Patents

Literature

97 results about "Pine resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pine resin is the harvested tree sap of a pine tree. Pine trees belong to the Pinus genus and the Pinaceae family and are abundant throughout the world, including North and South America, Asia, Africa and Europe. Pine trees are tapped for their sap, which is used in several industrial and medicinal applications.

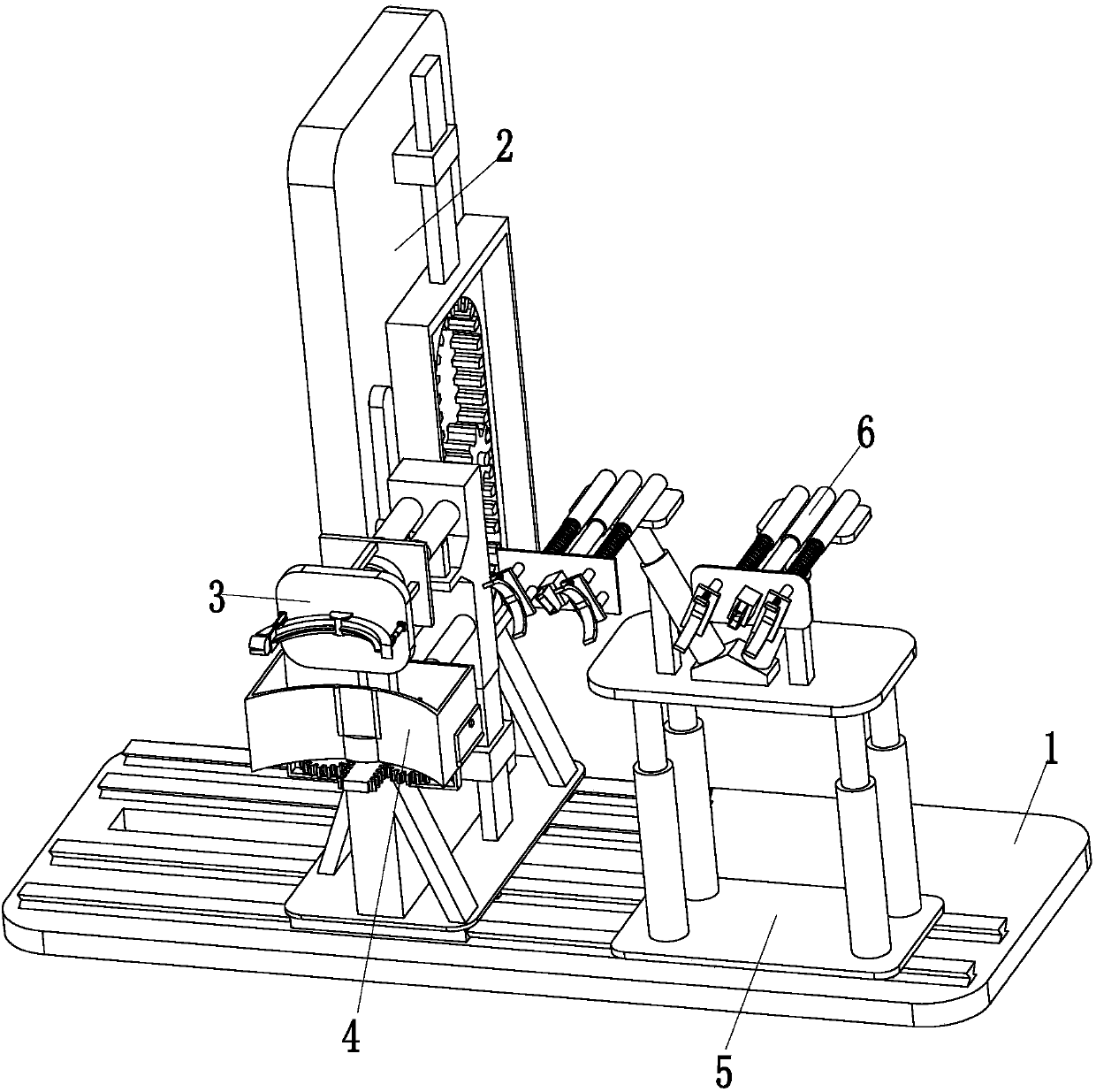

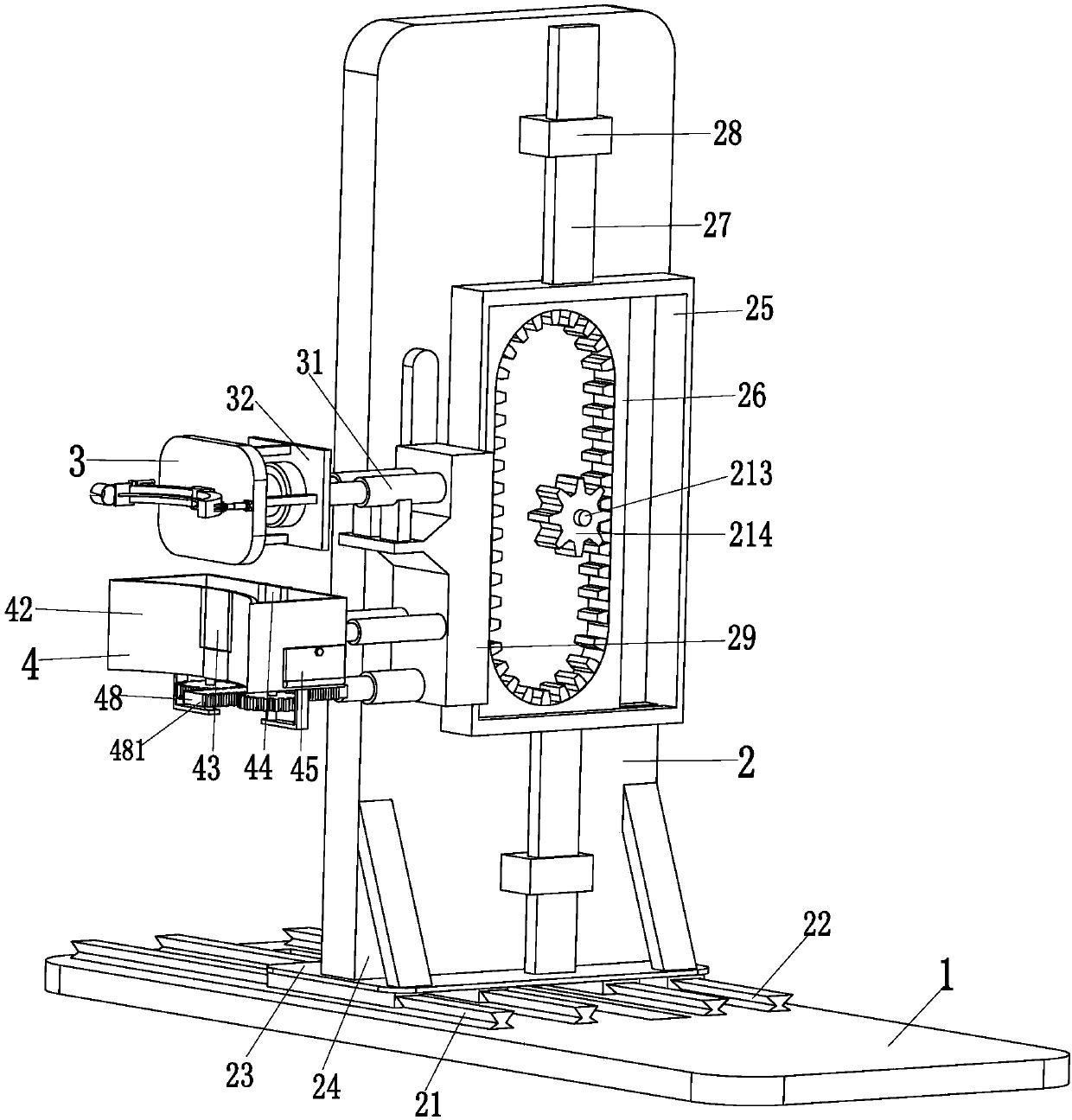

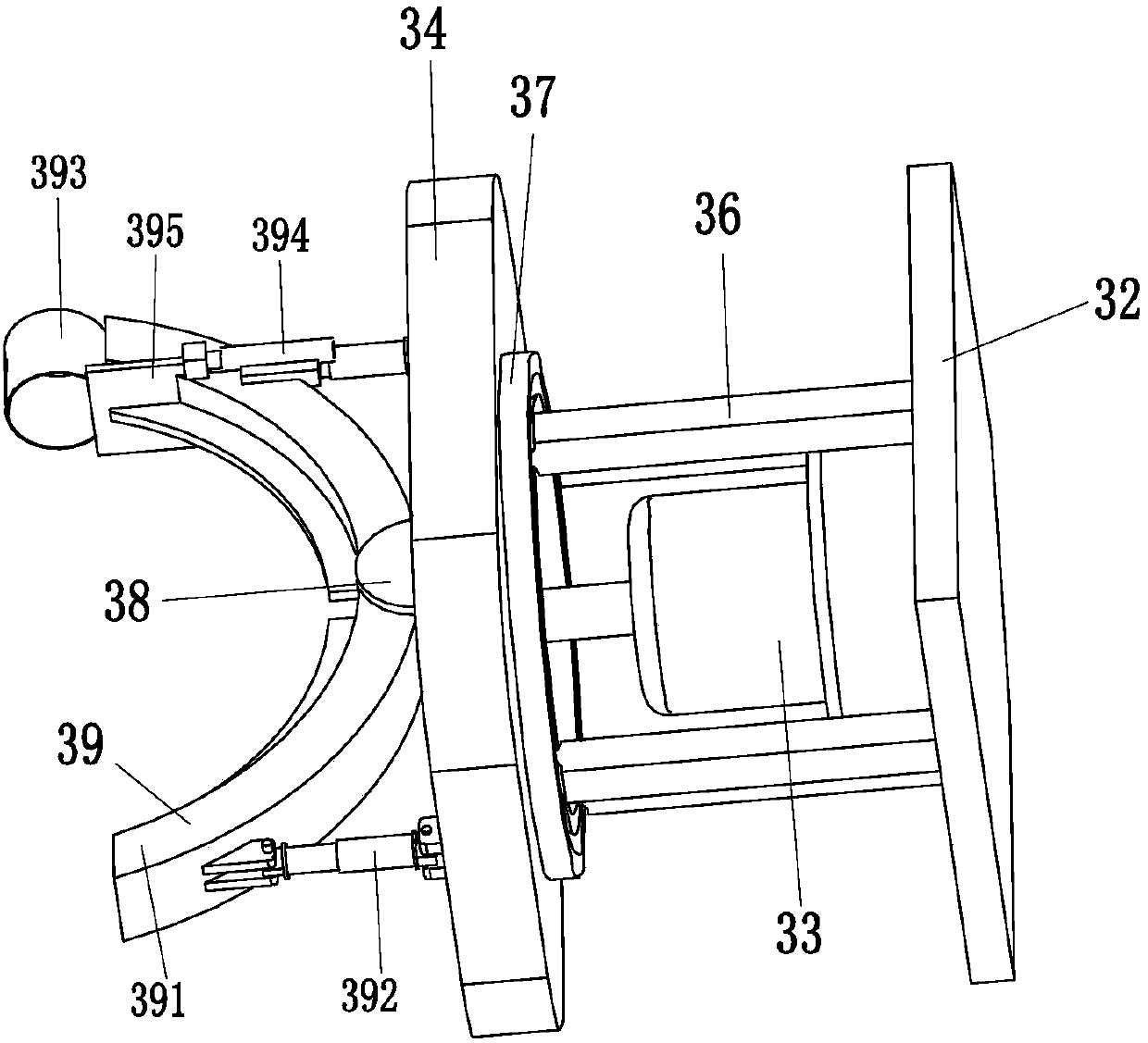

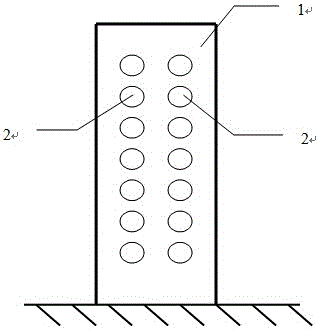

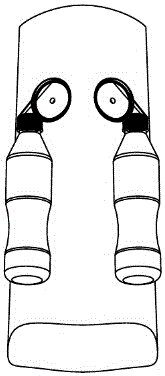

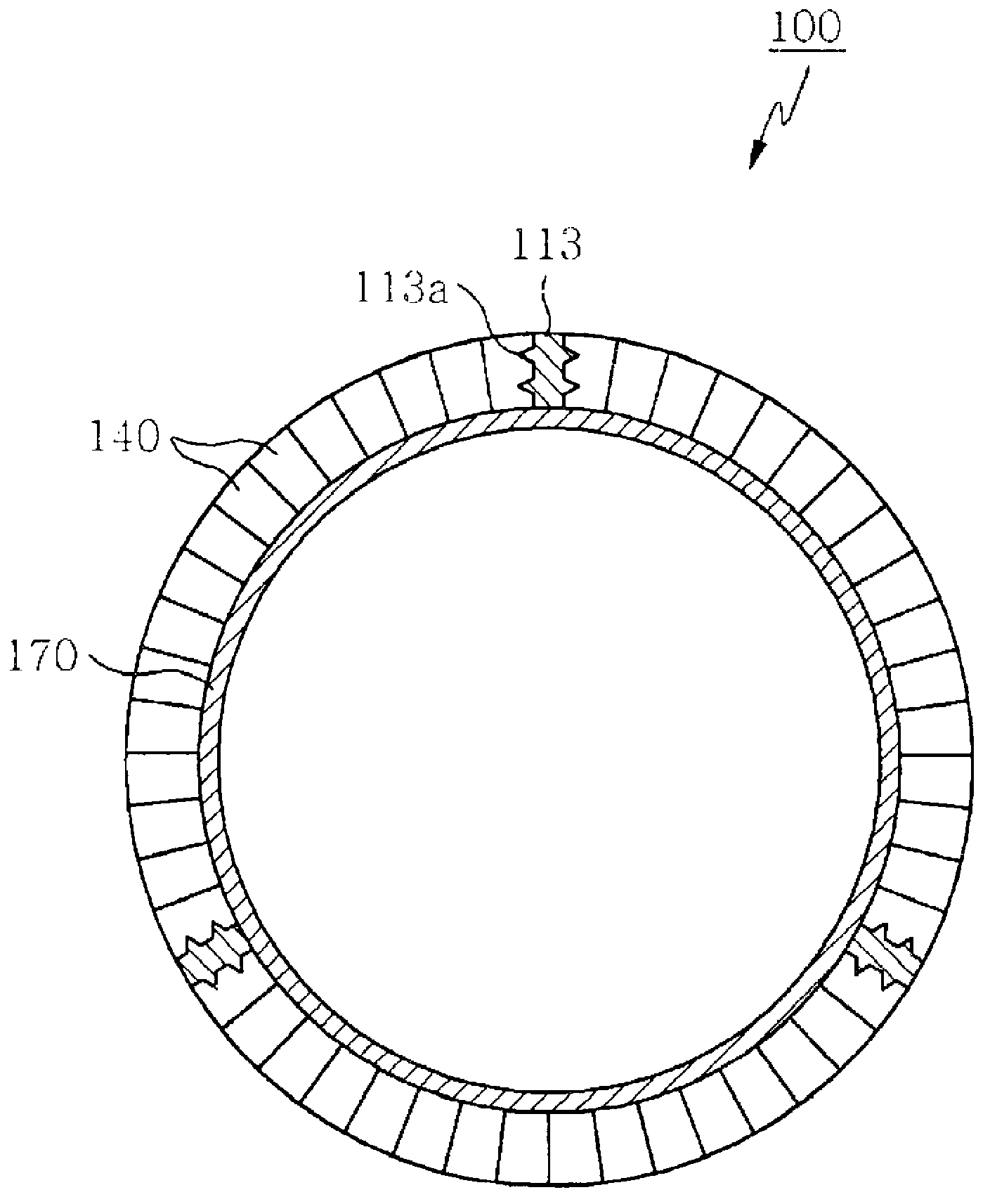

Pine bark treatment machine for acquiring rosin which mainly comprises natural resin and is raw material for preparing latex paint

The invention relates to a pine tree skin treatment machine for the collection of natural resin rosin, which is a raw material for latex paint preparation There are a rotating device and a lifting support device, the scraping device and the recovery device are installed on the rotating device, and the two slotting devices are symmetrically installed on the lifting support device. The invention can solve the problem that the existing manual scraping and grooving of pine trees have poor skin scraping effect and easily scratch the tree, the scraped pine bark cannot be recycled, two kinds of tools are required for scraping and straight grooving, and the inclined It is impossible to control the groove depth and other problems when grooving; it can automatically scrape the bark of pine trees, and automatically open straight grooves and oblique grooves for pine trees. Recycling, skin scraping and straight grooving require advantages such as a tool.

Owner:宋当建

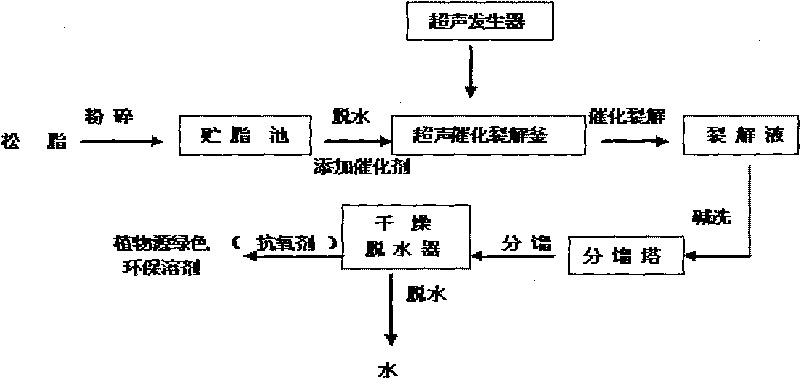

Method for preparing botanical solvent

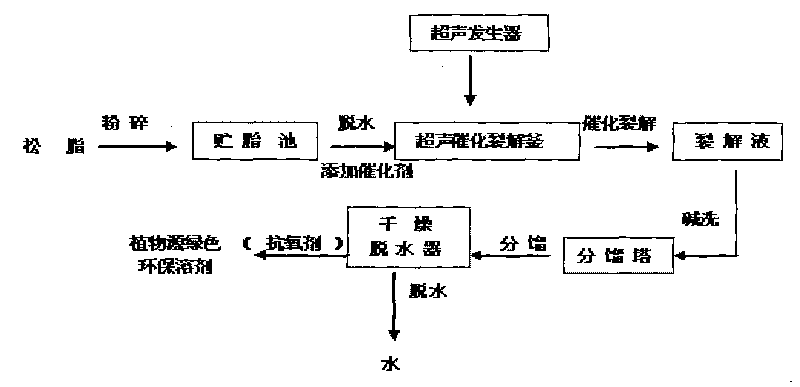

The invention provides a method for preparing a botanical environment-friendly solvent, and in particular relates to a method for preparing the botanical environment-friendly solvent from pine resin through ultrasonic catalytic cracking. Raw materials for preparing the botanical environment-friendly solvent are all from the pine resin, and have low price; the ultrasonic catalytic cracking method adopted has simple process, mild cracking conditions, environmental protection, and low energy consumption; cracking products are mainly safe and environment-friendly components such as terpene compounds and the like; and the obtained botanical environment-friendly solvent has high yield, low price, no conflict with human, and safety and environmental protection.

