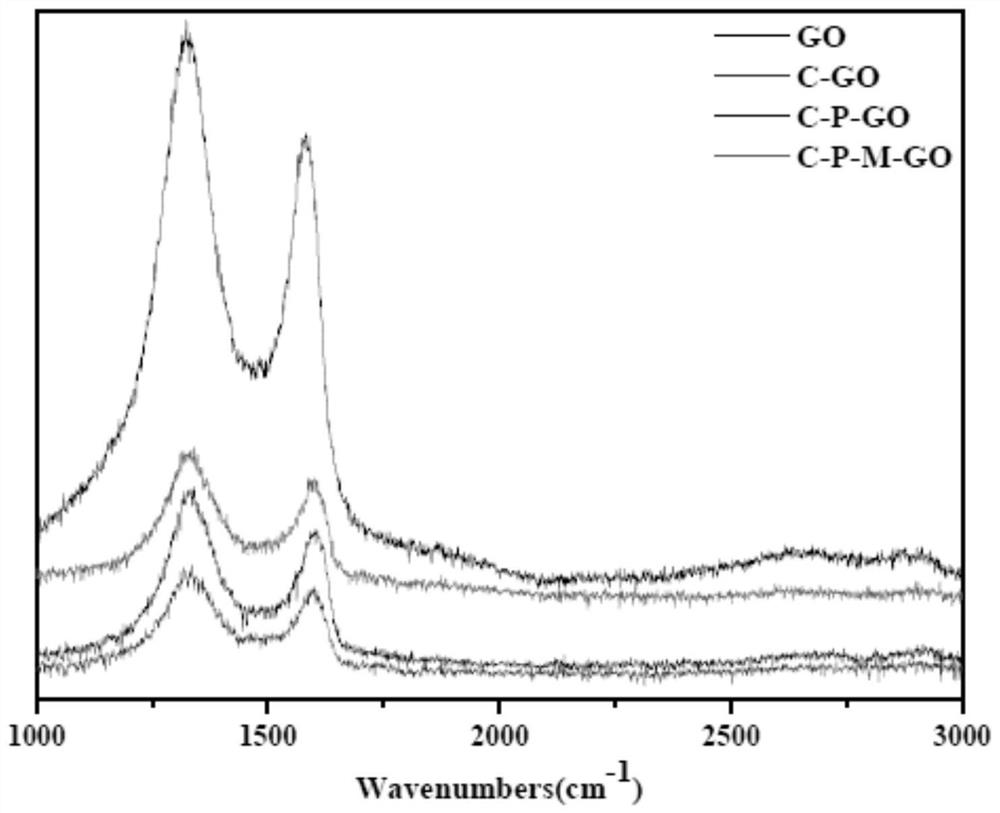

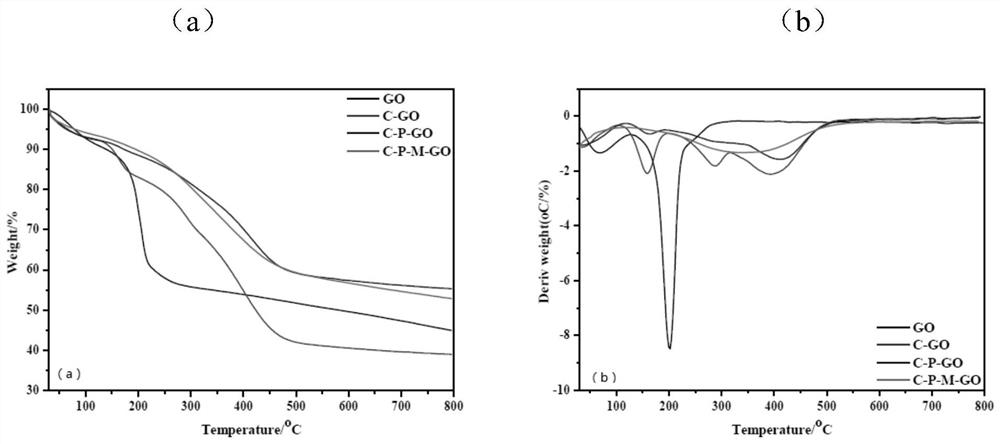

Preparation method of modified graphene oxide and method for preparing epoxy resin composite material by using modified graphene oxide

The invention relates to the field of composite materials, and in particular, relates to a preparation method of modified graphene oxide and a method for preparing an epoxy resin composite material by applying the modified graphene oxide. The preparation method of the modified graphene oxide comprises the following steps: 1, preparing aminated graphene oxide; 2, further preparing bromine-terminated graphene oxide; 3, preparing a monomer containing a catechol group; 4, preparing an intermediate product from the bromine-terminated graphene oxide and a monomer containing a catechol group; and 5, reacting the intermediate product with tetrabutylammonium fluoride to obtain the modified graphene oxide containing the catechol group. The preparation method of the epoxy resin composite material comprises the following steps: adding the modified graphene oxide into the epoxy resin, uniformly stirring and mixing, performing ultrasonic dispersion, adding the curing agent, uniformly stirring and mixing, performing vacuum drying, removing bubbles, and pouring into a mold for curing and molding. According to the modified graphene oxide prepared by the method provided by the invention, the compatibility with an epoxy resin matrix can be improved by low-dosage addition, and the mechanical property of an epoxy nano composite material can also be improved.

Owner:CHANGCHUN UNIV OF TECH

Reinforced Epoxy Nanocomposites and Methods for Preparation Thereof

The invention relates to reinforced epoxy nanocomposites, for example, cellulose nanocrystal (CNC) / epoxy nanocomposites, and methods for preparation thereof.

Owner:US SEC AGRI +1

Carbon nanotube-reinforced nanocomposites

A combination of MWNTs (herein, MWNTs have more than 2 walls) and DWNTs significantly improves the mechanical properties of polymer nanocomposites. A small amount of DWNTs reinforcement (<1 wt. %) significantly improves the flexural strength of epoxy matrix nanocomposites. A same or similar amount of MWNTs reinforcement significantly improves the flexural modulus (stiffness) of epoxy matrix nanocomposites. Both flexural strength and flexural modulus of the MWNTs and DWNTs-coreinforced epoxy nanocomposites are further improved compared with same amount of either DWNTs or MWNTs-reinforced epoxy nanocomposites. In this epoxy / DWNTs / MWNTs nanocomposite system, SWNTs may also work instead of DWNTs. Besides epoxy, other thermoset polymers may also work.

Owner:NANO

Amino-terminated modified graphene oxide and epoxy nano composite material thereof

ActiveCN111303486AHigh elongation at breakHigh tensile strengthCarbon compoundsEndcappingHeat resistance

The invention relates to amino-terminated modified graphene oxide and an epoxy nano composite material thereof. The modified graphene oxide is obtained by replacing -OH groups of carboxyl on the surface of graphene oxide with A groups, and the structure of the A groups is shown in the specification. The invention also discloses an epoxy nano composite material prepared by taking the modified graphene oxide as a raw material. According to the amino-terminated modified graphene oxide prepared by the invention, under the condition of low addition, the storage modulus and the glass-transition temperature of the epoxy nano composite material can be greatly improved, the rigidity and the heat resistance of the composite material can be improved, and meanwhile, the mechanical property, particularly the tensile property, can be remarkably improved, the comprehensive property is excellent, and the application prospect is excellent.

