Controllable fully biodegradable mulching film and preparation method thereof

A degradable mulch film and all-biological technology, which is applied in the field of controllable fully biodegradable mulch film and its preparation, can solve the problem that the fully biodegradable mulch film is greatly affected by light, temperature, moisture and soil environment, and hinders the movement of water and nutrients in the soil. Biodegradable mulch is not suitable for other problems, so as to achieve the effects of large-scale mechanized film laying, improved water vapor barrier performance, and excellent film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

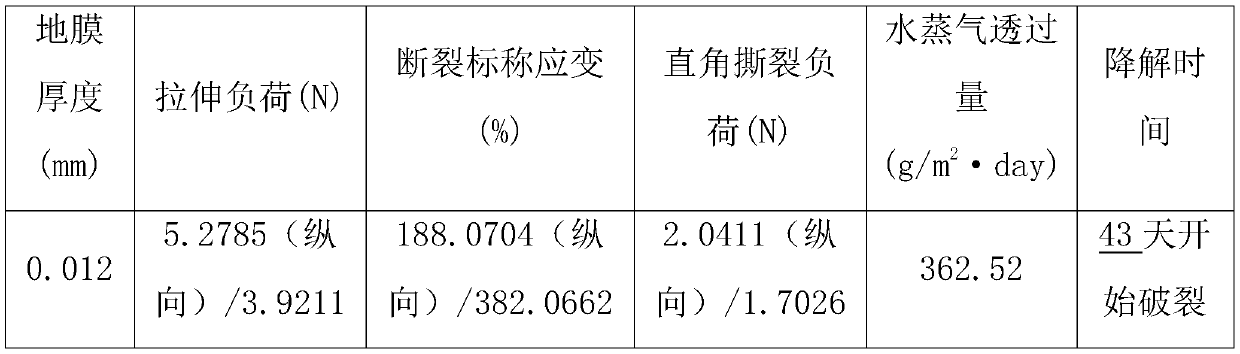

Embodiment 1

[0055] The "film function period" of tobacco-covered mulch in low-altitude areas in Southwest China is about 40 days