Owner:SHENZHEN NOPOSION AGROCHEM

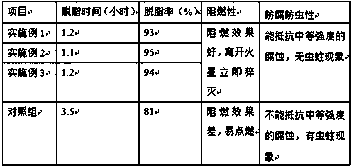

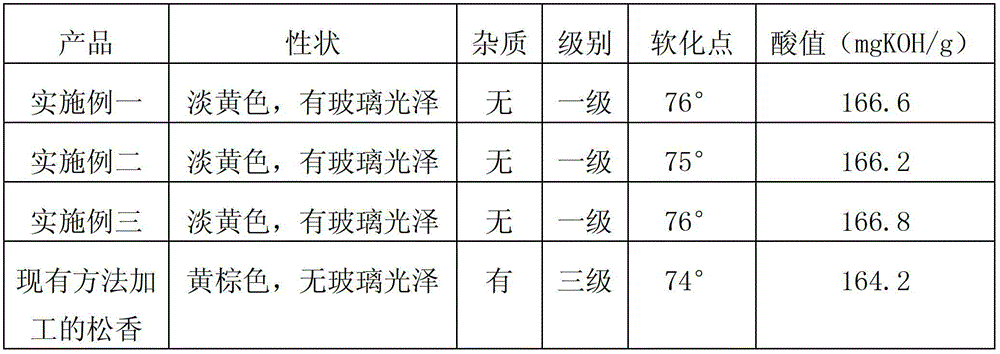

Processing method of pine resin

InactiveCN103087635AQuality improvementImprove solubilityTurpentine spiritsNatural resin purificationOxalatePine resin

The invention relates to a processing method of pine resin and belongs to the field of rosin production. The processing method of pine resin comprises the following steps of: a, dissolving, namely dissolving the pine resin by adopting a dissolving solution, wherein the dissolving solution comprises the following components in percentage by weight: 55-82% of turpentine oil, 17.5-44.5% of water and 0.1-0.5% of oxalic acid; b, clarifying and colating, namely placing the dissolved pine resin liquid in a transition pot to be clarified and then colating to obtain colature; c, acid washing, namely adding the oxalic acid for washing; d, washing, namely adding hot water for washing; e, clarifying and carrying out refined filtration, namely placing the pine resin liquid into the transition pot to be clarified and then carrying out refined filtration; and f, heating and distilling, namely placing the pine resin liquid in a rectifying tower to be subjected to the heating and distilling, so that rosin and turpentine oil finished products are respectively obtained. The processing method of rosin provided by the invention has the beneficial effect that the qualities of the rosin and turpentine oil obtained by processing pine resin are excellent, so that demand of downstream industries is met.

Owner:云南茶花林化有限公司

Water soluble printing ink and production thereof

A water soluble printing ink and its production are disclosed. The ink consists of pine resin 5-20 proportion, polystyrene 1-20 proportion, acrylate 2-8 proportion, pigment 4-20 proportion, emulsifier 1-10 proportion, mineral spirits 10-30 proportion, assistants 1-10 proportion and water 20-70 proportion. The process is carried out by adding solvent, emulsifier, pigment and filler into waste polystyrene. Its advantages include stable performance, good color fixing ability, fast dry speed, low cost and no environmental pollution.