Owner:SICHUAN UNIV

Epoxy nanocomposite with controllable phase structure and based on polyhedral oligomeric silsesquioxanes (POSS)

The invention discloses an epoxy nanocomposite based on polyhedral oligomeric silsesquioxanes (POSS) and a preparation method of the epoxy nanocomposite based on the POSS and relates to the epoxy nanocomposite with a controllable phase structure capable of improving effect and based on the POSS. The preparation method includes the following steps of allocating a POSS monomer, a chain transfer agent and an initiating agent in a solution according to the measuring amount through a reversible addition-fragmentation chain transfer (RAFT) method, conducting freeze thaw and degassing through liquid nitrogen, charging argon shield to enable the mixture to react, and obtaining PMAiBuPOSS; further allocating PMAiBuPOSS, Methl Methacrylate monomer (MMA) and an initiating agent in a solution, and obtaining POSS base block copolymer , namely, PMAiBuPOSS-b-PMMA, through the RAFT; conducting melt blending on the POSS monomer, epoxy resin, the prepared POSS base block copolymer to obtain blend precursor of the POSS and the epoxy, adding in a curing agent, fully stirring, dissolving the mixture the curing agent, pouring the blend into a die, conducting temperature programming and curing, and obtaining the nanocomposite with the controllable phase structure and based on the POSS.

Owner:XIAMEN UNIV

Flexible long-chain polyamine polyetheramine modified carboxylated graphene oxide and epoxy nanocomposite material

The invention provides flexible long-chain polyamine polyetheramine modified carboxylated graphene oxide. Through further preparation, an epoxy nanocomposite material system thereof is obtained. Withlow dosage of the polyetheramine modified carboxylated graphene oxide rich in flexible-chain amino group on the surface, mechanical property of the epoxy nanocomposite material can be greatly improved, especially toughness (elongation at break) and compression performance are remarkably improved. The product of the invention has an important application prospect.

Owner:SICHUAN UNIV

Photoluminescent transparent epoxy nanometer composite material, preparation method and application thereof

InactiveCN101338187BPhotoluminescence achievedHigh light transmittanceLuminescent compositionsPhotoluminescencePhosphor

The invention relates to a photoluminescence transparent epoxy nanometer composite material, a manufacturing method and the usage. The composite material comprises transparent epoxy resin matrix material and photoluminescence inorganic nanometer fillers uniformly dispersed in the epoxy resin matrix material; the transparent epoxy resin matrix material comprises epoxy resin and acid anhydrides epoxy curing agent. The epoxy resin is alicyclic epoxy resin, bisphenol A type epoxy resin or hydrogenated bisphenol A type epoxy resin. The acid anhydrides epoxy curing agent is methyl hexahydro-pthalicanhydride or hexahydrophthalic anhydride containing 1.0-5.0wt percent of curing accelerator. The curing accelerator is amine curing accelerator or imidazole curing accelerator. The composite materialof the invention is provided with good transparency and photoluminescence, can be used for substituting the traditional sealing mode of phosphor adding packaging material and can be directly applied to the sealing of LED luminescence semiconductor devices, large outdoor neon lamps, etc.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Transparent epoxy nano composite material and preparation method and use thereof

InactiveCN100509952COvercoming Light Scattering PhenomenonHigh light transmittanceOther chemical processesSilica nanoparticlesAging resistance

The present invention relates to a kind of transparent epoxy nano-composite material and its preparation method and application, the filler of this transparent epoxy nano-composite material is composite nano-inorganic filler; Said composite nano-inorganic filler comprises: silicon dioxide nano-particles as core, Titanium dioxide coated outside the silica nanoparticles as a shell and an outer layer of silicon dioxide coated outside the titanium dioxide shell; the transparent epoxy nanocomposite material of the present invention has good transparency, which is different from ordinary pure transparent Compared with epoxy, it has excellent ultraviolet shielding effect and greatly improved ultraviolet aging resistance; the transparent epoxy nanocomposite material also has the advantages of low thermal expansion coefficient, high thermal conductivity and the like; the invention is suitable for the packaging of light-emitting semiconductor devices such as LEDs.

Owner:广东中科顺威新材料科技发展有限公司

A modified zirconium phosphate-epoxy nanocomposite material and its preparation method

ActiveCN110591294BGood storage stabilityEfficient strippingAnti-corrosive paintsEpoxy resin coatingsActive agentFirming agent

The invention discloses a modified zirconium phosphate-epoxy nanocomposite material and a preparation method thereof; the preparation method comprises: mixing an intercalation agent, a surfactant and a solvent, adding layered zirconium phosphate, oscillating evenly, and ultrasonically dispersing, Obtain the single-layer zirconium phosphate solution after stripping; adjust the pH of the single-layer zirconium phosphate solution with a stripping agent, centrifuge, wash, and pour off the supernatant; add zirconium phosphate and modifier to the solvent, and heat Stir and react at high temperature for 12-24 hours, after washing and drying, the modified zirconium phosphate is obtained; the modified zirconium phosphate is dispersed in a solvent, mixed with the ethanol solution of the curing agent, added epoxy resin, and stirred evenly to obtain the modified zirconium phosphate- Epoxy nano-composite material: Compared with epoxy resin, the modified zirconium phosphate-epoxy nano-composite material of the present invention has significantly improved mechanical properties and anti-corrosion properties.

Owner:SOUTH CHINA UNIV OF TECH

A quantum dot/epoxy resin nanocomposite material with high transparency and high fluorescence efficiency, its preparation and application

ActiveCN103937158BHigh transparencyExcellent fluorescence performanceSemiconductor devicesGlycidyl methacrylateFluorescence

Owner:BEIJING UNIV OF CHEM TECH

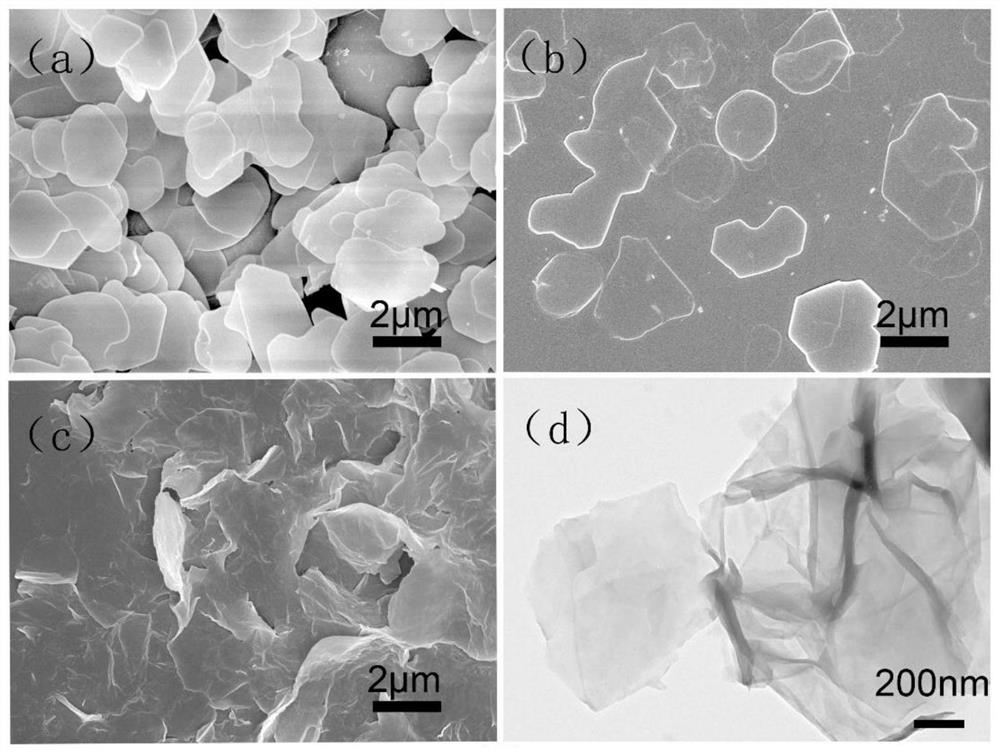

A kind of preparation method of waterborne graphene epoxy resin nanocomposite material

