A kind of high barrier biodegradable material and its preparation method and application

A biodegradable material and biodegradable resin technology, applied in the field of high-barrier biodegradable materials and their preparation, can solve problems such as poor barrier properties, and achieve the effects of improving water vapor barrier properties, extending diffusion paths, and reducing free volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

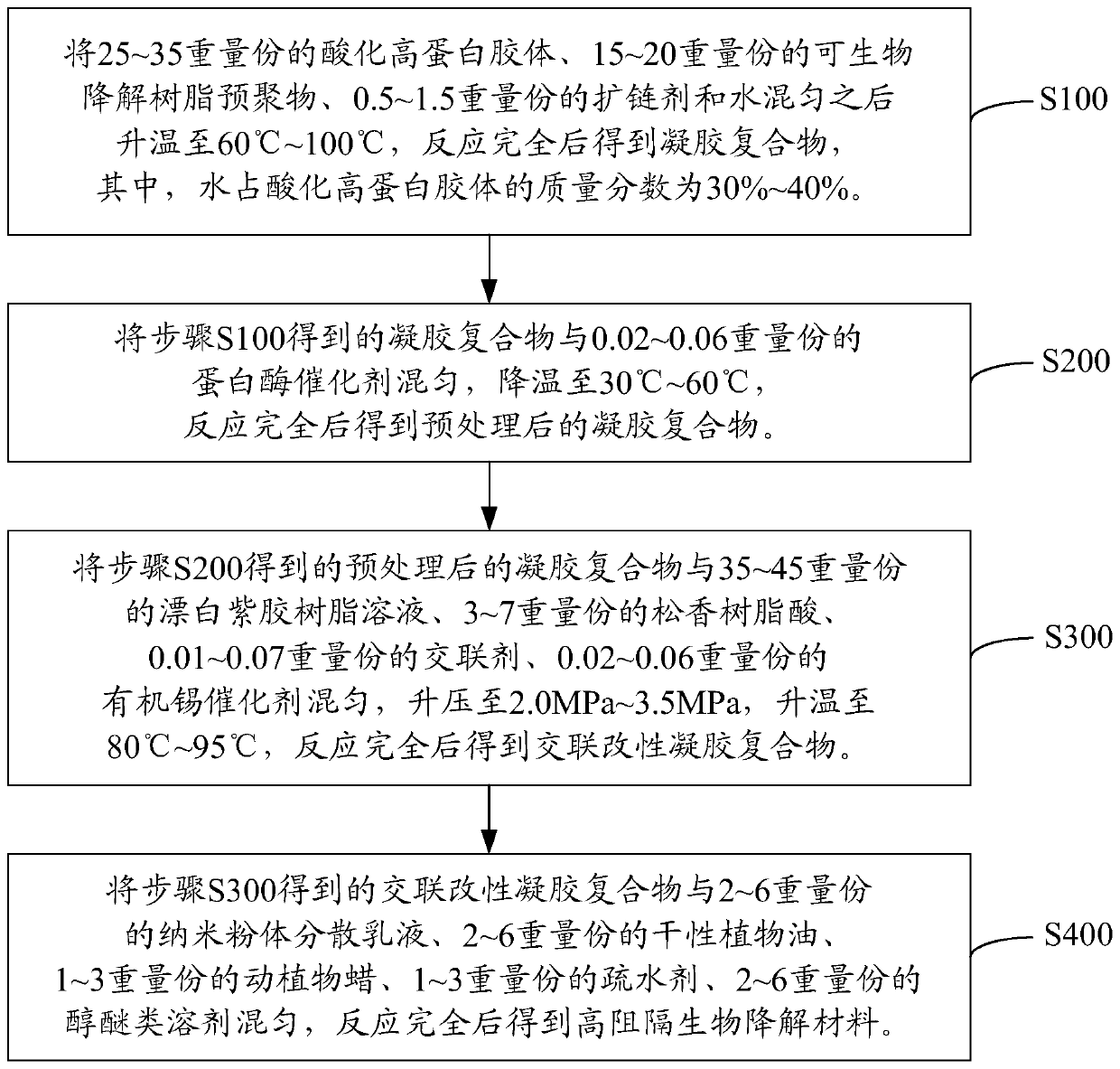

[0056] See figure 1 , the preparation method of the high barrier biodegradable material of one embodiment, comprises the following steps:

[0057] S100, mixing 25-35 parts by weight of the acidified high-protein colloid, 15-20 parts by weight of the biodegradable resin prepolymer, 0.5-1.5 parts by weight of the chain extender and water, and then raising the temperature to 60°C-100°C, After the reaction is complete, a gel complex is obtained, wherein the mass fraction of water in the acidified high-protein colloid is 30% to 40%.

[0058] Preferably, the acidified high protein colloid is prepared by the following steps:

[0059] S110. The animal gelatin protein or soybean protein isolate is boiled in boiling water until it is dehydrated and denatured, and then subjected to acid hydrolysis treatment to obtain fat-free high protein after purification.

