A kind of epoxy nanocomposite material of tannic acid modified graphene oxide

A composite material and epoxy nanotechnology, which is applied in the field of epoxy nanocomposite materials, can solve the problems of insufficient compatibility and interface bonding strength, and the mechanical properties of composite materials cannot meet the requirements, so as to improve the compatibility and interface bonding strength. , Improve mechanical properties, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, the preparation of tannic acid modified graphene oxide / epoxy nanocomposite material (TA-GO / EP) of the present invention

[0034] 1. Preparation of tannic acid modified graphene oxide

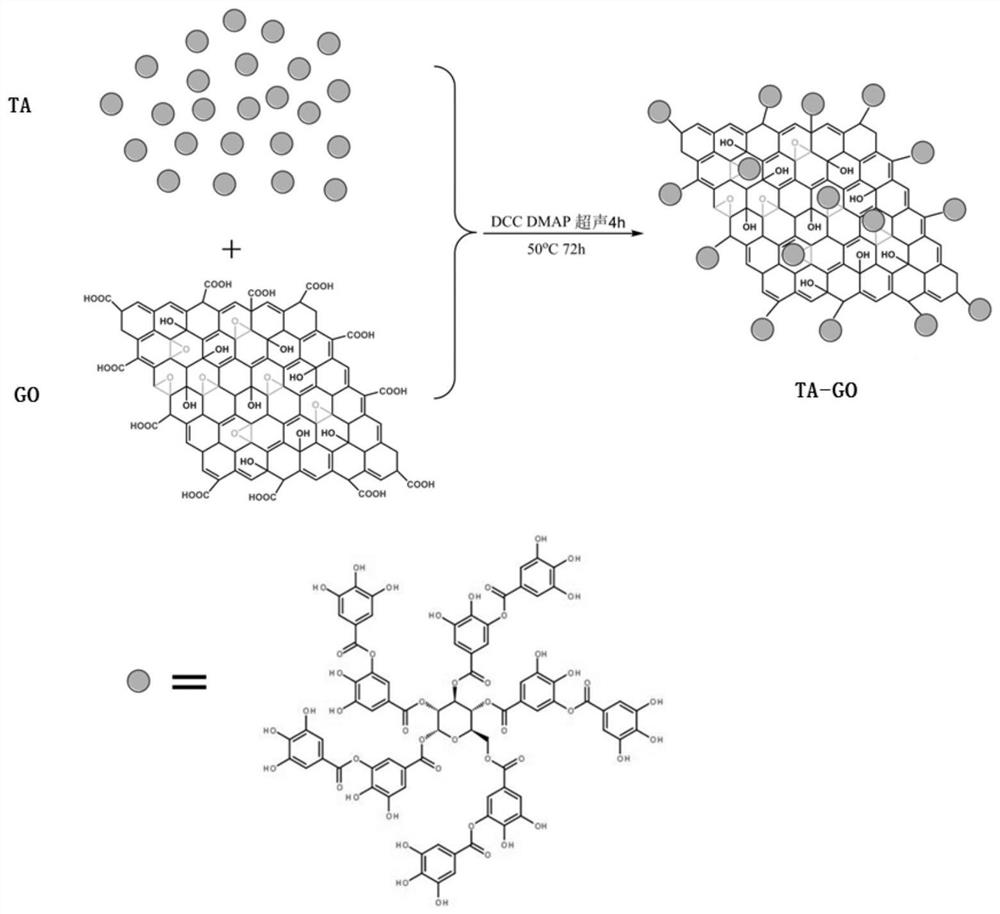

[0035] according to figure 1 The synthetic route shown is to synthesize the tannic acid-modified graphene oxide (TA-GO) of the present invention.

[0036] Weigh 0.5g graphene oxide (GO) (C / O molar ratio is (6.9-7.1): 3, can be purchased from Beijing Carbon Century Technology Co., Ltd.) cell crushing ultrasonic dispersion in 100mL dry dimethyl sulfoxide (DMSO ), sequentially add dimethylepoxypyridine (DMAP) and N,N-dicyclohexylcarbodiimide (DCC) to the dispersed GO suspension, and ensure that m(GO):n(DMAP) :n(DCC) is 0.4g:9.6mmol:0.8mmol. The mixture was ultrasonically activated in a water bath at room temperature for 4 h. After the activation, under stirring, 2 g of tannic acid (TA) in 50 mL of DMSO was slowly dropped into the three-necked flask at a constant rate, and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com