Patents

Literature

44results about How to "No volatilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foam sheet-forming composition, heat conductive foam sheet and process for the production thereof

A sheet-forming composition is provided which has a construction comprising a combination of a heat-polymerizable binder component containing at least one (meth)acrylic monomer or its partial polymer, a heat conductive filler, a heat polymerization initiator for the binder component and a foaming agent. A process for making a heat conductive foam sheet also is provided.

Owner:3M INNOVATIVE PROPERTIES CO

Treatment method for wood surface defects

InactiveCN102632528AWon't fall offPromote infiltrationIrregularity removal devicesPolymer scienceAdhesive

The invention provides a treatment method for wood surface defects. The treatment method comprises the following steps: (1) cleaning up wood surface defect parts; (2) spraying or wetting the peripheries of the defect parts by using alcohol, an acrylic paint or an adhesive; (3) coating the defect parts by directly using the acrylic paint / the isocyanate adhesive or firstly filling in repairing putty and then coating by using the acrylic paint / the isocyanate adhesive; (4) carrying out indoor natural surface drying for over 3 hours or after baking for 20-120 minutes at the temperature of 30-80 DEG C for complete curing, carrying out light sand treatment on the surface for painting to enable the adhesive or paint to evenly penetrate into the defects so as to achieve a better bonding effect, and ensure that the defect parts cannot crack again in the using process of a repaired wood board, and the acrylic paint and the isocyanate adhesive do not have volatility, thus not polluting the environment and being environmentally-friendly.

Owner:GUANGDONG YIHUA TIMBER IND

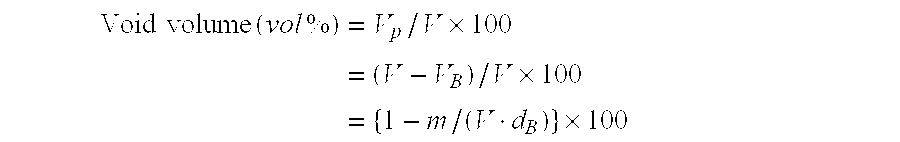

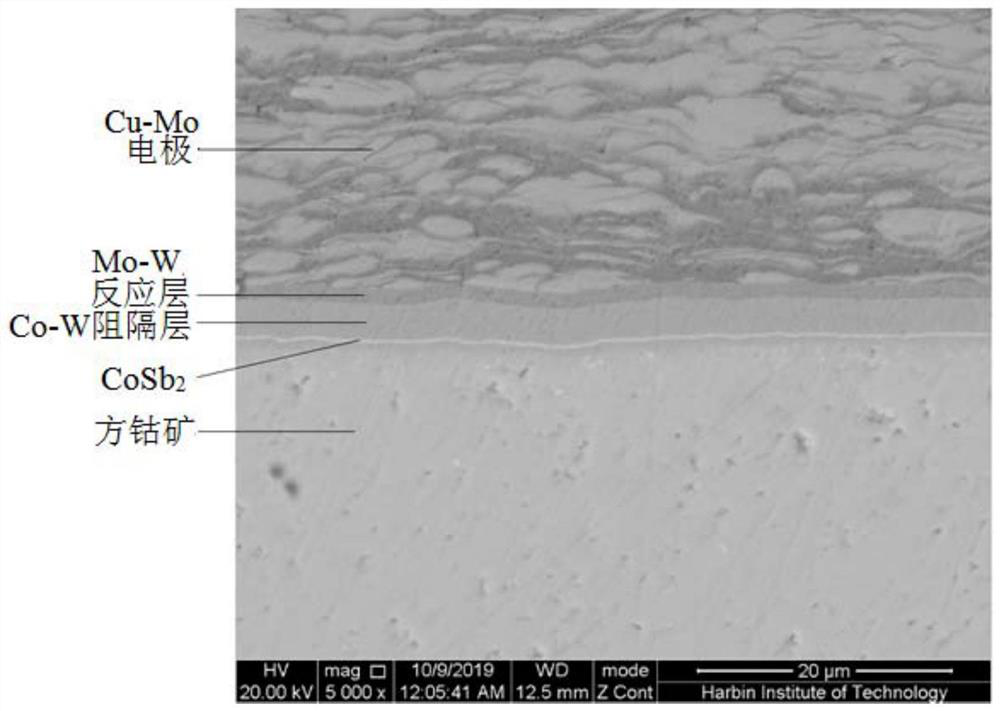

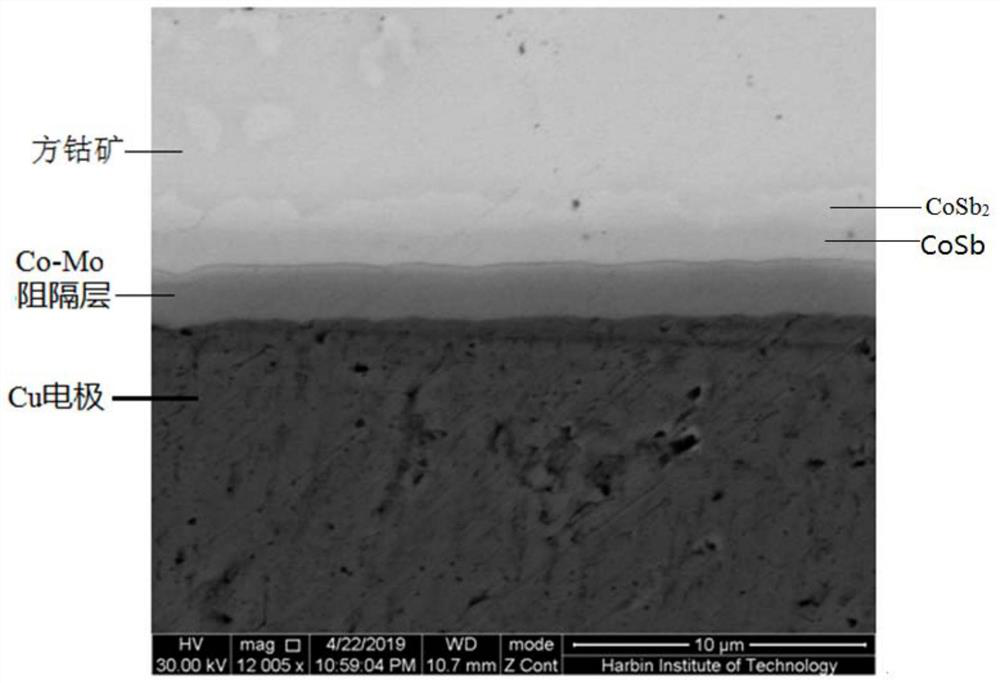

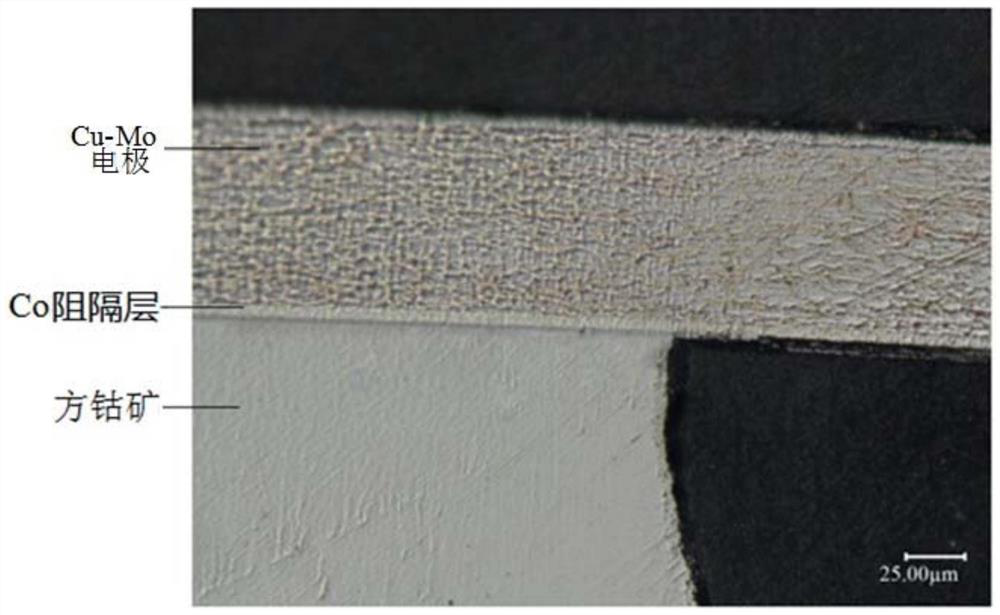

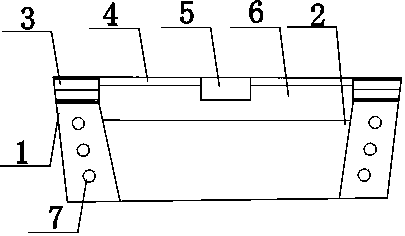

Rapid diffusion welding connection method for skutterudite thermoelectric material and electrode

ActiveCN111014929AImprove thermoelectric conversion efficiencyGuaranteed thermoelectric conversion efficiencyWelding/soldering/cutting articlesNon-electric welding apparatusSkutteruditeElectroplating

The invention discloses a rapid diffusion welding connection method for a skutterudite thermoelectric material and an electrode, and relates to a diffusion welding connection method. The method aims to solve the problems of Sb element volatilization and element diffusion when the existing skutterudite thermoelectric material is connected with an electrode. The method comprises the steps of takingan electrode, cleaning a to-be-welded surface, electroplating an alloy barrier layer on the surface of the to-be-welded surface of the electrode, cleaning the to-be-welded surface of the skutteruditethermoelectric material, and performing diffusion welding. The barrier layer is prepared on the electrode side through an electroplating method, diffusion welding is achieved between the barrier layerand the skutterudite thermoelectric material under the relatively low pressure and at the relatively low temperature, element diffusion of weld joint elements and skutterudite does not exist in the process, and Sb element volatilization and element diffusion can be prevented. The method is suitable for welding the skutterudite thermoelectric material and the electrode.

Owner:HARBIN INST OF TECH

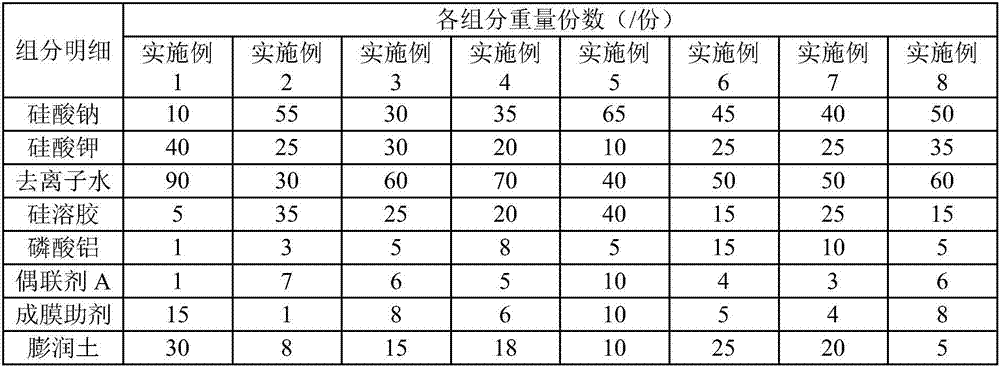

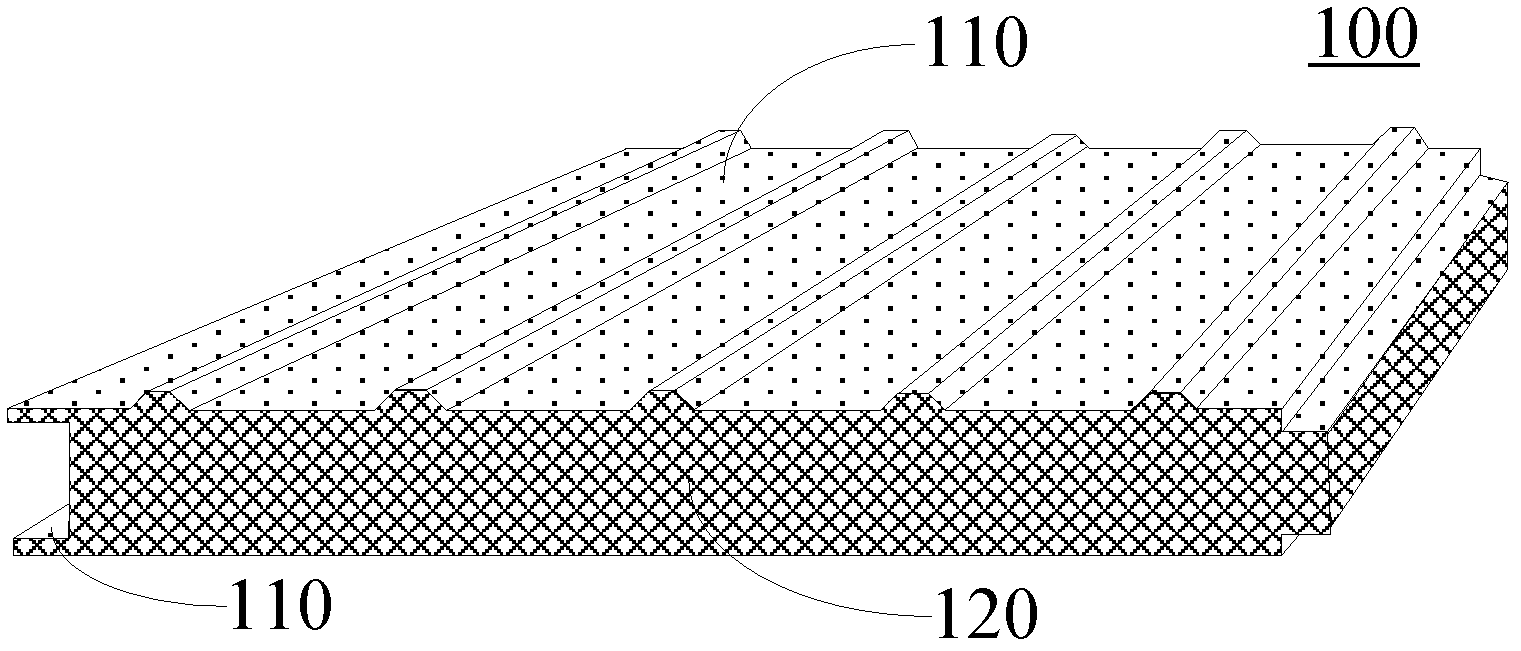

Fireproofing-thermal insulation-decoration integrated board and preparation method thereof

ActiveCN107263948AFree from destructionShorten the replacement periodCovering/liningsNon-macromolecular adhesive additivesAdhesiveThermal insulation

The invention belongs to the technical field of energy-saving and environment-friendly material, and particularly relates to a fireproofing-thermal insulation-decoration integrated board and a preparation method thereof. The fireproofing-thermal insulation-decoration integrated board disclosed by the invention comprises a fireproofing and thermal insulation felt, adhesive A, and a decorative board, and the fireproofing and thermal insulation felt is stuck on the decorative board by the adhesive A, so that the fireproofing-thermal insulation-decoration integrated board is formed. The invention overcomes the problems of high cost and easy powder dropping existing in conventional thermal insulation felts, and the product has better performance, and is more environment-friendly; the fireproofing and thermal insulation felt of the fireproofing-thermal insulation-decoration integrated board does not drop powder, and can be firmly combined with the decorative board under the effect of the adhesive A to form the fireproofing-thermal insulation-decoration integrated board, and thereby the effect of integrating fireproofing, thermal insulation and decoration together is achieved; the fireproofing grade of the fireproofing-thermal insulation-decoration integrated board disclosed by the invention is grade A1, the thermal insulation effect is good, product industrialization can be realized, and the difficulty of construction is low.

