Amino-terminated modified graphene oxide and epoxy nano composite material thereof

A technology on the surface of oxidized stone and graphene, which is applied in the direction of carbon compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of high heat distortion temperature, difficult synthesis of TLCP, difficult processing, etc., so as to improve elongation at break and application Good prospects and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

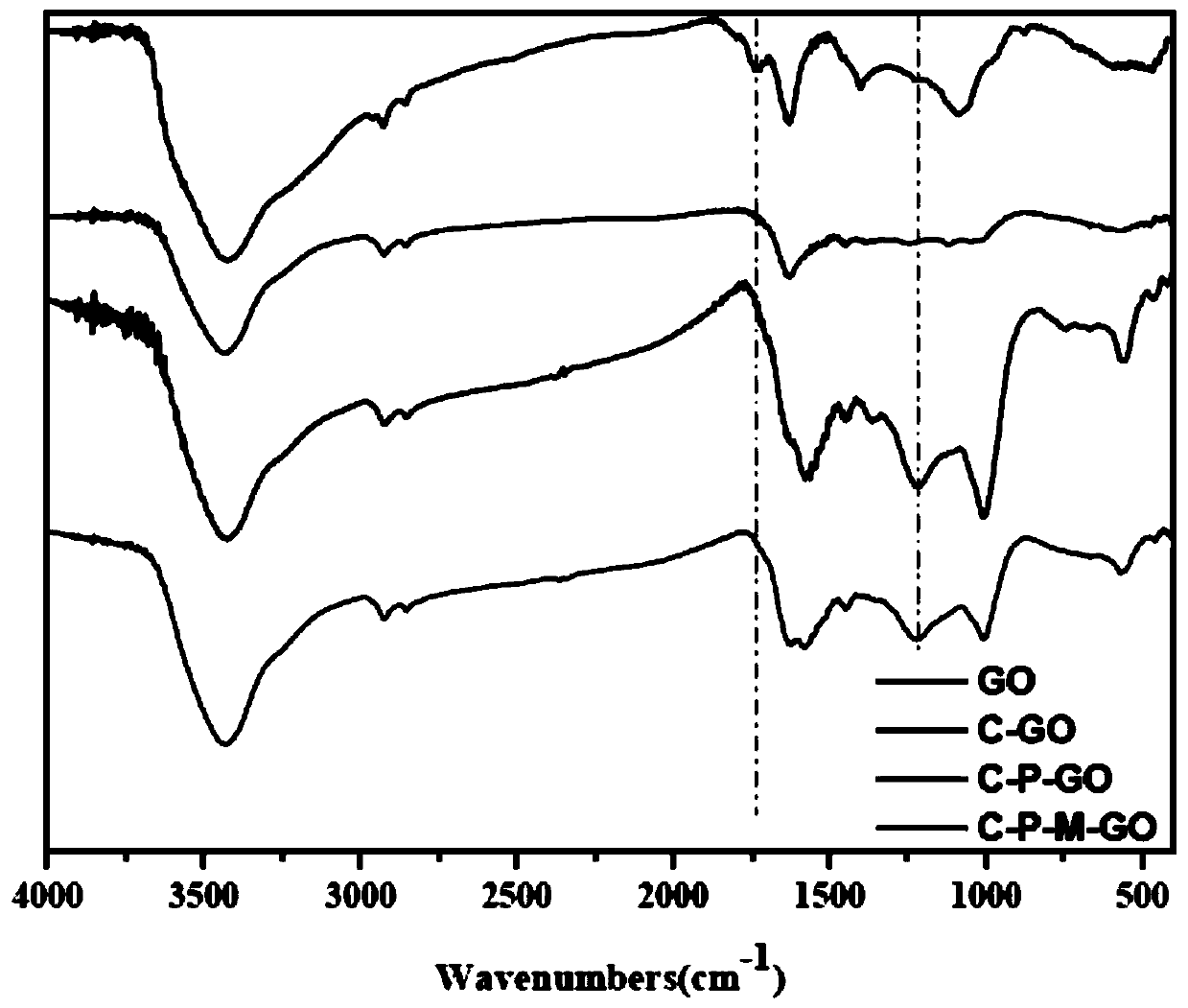

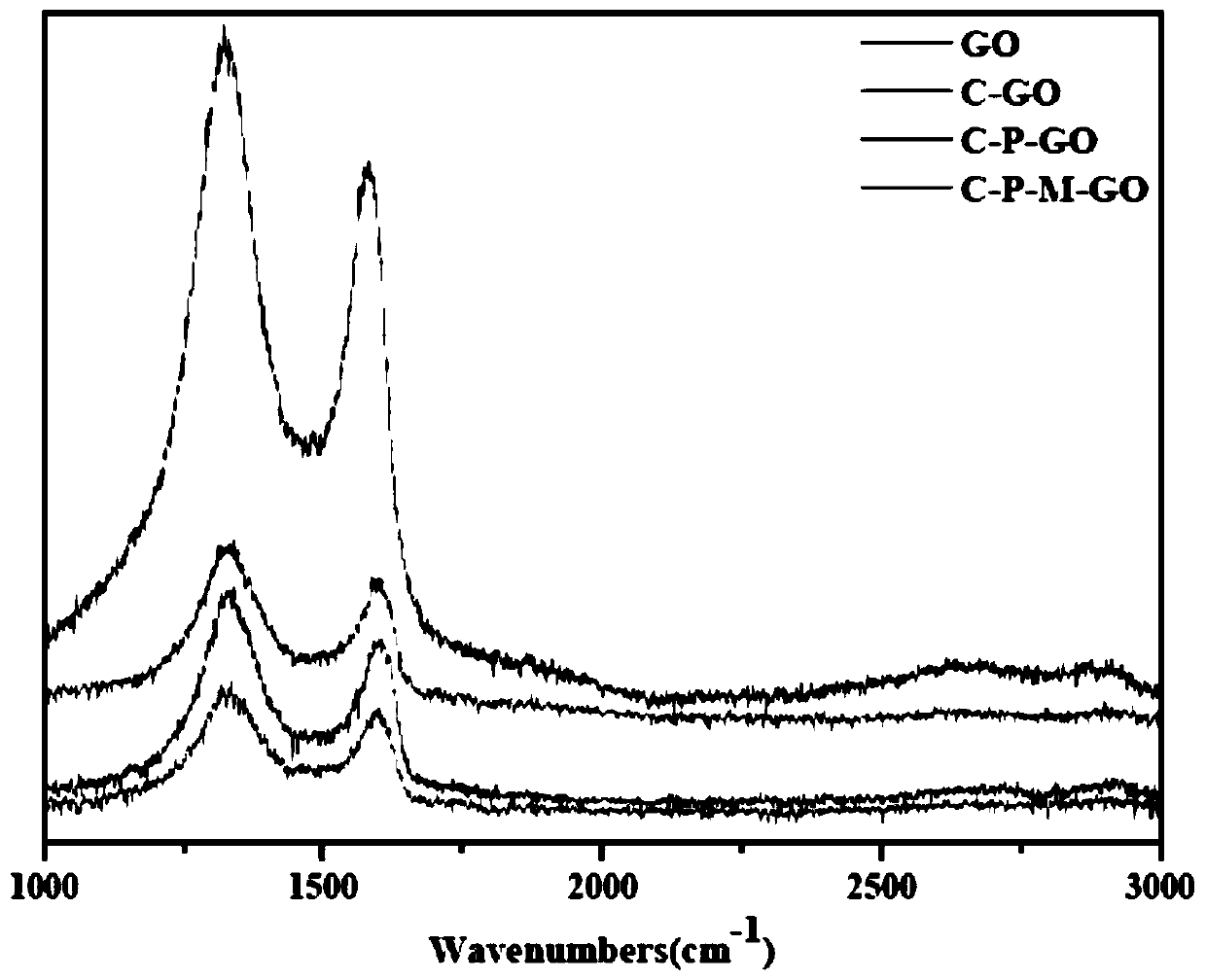

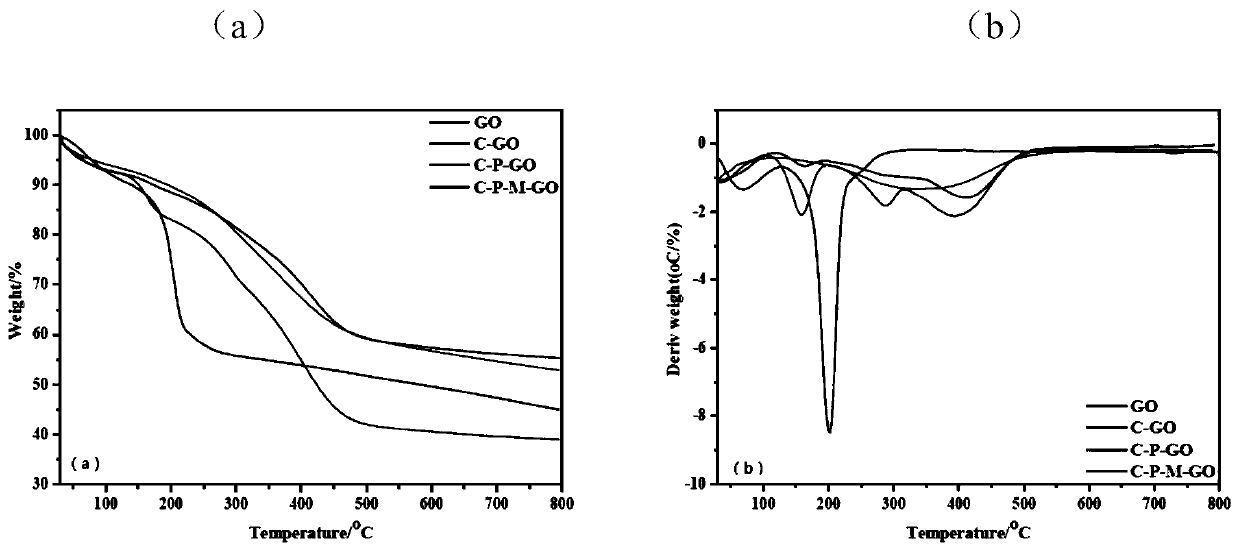

[0041] Embodiment 1, the preparation of modified graphene oxide of the present invention

[0042] (1) Preparation of intermediate product 1 (C-GO)

[0043] Weigh 1 g of graphene oxide (GO, C / O molar ratio (6.9-7.1): 3, purchased from Beijing Carbon Century Technology Co., Ltd.), and