Granular evaporation material, film forming method of evaporation film, and evaporation film

A film-forming method and granular technology, which is applied in the field of vapor deposition, can solve the problems of labor and time consumption, increased production cost, and impurities mixed in, and achieve the effect of low energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

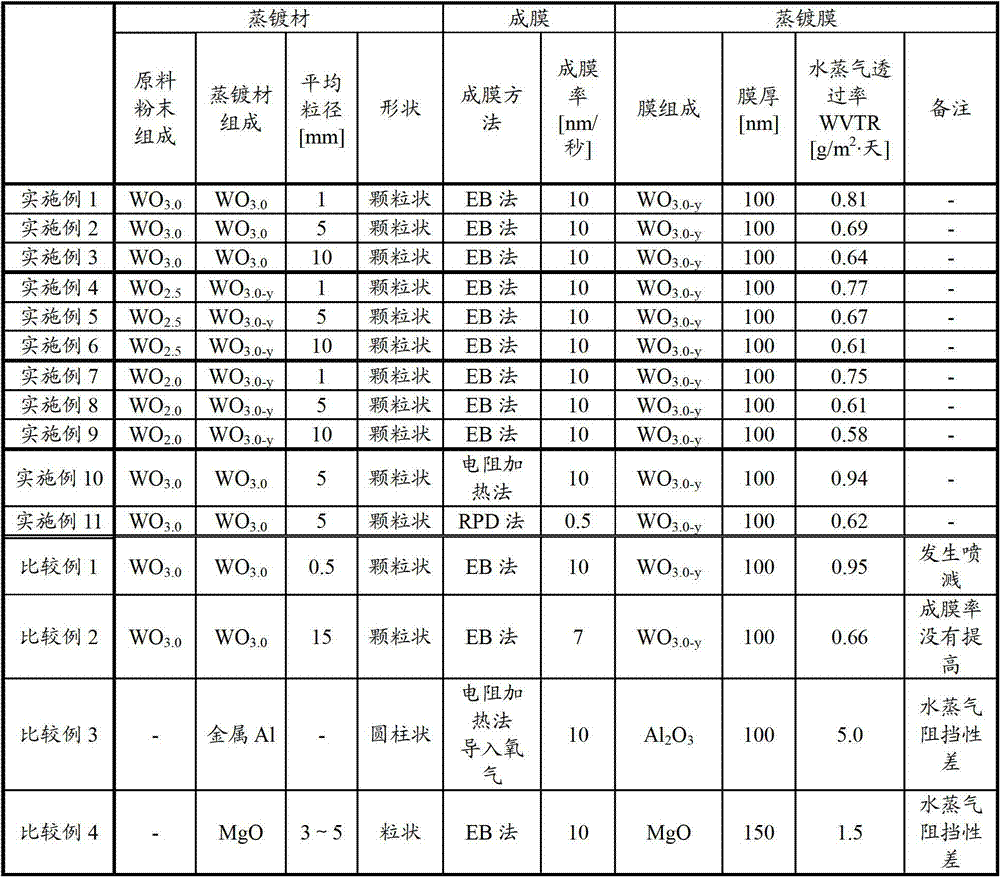

Examples

Embodiment 1

[0042] First, prepare high-purity WO with an average particle size of 1.2 μm and a purity of 99.7% as a raw material powder. 3 powder, prepare polyvinyl butyral as a binder, prepare acetone and ethanol as an organic solvent, and mix polyvinyl butyral, acetone, and ethanol at a mass ratio of 2.5:12.5:85 to prepare an adhesive. mixture liquid.

[0043] Next, put 100g of the raw material powder into the bowl of a rotary vane type small granulator (KAWATA Corporation; SUPERMIXER PICCOLO), and add a total of 20g of the above-prepared binder solution into 3 times of 8g, 8g, and 4g, each time When the binder solution was injected, the mixture was stirred at a rotation speed of 750 rpm for 30 seconds, thereby granulating, and granules having an average particle diameter of 1 mm were prepared.

[0044] Next, as a firing step, in order to remove the organic solvent, the temperature was raised from room temperature to 70°C within 1 hour and kept at 70°C for 1 hour, and in order to remov...

Embodiment 2、3

[0047] Except having set the average particle diameter of a vapor deposition material to 5 mm and 10 mm, it carried out similarly to Example 1, and formed a particulate vapor deposition material and formed a vapor deposition film into a film.

Embodiment 4~6

[0049] Using high-purity WO with an average particle size of 1.2μm and a purity of 99.7% 2.5 Except that the powder was used as a raw material powder, a particulate vapor deposition material was formed and a vapor deposition film was formed in the same manner as in Examples 1 to 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com