Owner:天津朗华科技发展有限公司

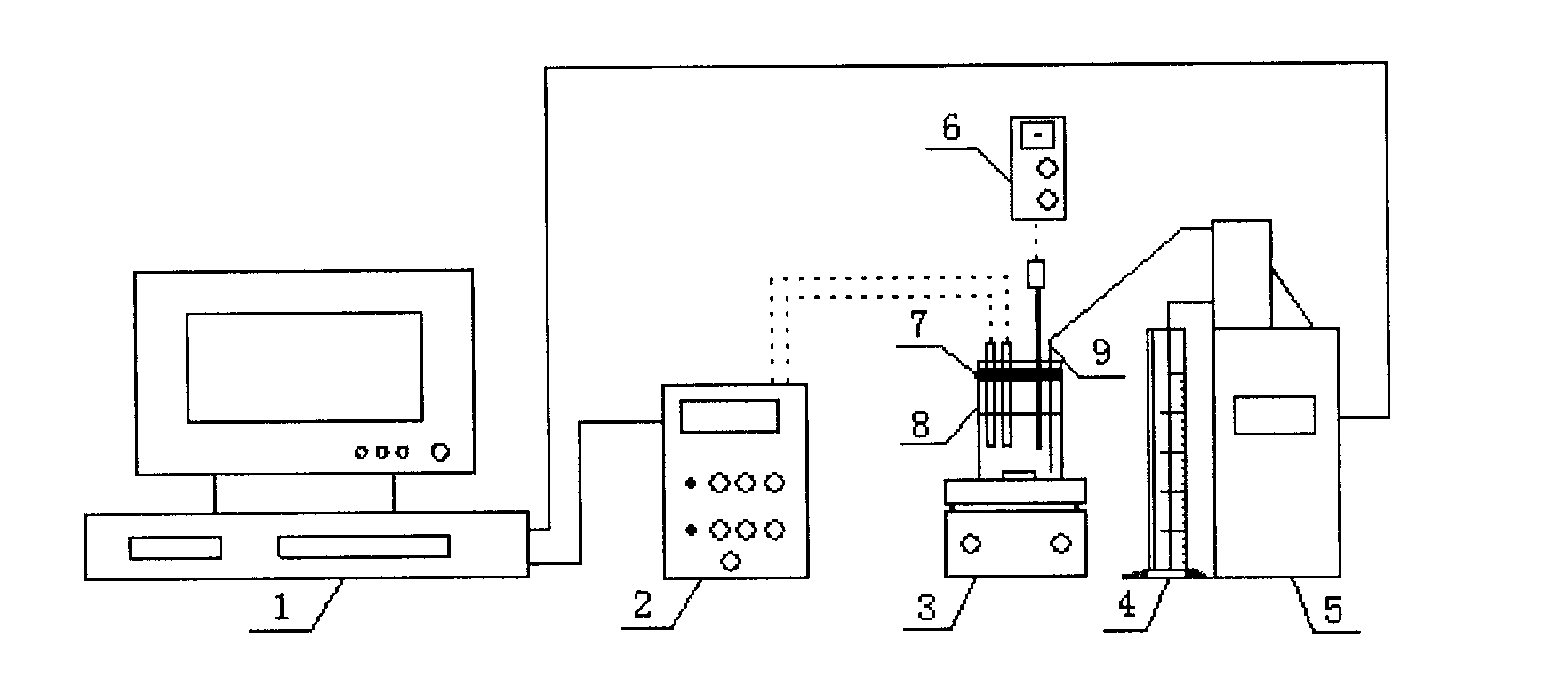

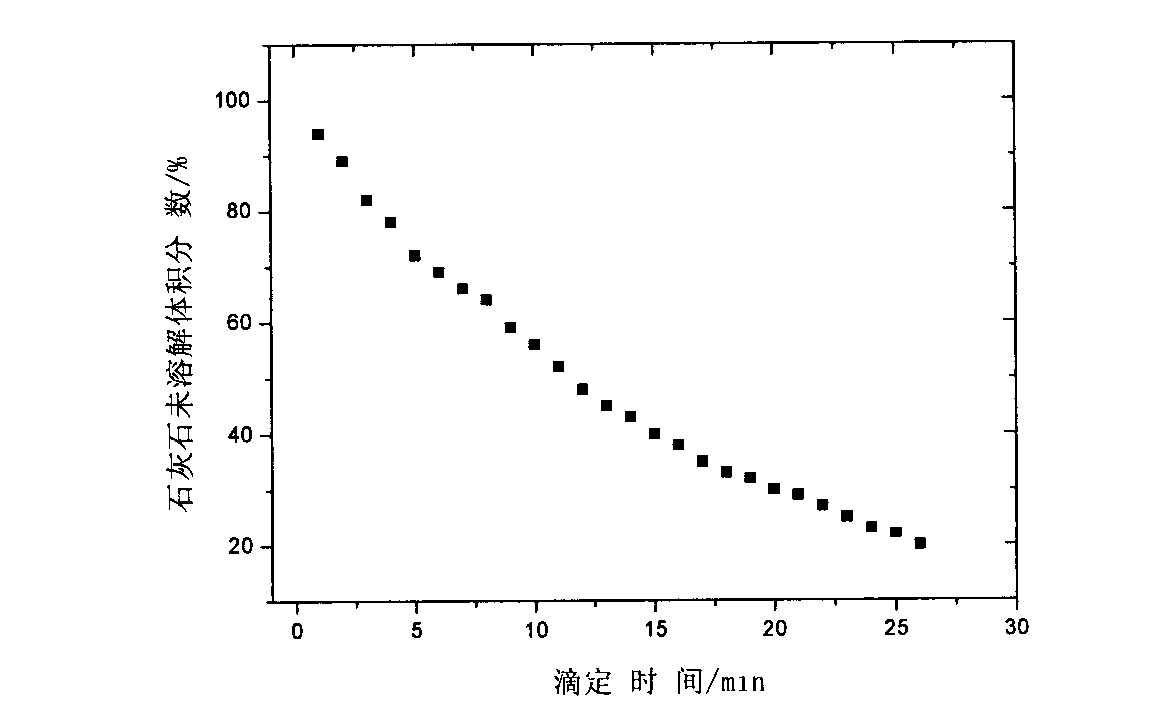

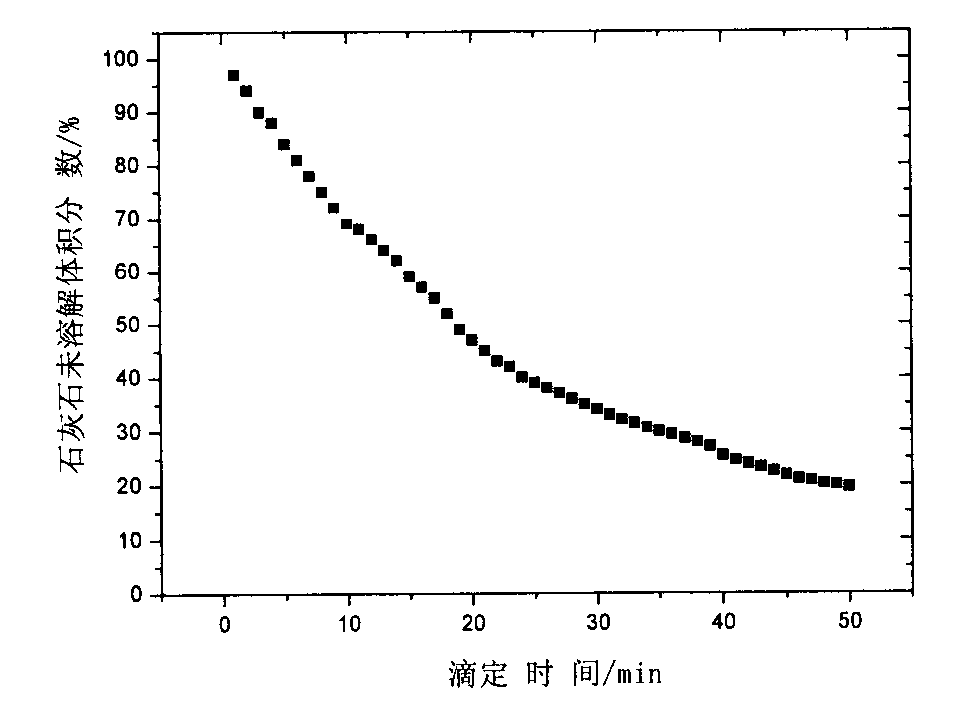

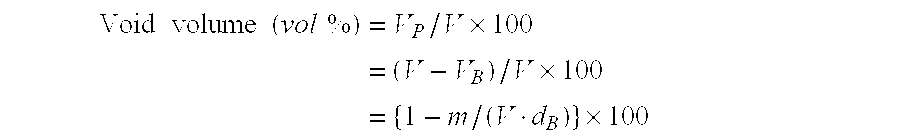

Method for testing limestone reaction activity

InactiveCN102721784ANo volatilizationGuaranteed accuracyChemical analysis using titrationFlue gasSlurry

The invention provides a method for testing a limestone reaction activity, comprising preparing an acidic reagent and limestone slurry, and adding the acidic reagent in drops into the limestone slurry to react and test the reaction activity, wherein the acidic reagent is a sulfuric acid solution, a particle size of the tested limestone powder particles is 200 to 300 meshes, and the acidic reagent is added in drops into a reactor at a certain rate. The temperature of the limestone slurry in the reactor is constant. A computer collects a titration rate of the acidic reagent and a pH-value change curve during the reaction in real time. The method employs a shrinking core model, calculates, by using a calculating model for limestone activity, to obtain an undissolved volume fraction of the limestone quantitatively and then determine the limestone reaction activity quantitatively. The test method provided in the invention is simple and practical, has accurate measurement results, and can correctly evaluate the desulphurization reaction activity of the limestone and provide a theoretical basis for an early stage design of a flue gas desulphurization system.