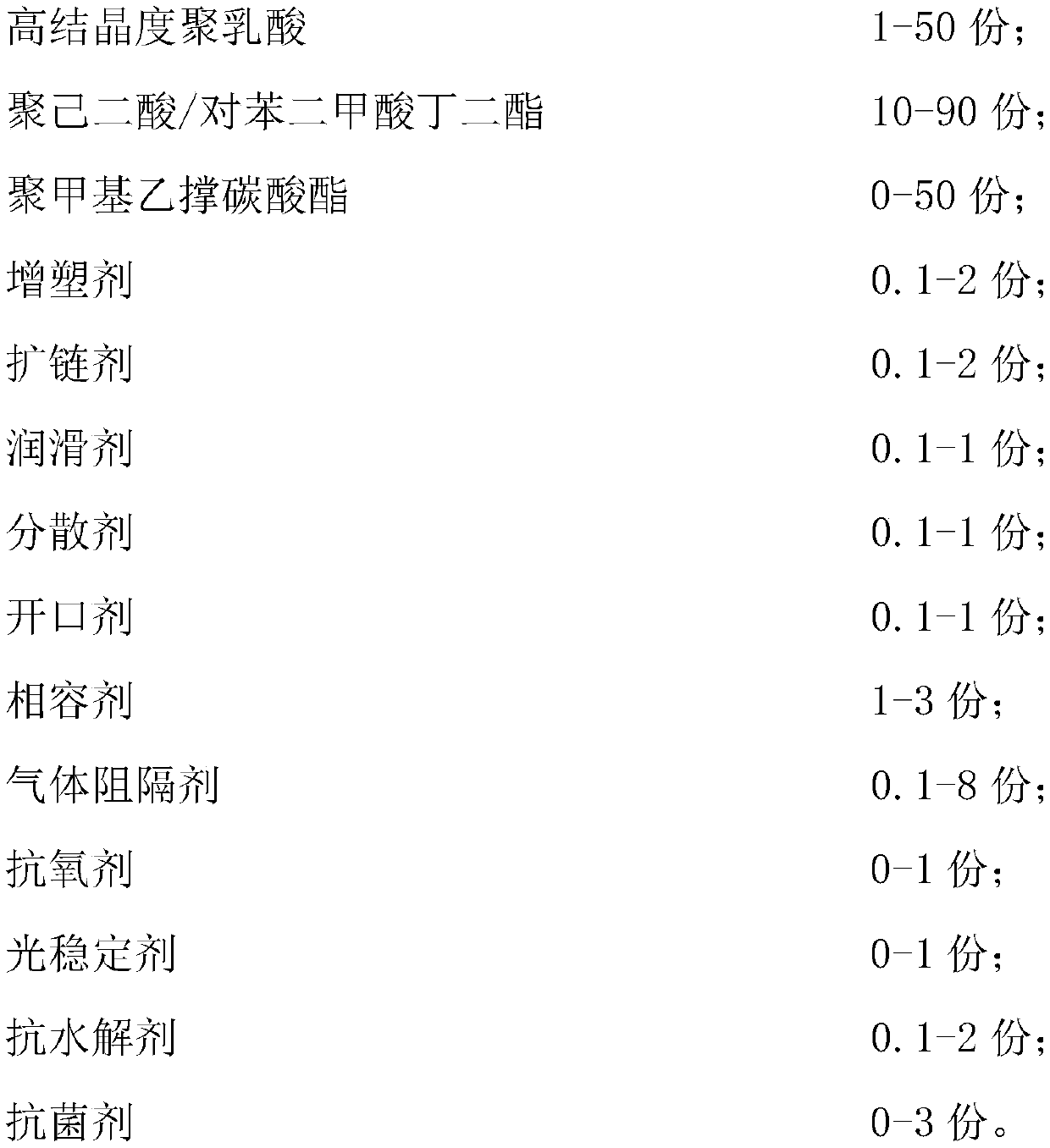

[0056] The raw materials of the fully biodegradable plastic film of the present embodiment weigh each component by the following parts by weight:

[0057] 25 parts of high crystallinity polylactic acid, 75 parts of polybutylene adipate / terephthalate, 0.3 parts of epoxy soybean oil, 0.6 parts of polyethylene glycol-8000, 0.6 parts of hexamethylene diisocyanate, stearin 0.2 parts of calcium carbonate, 0.3 parts of oxidized polyethylene wax, 0.4 parts of oleic acid amide, 0.03 parts of dicumyl peroxide, 1.5 parts of styrene-maleic anhydride random copolymer, 3 parts of organically modified nano-montmorillonite, 0.3 parts of composite antioxidant, 1.5 parts of diphenylmethane diisocyanate, 2 parts of 4,5-dichloro-N-octyl-3-isothiazolinone.

[0058] Preparation steps and conditions are:

[0059] 1) Dry high crystallinity polylactic acid and polyadipate / butylene t...

Embodiment 2

[0069] The "film function period" of peanut-covered mulch in the Liaohe Plain in Northeast China is about 65 days

[0070] The raw materials of the fully biodegradable plastic film of the present embodiment weigh each component by the following parts by weight:

[0071] High crystallinity polylactic acid 15 parts, polyadipate / butylene terephthalate 80 parts, polymethylethylene carbonate 5 parts, acetyl tributyl citrate 0.3 parts, polyethylene glycol-4000 0.4 parts , 0.8 parts of ethylene-methyl acrylate-glycidyl methacrylate terpolymer, 0.2 parts of stearic acid, 0.4 parts of glyceryl monostearate, 0.3 parts of ethylene bisstearic acid amide, grafted olefin copolymer 1.8 parts of glycidyl methacrylate, 4 parts of organic bentonite, 0.5 parts of composite antioxidant, 0.6 parts of composite light stabilizer, 1.2 parts of aromatic polycarbodiimide, N-n-octyl 1,2-benzoiso Thiazolin-3-one 1.5 parts.

[0072] Preparation steps and conditions are:

[0073] 1) Dry polylactic acid wi...

Embodiment 3

[0082] The "film function period" of the cotton-covered plastic film in the western margin of the Junggar Basin in Xinjiang is about 75 days

[0083] The raw materials of the fully biodegradable plastic film of the present embodiment weigh each component by the following parts by weight:

[0084] High crystallinity polylactic acid 15 parts, polyadipate / butylene terephthalate 70 parts, polymethylethylene carbonate 15 parts, tributyl citrate 0.3 parts, polyethylene glycol-6000 0.5 parts, 1 part of epoxy chain extender, 0.3 part of zinc stearate, 0.5 part of cosmetic grade white mineral oil, 0.2 part of erucamide, 0.05 part of dibenzoyl peroxide, styrene-maleic anhydride random copolymer 2 6 parts, 6 parts of organic coated potassium aluminum silicate, 0.5 part of composite antioxidant, 0.7 part of composite light stabilizer, 1 part of 2-oxazoline compound, 2 parts of chlorothalonil.

[0085] Preparation steps and conditions are:

[0086] 1) Dry polylactic acid with high crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com