Owner:黎烔光

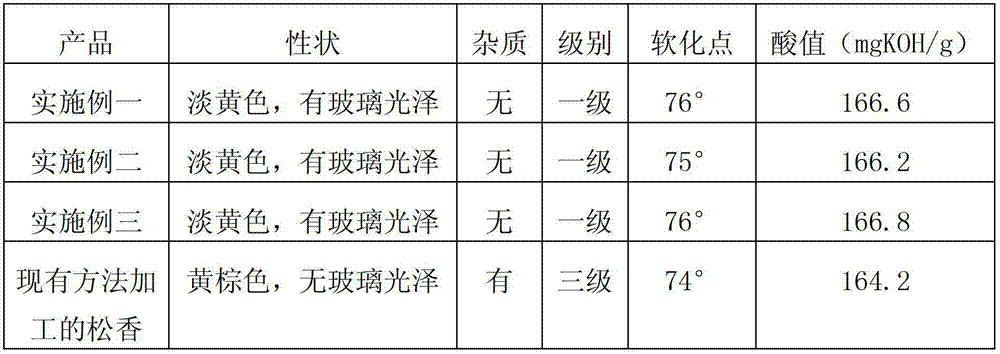

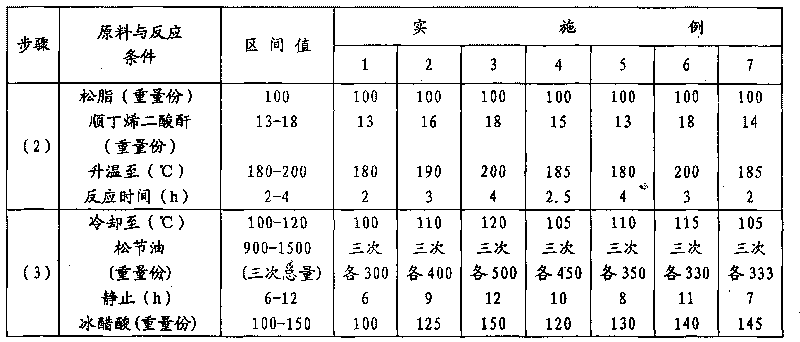

Method for producing maleopimaric anhydride

InactiveCN101747303ASimple production processNo pollution in the processOrganic chemistryEpoxyPine resin

The invention relates to a method for producing maleopimaric anhydride, which adopts pine resin as the raw material and utilizes self-contained turpentine as solvent. Resin acid and maleic anhydride which are changed into conjugated double bonds in the pine resin are heated to 180 to 200 DEG C, and then are separated after diene addition reaction is carried out for 2 to 4 hours, so as to obtain a white crystal, i.e. the product of maleopimaric anhydride. The method has the advantages that the production process of maleopimaric anhydride is simplified, so that the production cost is remarkably reduced; the solvents used for synthetic reaction and separation are the same solvent, i.e. the pine resin, which is non-toxic and pollution-free and can be repeatedly used after being recycled; maleopimaric anhydride is produced in the method, so that the successful solidification of epoxy resin can be realized; the prepared solidified product is superior to methyl tetrahydrophthalic anhydride in the aspect of heat resistance and strength; and simultaneously, the separated residual pine resin can be used as the raw material producing biomass fuel oil, so that the composite economic benefit is increased.

Owner:ZHEJIANG FORESTRY ACAD

Expanded bamboo salt producing method

InactiveCN103416716AReduce consumptionReduce manufacturing costFood preparationPine resinEngineering

An expanded bamboo salt producing method comprises the following seven steps: 1, preparing materials, including bamboo material selection, bamboo barrel production, and preparation of salt to be processed and pine wood as fuel; 2, filling the salt into bamboo barrels; 3, selecting a roasting furnace; 4, charging, including substeps of examining and cleaning the furnace before charging, installing a grate and charging the bamboo barrels; 5, igniting, roasting, and dewatering the salt; 6, expanding the dewatered salt; and 7, postprocessing the expanded bamboo salt. Only through two hot processing stages of dewatering and expanding, the expanded bamboo salt produced by the expanded bamboo salt producing method is heated to the maximum temperature 835 DEG C; after repeatedly expansion for 3-5 times, the vast majority of heavy metal ions can be removed, a majority of beneficial components in the bamboo and pine resin can be fused, and organic impurities in edible salt can be burned out; the expanded bamboo salt producing method is low in energy consumption, short in production cycle, little in salt loss, high in yield of the bamboo salt and low in production cost; and sold bamboo salt products are low in price, can be easily accepted by consumers and have a wide consumer group.

Owner:浙江临安三和园竹盐食品有限公司

Preparation method for environmentally-friendly biomass deodorant

InactiveCN105396165AImprove reliabilityIn line with the concept of health and environmental protectionDeodrantsCinnamomum camphoraPine resin

The invention discloses a preparation method for an environmentally-friendly biomass deodorant, and belongs to the field of deodorants. The preparation method comprises: mixing pine resin with petroleum ether to perform distillation, performing extraction and layering on a distillation product to obtain an oil layer, and performing distillation to obtain turpentine oil; performing extraction and refinement on a bamboo pole to obtain bamboo vinegar; performing mixed grinding on fresh ginger, mint, purple perilla and cinnamomum camphora seeds, and adding absolute ethanol to perform ultrasonic extraction so as to obtain an extraction phase; distilling the extraction phase, mixing the distilled extraction phase with the turpentine oil and the bamboo vinegar, and performing sealed storage; and adding tea residue powder and wormcast, performing concentration under reduced pressure to form a muddy material, and drying the muddy material to obtain the environmentally-friendly biomass deodorant. The deodorant prepared with the method is prepared from extracted bamboo vinegar, the turpentine oil and the like from natural plants and is high in reliability, consistent with a concept of health and environmental protection, nontoxic and harmless, and generated odor does not cause various adverse reactions, so that the deodorant has very wide market prospects.

Owner:梅庆波

Pine-juice beer and its brewing method

The invention relates to a kind of beer and the brewing method that is made up from 12.5-15.5wt% barley malt, 3.5-5.5wt% rice, 0.08-0.1wt% hop, 0.08-0.1wt% pine resin powder, and the rest is washing water and saccharification water according 3-4: 6-7. The method includes the following steps: washing barley malt and rice to gain washing water, adding saccharification water to gain wheat extract, adding the wheat extract into hop and pine resin powder, boiling, cooling, oxygenating, and adding yeast water 0.7-0.91 / kg, ferment, and sterilizing. The method is simple and the bear has health care function.