Owner:ANGANG STEEL CO LTD

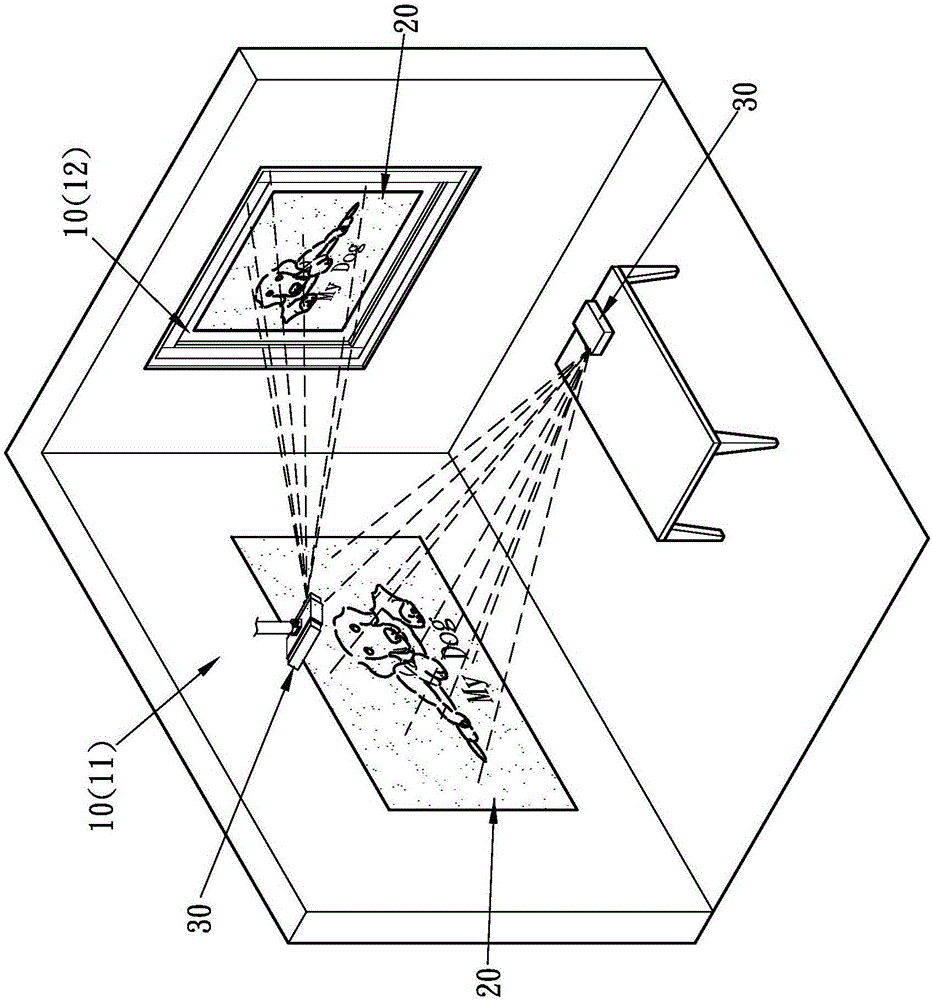

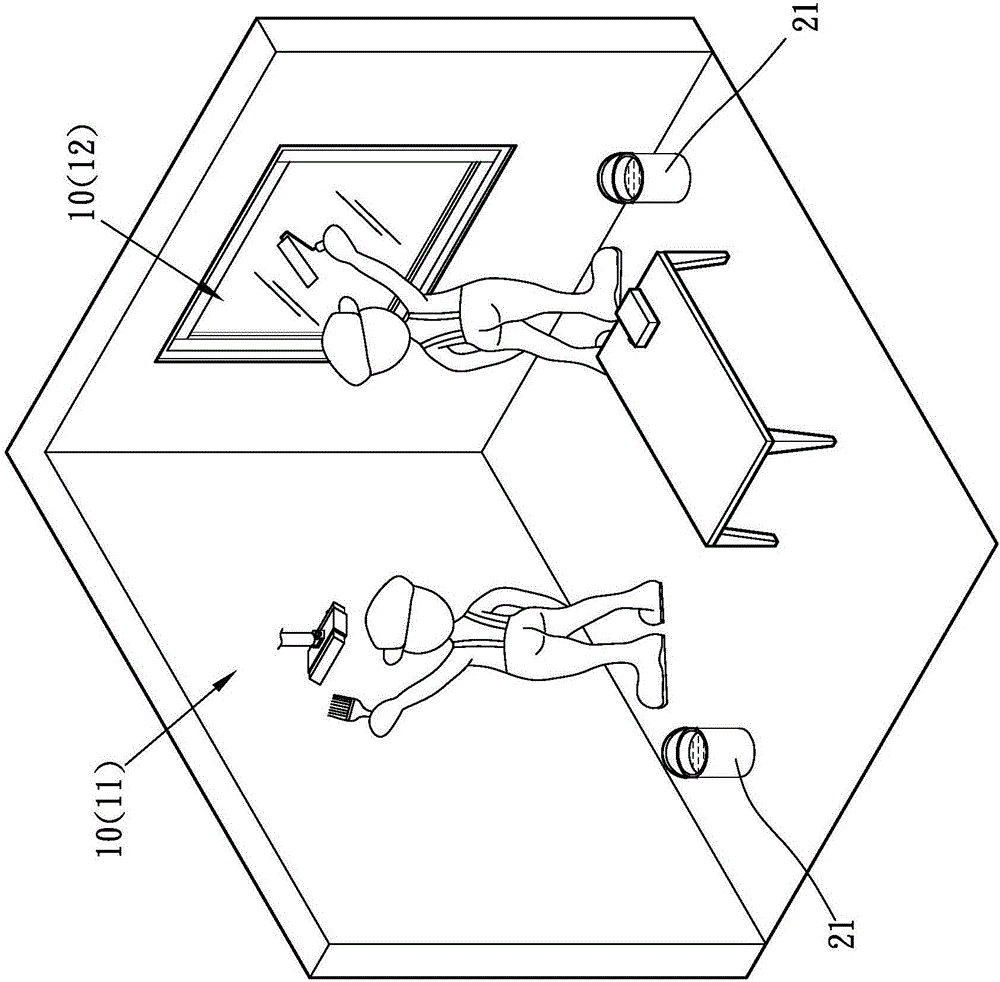

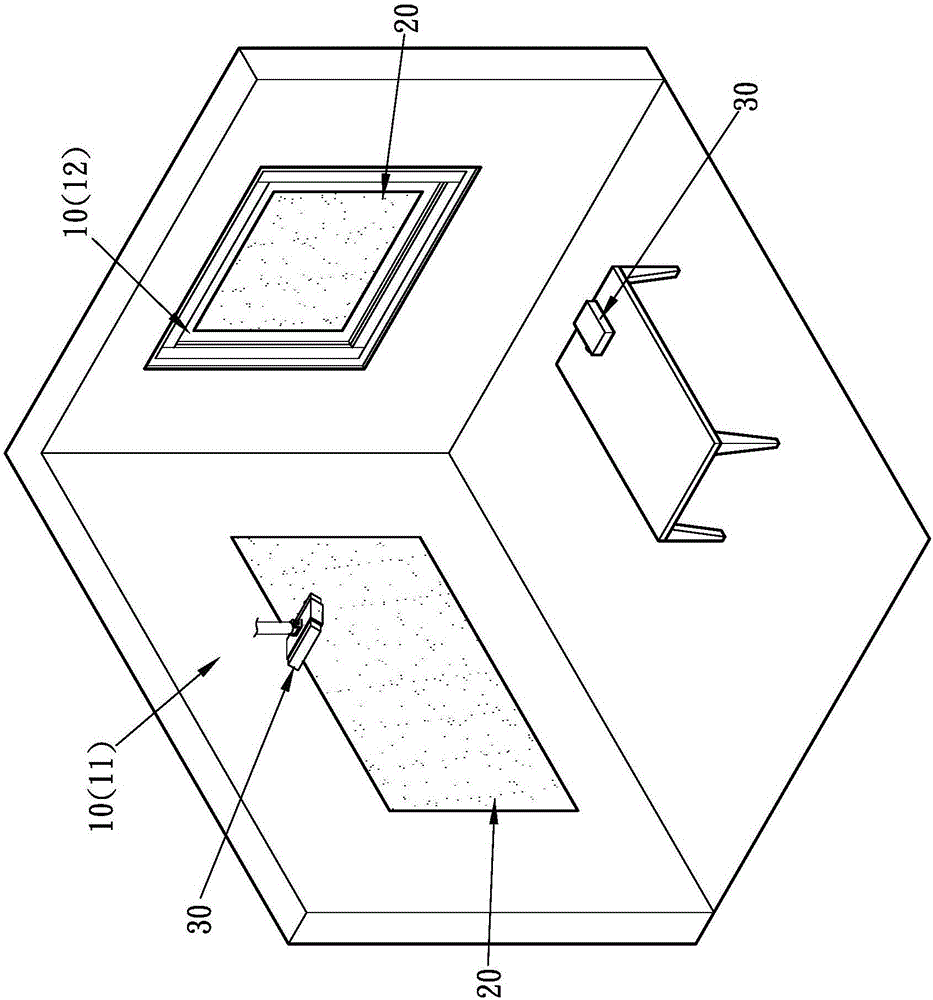

Screen material, sprinkler device, projection screen device and use method thereof

InactiveCN106590378AImprove picture qualityHigh resolutionProjectorsPolyurea/polyurethane coatingsAcrylic resinSilicon dioxide

The present invention mainly provides a screen material, a sprinkler device, a projection screen device and a method of using the same, and mainly provides an application in which at least one projection device can display an image after projection. The projection screen device comprises a substrate, and at least one screen coating layer which is formed by applying a liquid screen coating to the preset portion of the surface of the substrate. The composition and weight percentage of the screen coating are: water-soluble polyurethane 20%-30%, water-soluble acrylic resin 20%-30%, silica powder 20%-30%, sodium polyacrylate thickener 2%-5%, silicone emulsion defoamer 2%- 5%, water-soluble emulsified wax 2%-5%, acrylic polymer solution 2%-5% and pure water. By using the above-described technique, the screen material having the characteristics of the water-soluble paint is coated on a substrate of any material, the projection screen is formed as a positive projection and a back projection, and the image display has high quality, high-definition and high-resolution effect, so the application is quite extensive.

Owner:新玉实业股份有限公司 +1

Preparation method of cimetidine

The invention discloses a preparation method of cimetidine. The method comprises the following steps: (1) carrying out condensation reaction on 2-(methylimidazole-4-yl) methyl thioethylamine and N-cyanamide dialkyl carbonate in hot alcohol dehydratum, distilling out alcohol at ordinary pressure, cooling to a room temperature, crystallizing and filtering to obtain N-cyanogroup-N'-[2-(5-methylimidazole-4-yl) sulphur methyl ethyl]-O-R isourea; (2) carrying out amination reaction on the N-cyanogroup-N'-[2-(5-methylimidazole-4-yl) sulphur methyl ethyl]-O-R isourea and methylamine in a reaction medium, after reaction is ended, distilling methylamine at ordinary pressure, cooling to room temperature and crystallizing to obtain a cimetidine crude product; and (3) decoloring the cimetidine crude product in absolute ethyl alcohol, cooling, crystallizing, drying in vacuum, and crushing to obtain a cimetidine refined product. According to the preparation method, the environment pollution caused by by-product methyl mercaptan / sodium methyl mercaptide in an existing cimetidine production process can be solved; the production process is simplified; the cost is reduced; and the product quality is improved.

Owner:YANCHENG KAILI PHARMA

Preparation method of environmental-friendly water-based paper ink

The invention discloses a preparation method of environmental-friendly water-based paper ink. The preparation method comprises the following several steps of weighting materials, and weighing the following raw materials in parts by weight for later use: 25-35 parts of polyamide resin, 10-15 parts of nitrocellulose resin, 1-3 parts of acrylic emulsions, 10-15 parts of pigment filter cakes, 1-2 parts of surface active agents, 0.5-1 part of organic silicon defoaming agents, 1-3 parts of silicon dioxide, 0.5-0.8 part of stabilizing agents, 0.5-0.8 part of adhesive force accelerating agents, 1-3 parts of wax powder and 20-35 parts of deionized water; then preparing a resin solution; then pre-dispersing and dispersing; finally filtering and packaging to obtain finished ink. The preparation method disclosed by the invention has the advantages of simple equipment, good process controllability and the like.

Owner:SUZHOU ZHONGYA INK

Foam sheet-forming composition, heat conductive foam sheet and process

A sheet-forming composition is provided which has a construction comprising a combination of a heat-polymerizable binder component containing at least one (meth)acrylic monomer or its partial polymer, a heat conductive filler, a heat polymerization initiator for the binder component and a foaming agent. A process for making a heat conductive foam sheet also is provided.

Owner:3M INNOVATIVE PROPERTIES CO

Pine resin collection method

The invention belongs to the field of economic forestry, and a method for collecting rosin. The steps of the method for collecting rosin are as follows: a hole is drilled from the bottom layer of a pine tree, the position of the hole is parallel to the horizontal plane, and the surface of the drilled tree is coated with grease After the grease receiving container is full, remove the grease receiving container, and collect the rosin into the large bucket. Based on the bottom hole, go to the upper second layer along the tree trunk. , Drill the hole, the position of the hole is parallel to the horizontal plane of the first layer of hole, apply grease enhancer on the inner surface of the drilled tree hole, install the grease receiving container to be embedded in the second layer of hole, after the grease receiving container collects rosin full , remove the grease receiving container, and collect the rosin into the vat uniformly. Combined with applying a fat-enhancing agent, the fat-receiving container is directly embedded in the fat-collecting hole, and the yield of collected rosin, rosin and turpentine is increased. It can be widely used to collect turpentine in forest areas.

Owner:周健

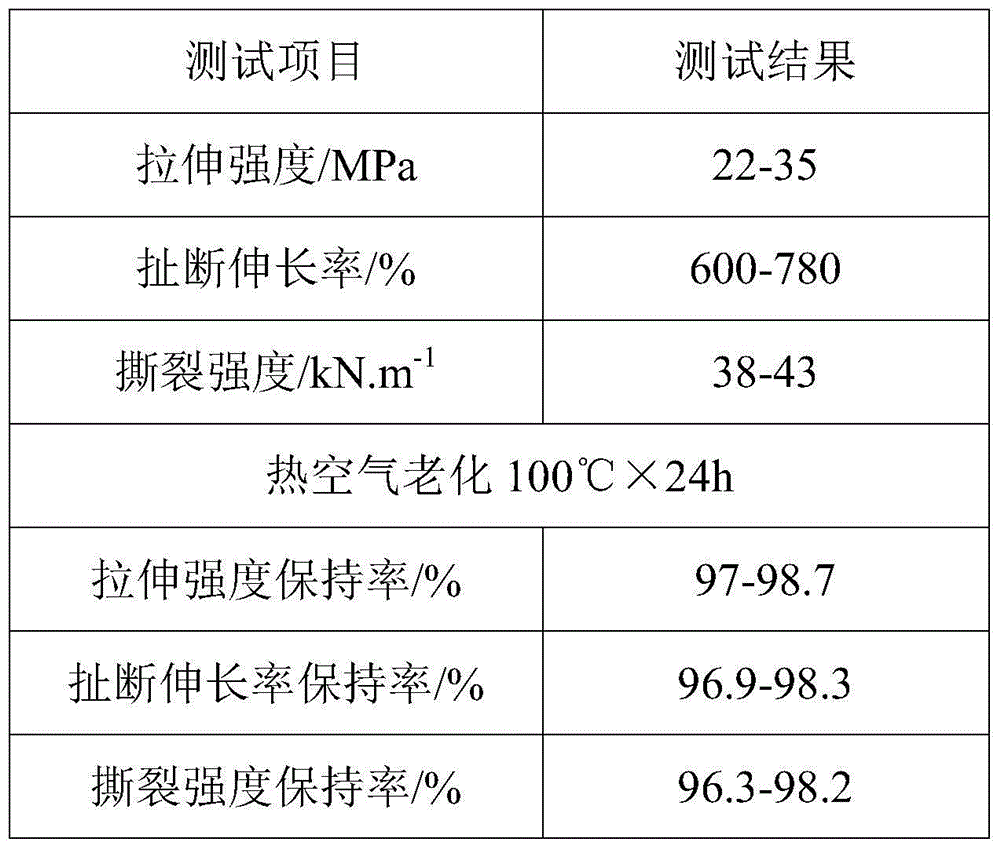

Nano-material-modified natural rubber cable material

InactiveCN104629103AImprove aging resistanceImprove mechanical propertiesRubber insulatorsPolymer scienceAlloy

The invention discloses a nano-material-modified natural rubber cable material which is prepared from natural rubber, liquid isoprene rubber, modified superfine lana powder, superfine acrylate rubber powder, stearic acid, zinc oxide, nano calcium carbonate, carbon black, nano alloy, sulfur, 1,4-bis-tert-butyl-peroxycumene, diallyl phthalate, castor oil, bis octadecanol ester, bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, an anti-aging agent and an accelerator. The nano-material-modified natural rubber cable material has the advantages of excellent mechanical properties and favorable aging resistance; and the cable prepared from the material has the advantages of favorable comprehensive properties and long service life.