ActiveCN104231547BImprove interface compatibilityImprove bindingHigh concentrationInterfacial adhesion

The invention discloses a method for preparing a water-based graphene epoxy resin nanocomposite material. The specific steps are as follows: the graphene oxide obtained by the Hummers method is functionally modified and dispersed to obtain a high-concentration graphene aqueous dispersion; Add epoxy resin to the graphene aqueous dispersion, stir evenly, remove water under vacuum conditions and add curing agent to mix; after high temperature curing, the graphene / epoxy resin nanocomposite material is obtained, the operation process is simple and controllable, and it is easy to scale Batch preparation and synthesis; through the acquisition of highly stable graphene aqueous dispersion, graphene and epoxy resin have excellent interfacial compatibility and bonding force; effectively improve the bonding force between epoxy resin and substrate, corrosion resistance and Impact resistance: Compared with conventional water-based epoxy resin materials, the hardness of the water-based graphene / epoxy resin nanocomposite prepared by the present invention is increased by 1.5 times, and the impact resistance is increased by 12 times.

Owner:QINGDAO REALEADER ADVANCED MATERIALS TECH

A flexible long-chain polyamine-based polyetheramine modified carboxylated graphene oxide and its epoxy nanocomposite

The invention provides flexible long-chain polyamine polyetheramine modified carboxylated graphene oxide. Through further preparation, an epoxy nanocomposite material system thereof is obtained. Withlow dosage of the polyetheramine modified carboxylated graphene oxide rich in flexible-chain amino group on the surface, mechanical property of the epoxy nanocomposite material can be greatly improved, especially toughness (elongation at break) and compression performance are remarkably improved. The product of the invention has an important application prospect.

