Method for producing maleopimaric anhydride

A technology of maleopimaric anhydride and a production method, applied in the direction of organic chemistry, etc., can solve the problems of large investment in production equipment and complex production process, and achieve the effects of improving comprehensive economic benefits, reducing production costs, and simplifying production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

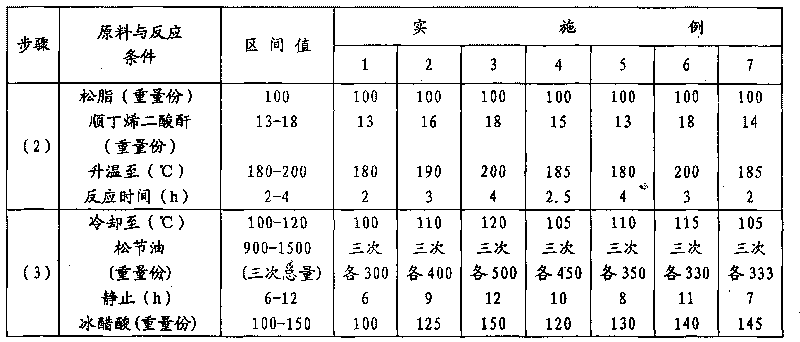

[0016] Example 1 (refer to the raw materials listed in Example 1 in the above table and their proportions by weight, reaction temperature and time parameter values):

[0017] In the reaction kettle, add 100 parts by weight of rosin, heat to melt, then add 13 parts by weight of maleic anhydride, continue to heat up to 180°C, and the reaction will stop for 2 hours. When the reactant is cooled to 100°C, add 300 Parts by weight of turpentine oil as a solvent, stir well and let stand for 6 hours, centrifuge to separate the upper solvent, leaving a light yellow precipitate, repeat the above process 3 times, add 300 parts by weight of new turpentine each time, and stir evenly and then stand still Let it stand for 6 hours, centrifuge the upper solvent, and finally recrystallize the light yellow precipitate left after three times of dissolution with 100 parts by weight of glacial acetic acid to obtain white crystals. Wash them with water for 2-3 times and dry at 100°C to obtain the purity....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com