Owner:无为县茂林电缆材料有限公司

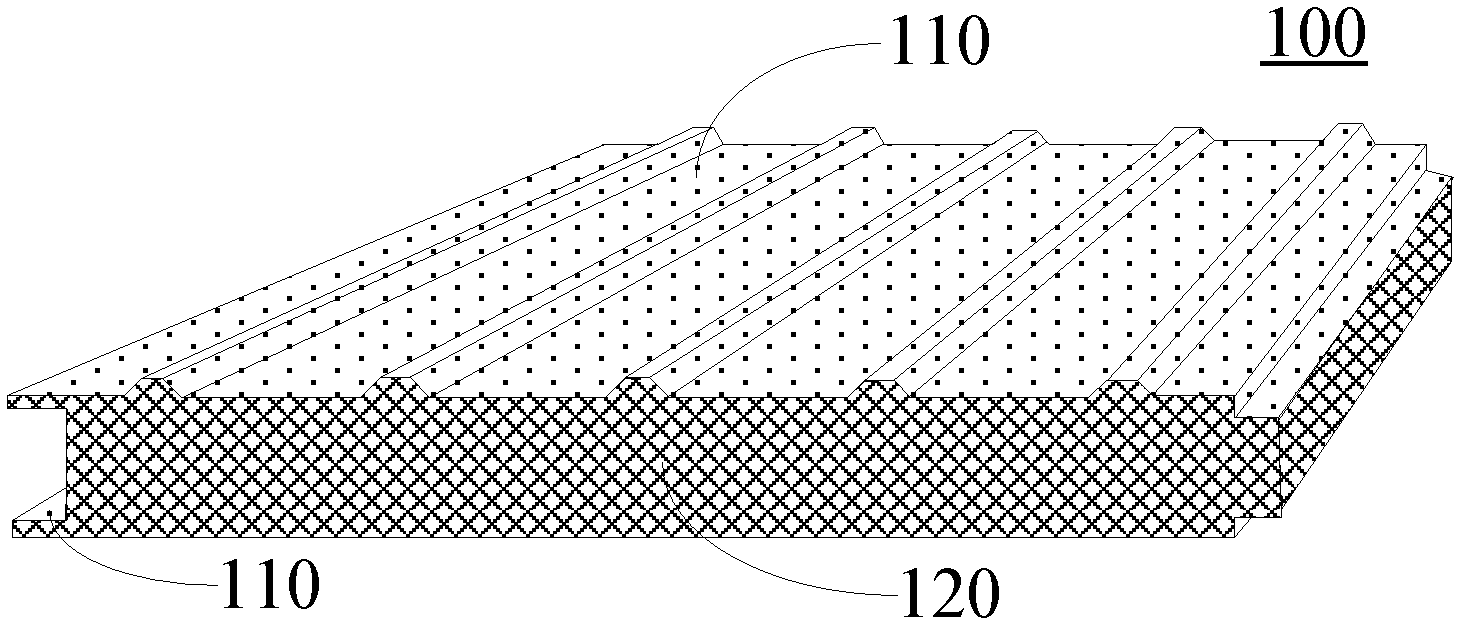

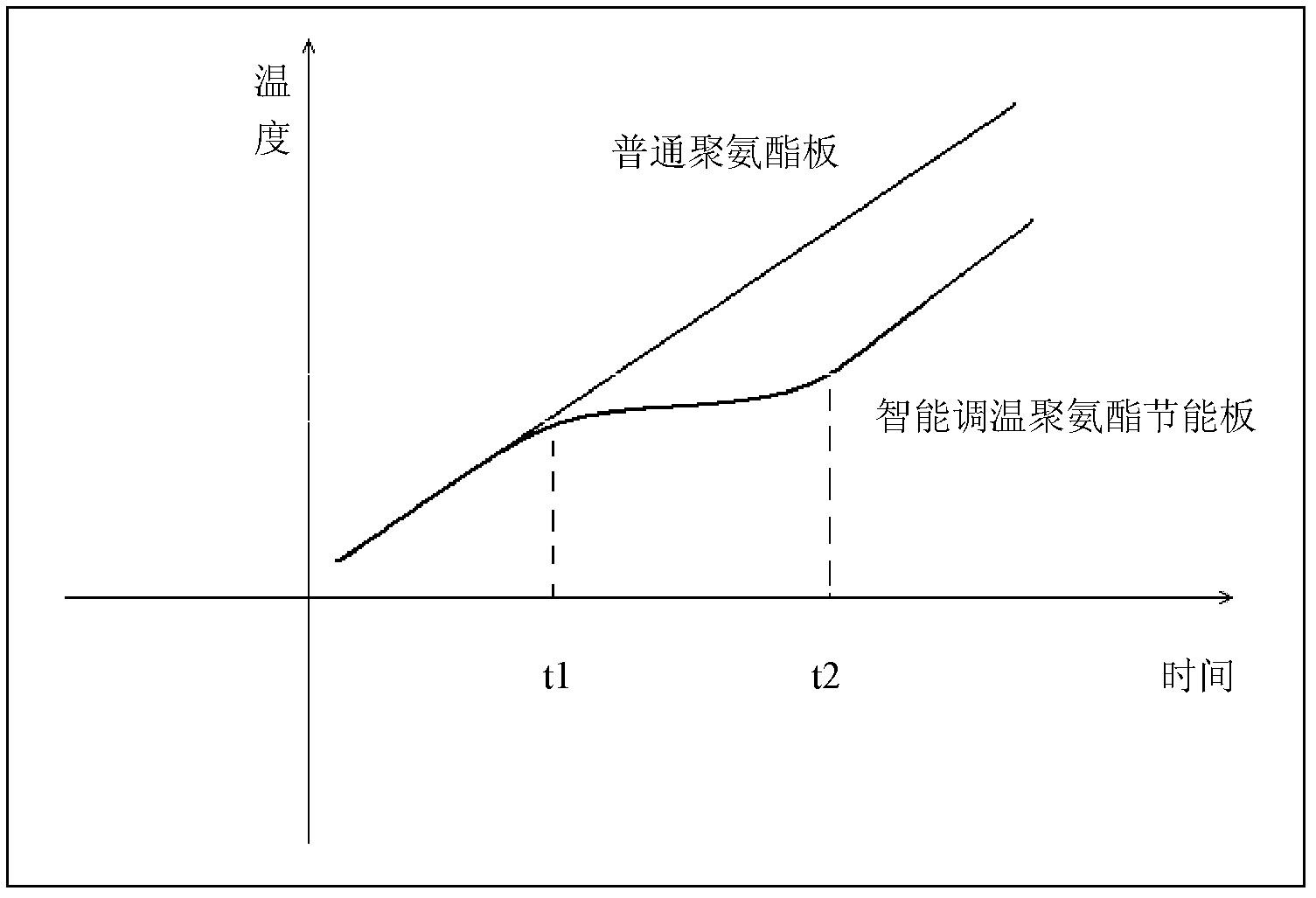

Intelligent temperature regulating polyurethane energy-saving plate and manufacturing method thereof

InactiveCN102322110AImprove performanceExtended service lifeConstruction materialPhase-change materialSteel plates

The invention relates to an intelligent temperature regulating polyurethane energy-saving plate, comprising two colour steel plates and a polyurethane composite board which is arranged between the two colour steel plates, is bonded with the colour steel plates and is doped with organic energy storage phase change material and nano processing aid, wherein the organic energy storage phase change material accounts for 5-20% of the weight of the polyurethane composite board, and the nano processing aid accounts for 0.5-2% of the weight of the polyurethane composite board. The intelligent temperature regulating polyurethane energy-saving plate contains the energy storage phase change material and has good temperature regulating and heat insulating effects, when ambient temperature is higher than a set temperature, the energy storage phase change material absorbs heat and prevents the temperature from rising, and when the ambient temperature is lower than the set temperature, the energy storage phase change material releases heat and prevents the temperature from decreasing, thus intelligent temperature regulation is realized by virtue of the effect of the energy storage phase change material. Besides, the invention also relates to a manufacturing method of the intelligent temperature regulating polyurethane energy-saving plate.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

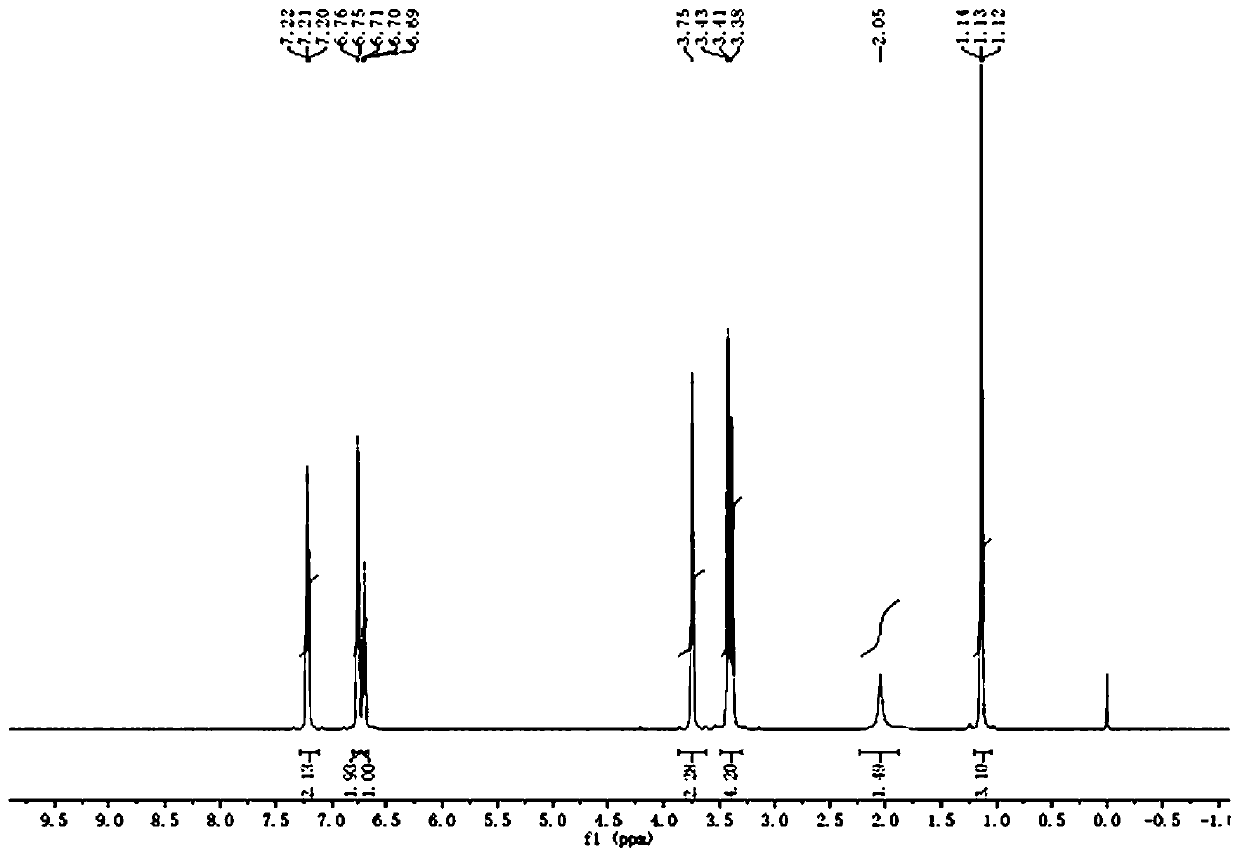

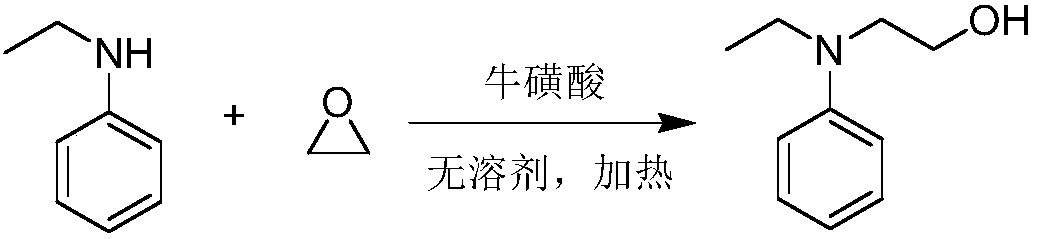

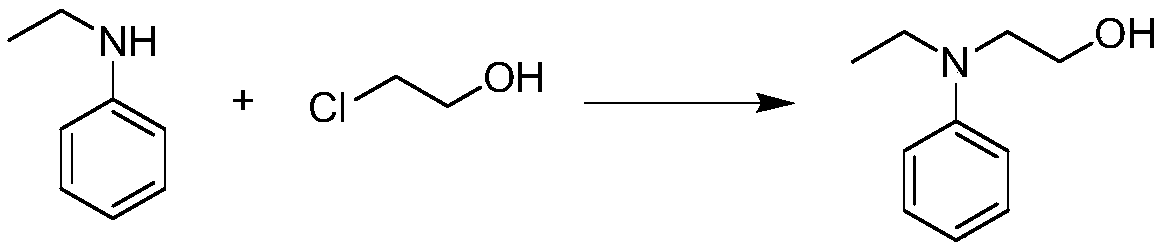

Method for preparing N-ethyl-N-hydroxyethylaniline

InactiveCN108117492AReduce dosageImprove catalytic performanceOrganic compound preparationAmino-hyroxy compound preparationEthylene oxideSolvent

The invention discloses a method for preparing N-ethyl-N-hydroxyethylaniline. The method comprises the following steps: by taking N-ethylaniline and ethylene oxide as raw materials, in the absence ofa solvent, under catalysis of taurine, performing programmed heating, directly synthesizing N-ethyl-N-hydroxyethylaniline, cooling, and discharging, thereby obtaining a finished product. The method iseasy in raw material obtaining, good in atom economy, gentle in reaction condition, green and environment-friendly, simple and efficient and applicable to industrial production.