Owner:SICHUAN UNIV

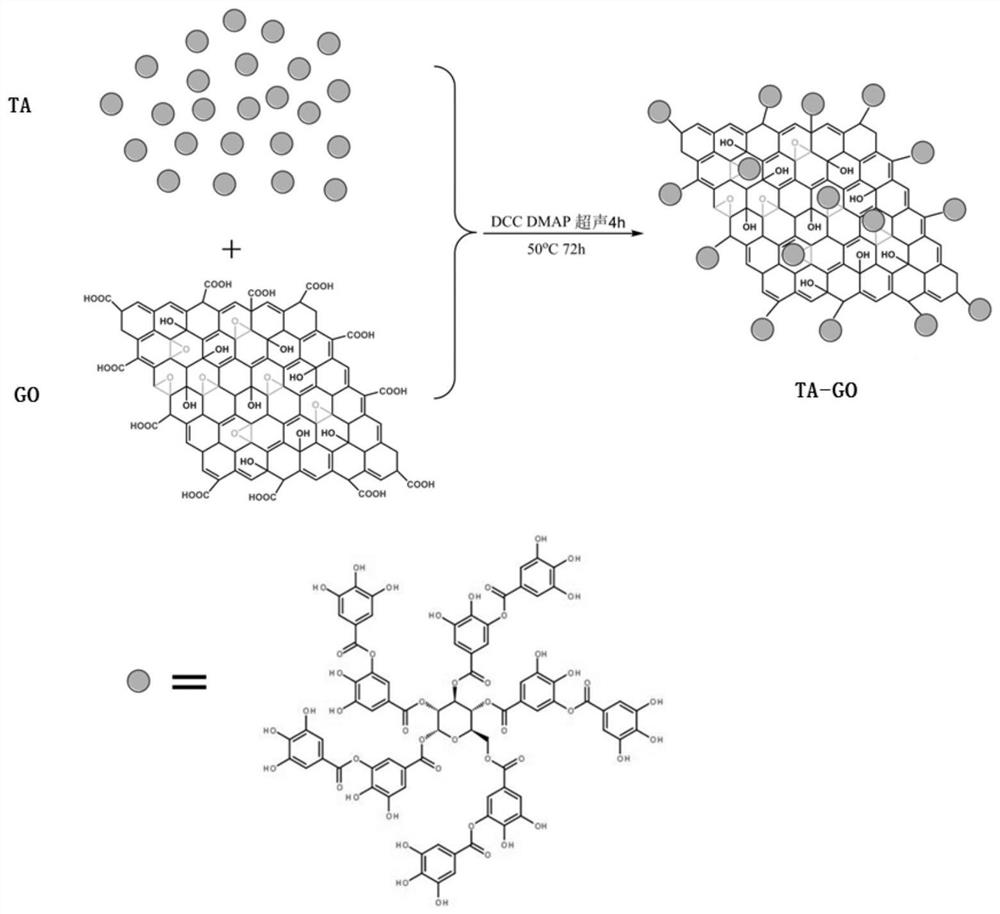

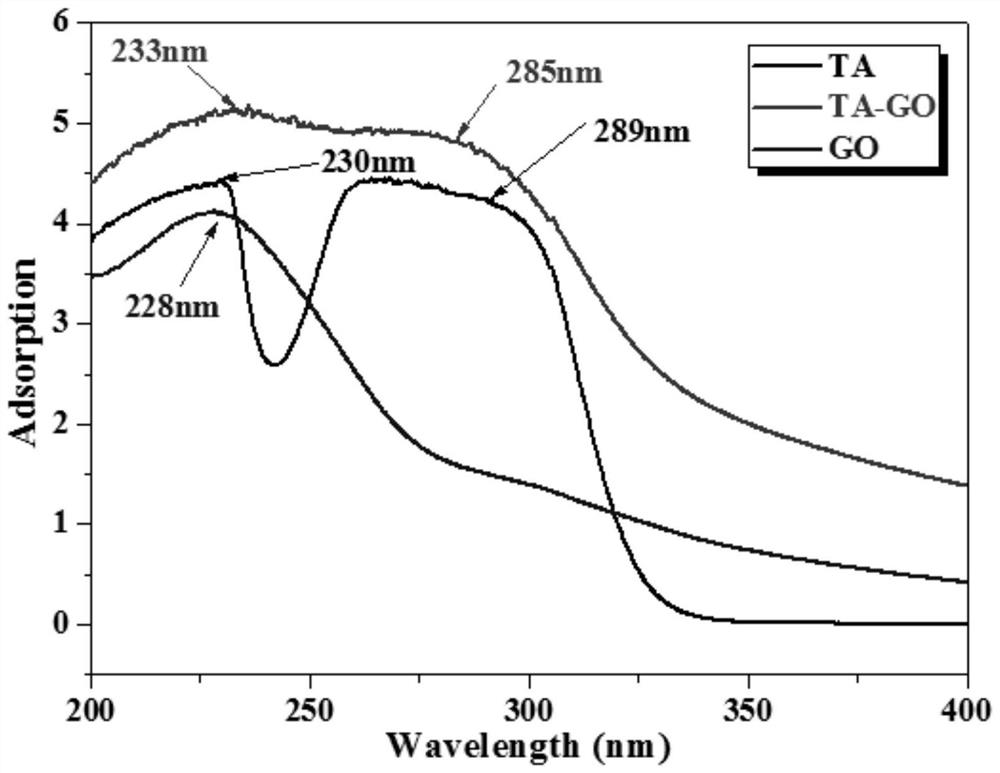

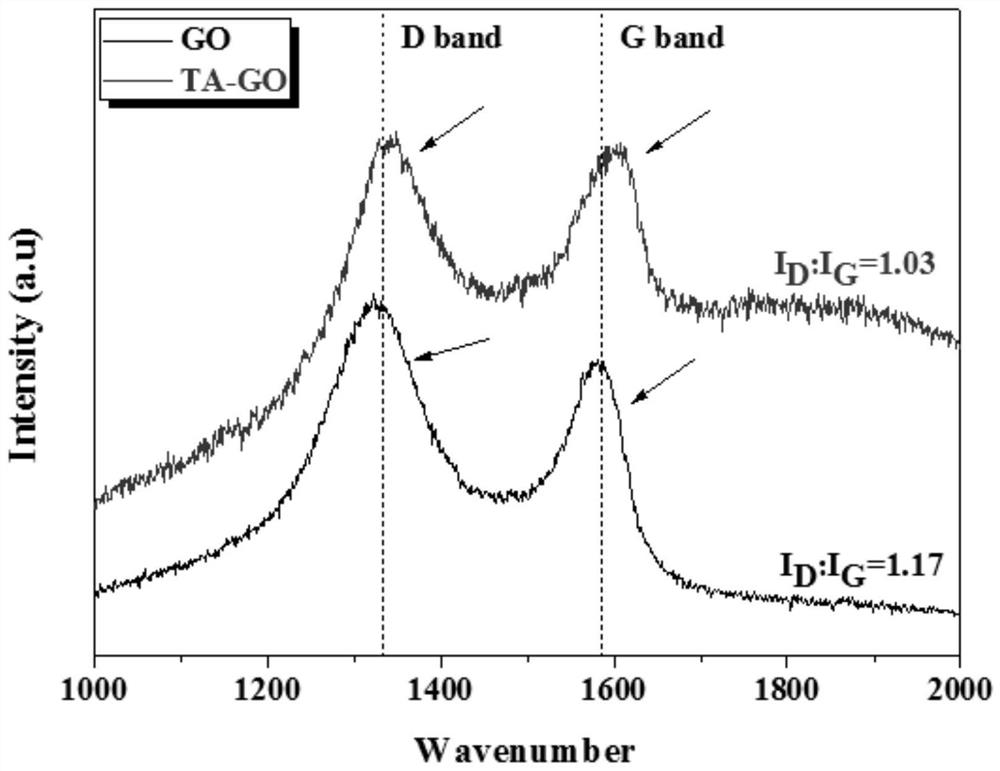

A kind of epoxy nanocomposite material of tannic acid modified graphene oxide

ActiveCN109880294BGood compatibilityImprove the bonding strength of the interfacePolymer scienceFirming agent

The invention provides an epoxy nanocomposite material, which is prepared from the following raw materials: tannic acid modified graphene oxide (TA-GO), epoxy resin and curing agent. The present invention also provides a preparation method of the above-mentioned epoxy nanocomposite material. The experimental results show that TA-GO and epoxy resin have super compatibility and interfacial bonding strength, and the cross-linking density of the composite material system is greatly improved under the extremely low addition amount of TA-GO, and the mechanical properties of the composite material system have been significantly improved. epoxy nanocomposites.

Owner:SICHUAN UNIV

Transparent epoxy nanometer composite material, preparation method and application thereof

InactiveCN101338066BOvercoming Light Scattering PhenomenonHigh light transmittanceOther chemical processesResin matrixSilicon dioxide

The invention relates to transparent epoxy nano composite material, and a preparation method and purposes thereof. The composite material comprises epoxy resin matrix material and composite nano inorganic filler which is evenly distributed in the epoxy resin matrix material; the composite nano inorganic filler consists of a zinc oxide quantum dot which is taken as a core and has grain size of 2nmto 10nm and a silicon dioxide outer layer which is taken as a shell and coated on the zinc oxide quantum dot; the epoxy resin matrix material consists of epoxy resin and epoxy curing agent; the epoxyresin is bisphenol-A epoxy resin or hydrogenated bisphenol-A epoxy resin; the epoxy curing agent is estolide curing agent which contains 1.0 weight percent to 5.0 weight percent of curing accelerator; the curing accelerator is amine curing accelerator or imidazole curing accelerator. The transparent epoxy nano composite material of the invention has excellent transparency, good fluorescence and phosphorescence effect compared with common pure transparent epoxy, and can replace traditional fluorescent powder. The invention is applicable in packaging LED and other luminescent semiconductor devices.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A kind of amino-terminated modified graphene oxide and its epoxy nanocomposite material

The invention relates to an amino-terminated modified graphene oxide and an epoxy nanocomposite material thereof. Specifically discloses a modified graphene oxide, which is obtained by replacing the -OH group on the carboxyl group on the surface of graphene oxide with an A group. The structure of the A group is as follows; Graphene oxide is used as a raw material to prepare epoxy nanocomposites. The amino-terminated modified graphene oxide prepared by the present invention can greatly improve the storage modulus and glass transition temperature of the epoxy nanocomposite material under low addition, and improve the rigidity and heat resistance of the composite material , and at the same time can significantly improve the mechanical properties, especially the tensile properties, with excellent comprehensive properties and excellent application prospects.