ultrasonically disperse the cells in 300 mL of dry dimethylformamide (DMF). , the dispersed GO suspension was added to a 1000mL three-necked flask, and 4,4'-diaminodicyclohexylmethane (PACM), dimethylepoxypyridine (DMAP) and N,N-bicyclohexyl Hexylcarbodiimide (DCC), and ensure that m(GO):n(PACM):n(DMAP):n(DCC) is 1g:30mmol:10mmol:10mmol. The mixture was reacted at 90°C for 24 hours. After the reaction was completed, it was cooled to room temperature, filtered under reduced pressure using a 0.45 μm polytetrafluoroethylene filter, and washed 5 times with DMF to remove unreacted 4,4'-di Aminodicyclohexylmethane, catalyst, to obtain intermediate product 1 (C-GO).

[0044] (2) Preparation of intermed...

Embodiment 2

[0048] Embodiment 2, the preparation of modified graphene oxide / epoxy nanocomposite material (C-P-M-GO / EP) of the present invention

[0049] According to the formula shown in Table 1, weigh the modified graphene oxide C-P-M-GO, ultrasonically disperse it in the acetone solution at a ratio of 1:1 mg / mL, and add 70 g of TDE-85 epoxy resin to the solution uniformly dispersed after ultrasonic (purchased from Tianjin Jingdong Chemical Composite Material Co., Ltd.), and the solvent was removed by mechanical stirring at 65°C. Weigh 4,4' diaminodiphenylmethane (DDM) and 3,5-diethyl-2,4 toluenediamine (DETDA) mixed curing agent, add modified graphene oxide / TDE-85 epoxy resin In the mixed solution, electric stirring at a constant speed for 15 minutes, so that the curing agent and the resin are fully mixed. The obtained mixture was placed in a vacuum drying oven and dried in vacuum for 30 min to remove the air bubbles introduced during the stirring process. Finally, pour the vacuum-dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com