Owner:JIANGSU YUANDA XIANLE PHARMA

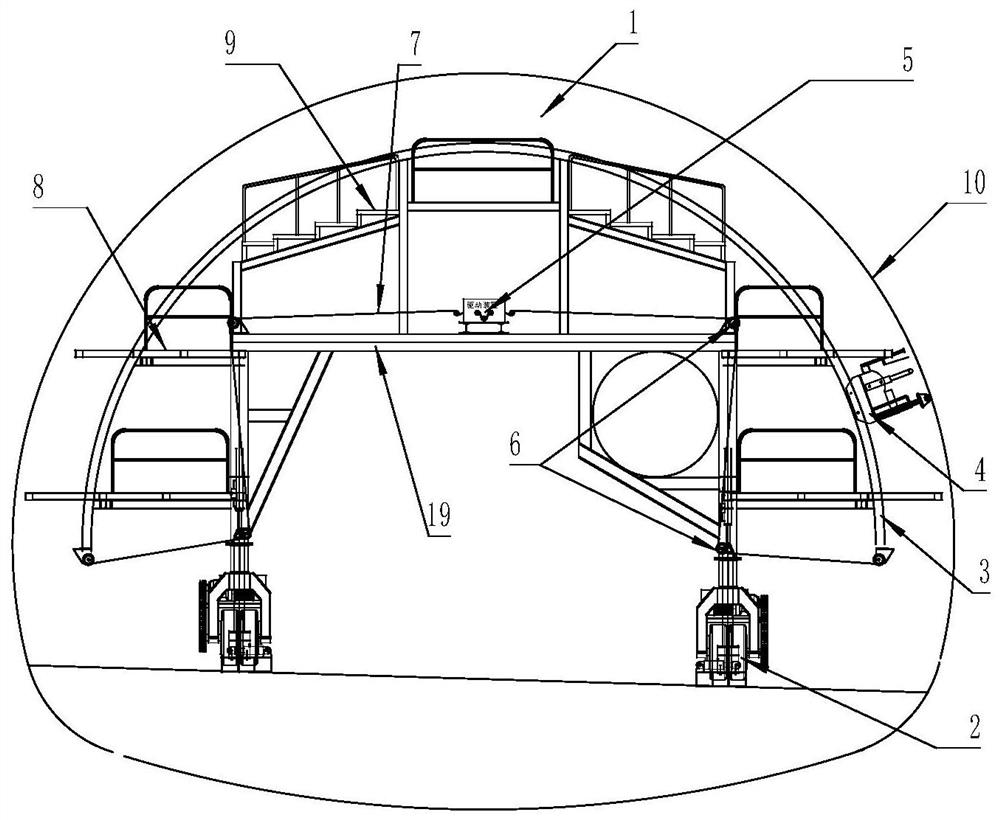

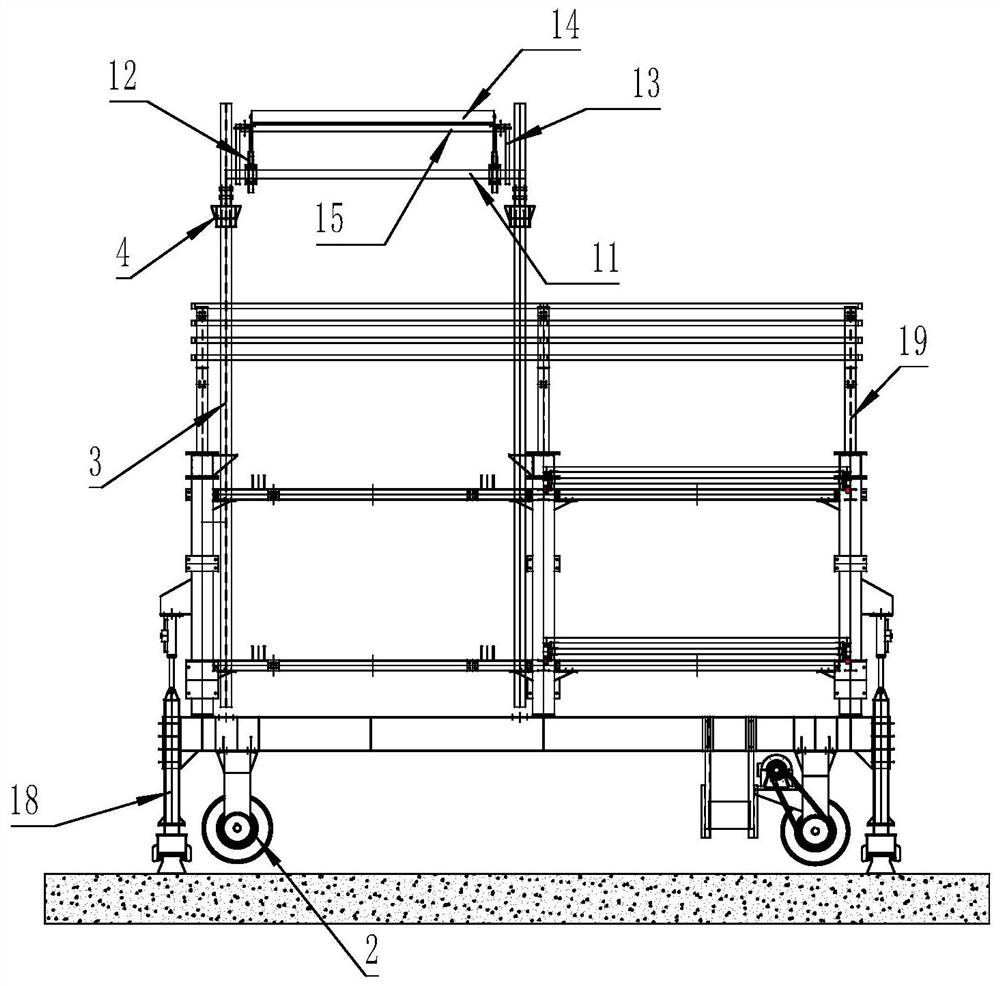

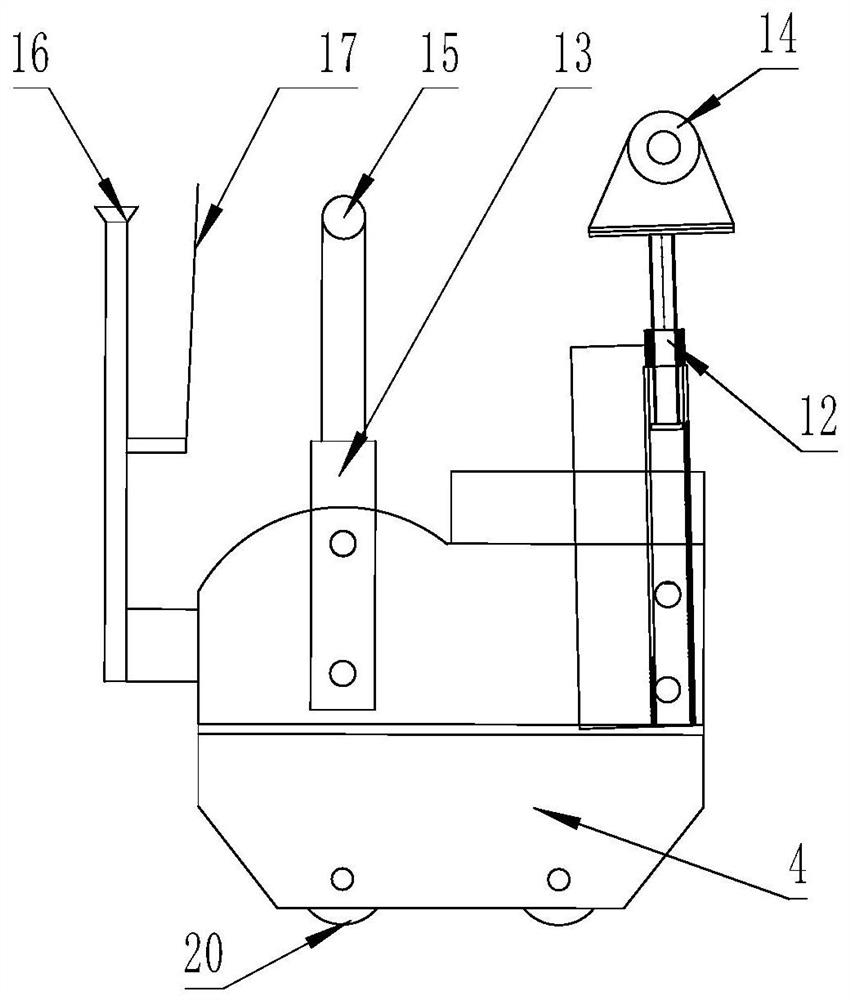

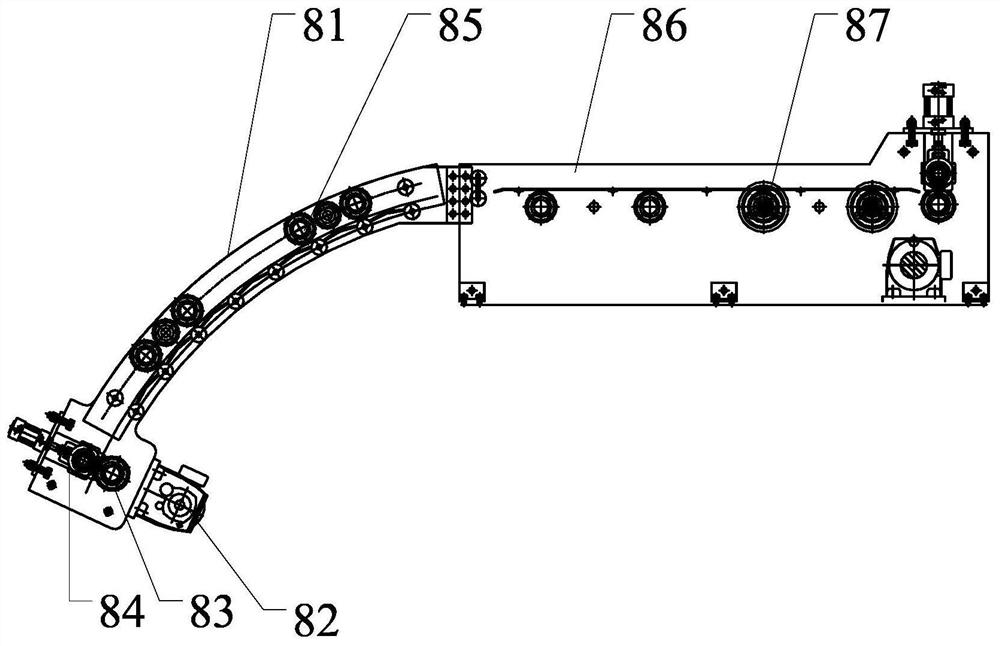

Use method of tunnel lining maintenance film-coating trolley

PendingCN112627847AMoisturizing assuranceAbsorptiveMining devicesUnderground chambersArchitectural engineeringMechanical engineering

The invention provides a use method of a tunnel lining maintenance film-coating trolley. The use method comprises the steps that film-coating maintenance is conducted on the inner wall of lining concrete, and a film-coating roll is manually mounted by an operator; a valve of an airflow cleaning nozzle is opened, a trolley driving device is started, a film-coating trolley is pulled through a pulling rope to walk upwards along a trolley track, and dust on the surface of the inner wall of the lining concrete is continuously cleaned through airflow by the airflow cleaning nozzle; meanwhile, a film-coating roll on a film roll inserting shaft is pulled out, and a film-coating pressing roller rotates to jack and press the film-coating roll to be continuously attached to the inner wall of the lining concrete for film coating; and film-coating maintenance construction of the inner wall of the lining concrete at the rear section is continuously conducted through the film-coating trolley. According to the lining film-coating maintenance trolley, the film-coating trolley drives a film-coating mechanism to conduct moisturizing maintenance on the surface, attached to the inner wall of the lining concrete, of the film-coating roll, moisture emitted in the concrete is reserved on the surface of the concrete for a long time, moisturizing of the inner wall of the lining concrete during maintenance can be ensured, the construction progress is accelerated, and the construction quality is improved.

Owner:LUOYANG GAOFEI BRIDGE MACHINERY CO LTD

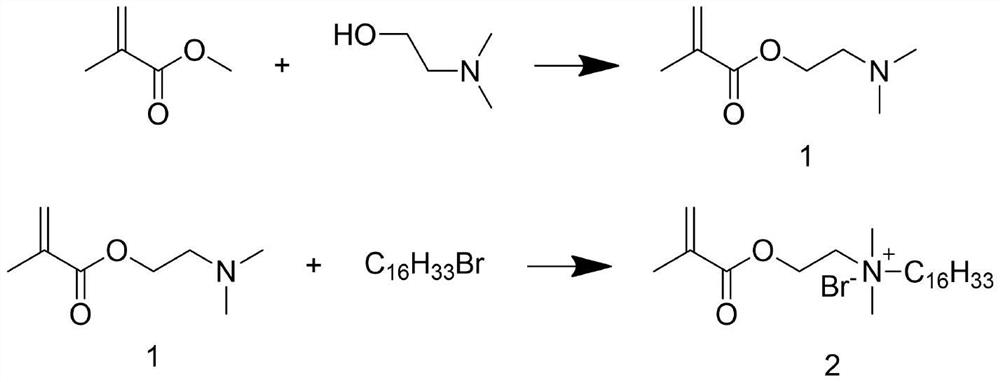

Graphene-based composite antibacterial material and preparation method thereof

InactiveCN113712038AExtended service lifeReduce manufacturing costBiocideDisinfectantsBiotechnologyCell membrane

The invention discloses a graphene-based composite antibacterial material and a preparation method thereof. According to the composite antibacterial material, modified graphene reacts with an antibacterial enhancer, so that the surface of the modified graphene is coated with a layer of latticed antibacterial enhancer molecules, then chlorination treatment is conducted, secondary amine on the antibacterial enhancer molecules is chlorinated, and the composite antibacterial material is prepared. The composite antibacterial material has multiple sterilization layers, can effectively destroy bacterial cell membranes, denature bacterial proteins, hinder bacterial metabolism and further kill bacteria, and the sterilization layers of the composite antibacterial material are all connected through chemical bonds, so that the antibacterial components in the composite antibacterial material are free of precipitation, volatilization and particle shedding, the service life of the composite antibacterial material is greatly prolonged, a nano-silver material is not needed, and the preparation cost of the composite antibacterial material is greatly reduced.

Owner:安徽新虹新材料科技有限公司

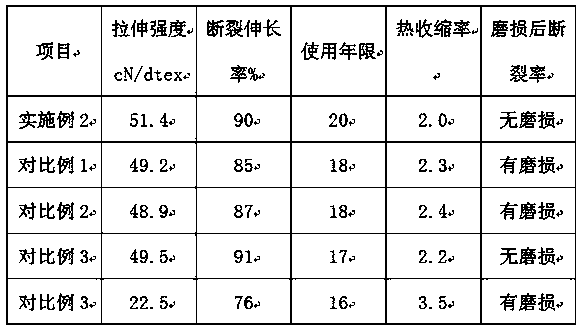

Preparation method for producing wear-resistant generated artificial straw filament from recycled PET bottle flakes

InactiveCN109183183AStable shrinkageStructural stability is not easySpinning solution de-aeratingFlame-proof filament manufacturePolyesterWear resistant

The invention discloses a preparation method for producing a wear-resistant generated artificial straw filament from recycled PET bottle flakes. The method comprises the following steps: drying amorphous polyester bottle flakes in a low-temperature drying way; and re-proportioning the dried bottle flakes, uniformly mixing the dried bottle flakes, then, pouring the mixture into a spinning storage bin, then, feeding into a screw extruder for extrusion melting to obtain a melt, and carrying out metering, spinning, cooling and oiling, traction feeding, rolling and low-temperature stretching. The generated artificial straw filament prepared by using the preparation method disclosed by the invention has the characteristics of high strength, long service time and good wear resistance and toughness; and the preparation method is simple and easy to operate, low in cost, high in performance cost ratio, environment-friendly, energy-saving and capable of producing the wear-resistant generated artificial straw filament from the recycled PET bottle flakes and further widening the recycle space of waste PET.

Owner:含山县胜发塑料制品有限公司

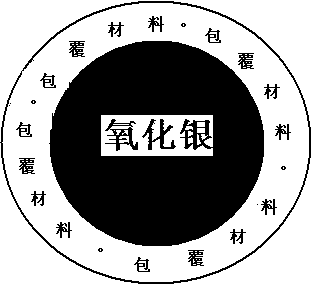

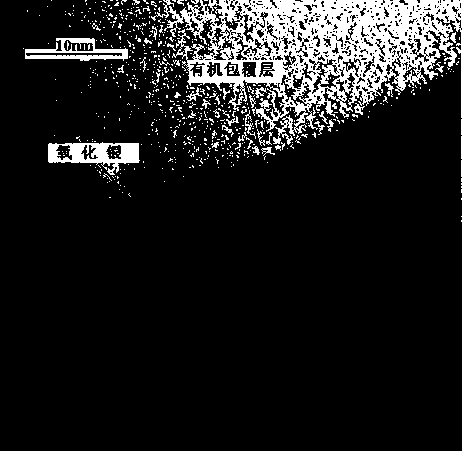

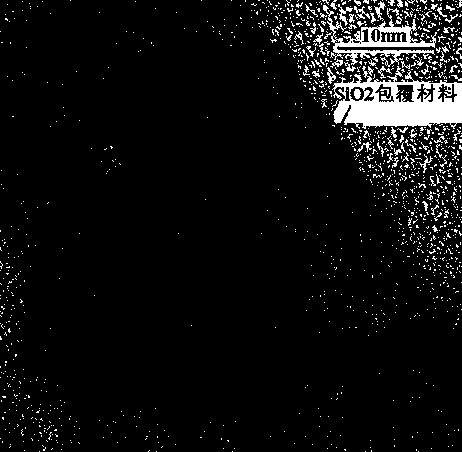

High-temperature resistant ceramic antibacterial agent coated with inorganic nano-material and preparation technology of high-temperature resistant ceramic antibacterial agent

The invention provides a new preparation technology of a ceramic antibacterial agent capable of resisting high-temperature sintering. The new preparation technology is characterized in that the antibacterial active agent is subjected to surface coating by the nano inorganic material so that the coated antibacterial active agent has obvious high-temperature resistant property. The adopted coated material is silicon oxide, zirconium phosphate, or multicomponent inorganic material such as 0.5xAl2O3-(2-0.75x)SiO2-1.0ZnO-2.0CaO(x is 0.0-1.0), and antibacterial active center is silver oxide. After the coated antibacterial active material is calcinated for 30 minutes at 1250 DEG C to 1350 DEG C, the antibacterial activity is still evident, the defect of bad high-temperature resistant property of the existing antibacterial agent is overcome, and the quantity of the antibacterial active agent added to glaze can be obviously reduced. The coated antibacterial active material can be directly added to glaze water and is uniformly mixed for direct glazing, and high-temperature calcination is finally carried out to prepare antibacterial ceramic. The antibacterial ratio of the prepared antibacterial ceramic to common viruses and bacteria such as escherichia coli, staphylococcus aureus is more than 99%.

Owner:MINNAN NORMAL UNIV +1

Preparation technique of solid universal glue

ActiveCN101503601AHigh solid contentNo volatilizationLayered productsFilm/foil adhesivesAdhesiveEngineering

The invention discloses a preparation process for a solid all-purpose adhesive. The preparation process comprises the following steps: 1): filtering solid all-purpose adhesive slurry through a 80 to 100-mesh sieve; 2): pressurizing and spaying the solid all-purpose adhesive slurry obtained in the step 1) onto a carrier film with the spraying thickness of 1 to 2 mm; 3): sending the carrier film which is coated with the solid all-purpose adhesive slurry and is obtained in the step 2) into an oven for drying, and setting the temperature in the oven at 40 to 85 DEG C and the drying time for 1 to 5 minutes; 4): adopting a film laminator to press a top film on the solid all-purpose adhesive layer of the carrier film obtained in the step (3) so as to prepare the filmily solid all-purpose adhesive, and setting the laminating pressure at 60 to 80N / cm<2> and the laminating time at 5 to 30 seconds; and 5): carrying out the edge cutting and sealing treatment of the solid all-purpose adhesive obtained in the step 4). The product prepared by the process is filmily and can be made into any shape as required by customers; and in addition, the solid all-purpose adhesive has even painting, and quick and convenient construction.