Owner:SICHUAN UNIV

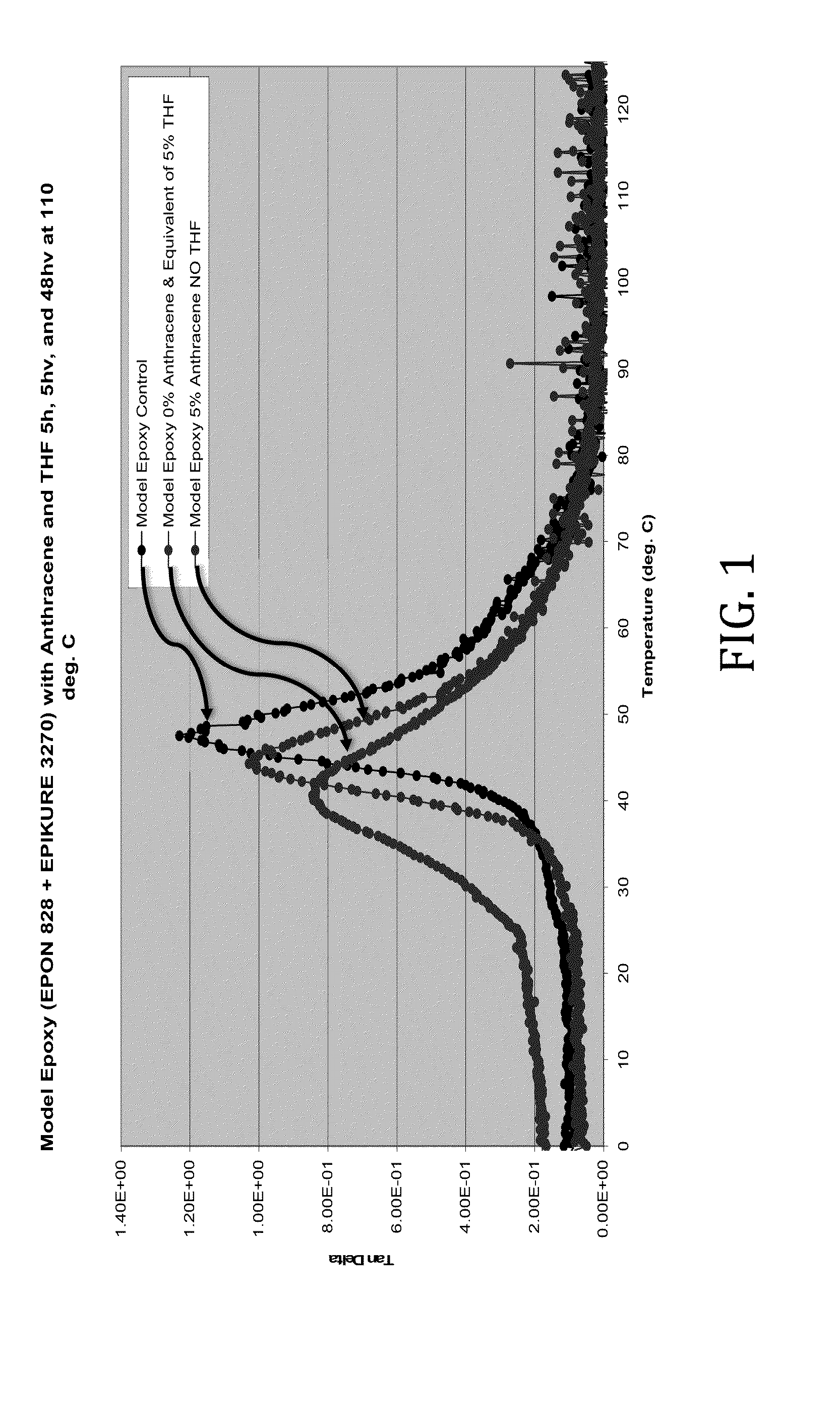

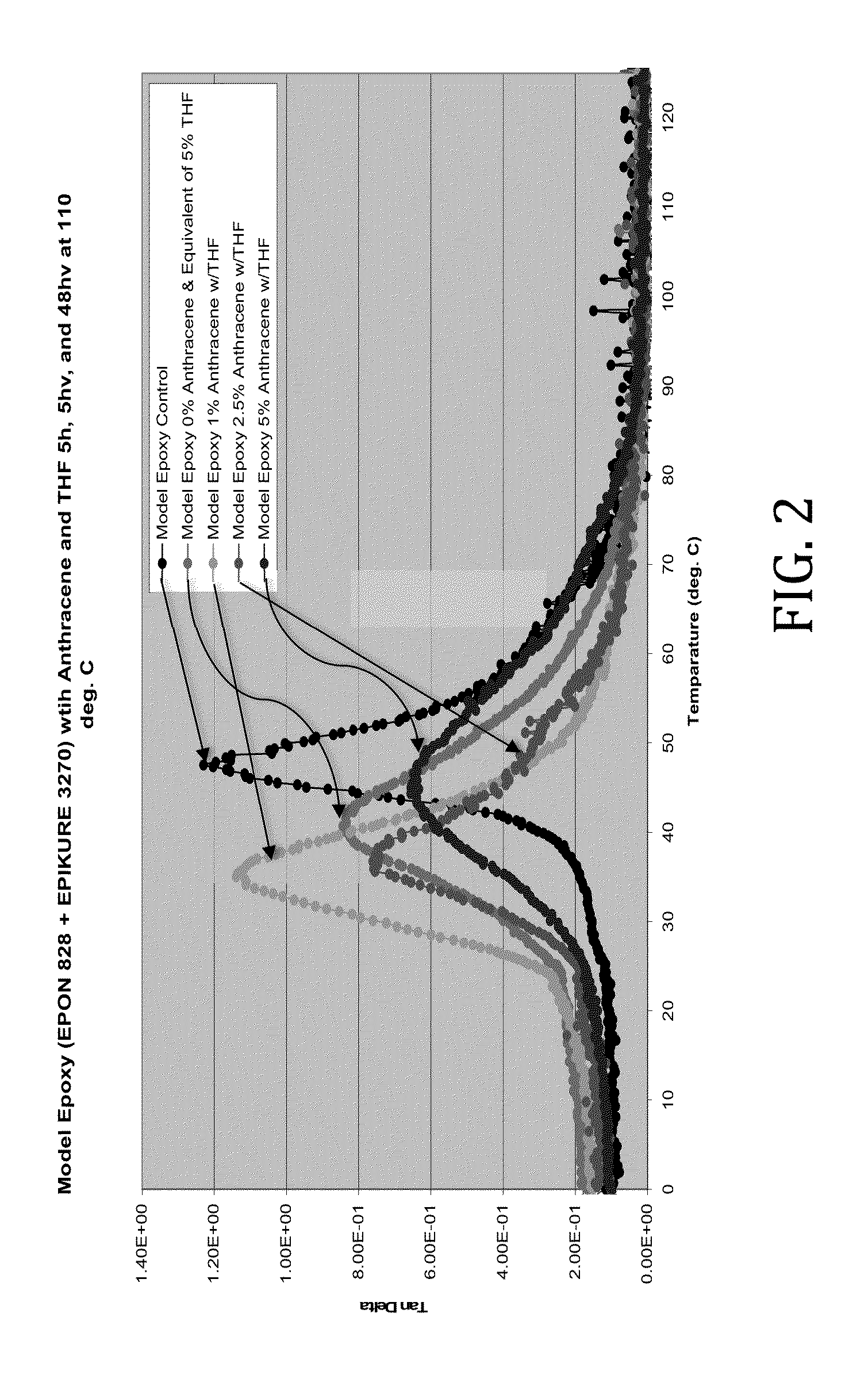

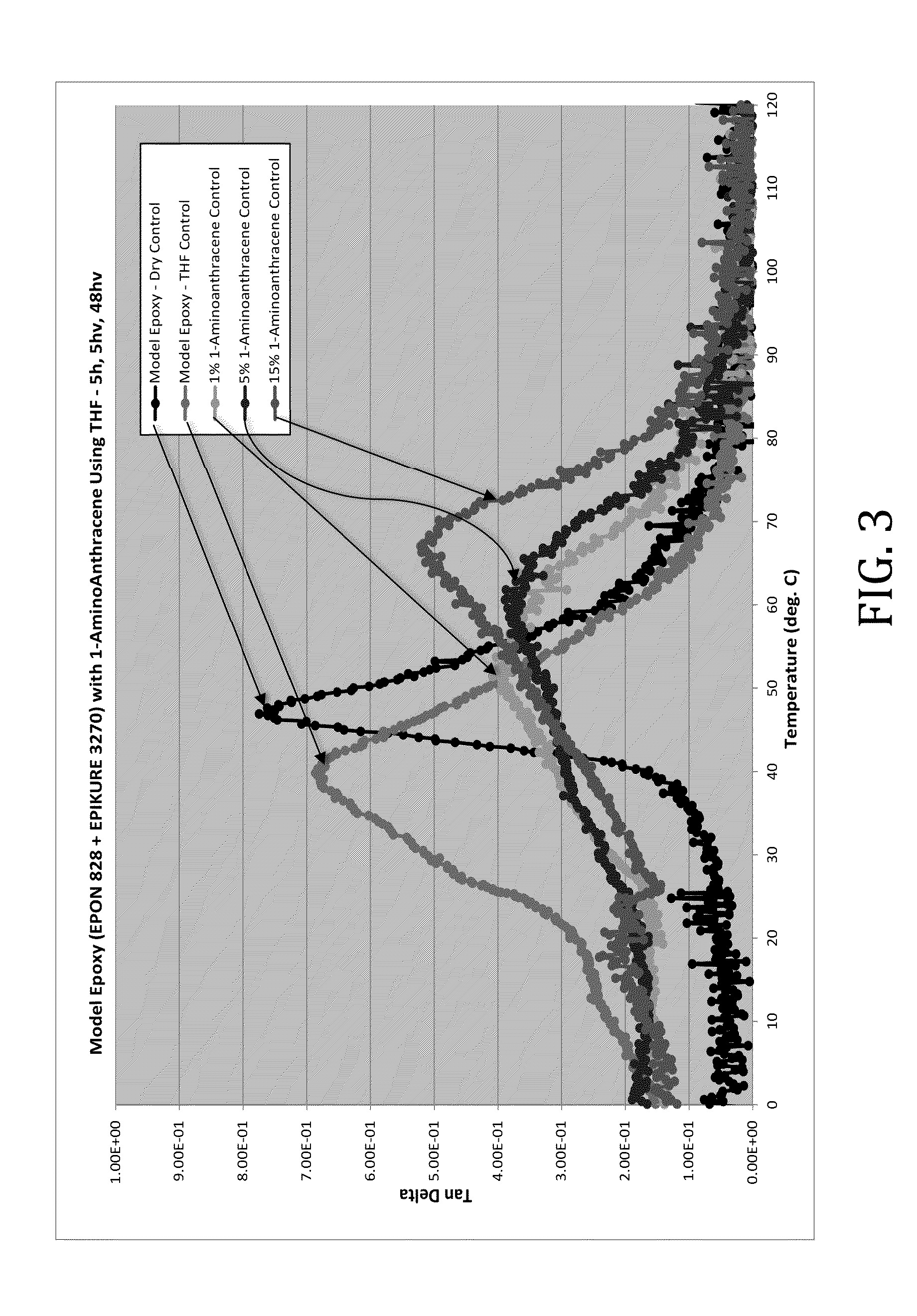

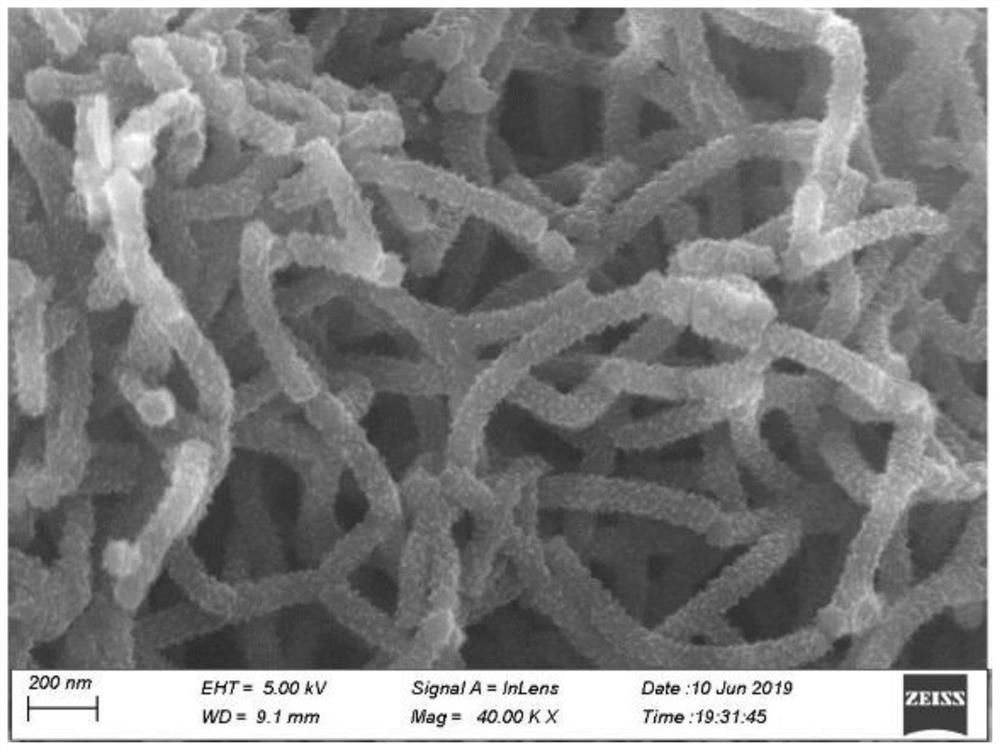

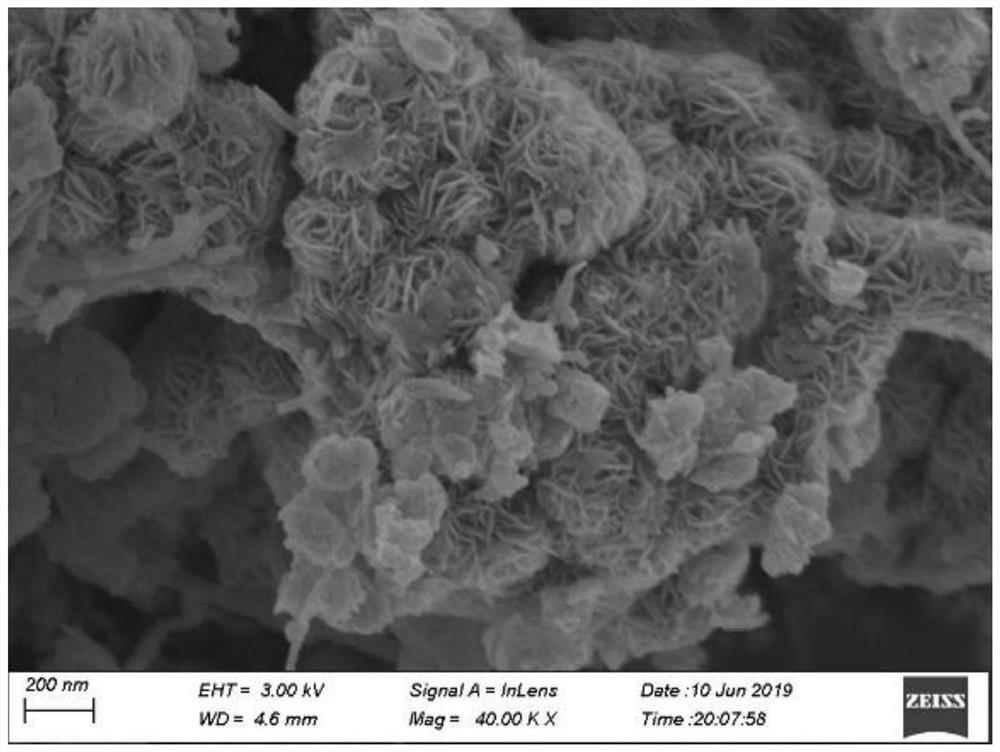

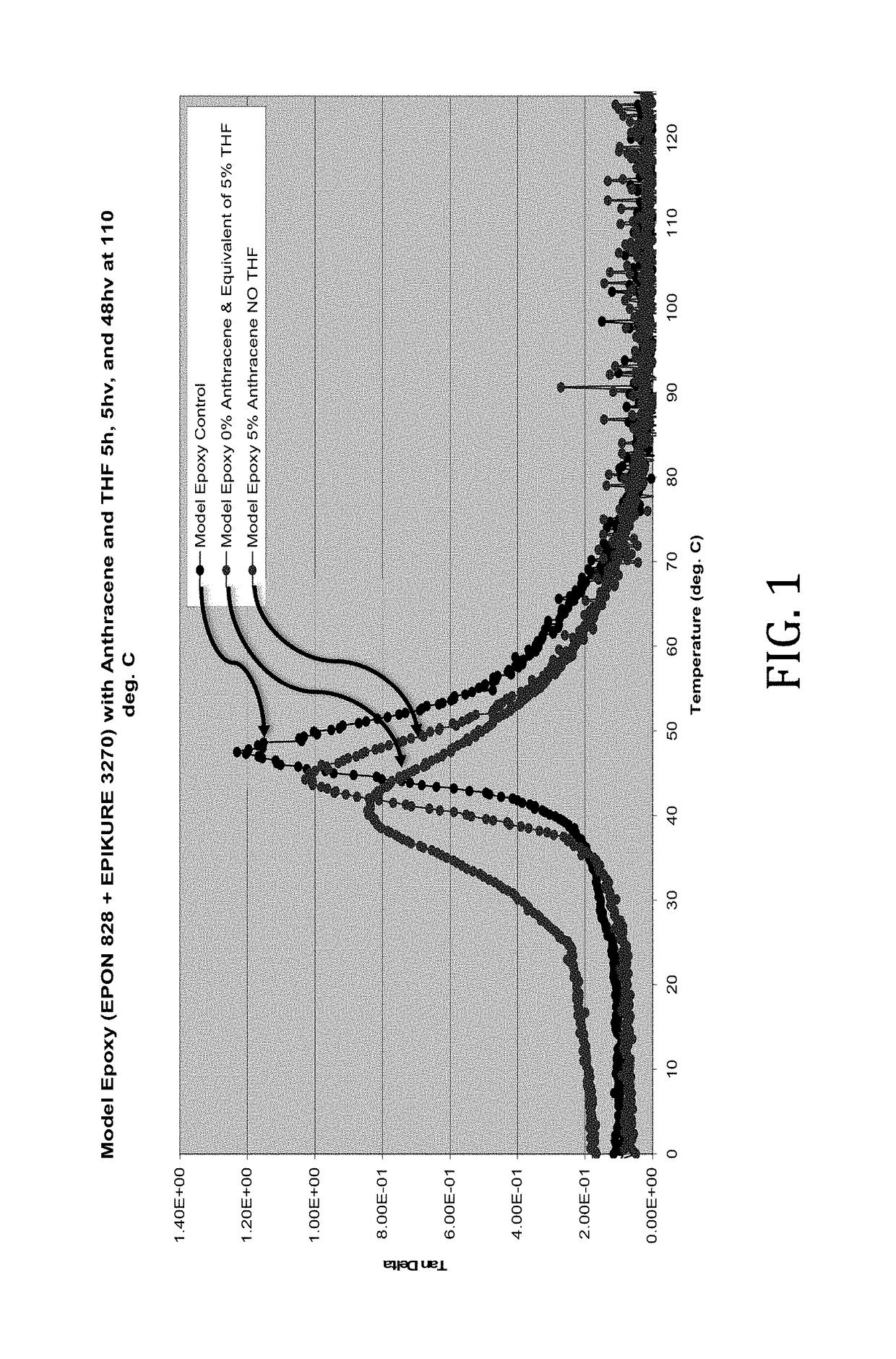

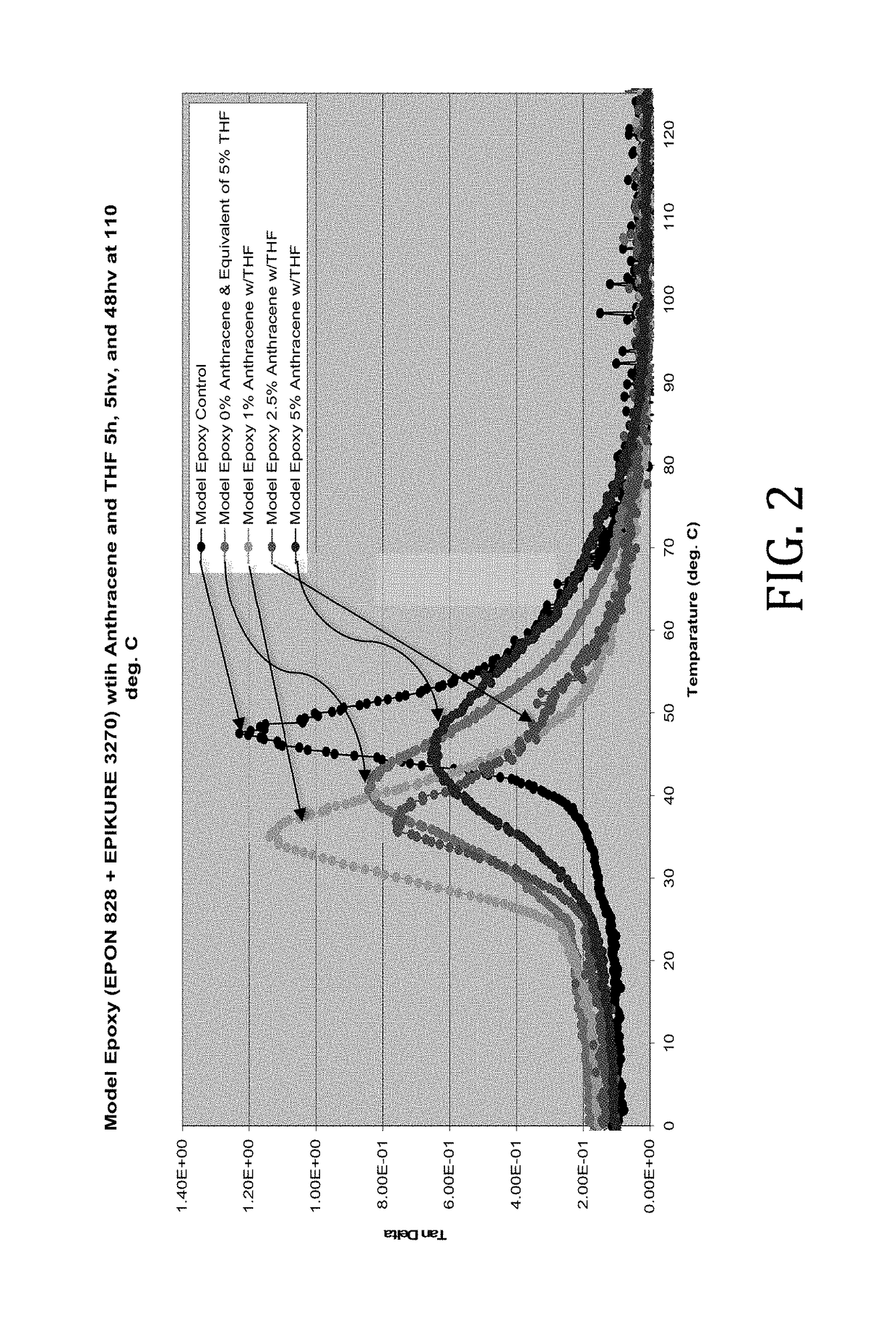

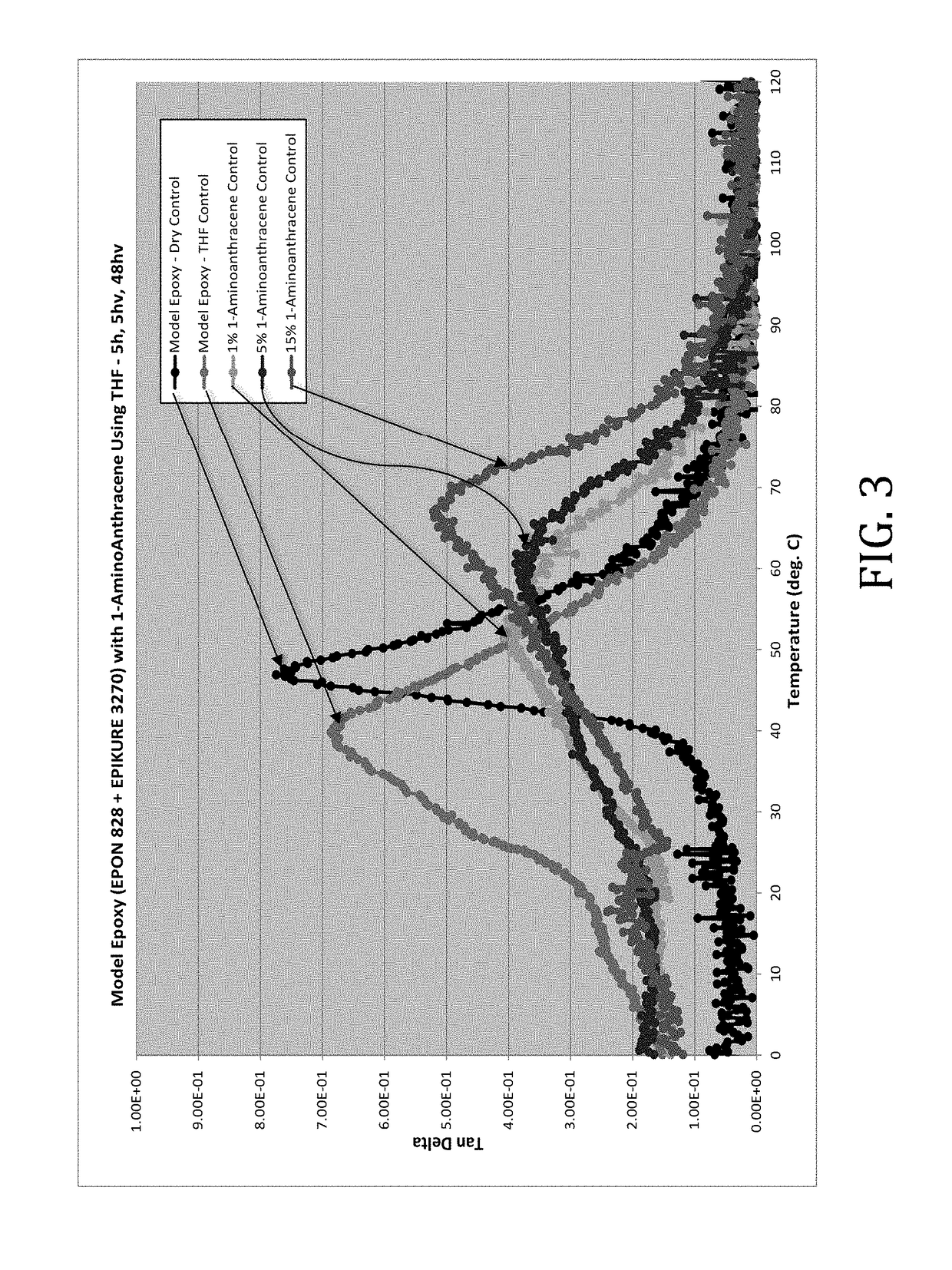

Aminoanthracene-epoxy nanocomposite containing free anthracene

Polymeric nanocomposite materials are provided comprising polycyclic aromatic hydrocarbon compounds. During polymer synthesis, polycyclic aromatic hydrocarbon groups are directly incorporated into the polymer network. Free polycyclic aromatic hydrocarbon compounds are also dispersed within the polymer matrix. The resulting