Owner:阴胜元

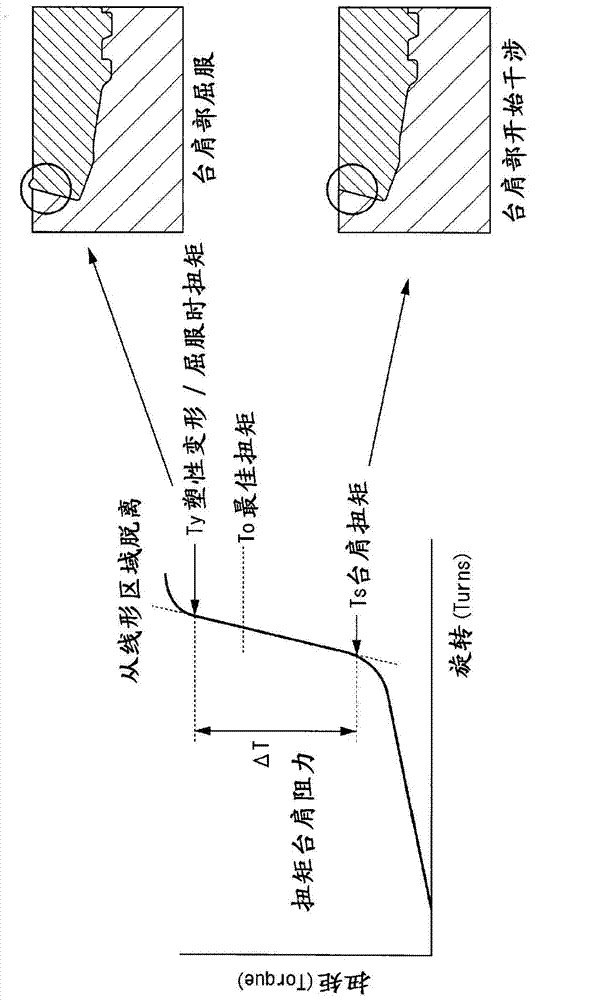

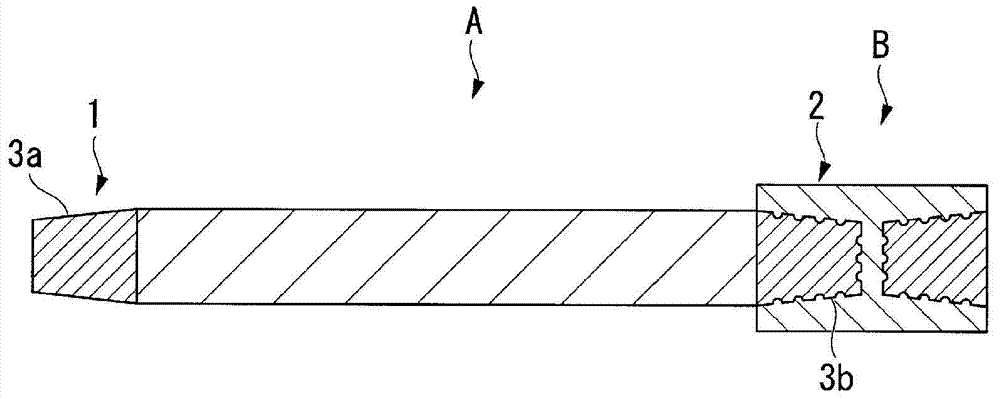

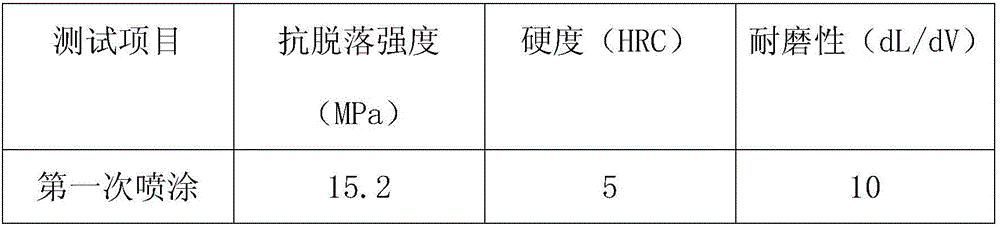

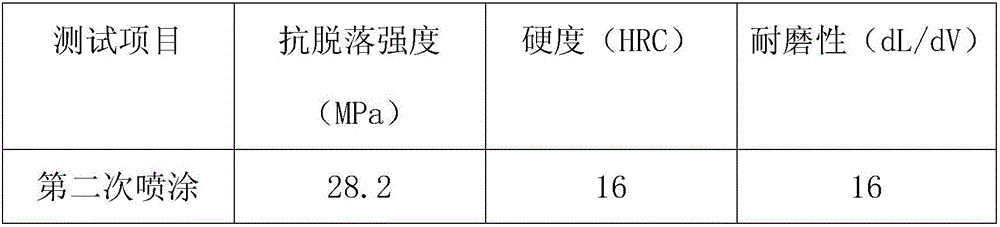

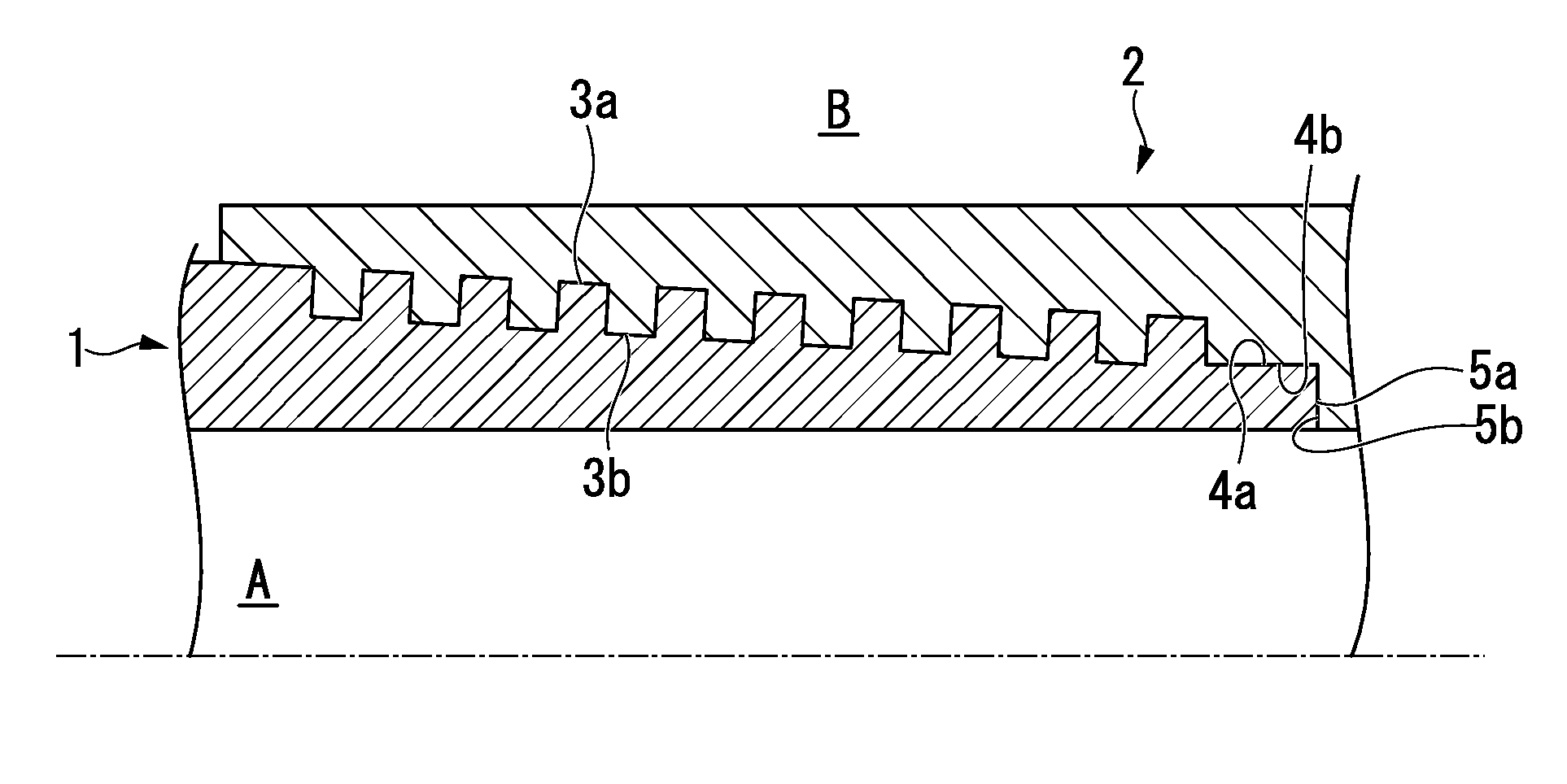

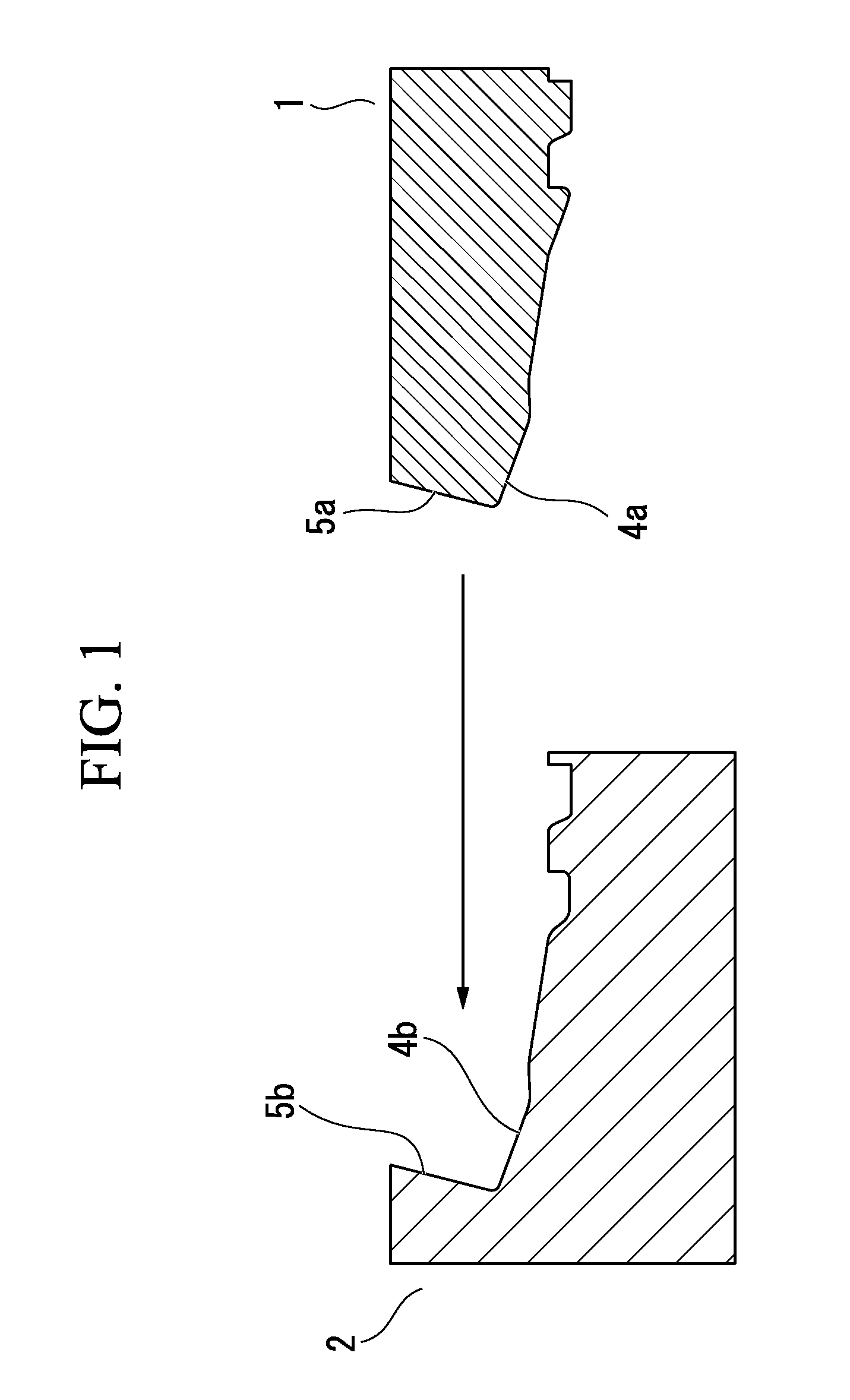

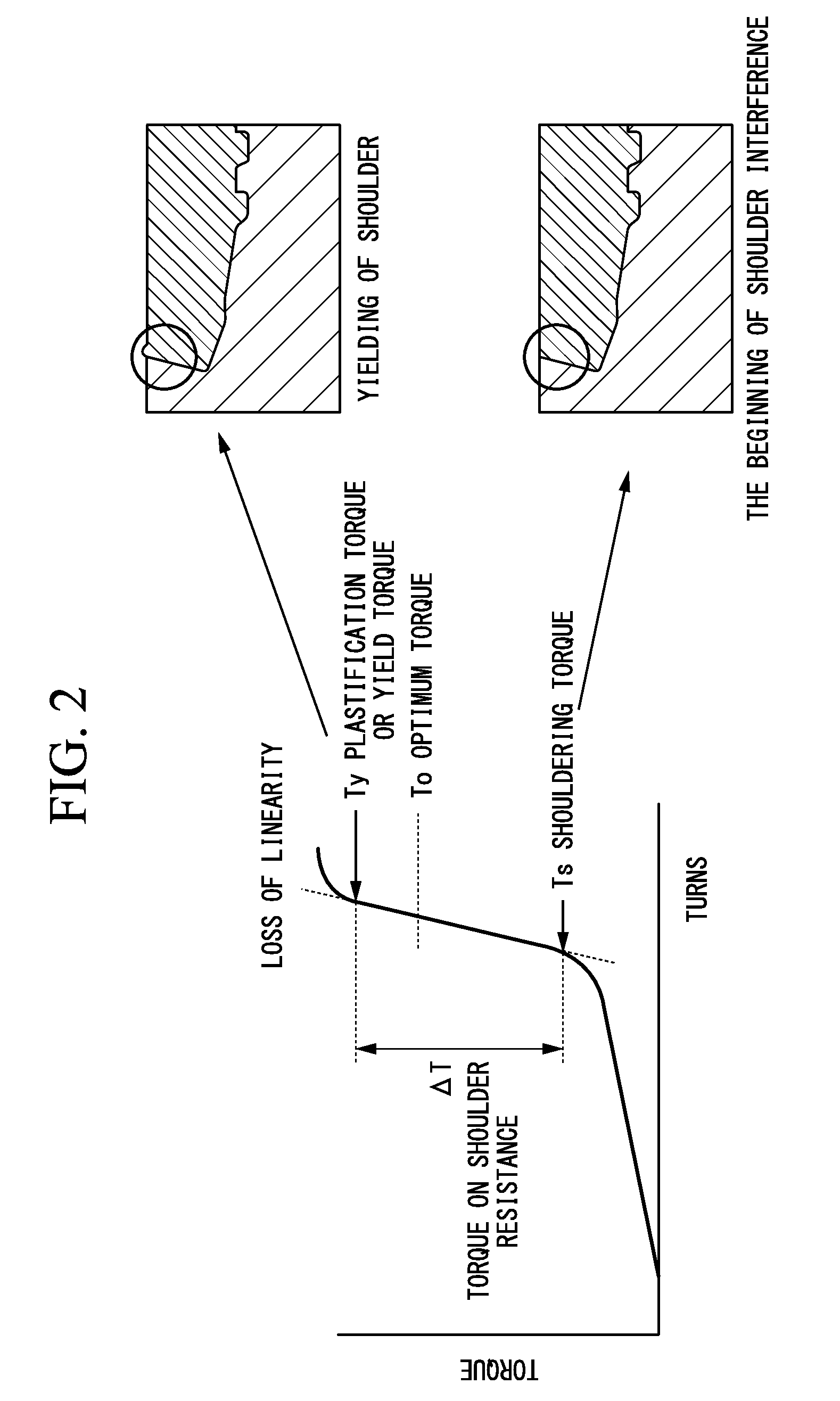

Tubular threaded fitting and lubricant film-forming composition used therefor

ActiveCN104520414AReduce coefficient of frictionIncrease coefficient of frictionDrilling rodsCorrosion preventionOrganic acidWax

Provided is a composition for forming a lubricant film on a tubular threaded fitting, the composition being characterized by containing melamine cyanurate, a basic aromatic organic acid metal salt, and at least one species selected from: a pine resin-based material; wax; a metal soap; and a lubricating powder.

Owner:NIPPON STEEL CORP +1

Novel wax oil and coating technology thereof

ActiveCN106497427AEasy to operateHigh surface hardnessWax coatingsAntifouling/underwater paintsWaxPine resin

The invention relates to the technical field of wax oil coating, in particular to novel wax oil and a coating technology thereof. The novel wax oil is prepared from, by mass, 10-20 parts of castor bean wax, 5-10 parts of yellow fir wax, 6-8 parts of laurel wax, 8-12 parts of castor oil, 5-10 parts of peanut oil, 6-8 parts of essential oil, 4-6 parts of pine resin, 3-5 parts of copal resin, 1-3 parts of manganese dioxide, 0.5-0.8 part of an orange peel resisting flatting agent and 0.3-0.5 part of ORA-100. According to the novel wax oil, wood is coated through a three-layer-type crossed spraying method, operation is convenient, tight combination between the novel wax oil and wood can be enhanced, the surface hardness is enhanced, water and fouling are prevented, and the appearance attractiveness is improved.

Owner:ZHEJIANG XIYINGMEN WOOD

Tubular threaded joint and lubricating coating forming composition for use therein

Provided is a composition for forming a lubricating coating to a tubular threaded joint. The composition contains a melamine cyanurate, a basic metal salt of an aromatic organic acid, and one or more kinds selected from the group consisting of a pine resin-based material, a wax, a metal soap, and a lubricating powder.

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

Pine resin collection method

The invention belongs to the field of economic forestry, and a method for collecting rosin. The steps of the method for collecting rosin are as follows: a hole is drilled from the bottom layer of a pine tree, the position of the hole is parallel to the horizontal plane, and the surface of the drilled tree is coated with grease After the grease receiving container is full, remove the grease receiving container, and collect the rosin into the large bucket. Based on the bottom hole, go to the upper second layer along the tree trunk. , Drill the hole, the position of the hole is parallel to the horizontal plane of the first layer of hole, apply grease enhancer on the inner surface of the drilled tree hole, install the grease receiving container to be embedded in the second layer of hole, after the grease receiving container collects rosin full , remove the grease receiving container, and collect the rosin into the vat uniformly. Combined with applying a fat-enhancing agent, the fat-receiving container is directly embedded in the fat-collecting hole, and the yield of collected rosin, rosin and turpentine is increased. It can be widely used to collect turpentine in forest areas.