Owner:SHANDONG EVERGAIN ADHESIVE CO LTD

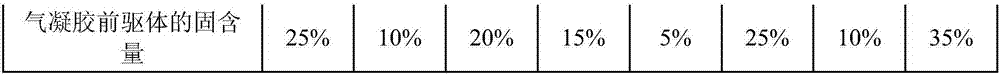

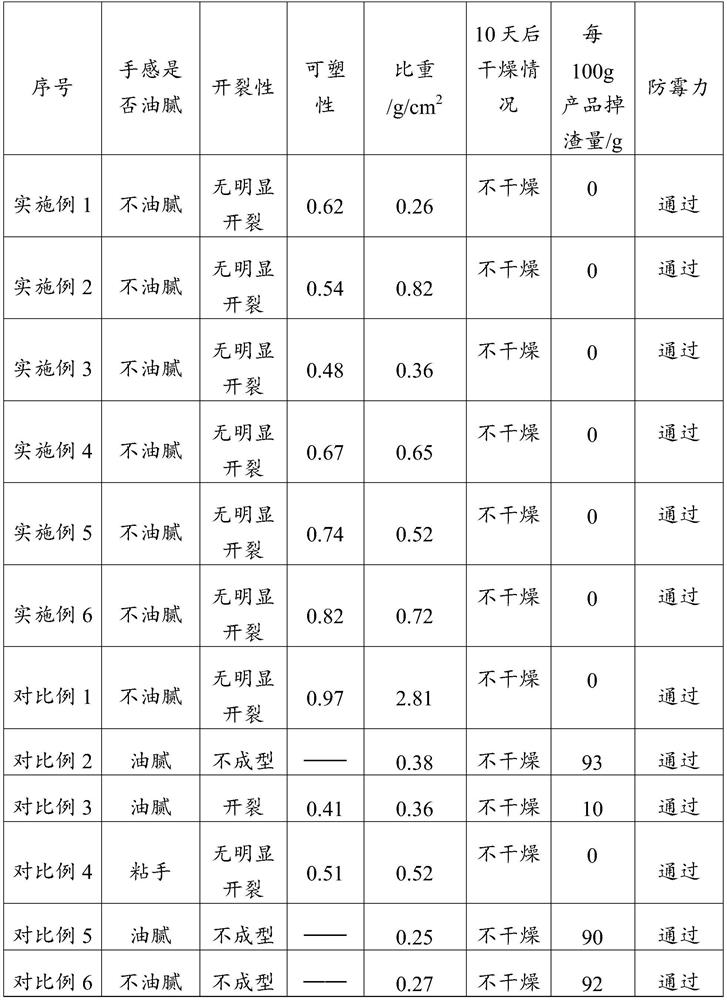

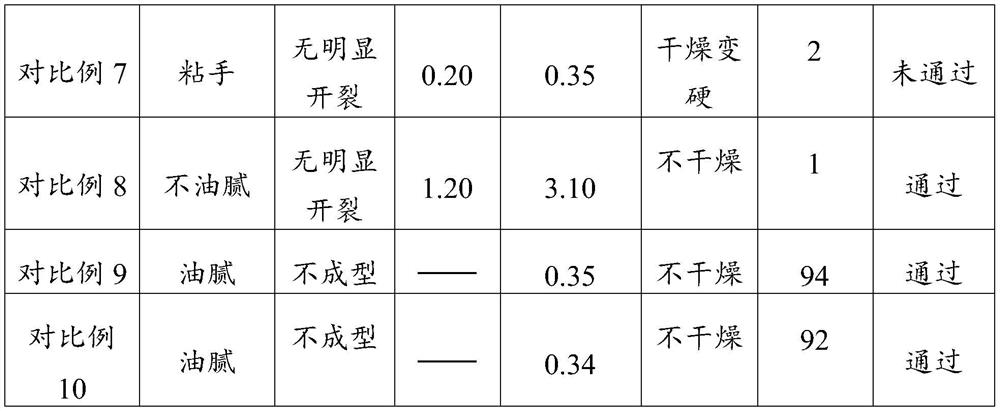

3D printing mud and preparation method thereof

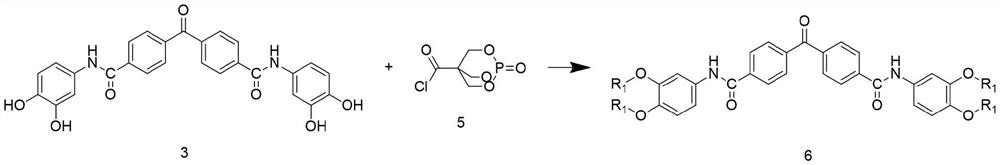

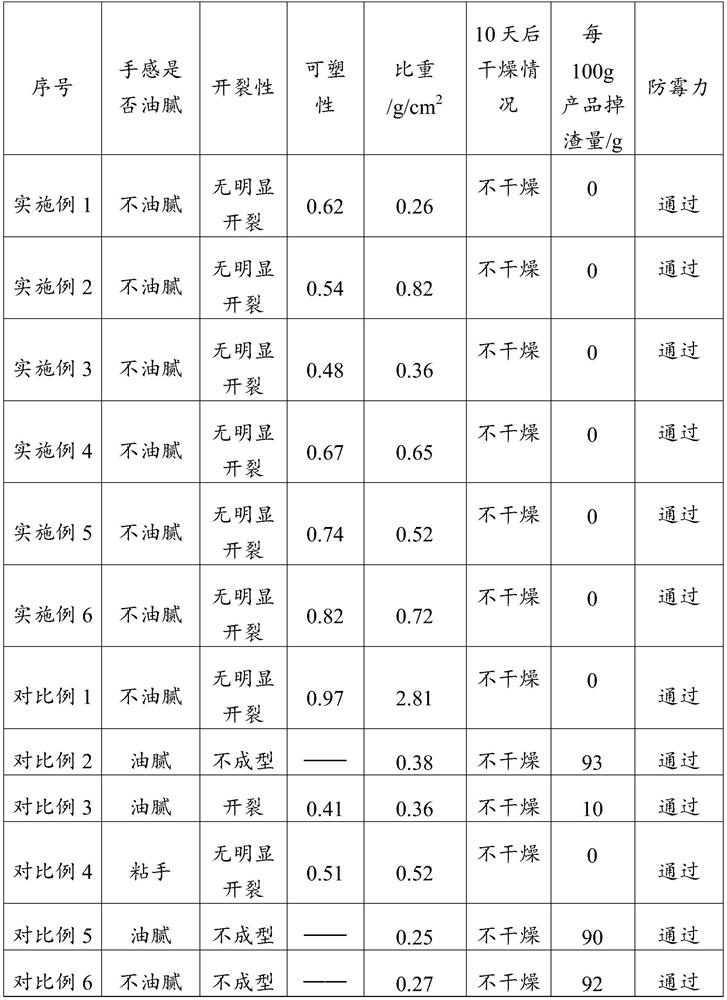

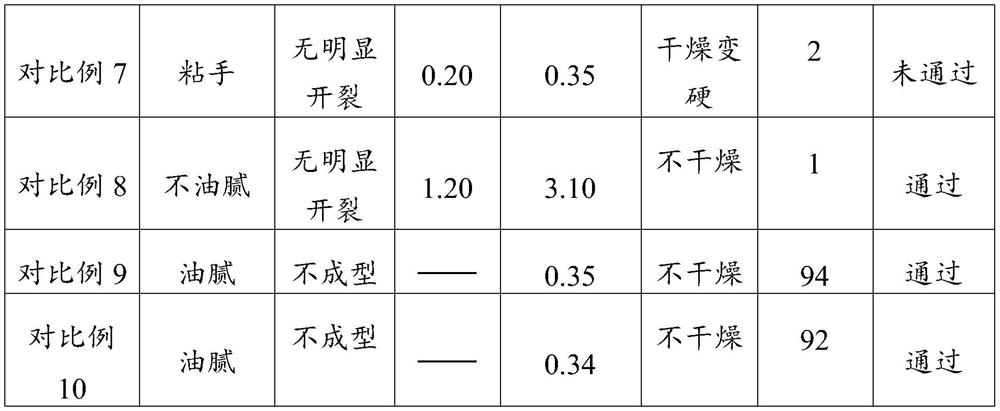

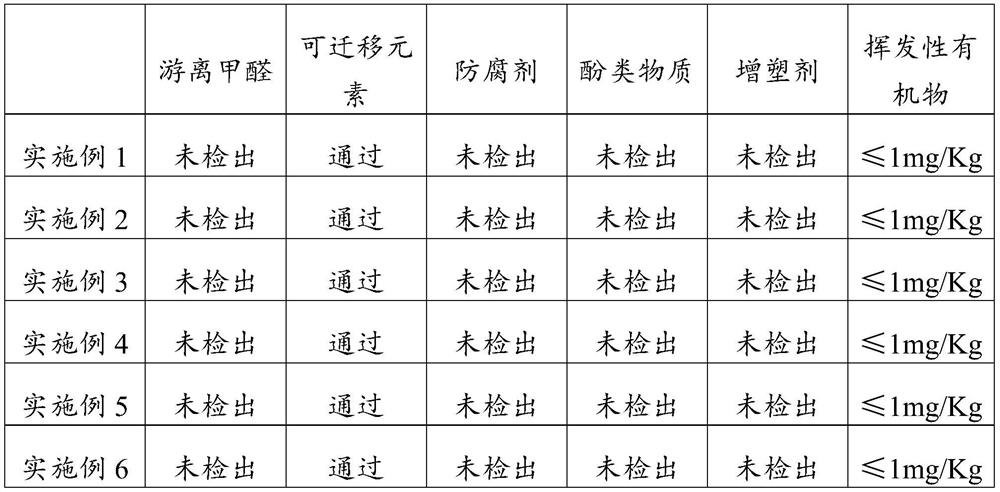

ActiveCN112409795AGood plasticityLight textureAdditive manufacturing apparatusSiloxanePolymer chemistry

The invention relates to 3D printing mud and a preparation method thereof. The preparation method comprises the steps that a filler, polysiloxane, a coupling agent and an activating agent are mixed according to a certain proportion; and heating is conducted for reaction to form the 3D printing mud. According to the method, the viscosity among printing mud, mud and mud is increased by utilizing thereaction between the coupling agent and polysiloxane with reaction activity, then the fracture and repair of chemical bonds between the coupling agent and polysiloxane are adjusted by adding the activating agent, and the specific gravity of the printing mud is greatly reduced by introducing hollow ions, so that the printing mud has the characteristics of light weight, smoothness, easiness in molding and the like. The 3D printing mud has the advantages of being smooth, soft, non-greasy, non-sticky, free of slag falling, long in service life, capable of effectively inhibiting bacteria and mouldand the like.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

