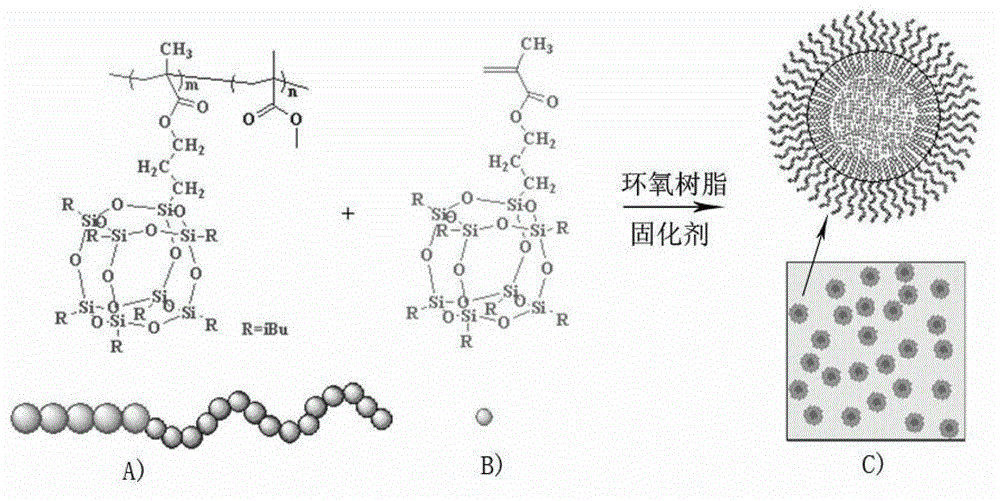

Epoxy nanocomposite with controllable phase structure and based on polyhedral oligomeric silsesquioxanes (POSS)

A composite material, epoxy nanotechnology, applied in epoxy nanocomposite materials and their preparation, in the field of epoxy nanocomposite materials based on POSS, can solve the problems that are not involved, achieve improved compatibility, strong operability, Easy to achieve the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

