Preparation process of transparent epoxy nanocomposite material for encapsulating high-power LED (light-emitting diode)

A nanocomposite material and LED packaging technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor compatibility between nanoparticles and polymer matrix, poor compatibility between toughener and epoxy resin, and nanoparticle dispersion. Difficult to solve and other problems, to achieve the effect of good transparency, not easy to crack, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

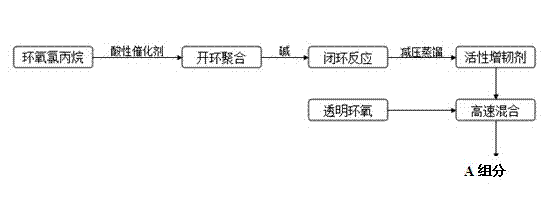

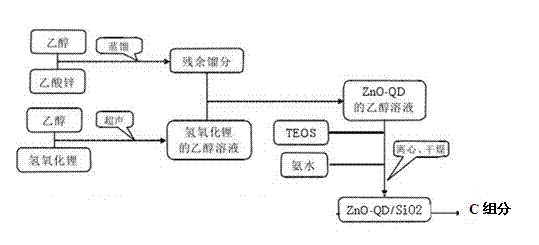

[0031] like figure 1 , 2 , 3 and 4: a preparation process of a transparent epoxy nanocomposite material for high-power LED packaging, comprising the following steps:

[0032] 1) Using epichlorohydrin as a raw material to add an acidic catalyst to carry out ring-opening polymerization;

[0033] 2) Add alkali to the reaction system of step 1) to carry out the closing reaction;

[0034] 3) Extracting, filtering, drying, distilling and vacuuming the solution obtained in step 2) to obtain a long-chain linear glycidyl ether epoxy resin, that is, an active toughening agent;

[0035] 4) Mix the above active toughening agent with transparent epoxy at high speed to obtain the required toughening agent, namely component A;

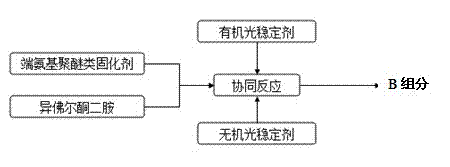

[0036] 5) Mix the amino-terminated polyether curing agent and isophorone diamine to obtain a mixed solution;

[0037] 6) Add o-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com