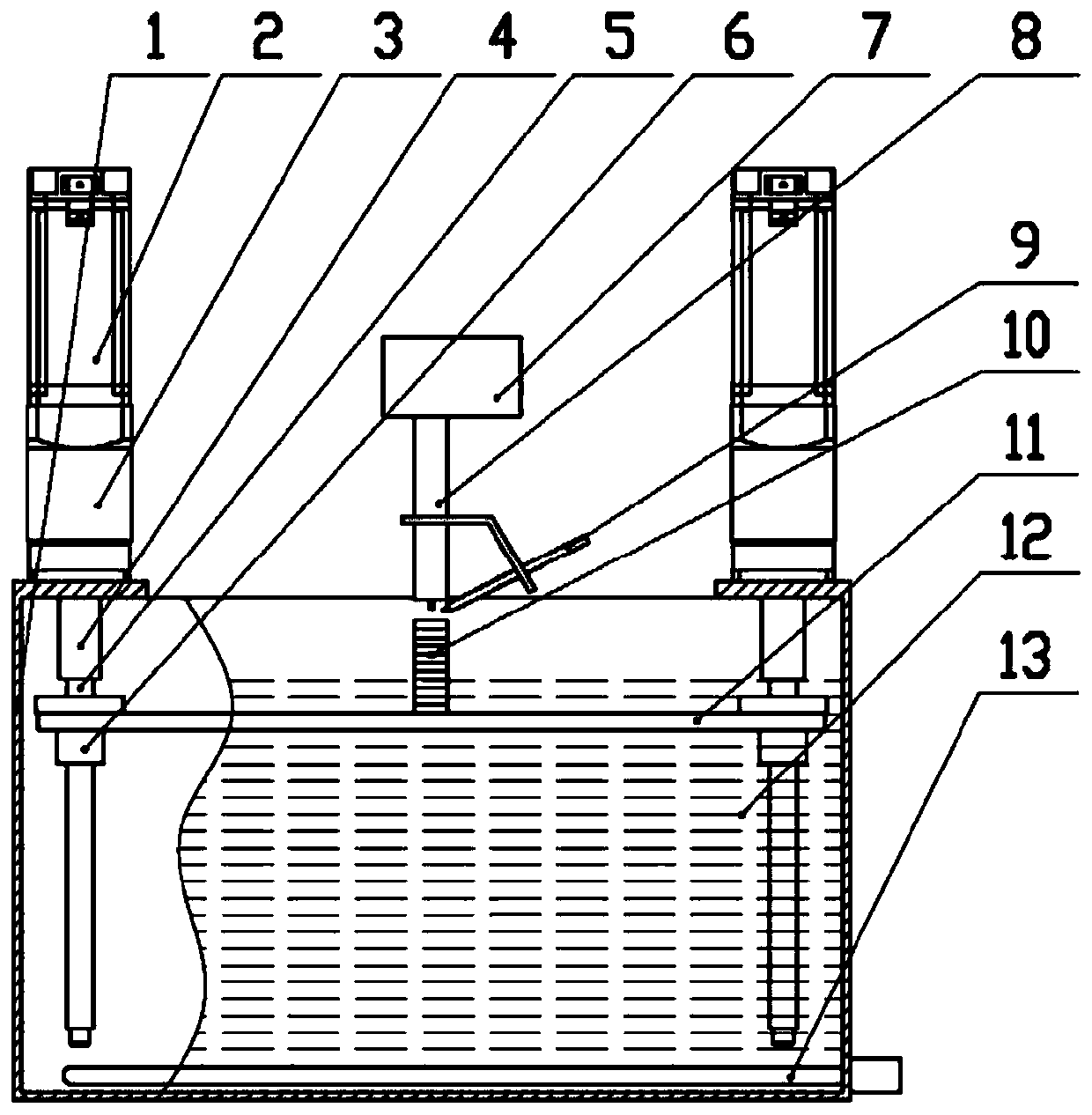

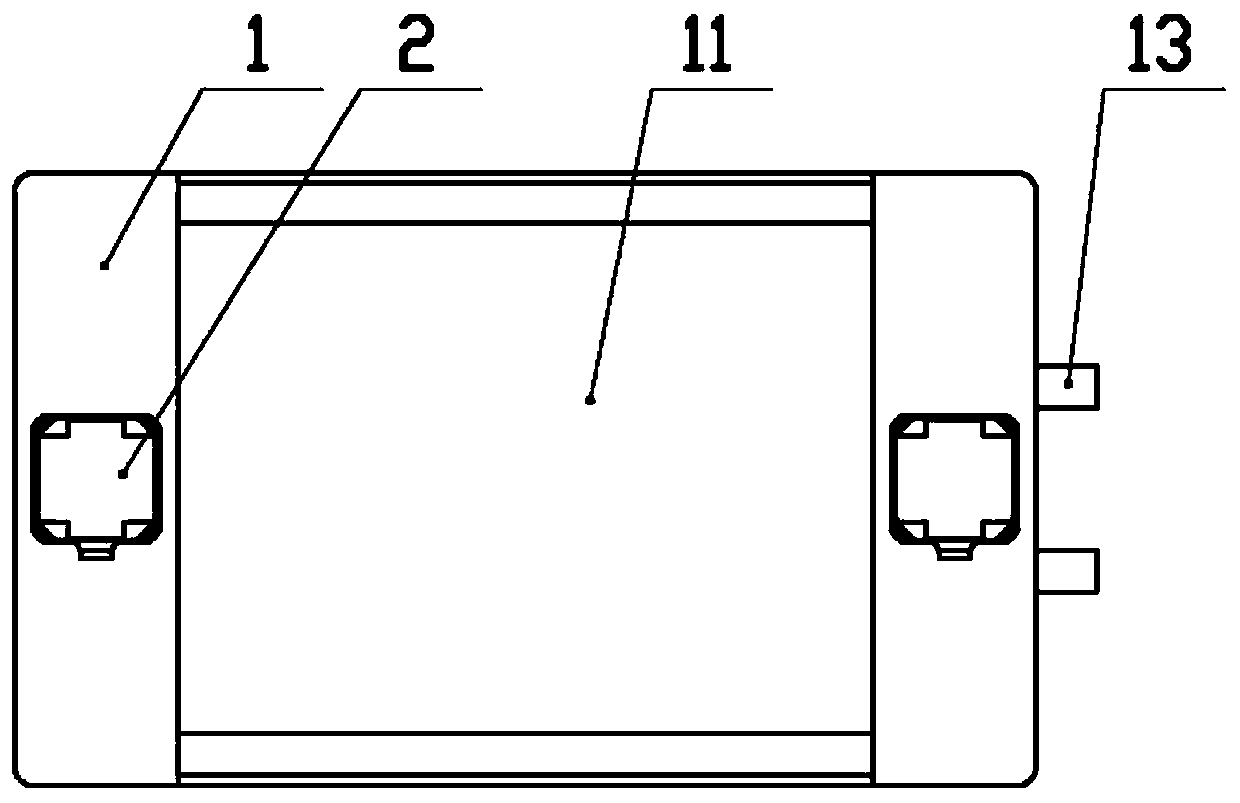

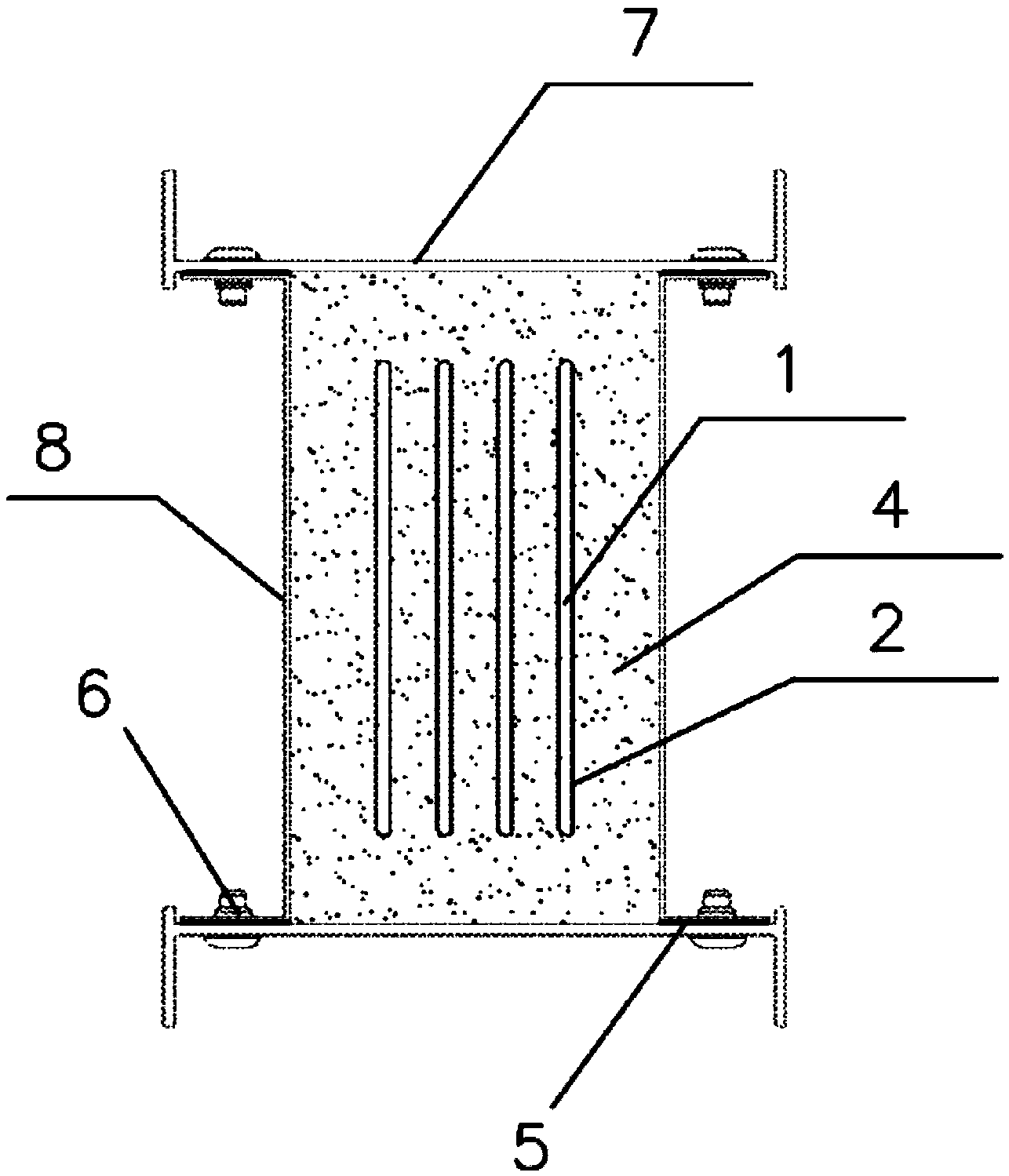

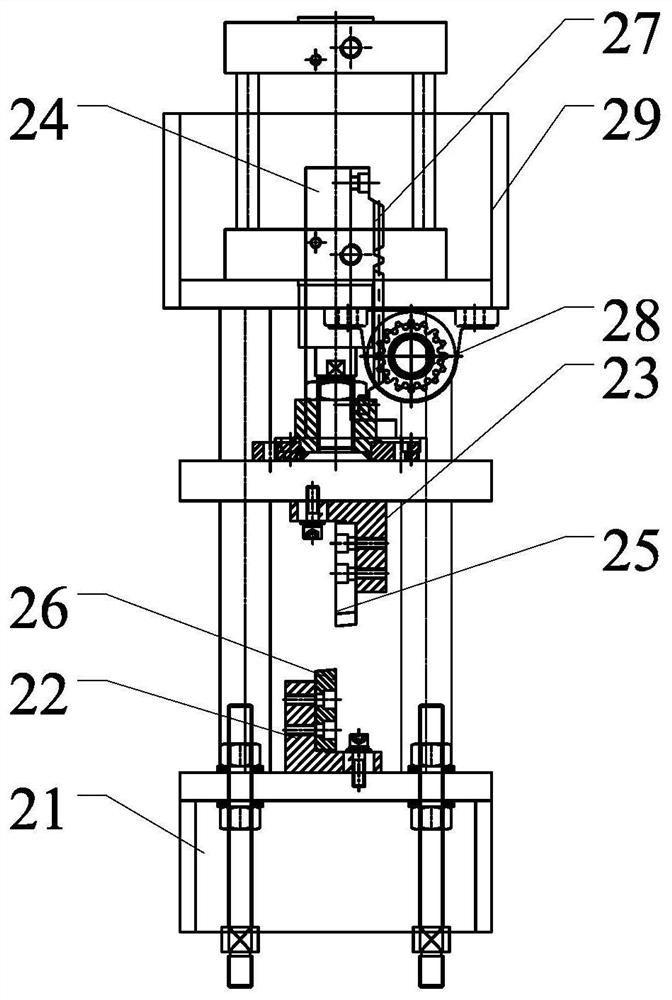

Cooling device for manufacturing process of electric arc printing additional material

PendingCN111037162ASimple and reliable structureImprove cooling efficiencyAdditive manufacturing apparatusWelding/cutting auxillary devicesCooling coilProcess engineering

The invention belongs to the technical field of additional material manufacturing equipment, and particularly relates to a cooling device for the manufacturing process of an electric arc printing additional material. Two servo motors are fixed to the two sides of the upper side of a cooling tank correspondingly after being directly connected with a speed reducer. A lower output shaft of the speedreducer is connected with a lead screw through a coupler and drives the lead screw to rotate. A nut is fixed to a lifting base plate and connected with the lead screw through threads. The lead screw can drive the nut and the lifting base plate to rise or fall in the cooling tank when rotating. Cooling liquid is arranged in the cooling tank. A cooling coiled pipe is arranged at the bottom of the cooling tank. Cooling water is injected into the cooling coiled pipe through a water pump. Through the cooling of constant-temperature water of the cooling coiled pipe, the heat absorbed by the coolingliquid can be brought away in time, it is ensured that the cooling liquid is not solidified, the long-term electric arc printing work is ensured, meanwhile the temperature of the cooling liquid in thenext time of printing can be ensured, the cooling device has the advantages of being high in cooling efficiency and good in cooling effect, not influencing the existing structure properties of the product and the like, and the simple, rapid and efficient cooling in the manufacturing process of the electric arc printing additional material is realized.

Owner:XIAN JUNENG EQUIP TECH CO LTD

Fireproof bus groove

InactiveCN104332914AHigh protection levelNot easy to slip offTotally enclosed bus-bar installationsFastenerElectrical conductor

The invention discloses a fireproof bus groove which is composed of a shell, conductors, insulating layers, fireproof filler and PE conductors. The shell is formed by fixedly connecting an [-shaped cover plate and side plates, the conductors are arranged inside the shell at intervals after the insulating layers coat the outsides of the conductors, the intervals of the conductors are filled with the fireproof filler which is a mineral material, each insulating layer is made by a gold belt, interlayers are arranged at joints of the shell and fastened by fastening members to prevent overflowing of the fireproof filler after the fireproof bus shell is loose under vibration, and the PE conductors are arranged at the edges, close to the side plates, inside the shell.

Owner:JIANGSU HUAPENG INTELLIGENT ELECTRICAL

Production technology of oily gel

ActiveCN105434198AImprove practicalityNo volatilizationCosmetic preparationsHair cosmeticsIsopropyl palmitateEthylene glycol

The embodiment of the invention discloses a production technology of an oily gel. With the adoption of the oily gel disclosed by the invention, the problem that users require keeping hair styling for a long time is solved, and especially, when the oily gel is applied to lips and hair, the hair styling can be kept for a long time, therefore the practicability is extremely high; the production technology comprises the following steps: (1), mixing materials of an A component, heating to be 100 DEG C, stirring for 1.5 hours, filtering to obtain filtrate, wherein the materials of the A component comprise 55-58 parts by weight of mineral oil, 16-17 parts by weight of isopropyl palmitate, 16 parts by weight of PX-100 and 4-7 parts by weight of ethylene glycol distearate.