[0060] S120. Grinding the fat-free high protein and water, the mass ratio of high protein to water is 1:1-1:2, until the D97 of...

Embodiment 1

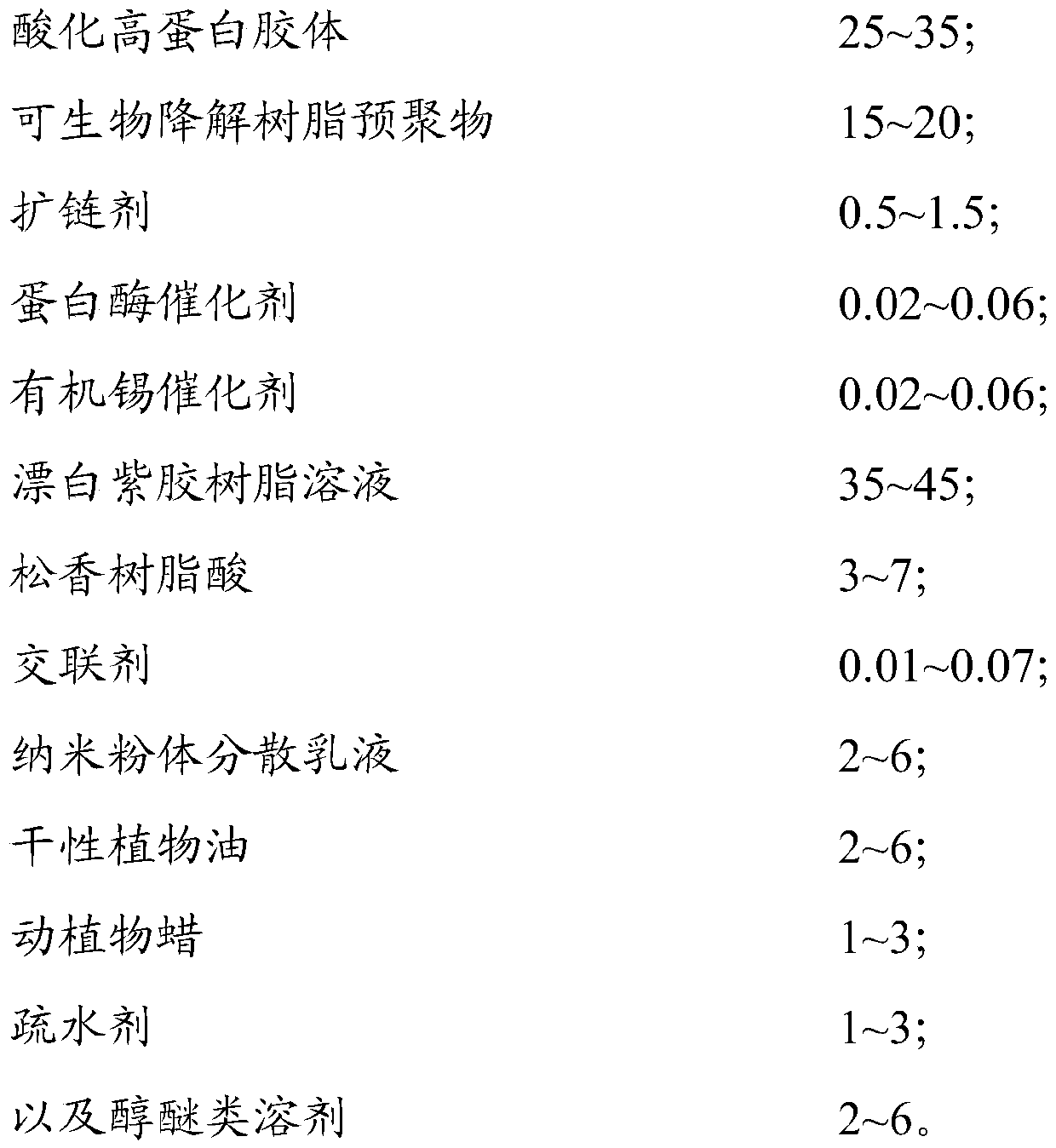

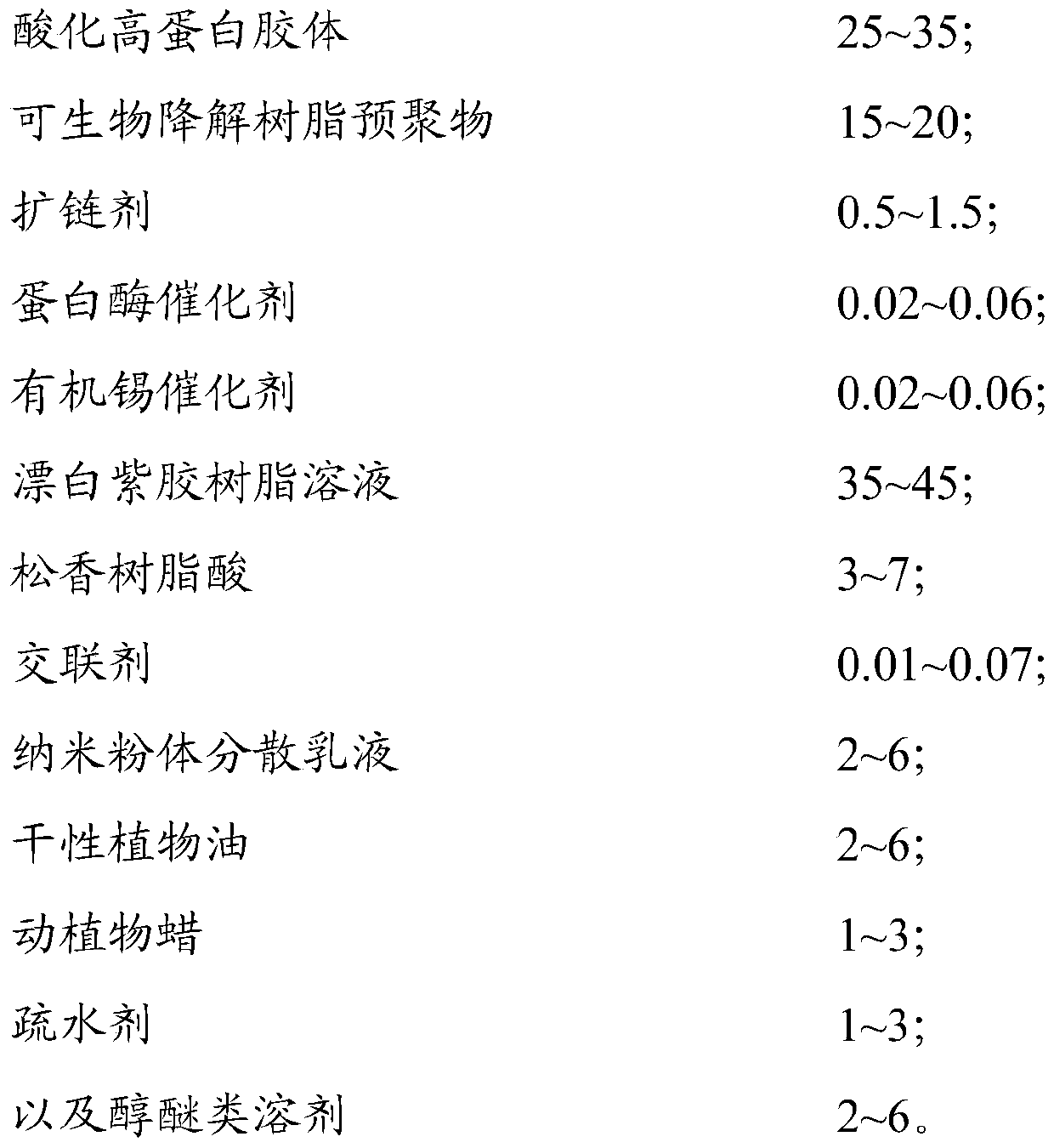

[0080] The raw materials of the high-barrier biodegradable material in this embodiment weigh each component in the following parts by weight:

[0081] 28 parts of acidified gelatin protein colloid, 15 parts of carboxyl-terminated propylene carbonate (PPC) prepolymer, 0.5 parts of ethylene-methyl acrylate-glycidyl methacrylate terpolymer, 0.02 parts of protease catalyst, dilauric acid dilaurate 0.02 parts of butyl tin, 35 parts of bleached shellac resin solution, 3 parts of rosin resin acid, 0.01 part of dibenzoyl peroxide, 2 parts of nano silicon-based oxide (SiOx) dispersion emulsion, 2 parts of linseed oil, 1 part of beeswax, 1 part of fluorooctylvinyldimethoxysilane, 2 parts of n-butanol.

[0082] The preparation method of the high barrier biodegradable material of the present embodiment comprises the following steps:

[0083] Mix the acidified high protein colloid of 28 parts by weight, the carboxyl-terminated propylene carbonate (PPC) prepolymer of 15 parts by weight, th...

Embodiment 2

[0088] The raw materials of the high-barrier biodegradable material in this embodiment weigh each component in the following parts by weight:

[0089] 30 parts of acidified gelatin protein colloid, 20 parts of carboxyl-terminated carbon dioxide group barrier type TPU prepolymer, 0.8 part of styrene-glycidyl methacrylate copolymer, 0.03 part of protease catalyst, 0.03 part of stannous octoate, bleached shellac resin solution 40 parts, rosin resin acid 5 parts, sodium citrate 0.03 parts, nano-montmorillonite dispersion emulsion 4 parts, tung oil 4 parts, citrus vegetable wax 2 parts, perfluorooctyl vinyl dimethoxysilane 2 parts, propylene glycol 4 parts of ether.

[0090] The preparation method of the high barrier biodegradable material of the present embodiment comprises the following steps:

[0091] Mix 30 parts by weight of acidified high-protein colloid, 20 parts by weight of carboxyl-terminated carbon dioxide-based barrier TPU prepolymer, 0.8 parts by weight of styrene-gly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com