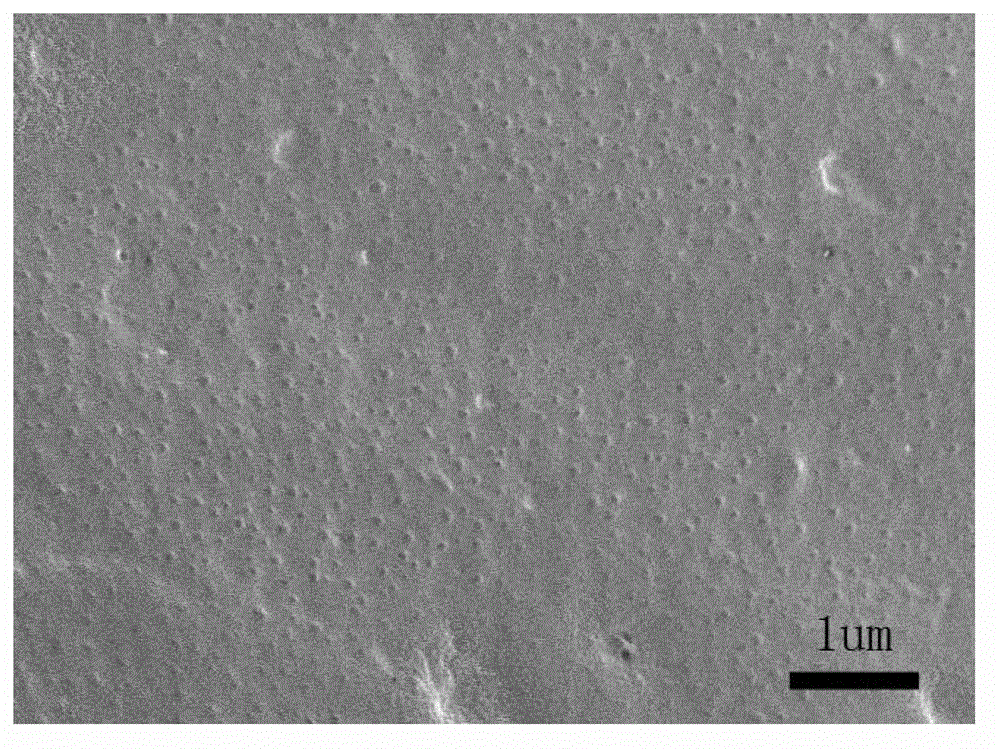

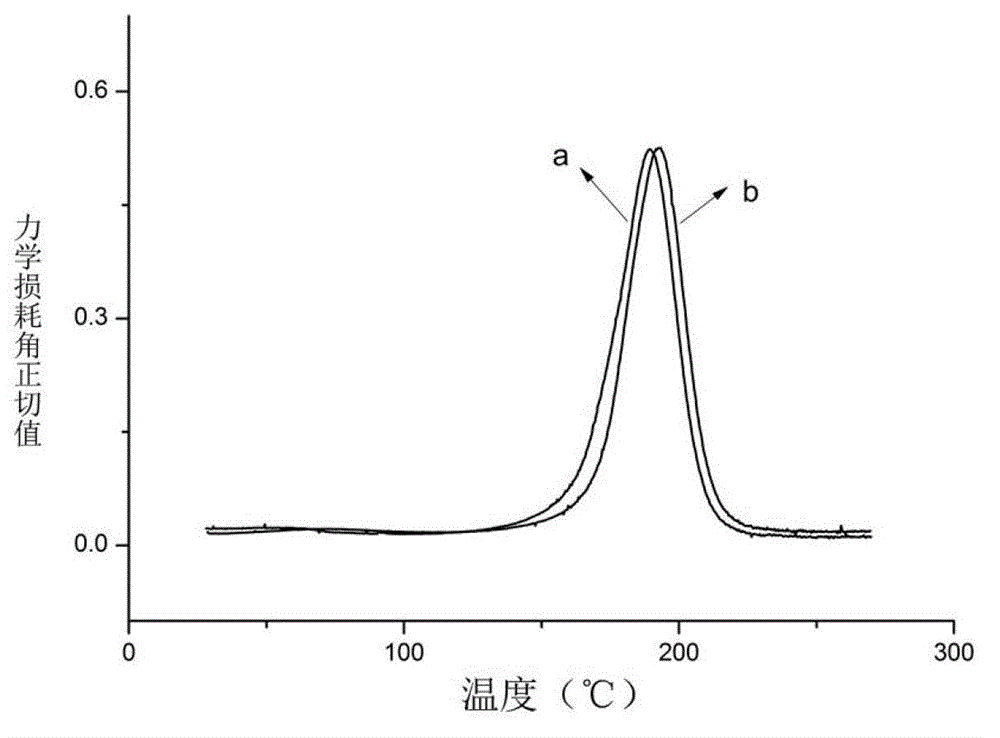

Embodiment 1

[0035] Prepare POSS monomer (MAiBuPOSS): chain transfer agent (CDB): initiator (AIBN) = 20:1:0.2 tetrahydrofuran solution system, the monomer concentration is 0.7mol / L, put the solution in the reactor and freeze it with liquid nitrogen After melting and degassing for three to five times, fill it with argon to protect the reaction for 48 hours. After the reaction, freeze it with liquid nitrogen to stop the reaction, add a small amount of tetrahydrofuran to dilute, drop it into methanol for precipitation, dry the precipitate and take a sample for NMR test. Repeat this step for repeated precipitation Until there is no POSS monomer, dry to obtain pink PMAiBuPOSS. The molar ratio of methyl methacrylate monomer (MMA): PMAiBuPOSS: initiator (AIBN) = 16000: 20: 1 prepares a tetrahydrofuran solution system with a monomer concentration of 4 mol / L, and puts the solution in the reactor with liquid After three to five times of nitrogen freeze-thaw degassing, fill with argon to protect the ...

Embodiment 2

[0038] Prepare POSS monomer (MAiBuPOSS): chain transfer agent (CDB): initiator (AIBN) = 20:1:0.2 tetrahydrofuran solution system, the monomer concentration is 0.7mol / L, put the solution in the reactor and freeze it with liquid nitrogen After melting and degassing for three to five times, fill it with argon to protect the reaction for 48 hours. After the reaction, freeze it with liquid nitrogen to stop the reaction, add a small amount of tetrahydrofuran to dilute, drop it into methanol for precipitation, dry the precipitate and take a sample for NMR test. Repeat this step for repeated precipitation Until there is no POSS monomer, dry to obtain pink PMAiBuPOSS. The molar ratio of methyl methacrylate monomer (MMA): PMAiBuPOSS: initiator (AIBN) = 16000: 20: 1 prepares a tetrahydrofuran solution system with a monomer concentration of 4 mol / L, and puts the solution in the reactor with liquid Nitrogen freeze-thaw degassing three to five times, then filled with argon to protect the re...

Embodiment 3

[0040] Prepare POSS monomer (MAiBuPOSS): chain transfer agent (CDB): initiator (AIBN) = 30:1:0.2 tetrahydrofuran solution system, the monomer concentration is 0.7mol / L, put the solution in the reactor and freeze it with liquid nitrogen After melting and degassing for three to five times, fill it with argon to protect the reaction for 48 hours. After the reaction, freeze it with liquid nitrogen to stop the reaction, add a small amount of tetrahydrofuran to dilute, drop it into methanol for precipitation, dry the precipitate and take a sample for NMR test. Repeat this step for repeated precipitation Until there is no POSS monomer, dry to obtain pink PMAiBuPOSS. The molar ratio of methyl methacrylate monomer (MMA): PMAiBuPOSS: initiator (AIBN) = 16000: 20: 1 prepares a tetrahydrofuran solution system with a monomer concentration of 4 mol / L, and puts the solution in the reactor with liquid After three to five times of nitrogen freeze-thaw degassing, fill with argon to protect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com