Owner:周健

Slash pine artificial forest transformation technology

The invention discloses a slash pine artificial forest transformation technology. The slash pine artificial forest transformation technology comprises the steps of slash pine forest stand selection standard, a forest stand survey, a single tree survey, forest stand transformation, protection measures and the like. Based on the status quo of slash pine timber forests, forest stands with a good forest stand soil productivity basis are selected, a scientific and reasonable transformation technology is adopted, a single timber wood target is replaced with a multi-purpose forest stand cultivation mode which integrates seedling growing superior tree protection, big-diameter wood cultivation and high-rosin-yield single-plant management, through broad-leaved trees under a forest, the soil productivity is renewed and maintained, the nutrient requirement for timber wood and rosin production is guaranteed, and therefore requirements for different production targets and different interests parties are guaranteed.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

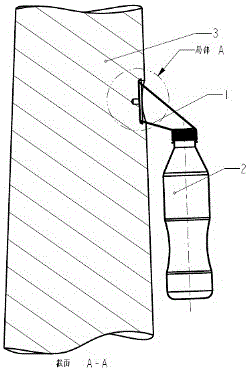

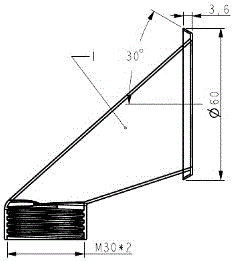

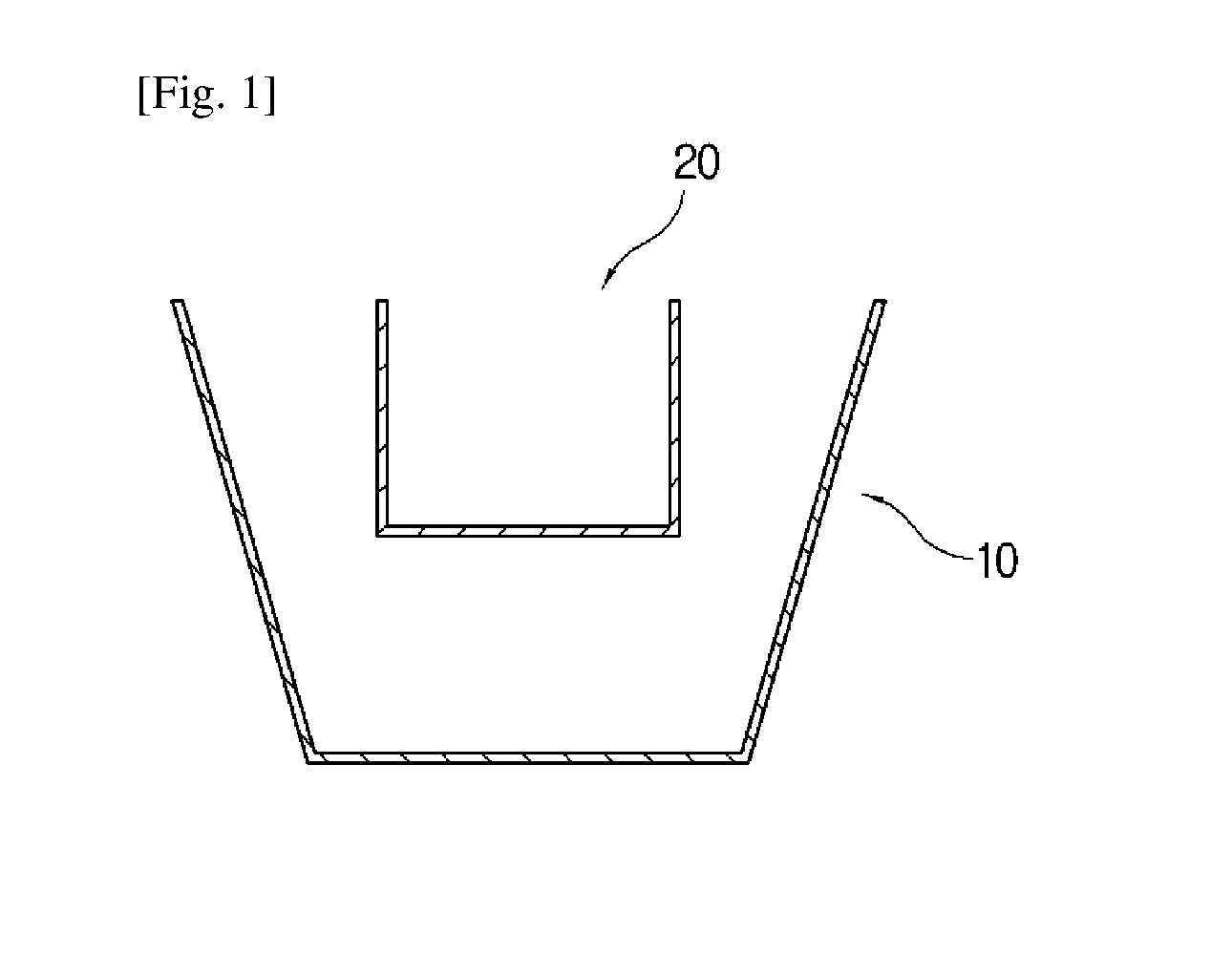

Pine resin collector

The invention belongs to the field of economic forestry, and particularly relates to a pine resin collector for collecting pine resin. The pine resin collector is characterized by consisting of a pine resin collector connector and a collecting bottle; the connection relation is that the outer circumference part of the inclined upper part of the pine resin collector connector is in interference fit with the inner circumference part of a drilling part of a pine tree; the inclined lower part of the pine resin collector connector is connected with a bell mouth in the upper part of the collecting bottle; the thread size of the collecting bottle is M30 mm; a large number of standard drinking mineral water bottles which can be recovered on the market can be fully utilized; waste can be utilized; the production is clean; the environment is protected; the pine resin collector can ensure the increment of the yield of pine resin, rosin and turpentine oil; the economic benefit is increased on the premise of reducing cutting surfaces, increasing yield and improving pine resin quality.

Owner:周健

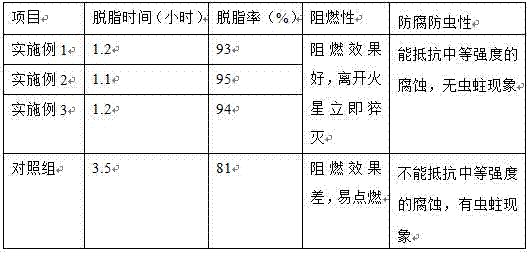

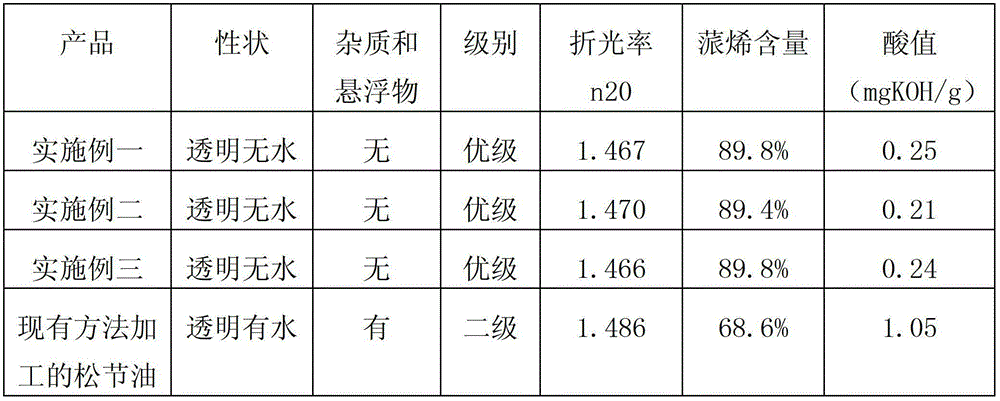

Treatment method for pine wood for furniture

ActiveCN107363666ADegreasing thoroughlyHigh densityPressure wood treatmentWood treatment detailsSurface layerPine resin

The invention relates to the technical field of furniture wood processing, and discloses a treatment method for pine wood for furniture. The treatment method for the pine wood for the furniture comprises the following steps that (1) in the process of removing pine resin, the pine wood is socked by using a deoil brightening agent firstly, when the moisture content of the wood reaches 80-90%, heating and stewing are conducted, then drying treatment is conducted at the temperature of 60-70 DEG C till the moisture content is 30-35%, and the process can remove the most pine resin in the surface layer the pin wood and can disperse the inner pine resin; (2) pine wood boards after being subjected to drying treatment are placed into a thermocompressor, after progressive temperature-raising and pressure-increasing treatment is conducted, wood layer structures cannot be damaged while the inner pine resin is pressed out step by step, moreover, the density of the pine wood is enhanced, and resin removing is more thoroughly; and (3) the wood after being cleaned and planed is subjected to functional polishing. According to the treatment method for the pine wood for the furniture, the efficiency can be enhanced, and meanwhile good mould proof performance, corrosion proof performance, water-repellent performance and flame-resistant performance are achieved.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

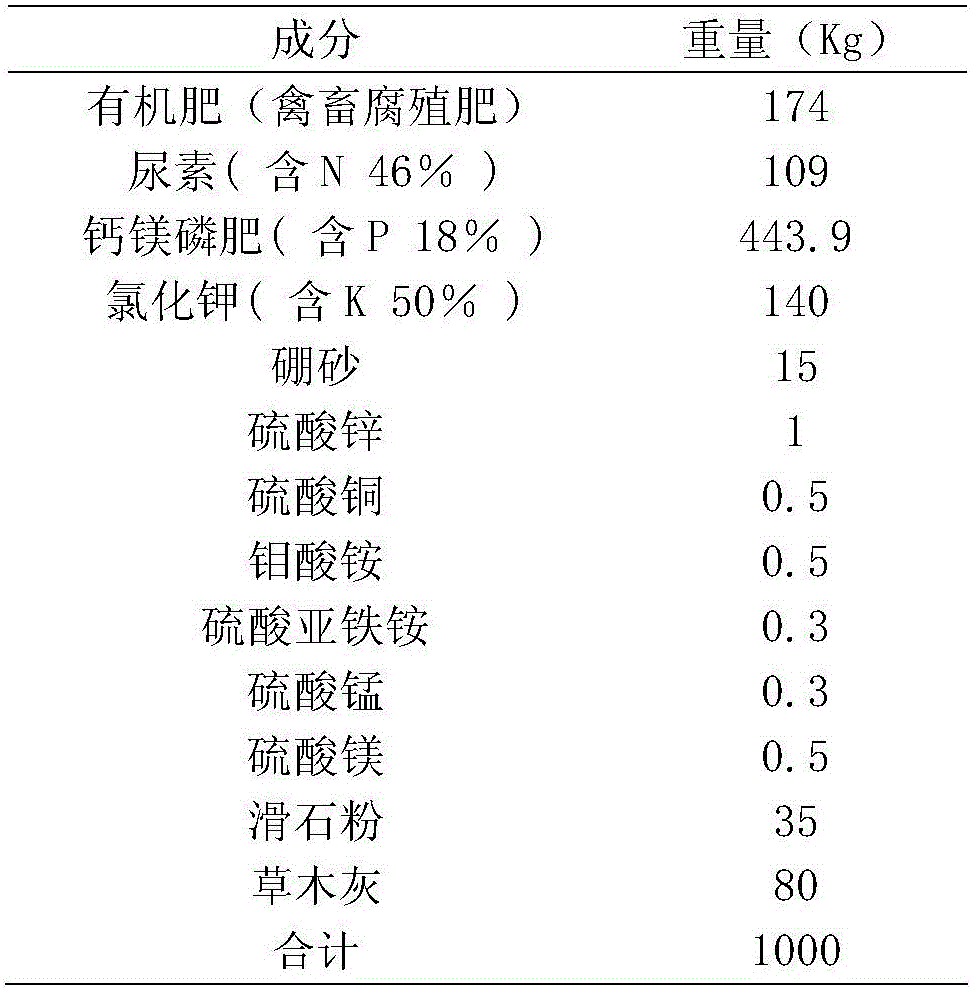

Pinus massoniana L. middle age forest specially used fertilizer, and fertilization method thereof

InactiveCN106396790AIncrease productionPromote photosynthesisMagnesium fertilisersFertilising methodsPine resinTrace element

The invention discloses a pinus massoniana L. middle age forest specially used fertilizer. The pinus massoniana L. middle age forest specially used fertilizer is mainly composed of, by weight, 17 to 25% of an organic fertilizer, 65 to 75% of major elements, 1.5 to 3.5% of trace elements, 3 to 5% of talcum powder, and 6 to 9% of plant ash, wherein in the major elements, nitrogen, phosphorus, and potassium effective components account for 20 to 25%, and in the trace elements, effective components account for 1.5 to 3.5%. The invention also discloses a corresponding fertilization method, and reasonable fertilization time and fertilizing amount. The pinus massoniana L. middle age forest specially used fertilizer is suitable for plants in pinus massoniana L. middle age forest and mature forest, is capable of completely satisfying requirements of plants in pinus massoniana L. middle age forest on nutrients, modifying soil, increasing resistance, improving photosynthesis conditions, increasing pine gum yield, accelerating growth of forest, and providing support for realization of rapid growth and high yield of pinus massoniana L. middle age forest.