Owner:广东雅丽诗科技有限公司

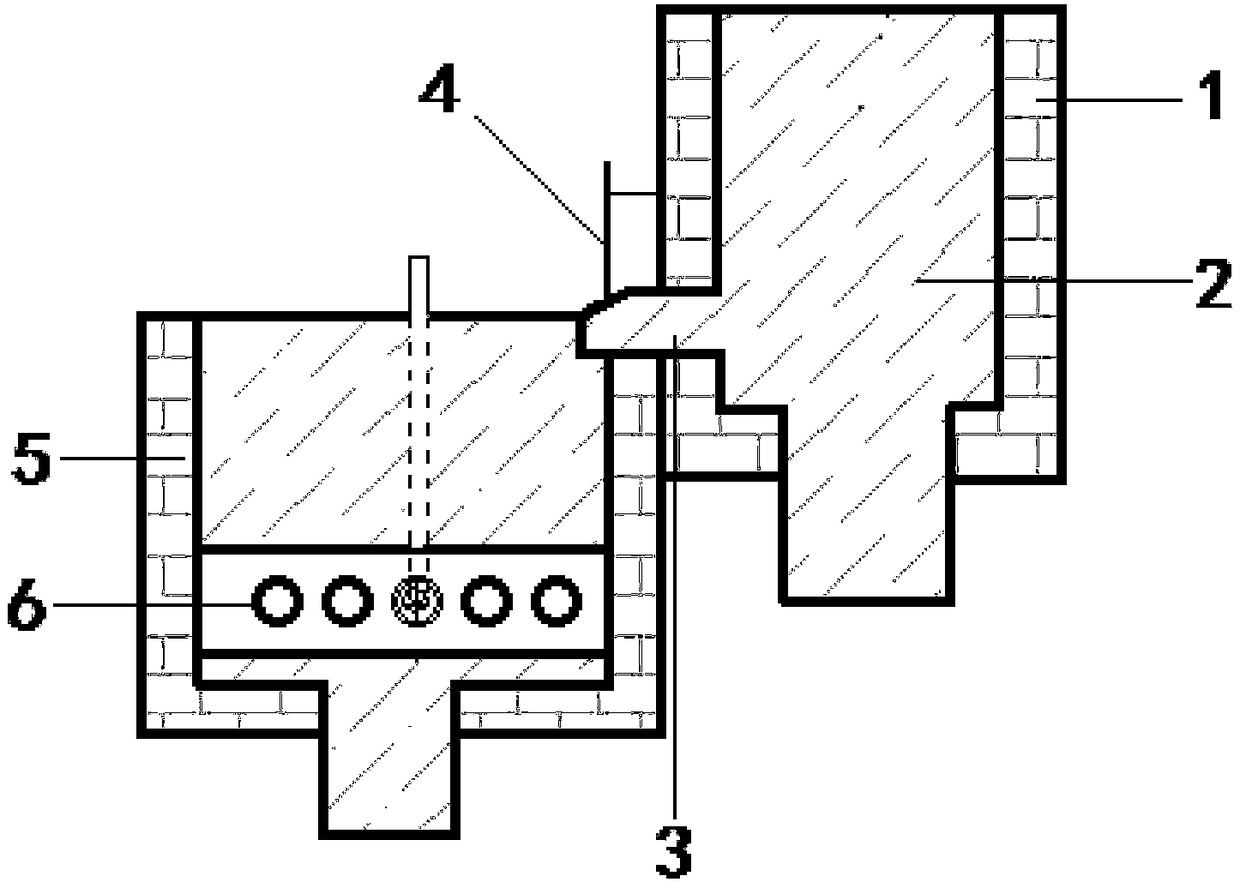

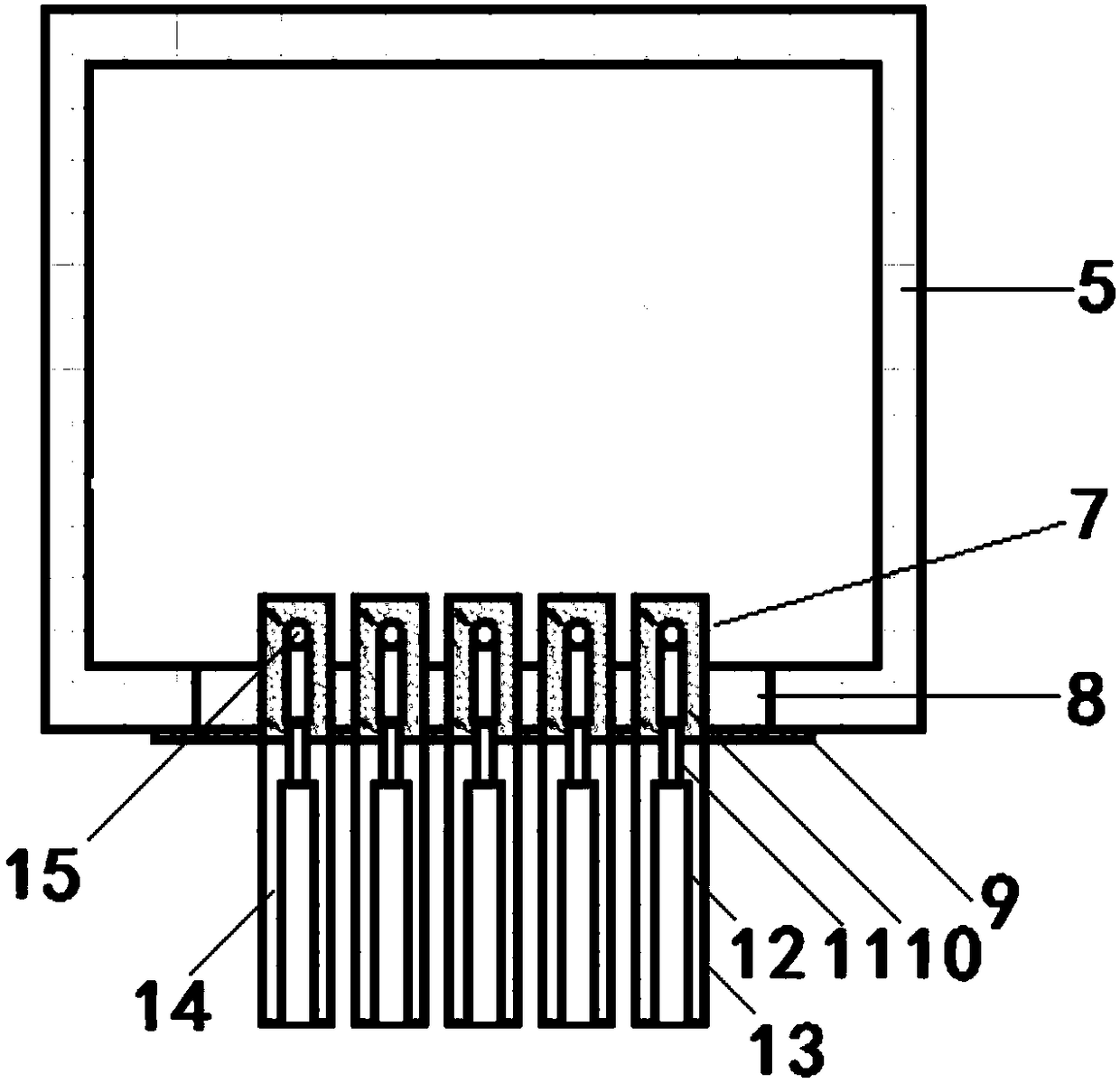

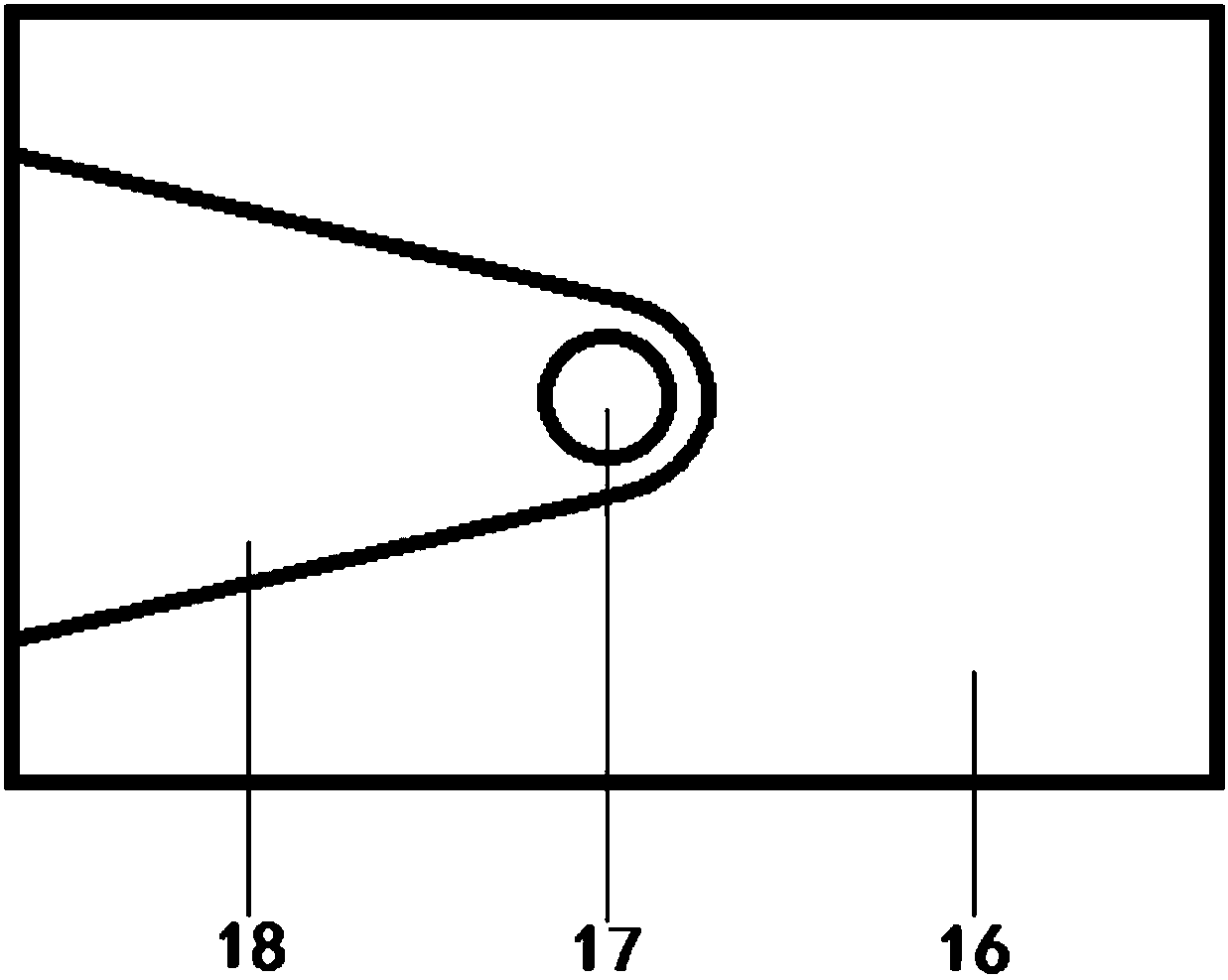

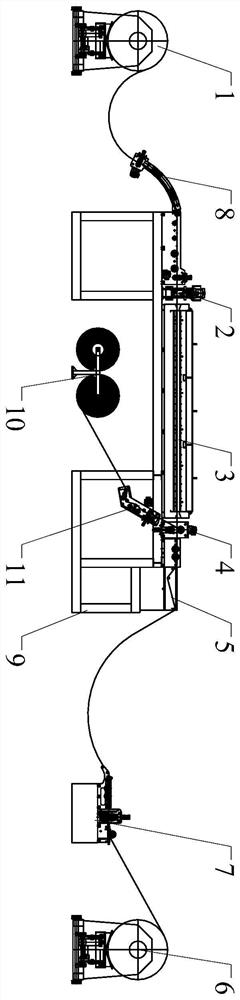

Non-launder copper alloy converter with quick head changing traction device

The invention discloses a non-launder copper alloy converter with a quick head changing traction device. A melting furnace and an insulation furnace are arranged to be in a form that furnace walls areconnected, the front portion is high and the back portion is low; a graphite releasing base containing a releasing hole and a releasing groove is arranged on the lower furnace wall of the melting furnace and the upper furnace wall of the insulation furnace; the melting furnace is connected behind the graphite releasing base; the insulation furnace is connected before the graphite releasing base;the flow of molten copper of the melting furnace is controlled by a first flow control rod; the quick head changing traction device consisting of a graphite control base, a graphite crystallizer, a crystallizer copper sleeve, a crystallizer steel cover and a cooling water cavity can sleeve the front end of the insulation furnace by a quick head changing hole; and the flow of molten copper of the insulation furnace is controlled by a second control rod. In the converter without a launder, the molten copper of the melting furnace nearly enters the insulation furnace directly without high heat and great volatilization of volatile metal; once towed wire blanks do not meet requirements, the traction can be immediately stopped to replace equipment, so that the staff and equipment safety is guaranteed; and the converter is safe, capable of saving energy, environmentally friendly and low in cost, and can improve the production efficiency of copper and copper alloy wire blanks.

Owner:安徽品志合金新材料有限公司 +1

Film laminating machine for plate

The invention discloses a film laminating machine for a plate. The machine comprises an uncoiling machine, a pneumatic shearing mechanism, a constant-temperature heating box, a film laminating mechanism, a circulating water cooling mechanism and a coiling machine; a tension mechanism is arranged between the coiling machine and the circulating water cooling mechanism; a first guiding feeding mechanism is arranged between the pneumatic shearing mechanism and the uncoiling machine; the first guiding feeding mechanism, the pneumatic shearing mechanism, the constant-temperature heating box, the film laminating mechanism and the circulating water cooling mechanism are sequentially fixed on a frame body from front to back; a composite film uncoiling mechanism is arranged at the bottom end of theframe body; a second guiding feeding mechanism is connected with the composite film uncoiling mechanism; and the second guiding feeding mechanism is arranged at the front end of the film laminating mechanism and is fixed on the frame body. A high-temperature melting mode is adopted for film laminating, the problem of film aging is solved, and meanwhile, a film forms a whole with the plate and is not prone to falling off, so volatilization of formaldehyde in glue is avoided and toxicity is small.

Owner:沧州中拓冷弯成型设备有限公司

Safety type self-temperature-limiting electric tracing band and preparation method thereof

InactiveCN114393760ANo volatilizationGuaranteed flame retardant performanceHeating element shapesDomestic articlesCarbon layerSide chain

The invention discloses a safety type self-temperature-limiting electric tracing band and a preparation method thereof.The electric tracing band is composed of nanometer conductive carbon black, two parallel buses and an insulating layer, the insulating layer is prepared by crosslinking modified polypropylene and a synergistic crosslinking agent, a modified polypropylene molecular chain contains a large number of phosphorus oxyacid structures, and the modified polypropylene molecular chain contains a large number of phosphorus oxyacid structures; polyphosphoric acid with strong dehydration property can be generated during combustion, oxygen-containing functional groups are dehydrated and carbonized, a condensed phase flame-retardant effect is played, and the oxygen-containing functional groups are attached to the surface of the material to form a carbon layer, so that the flame-retardant effect is ensured, flame-retardant substances are not volatilized and separated out, and the flame retardance is ensured; the synergistic cross-linking agent is added into the modified polypropylene, so that the amino on the synergistic cross-linking agent reacts with the epoxy group on the modified polypropylene to form a grid structure, and meanwhile, the side chain contains a large number of unsaturated long chains, so that the prepared electric tracing band has good toughness and is prevented from being broken.

Owner:安徽久泰电气有限公司

A kind of 3D printing mud and preparation method thereof

ActiveCN112409795BImprove adhesionPrevent filler powder droppingAdditive manufacturing apparatusPolymer sciencePolymer chemistry

The invention relates to a 3D printing mud and a preparation method thereof, comprising: mixing a filler, a polysiloxane, a coupling agent and an activator according to a certain proportion; heating and reacting to form a 3D printing mud. This method utilizes the reaction between the coupling agent and the reactive polysiloxane to increase the viscosity between the printing paste and the paste, and then adjusts the relationship between the coupling agent and the polysiloxane by adding an activator. The breaking and repairing of the chemical bonds of the hollow ions greatly reduces its specific gravity through the introduction of hollow ions, so that it is light in weight, smooth and easy to shape, lubricated and soft, non-slippery, non-sticky, non-slagging, and has a long service life. Effectively inhibit bacteria and mold and other excellent properties.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

A rapid diffusion welding connection method for skutterudite thermoelectric material and electrode

ActiveCN111014929BImprove thermoelectric conversion efficiencyGuaranteed thermoelectric conversion efficiencyWelding/soldering/cutting articlesNon-electric welding apparatusThermoelectric materialsCobalt

The invention relates to a fast diffusion welding connection method for a skutterudite thermoelectric material and an electrode, and relates to a diffusion welding connection method. The purpose is to solve the problems of Sb element volatilization and element diffusion when the existing skutterudite thermoelectric material is connected with electrodes. Method: Take the electrode and clean the surface to be welded, plate an alloy barrier layer on the surface of the electrode to be welded, clean the surface to be welded with skutterudite thermoelectric material, and perform diffusion welding. The present invention prepares the barrier layer by electroplating on the electrode side, and then realizes diffusion welding with the skutterudite thermoelectric material at a relatively low pressure and relatively low temperature, and there is no element diffusion between the weld element and the skutterudite in the process , can prevent the volatilization of Sb element and the occurrence of element diffusion. The invention is suitable for welding skutterudite thermoelectric materials and electrodes.

Owner:HARBIN INST OF TECH

Preparation technique of solid universal glue

ActiveCN101503601BHigh solid contentNo volatilizationFilm/foil adhesivesLayered productsFiltrationAdhesive

Owner:SHANDONG EVERGAIN ADHESIVE CO LTD

Controlled disinfection bottle stopper

InactiveCN106697542BOpen quicklyNo volatilizationClosuresClosure using stoppersActivated carbonEngineering

The invention discloses a controllable disinfection bottle plug. The controllable disinfection bottle plug comprises a bottle plug body, wherein end part control mechanisms are arranged on the upper surface of the bottle plug body and located at the two inner sides; the lower surfaces of the end part control mechanisms are detachably connected to the bottle plug body; grooves matched with the end part control mechanisms are formed in the bottle plug body; the end part control mechanisms are used for controlling a panel; the two ends of the panel extend in the end part control mechanisms, and a clamping buckle is arranged on the panel; the clamping buckle is clamped on a sealing material structure layer; an inner cavity is formed between the sealing material structure layer and the lower surface of the bottle plug body; the two sides of the sealing material structure layer are arranged at positions close to the upper surface, of the bottle plug body; an activated carbon adsorption body is arranged on the inner surface of the bottle plug body; and the activated carbon adsorption body is hermetically connected to the bottle plug body. The controllable disinfection bottle plug disclosed by the invention can be rapidly opened, and is high in use safety factor, simple to operate and high in sealing performance; and a medicinal liquid in a bottle is free from a volatilization phenomenon and capable of playing a purification role to a certain extent, so that a better use effect is achieved.

Owner:枣庄科技职业学院

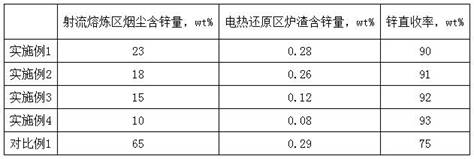

One-step zinc smelting method of molten pool spraying zinc concentrate

The invention discloses a one-step zinc smelting method of spraying zinc concentrate in a molten pool, which comprises the following steps: a. mixing the zinc concentrate with a flux and drying to obtain a mixed material; b. drying the mixed material obtained in the step a Spray directly into the molten pool of the jet smelting zone through the side blowing lance, react with oxygen-containing gas to oxidize and desulfurize, and obtain high-grade zinc slag and smelting flue gas; c, send the high-grade zinc slag obtained in step b into the electrothermal reduction zone for reduction to obtain Zinc vapor and slag. In the method of the present invention, by changing the feeding mode of the material, the mixed material is directly sprayed into the molten pool of the jet smelting zone by using a side-blown spray gun after drying, so that the zinc content in the flue gas in the smelting zone is significantly reduced, and the direct absorption of zinc is greatly improved. Yield, the zinc content of the slag obtained after reduction can be reduced to less than 0.1%. The slag yield is low and the amount of slag is small. It can be directly sold as general solid waste. The production capacity of a single series of zinc can meet the requirements of 5-50 million tons / year. kind of scale.

Owner:CHINA ENFI ENGINEERING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com