Pine resin collection method

A collection method and technology of pine resin, applied in the field of economic forestry, can solve the problems of road transportation, difficulty in maintenance of power transmission equipment, affecting the growth of pine trees, and large damage to pine trees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: a kind of turpentine collection method is characterized in that: the step of described pine resin collection method is as follows:

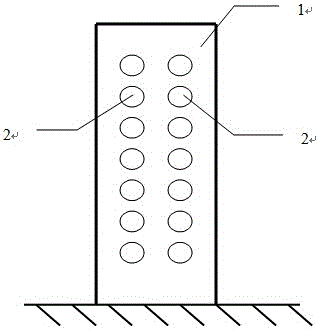

[0025] (1) Borehole 2 from the bottom layer of pine tree trunk 1, the position of hole is to be parallel with horizontal plane,

[0026] (2) On the inner surface of the tree hole of the drilled hole 2, apply a grease enhancer,

[0027] (3) Install the fat-receiving container and insert it into the hole of the first layer,

[0028] (4) After the resin receiving container is full of turpentine, take off the resin receiving container and collect the resin in a large bucket uniformly.

[0029] (5) Based on the bottom hole, drill hole 2 along the trunk 1 to the upper second layer. The position of the hole is parallel to the horizontal plane of the first layer of holes.

[0030] (6) On the inner surface of the tree hole of the drilled hole 2, apply a fat enhancer,

[0031] (7) Install the fat-receiving container and insert it in...

Embodiment 2

[0038] When the diameter of the pine tree is 17-27 centimeters, drill two holes, and the two holes are arranged in a horizontal plane. The remaining steps are used and will not be repeated.

Embodiment 3

[0040] When the diameter of the pine tree is more than 28 cm, drill three holes, and the three holes are arranged horizontally. The remaining steps are used and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com