Method for testing limestone reaction activity

A technology of reaction activity and test method, which is applied in the direction of chemical analysis by titration method, can solve the difficulty of selecting limestone parameters, the increase of investment and operation costs of desulfurization system, and the difficulty of limestone activity test technology to meet the wet flue gas desulfurization engineering design and desulfurization model optimization needs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

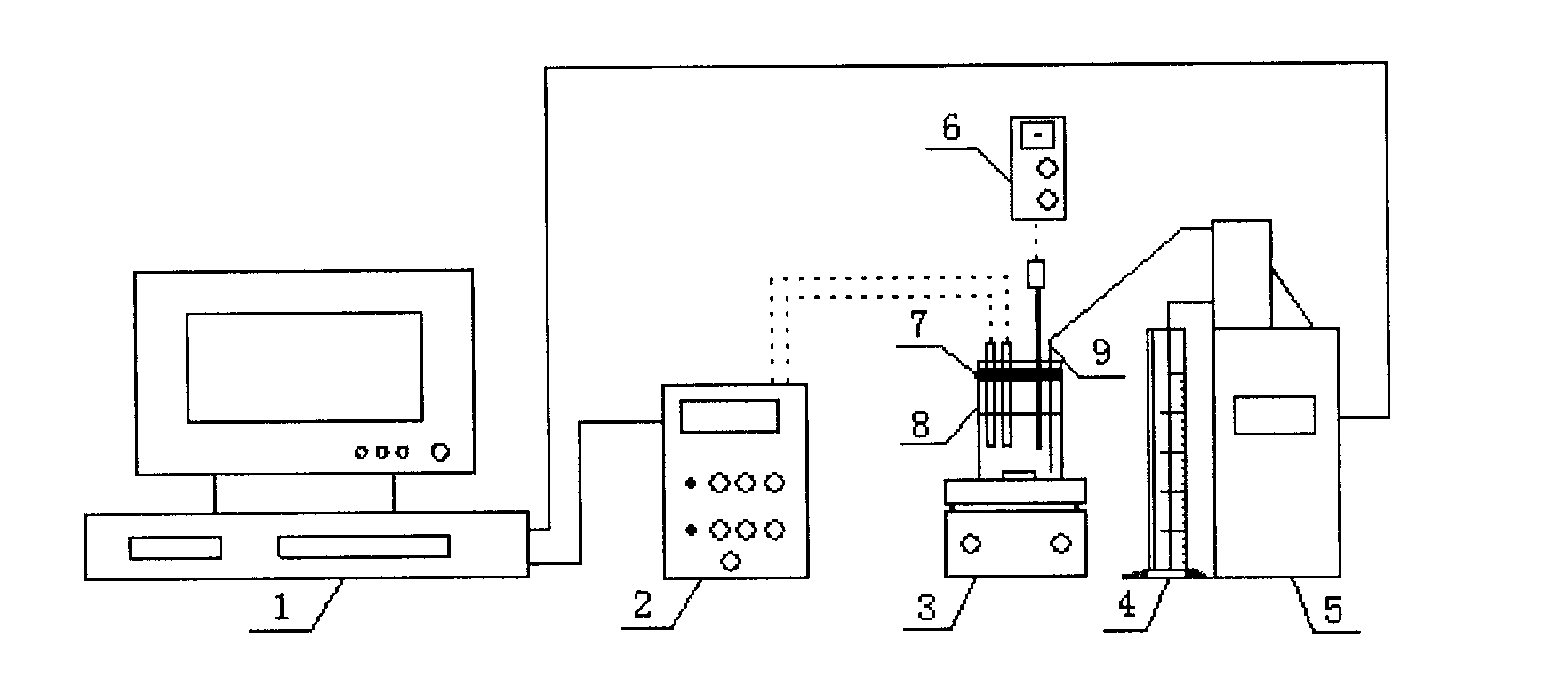

Method used

Image

Examples

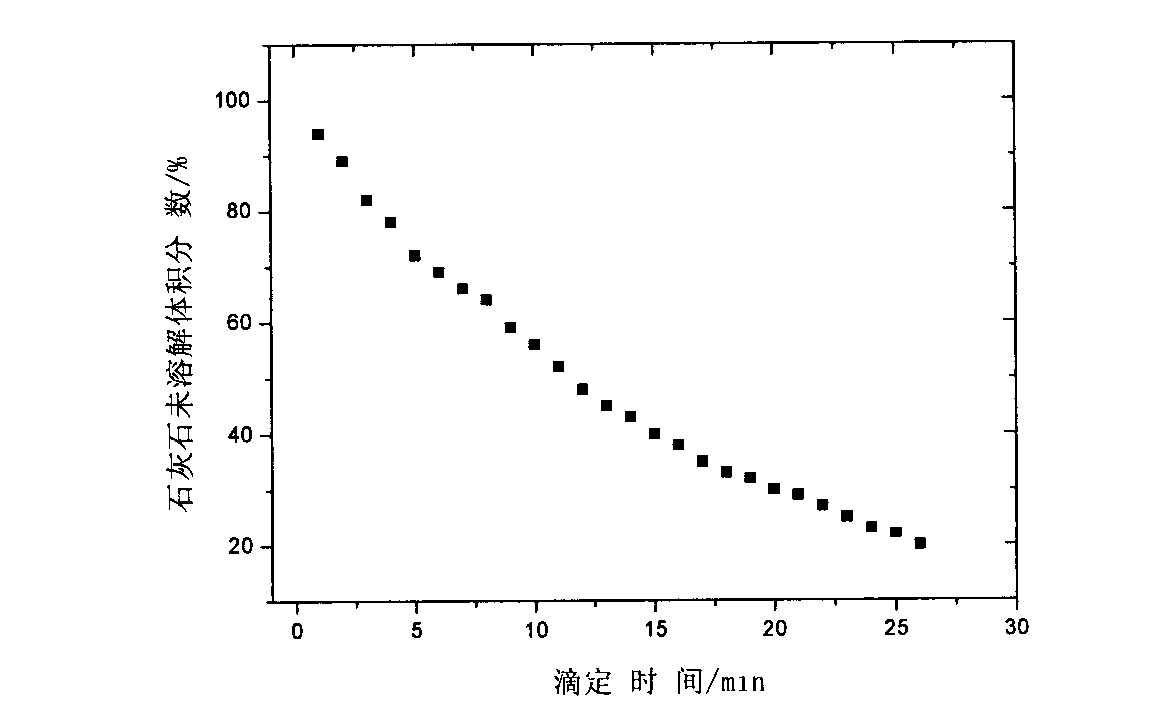

Embodiment 1

[0053] (1) Grind and sieve the limestone sample, process it into 200-300 mesh limestone powder, and store it in a dry container.

[0054] (2) CaCO in limestone samples 3 Content is 90.55%, MgCO 3 The content is 1.32%.

[0055] (3) Prepare a sulfuric acid solution with a concentration of 90%. When preparing the sulfuric acid solution, it should be noted that the acid solution must be dripped into the water for preparation; instead of dripping the water into the sulfuric acid solution, it is easy to boil and splash the acid.

[0056] (4) Prepare a 0.1mol / L calcium chloride solution, and pour 90ml of the calcium chloride solution into a 200ml beaker. The purpose of using the calcium chloride solution instead of water directly is to prevent the limestone from slightly dissolving in the solution, which would affect the results of the limestone activity measurement.

