High-heat-radiation solar cell backboard

A technology of solar cells and high heat dissipation, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as reflectivity, anti-aging performance, poor water resistance, lower working efficiency of solar cell backplanes, and rise in internal temperature, etc., to achieve Excellent anti-aging performance, outstanding protection effect, and the effect of lowering the working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

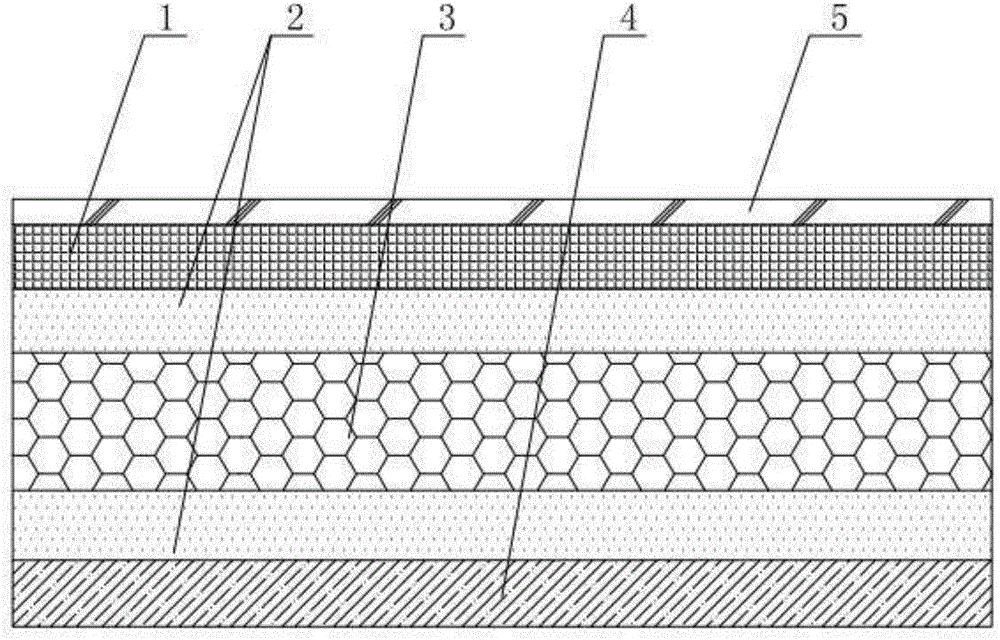

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, a high heat dissipation solar battery back plate includes a polyester film 3, a weather-resistant layer 1 is bonded to one side of the polyester film 3 through an adhesive layer 2, and an infrared reflective layer 5 is bonded to the surface of the weather-resistant layer 1. The other side of the ester film 3 is bonded with a weather-resistant adhesive layer 4 through a high adhesive layer 2 . The weather-resistant layer is a fluororesin modified polyolefin film with a concave-convex grid structure on the surface, and the density of the concave-convex grid structure is 1-7 grids / 10mm 2 . The thickness of the polyester film 3 is 80-400 microns. The thickness of the adhesive layer 2 is 0.5-40 microns. The thickness of the weather-resistant adhesive layer 4 is 40-60 microns.

[0017] The material of the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com