Owner:GUANGXI FORESTRY RES INST

Anti-anal fistula composition and process for its manufacture

The composition and process for preparing an anti-anal fistula composition which comprises providing a predetermined effective amount of natural substances of the genera Safflower, Notoginseng Radix, Lightyellow Sophora, Elecampane Redix, Rumex, Pine Resin, Sassafras Tree, Glycyrrhizae Radix, Testudinis Carapax, Rhei Rhizoma, Ephedrae Herba, Natrii Sulfas, Menthae Herba, Pasoniae Radix, Acontii Tuber, Corni Fructus, Gypsum, and Pelladendri Radix in an aqueous medium to form an initial mixture, extracting the initial mixture with water at a temperature of about 65°-75° C. for 1-2 hours to produce an aqueous mixture, filtering the aqueous mixture to produce a filtrate, and evaporating the filtrate to a moisture content of 30% to produce an extract which can be used as a treatment for hemorrhoid diseases including anal fistula.

Owner:PARK CHAN SIK

Novel rosin increasing agent for pinus massoniana

The invention provides a novel rosin increasing agent for pinus massoniana based on systematical research on the influence of plant mineral nutrients, plant growth regulators and pH on the rosin production of the pinus massoniana in order to improve the efficiency of rosin harvesting, ensure the supply of raw materials for rosin industry and promote healthy development of the rosin industry. The rosin increasing agent provided by the invention can significantly improve rosin production and rosin secretion of the pinus massoniana, and the rosin increasing period is two months or more. The rosinincreasing agent is composed of one or more of a plant growth regulator naphthalene acetic acid, brassinosteroid, and plant essential mineral nutrient elements Mg, Zn, Fe, Cu, B, Na, Cl and S.

Owner:梧州市林业技术推广站 +2

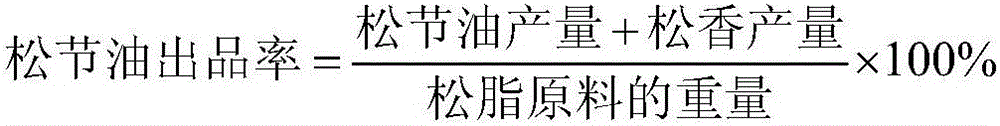

Pine resin processing method with pine resin processing yield increased

The invention relates to the field of pine resin processing and discloses a pine resin processing method with pine resin processing yield increased. The method includes the steps of pre-treatment, dissolution, water washing, clarification, residue recovery, distillation, and finish product collection. In the method, a raw material is pre-treated and is water-washed under supersonic wave; and during the dissolution, an internal heating coil is employed for heating the raw material, zeolite added to break the raw material; and meanwhile, through the residue recovery, vacuum distillation and the like, efficiency of pine resin processing is improved and yield of pine resin is increased. The method is free of big modification on devices and can achieve stable control, thereby achieving stable production and yield increasing.