[0057] (5) Place the beaker on the thermal stirring platform 3, and turn on the thermal stirring device and the ...

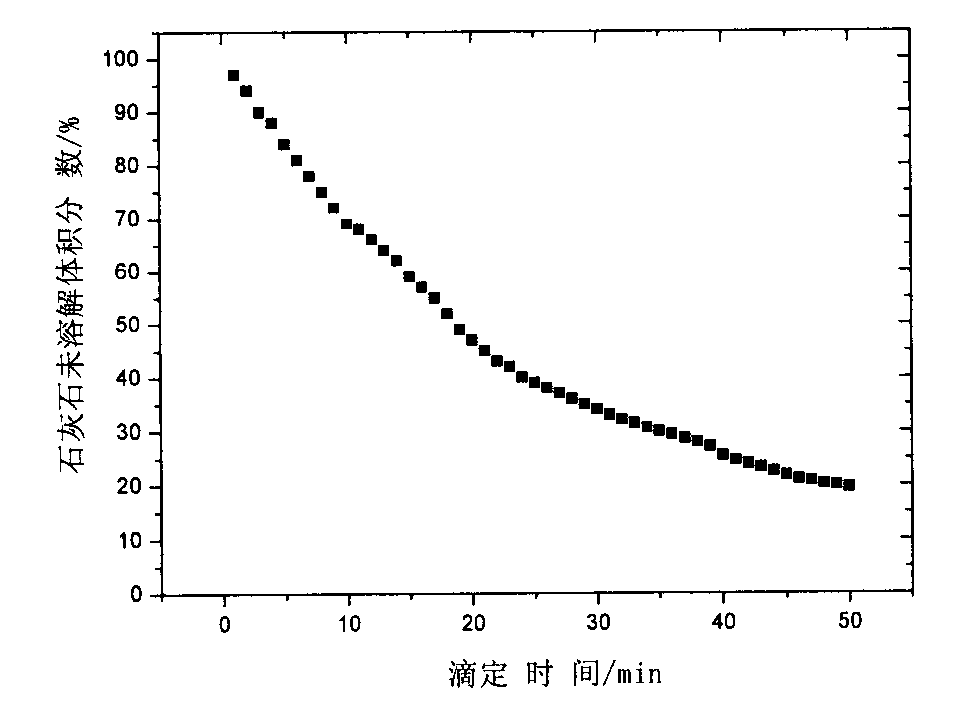

Embodiment 2

[0063] (1) Grind and sieve the limestone sample, process it into 200-300 mesh limestone powder, and store it in a dry container.

[0064] (2) CaCO in limestone samples 3 Content is 85.30%, MgCO 3 Content is 3.80%

[0065] (3) Prepare a sulfuric acid solution with a concentration of 70%.

[0066] (4) Prepare a 0.1mol / L calcium chloride solution, and pour 90ml of the calcium chloride solution into a 200ml beaker.

[0067] (5) Place the beaker on the thermal stirring platform 3, and turn on the thermal stirring device and the temperature control system. The temperature is controlled at 60±2° C., and the stirring speed is 500 r / min.

[0068] (6) Weigh 12g of limestone powder into a beaker and stir for 5 minutes to form a limestone suspension.

[0069] (7) Start the computer 1 and the pH meter 2, and connect the computer 1 and the communication interface of the pH meter 2.

[0070] (8) Start micrometering pump 5, sulfuric acid solution is titrated in limestone solution with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com