nanocomposite materials exhibit improvements in the thermal, rheological, and physical properties, including reinforcement, of the polymer material as compared to the unmodified polymer.

Owner:HONEYWELL FED MFG & TECHNOLOGI

A modified epoxy nanocomposite material based on layered nickel silicate-coated polyaniline composite nanofibers and its preparation method

The invention discloses a preparation method of layered nickel silicate-coated polyaniline composite nanofibers, comprising: reacting phytic acid, aniline and ammonium persulfate in a certain ratio to obtain phytic acid-doped modified polyaniline nanofibers, Further, a large amount of layered nickel silicate nanomaterials are loaded on the surface of the modified polyaniline nanofibers by hydrothermal method, and the layered nickel silicate-coated polyaniline composite nanofibers with a core-shell structure are obtained after centrifugation, washing and drying; The invention also discloses a preparation method of an epoxy resin composite material containing layered nickel silicate coated polyaniline composite nanofibers. The layered nickel silicate-coated polyaniline composite nanofibers with a core-shell structure disclosed by the present invention can not only disperse the polyaniline nanofibers uniformly in the epoxy matrix, improve the mechanical properties, but also significantly reduce the wear rate of the material and inhibit Combustion can be used to prepare epoxy nanocomposites with high wear resistance and good flame retardancy.

Owner:ANHUI UNIV OF SCI & TECH

Aminoanthracene—epoxy nanocomposite containing free anthracene

Polymeric nanocomposite materials are provided comprising polycyclic aromatic hydrocarbon compounds. During polymer synthesis, polycyclic aromatic hydrocarbon groups are directly incorporated into the polymer network. Free polycyclic aromatic hydrocarbon compounds are also dispersed within the polymer matrix. The resulting nanocomposite materials exhibit improvements in the thermal, rheological, and physical properties, including reinforcement, of the polymer material as compared to the unmodified polymer.

Owner:HONEYWELL FED MFG & TECHNOLOGI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com