Owner:广西兴业县新贵松脂厂

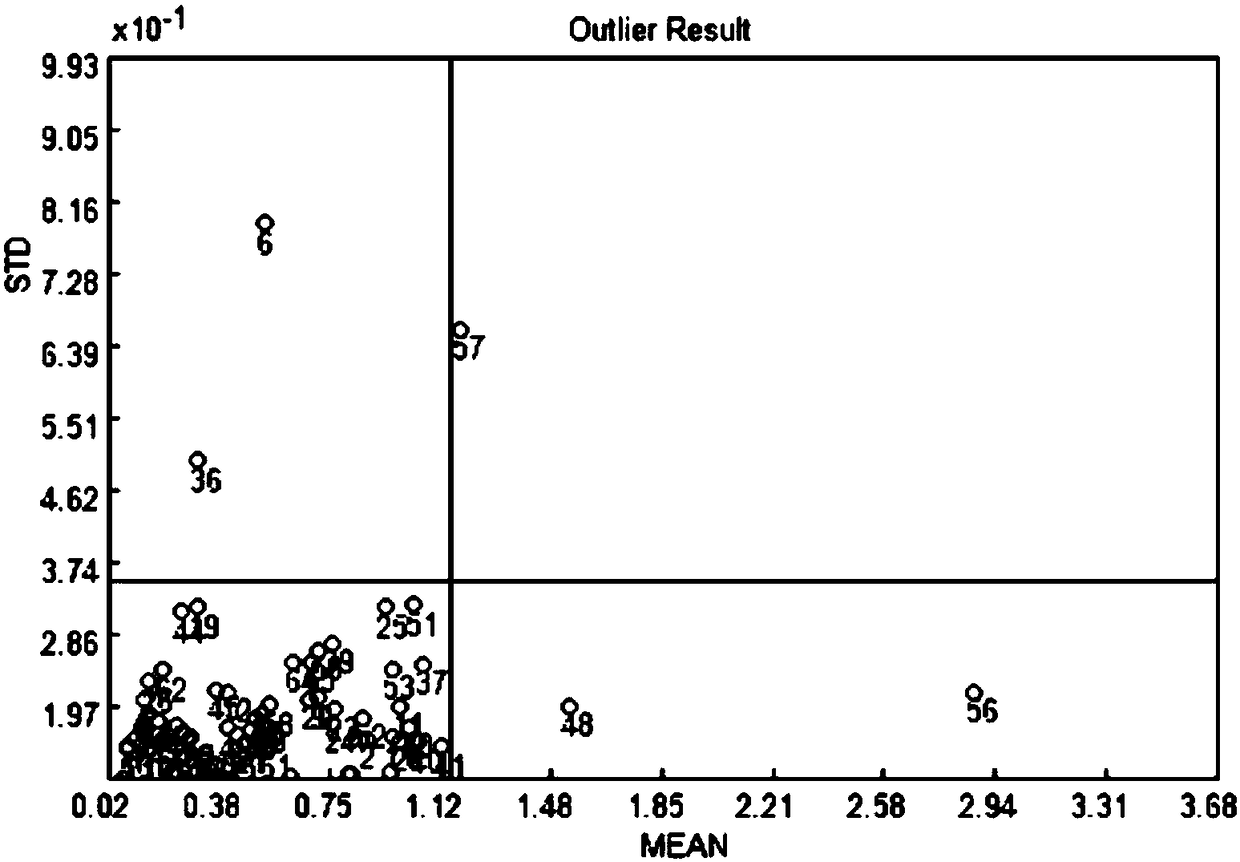

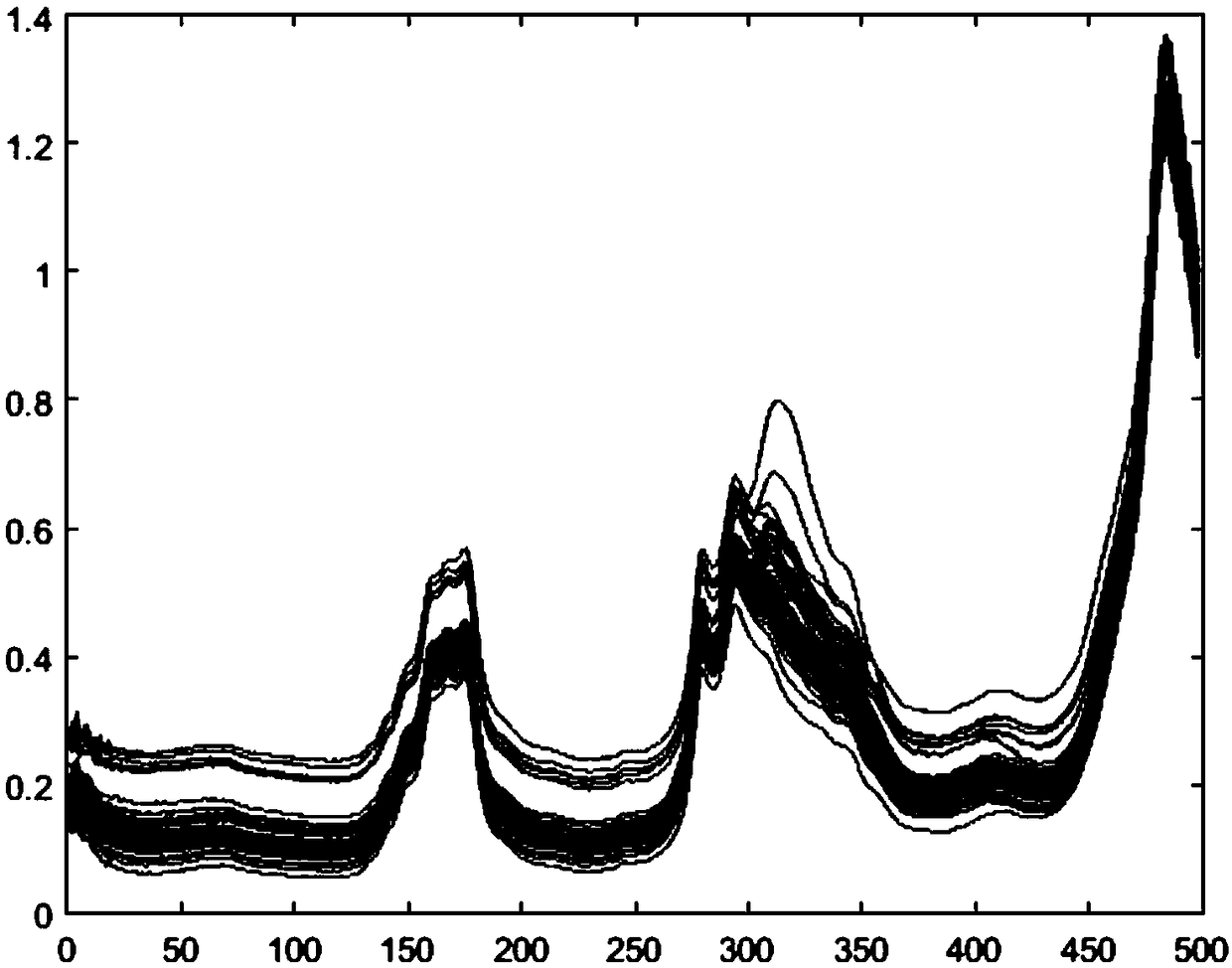

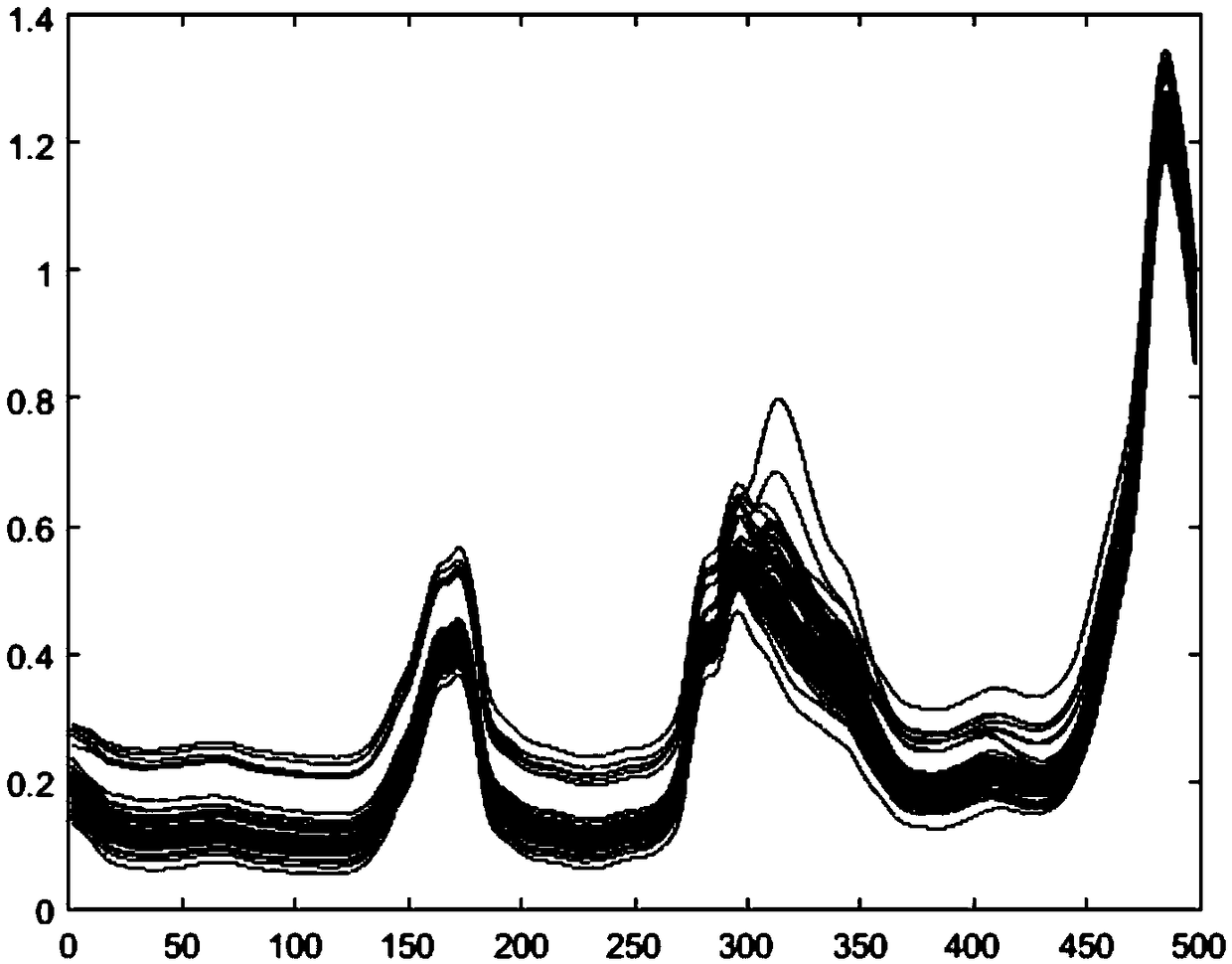

Method for fast identifying source tree varieties of pine gum by means of near infrared spectroscopy

InactiveCN108645809AQuick identificationAccurate identificationMaterial analysis by optical meansPine resinSpectral analysis

The invention discloses a method for fast identifying the source tree varieties of pine gum by means of the near infrared spectroscopy. The method is used for solving the problems that in the prior art, test methods for identifying the source tree varieties of doped pine gum, the efficiency is low, and the cost is high. The method for fast identifying the source tree varieties of the pine gum by means of the near infrared spectroscopy comprises the steps that multiple samples of the source tree varieties of the pine gum are collected and used for building a calibration set sample of a near infrared identification model; by means of spectral analysis, near infrared spectroscopy data of the samples is measured; the near infrared identification model with the samples corresponding to the resource varieties of the pine gum is built; near infrared spectroscopy data of the samples of the source tree varieties of the to-be-identified pine gum is measured, the near infrared spectroscopy data is put into the near infrared identification model for comparison, and then the source tree varieties of the pine gum of the samples are obtained.

Owner:GUANGXI UNIV FOR NATITIES

Preparation method of calcium rosin derivative chelate modified nano or light CaCO3 powder

InactiveCN108359274AFast delivery effectImprove powder propertiesPigment treatment with non-polymer organic compoundsResin acidPine resin

The invention discloses a preparation method of calcium rosin derivative chelate modified nano or light CaCO3 powder. The method comprises the following steps: smashed rosin / modified rosin or isolatedpine resin acid is added to acrylic acid or fumaric acid, the mixture is blended with excess Ca(OH)2 solution or lime milk and a surfactant, saponification is performed, and rosin / modified rosin derived calcium and calcium chelate or isolated resin acid derived calcium and calcium chelate are generated; then CO2 and excess Ca(OH)2 or lime milk are subjected to a reaction by means of supercavitation, CaCO3 is generated, nano or light CaCO3 precipitates modified with calcium rosin derivative chelate are prepared from rosin / modified pine resin acid or isolated pine resin acid and pine resin acidderived calcium and calcium chelate, and a powder material is prepared through pneumatic drying. The method adopts a simple process, the obtained calcium rosin derivative chelate modified nano or light CaCO3 powder has excellent performance, can remarkably improve physical properties of a material when used as an auxiliary or a modifying material and can be widely applied to various fields.

Owner:GUANGXI UNIV

Seal ring for motor

InactiveCN105153553AImprove cold resistanceGood temperature toleranceOther chemical processesActive agentPine resin

The invention relates to the technical field of seal rings, in particular to a seal ring for a motor. The seal ring for the motor is characterized by being prepared from, by weight, 50-60 parts of ethylene propylene rubber, 30-40 parts of neoprene, 2-4 parts of active agents, 14-18 parts of copper powder, 21-24 parts of calcium carbonate, 2-4 parts of organic silicon, 1-3 parts of peanut oil, 3-5 parts of anti-aging agents, 1-3 parts of accelerants, 2-4 parts of pine resin, 5-7 parts of lignin, 2-4 parts of lubricating agents, 11-15 parts of polyethylene glycol, 2-7 parts of kieselguhr and 1-2 parts of olive oil. The prepared seal ring has the good cold resistance and the temperature difference bearing property and is not prone to being cracked and crisped under the temperature fluctuation condition, and the good properties can be kept.

Owner:安徽创业机电设备有限公司

External application plaster and application thereof

The invention relates to a medicinal plaster for curing diseases, in particular to an external application plaster and an application thereof. The external application plaster comprises the following components according to the weight percentage: 20-40 of pine resin, 20-30 of frankincense, 10-15 of myrrh, 5-10 of dragons blood, 5-10 of honeysuckle flower, 5-10 of sesame oil and 5-10 of carrier gel. The invention is safe without toxic side effect, obvious pain removal effect and fast effect and enables clothes not to be dirtied after application.

Owner:史玉强

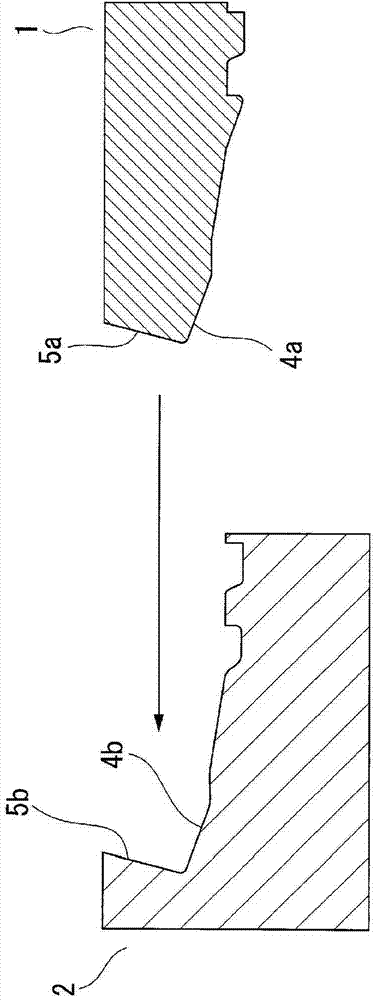

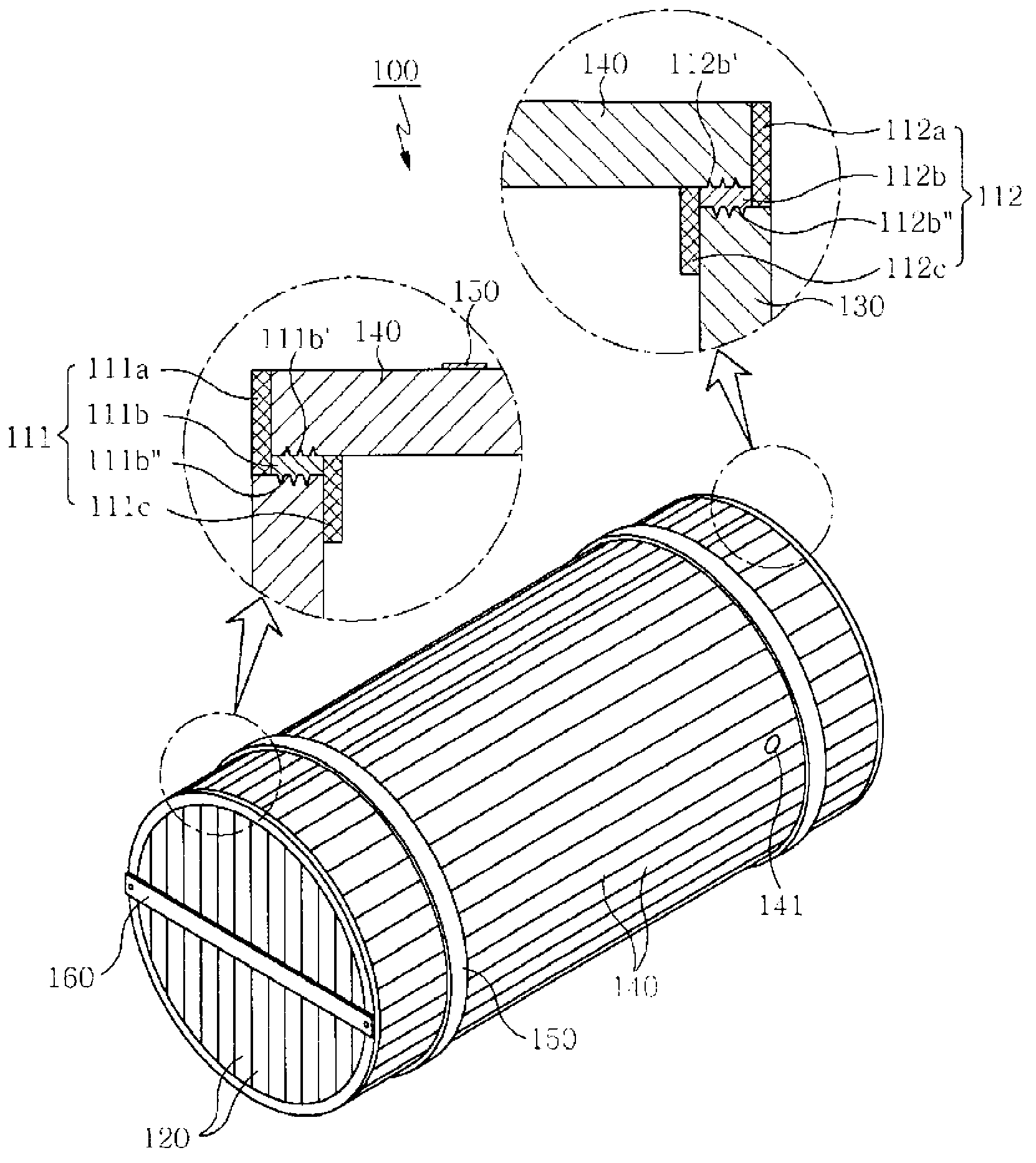

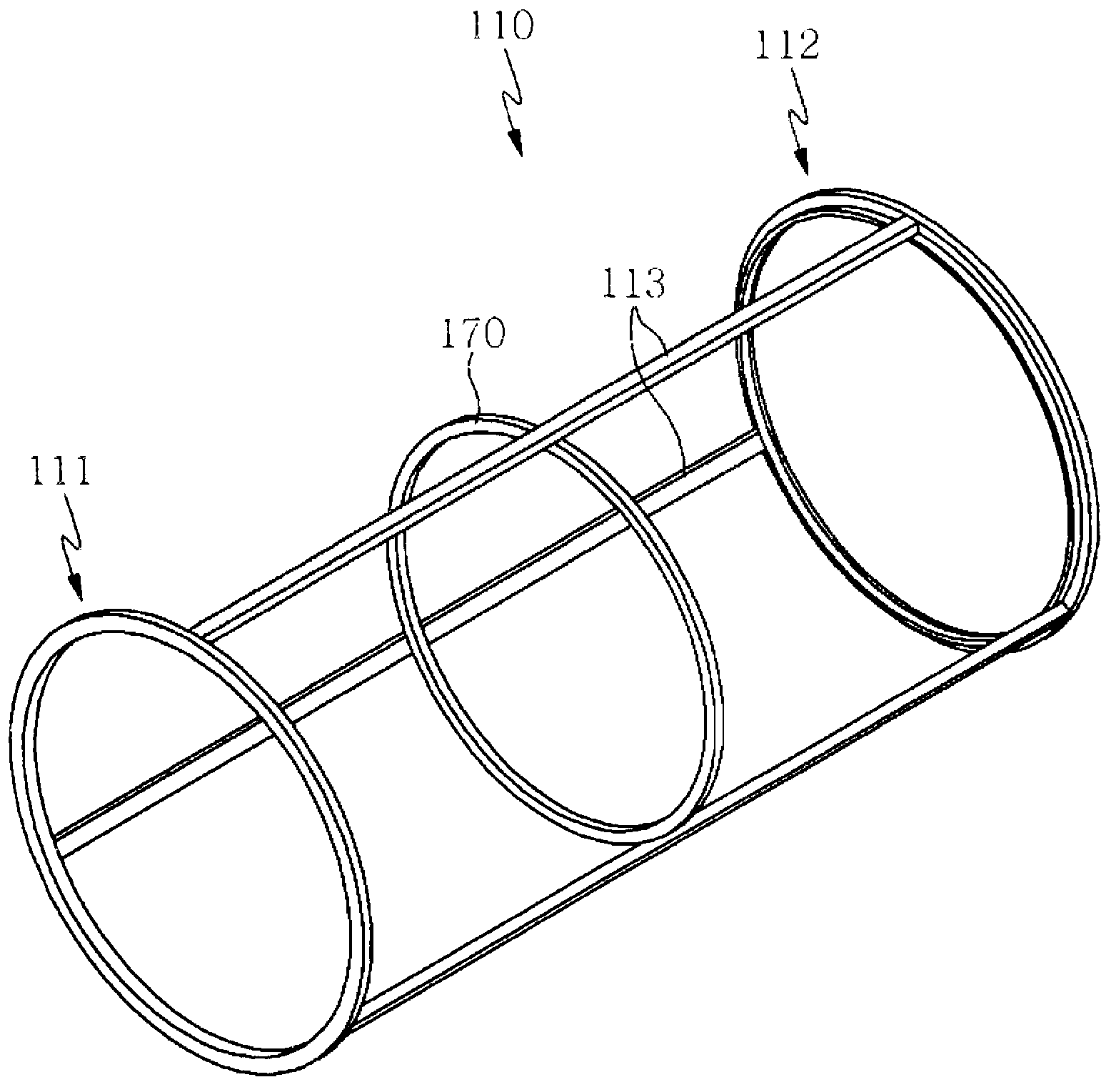

Wooden barrel for storing liquid consumables

InactiveCN103180227AEasy to manufactureLarge capacityClimate change adaptationLiquid flow controllersPine resinVolume expansion

The present invention relates to a wooden barrel for storing liquid consumables, wherein the objectives of the invention are overcoming the drawbacks of oak barrels of the prior art and preventing leakage and enabling long-term storage while retaining the scent and taste of wooden planks and pine, the objectives being achieved by manufacturing a wooden barrel capable of storing liquid consumables by means of inserting planks in a front rim, rear rim, and connecting bar of the wooden barrel, respectively, which fill the inner vessel and frame thereof. To achieve the above objectives, the wooden barrel of the present invention comprises: a wooden barrel frame including a front rim and rear rim having an annular cross-section connected by a connecting bar; a plurality of wooden barrel front planks each formed so as to have a polyhedral cross-section and a surface contacting another plank on the front rim of the wooden barrel frame in a leak-proof manner; a plurality of wooden barrel rear planks each formed so as to have a polyhedral cross-section and a surface contacting another plank on the rear rim of the wooden barrel frame in a leak-proof manner; a plurality of wooden barrel side planks each formed so as to have a polyhedral cross-section and a surface contacting another plank, either end thereof being arranged on the rear surface of the front rim and the front surface of the rear rim, respectively, wherein one of the wooden barrel side planks defines a filling hole through which liquid consumables can be fed into the wooden barrel for storage; a hoop that encloses, at both ends, the outer peripheries of the plurality of wooden barrel side planks so as to prevent the plurality of wooden barrel side planks from swelling on account of the liquid consumables stored therein and disengaging from the front and rear rims; ; and a front support bar and rear support bar disposed at the front ends of the front and rear rims, respectively, wherein both ends thereof are fixed by screws to the front and rear rims so as to prevent the plurality of wooden front and rear planks from swelling on account of the liquid consumables stored therein and disengaging from the front and rear rims. The plurality of wooden barrel front rims, wooden barrel rear rims, and wooden barrel side rims have the scent and taste of wood, and have a pine resin solution dissolved in alcohol and coated on the surfaces thereof or filled in the inner vessels thereof to prevent leakage.

Owner:柳利夏

Rosin oil refining technique

The present invention relates to a refining technology of turpentine oil, and is characterized in that 10 kilograms of salad oil is put in a boiler, after the temperature is warmed up to 180 to 220 DEG C, 3 kilograms of mammocks of a Korean pine root containing higher lipin are immerged in oil for blasting 10 to 15 minutes, then the mammocks of the Korean pine root are fished out of oil, and oil is poured in a container for natural cooling and depositing till the oil temperature reaches 70 to 80 DEG C; 3 kilograms of new salad oil is put in the boiler again, when the temperature is warmed up to 260 to 270 DEG C, the mammocks of the Korean pine root fished out of oil is immerged in new salad oil again for blasting 5 to 10 minutes, then the mammocks of the Korean pine root is fished out of oil again till the oil temperature is naturally cooled and deposited to 70 to 80 DEG C; when the oil gotten rid of sedimentary twice is mixed together to measure that turpentine oil content is 10 percent of salad oil, the present invention can go to the next technology to make turpentine oil dripping pill for storing and standby. Turpentine oil distilled by the method has no any poison and side effect for a human body, and is the most ideal leechdom for curing ulceration disease.

Owner:陈兰杰

Plate and making method therefor

InactiveCN101069976ASimple preparation processColor won't changeDomestic articlesFlat articlesPine resinPetuntse

The invention discloses woods for making furniture and bureaus and its preparation method. The products are formed by mixing the following components and weight ratio uniformly, rolling, molding, drying, grinding and polishing: petuntse powder (viscin thread mud) 40-60, orange skin powder 5-15, pine leaves powder 5-15, pine resin 10-25 and tung oil 10-25. The plates have no formaldehyde or other harmful substance. It is fireproof, durable, wear, anti- bristletail and anti-static. It also can form natural figure without decorating with other panels or any treatment on the surface. Its preparation technologies are simple, color can not change and it can be polished for renewal repeatedly.

Owner:曹廷亿

A kind of treatment method of pine wood for furniture

ActiveCN107363666BDegreasing thoroughlyHigh densityPressure wood treatmentWood treatment detailsSurface layerPine resin

The invention relates to the technical field of furniture wood processing, and discloses a treatment method for pine wood for furniture. The treatment method for the pine wood for the furniture comprises the following steps that (1) in the process of removing pine resin, the pine wood is socked by using a deoil brightening agent firstly, when the moisture content of the wood reaches 80-90%, heating and stewing are conducted, then drying treatment is conducted at the temperature of 60-70 DEG C till the moisture content is 30-35%, and the process can remove the most pine resin in the surface layer the pin wood and can disperse the inner pine resin; (2) pine wood boards after being subjected to drying treatment are placed into a thermocompressor, after progressive temperature-raising and pressure-increasing treatment is conducted, wood layer structures cannot be damaged while the inner pine resin is pressed out step by step, moreover, the density of the pine wood is enhanced, and resin removing is more thoroughly; and (3) the wood after being cleaned and planed is subjected to functional polishing. According to the treatment method for the pine wood for the furniture, the efficiency can be enhanced, and meanwhile good mould proof performance, corrosion proof performance, water-repellent performance and flame-resistant performance are achieved.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

A kind of wood wax oil and its coating process

ActiveCN106497427BEasy to operateHigh surface hardnessWax coatingsAntifouling/underwater paintsWaxPine resin

The invention relates to the technical field of wax oil coating, in particular to novel wax oil and a coating technology thereof. The novel wax oil is prepared from, by mass, 10-20 parts of castor bean wax, 5-10 parts of yellow fir wax, 6-8 parts of laurel wax, 8-12 parts of castor oil, 5-10 parts of peanut oil, 6-8 parts of essential oil, 4-6 parts of pine resin, 3-5 parts of copal resin, 1-3 parts of manganese dioxide, 0.5-0.8 part of an orange peel resisting flatting agent and 0.3-0.5 part of ORA-100. According to the novel wax oil, wood is coated through a three-layer-type crossed spraying method, operation is convenient, tight combination between the novel wax oil and wood can be enhanced, the surface hardness is enhanced, water and fouling are prevented, and the appearance attractiveness is improved.

Owner:ZHEJIANG XIYINGMEN WOOD

Processing method of pine resin

InactiveCN103087635BQuality improvementImprove solubilityTurpentine spiritsNatural resin purificationOxalateFiltration

The invention relates to a processing method of pine resin and belongs to the field of rosin production. The processing method of pine resin comprises the following steps of: a, dissolving, namely dissolving the pine resin by adopting a dissolving solution, wherein the dissolving solution comprises the following components in percentage by weight: 55-82% of turpentine oil, 17.5-44.5% of water and 0.1-0.5% of oxalic acid; b, clarifying and colating, namely placing the dissolved pine resin liquid in a transition pot to be clarified and then colating to obtain colature; c, acid washing, namely adding the oxalic acid for washing; d, washing, namely adding hot water for washing; e, clarifying and carrying out refined filtration, namely placing the pine resin liquid into the transition pot to be clarified and then carrying out refined filtration; and f, heating and distilling, namely placing the pine resin liquid in a rectifying tower to be subjected to the heating and distilling, so that rosin and turpentine oil finished products are respectively obtained. The processing method of rosin provided by the invention has the beneficial effect that the qualities of the rosin and turpentine oil obtained by processing pine resin are excellent, so that demand of downstream industries is met.

Owner:云南茶花林化有限公司

Waterproofing agent composition and method of preparing the same

InactiveUS20160186010A1Improve adhesionOther chemical processesNatural resin coatingsOrganic solventPine resin

A waterproofing agent composition comprises 100 parts by weight of the pine resin, 20 to 70 parts by weight of an expanded styrene resin, 1 to 10 parts by weight of a vinyl-based resin and 100 to 750 parts by weight of an organic solvent. The waterproofing agent composition is a liquid and exhibits superior adhesion to various materials, thus providing proofing characteristics, humidity resistance and permeability resistance to surfaces of various materials water. In addition, the waterproofing agent composition may provide heat insulation characteristics along with waterproofing characteristics, humidity resistance and permeability resistance to subjects or bases, thus being used for various purposes.

Owner:CREAT&REUSE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com