Preparation method for producing wear-resistant generated artificial straw filament from recycled PET bottle flakes

A technology of artificial turf and bottle flakes, which is applied in the manufacture of rayon, heat treatment of rayon, and single-component polyester rayon, etc. It can solve the problems of frequent use of artificial turf, low surface hardness, and strong wear , it is not easy to achieve structural stability, small degree of heat shrinkage, and good degree of perfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

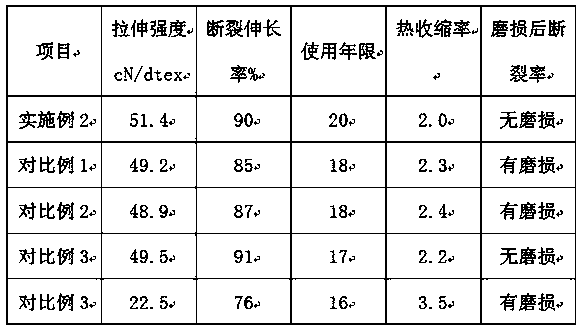

Examples

Embodiment 1

[0025] A preparation method for recycling PET bottle flakes to produce wear-resistant regenerated artificial turf, the method comprises the following steps:

[0026] (1) Crushing and cleaning: Cut and crush waste polyester bottles into flakes with a diameter of 8-20mm, and then hot wash and dehydrate with clean water at a temperature of 60-80°C;

[0027] (2) Weighing raw materials: including the following components in parts by weight: 117 parts of recycled PET, 2 parts of masterbatch, 2 parts of flame retardant, 1.5 parts of heat stabilizer, 1 part of toughening agent, terpene 8 parts of resin, 1.5 parts of PEG, 2 parts of SEBS-g-MAH, 2 parts of antioxidant, 21 parts of filler;

[0028] (3) Rapid drying: the raw materials are fed into the vacuum drum dryer through the feeder and continuously rolled and stirred, heated by the heating mantle to 140°C~180°C for crystallization for 1 hour, and then dried at this temperature for 4~6 Hours, during which the vacuum pump is used to ...

Embodiment 2

[0039] A preparation method for recycling PET bottle flakes to produce wear-resistant regenerated artificial turf, the method comprises the following steps:

[0040] (1) Crushing and cleaning: Cut and crush waste polyester bottles into flakes with a diameter of 8-20mm, and then hot wash and dehydrate with clean water at a temperature of 60-80°C;

[0041] (2) Weighing raw materials: including the following components in parts by weight: 125 parts of recycled PET, 2 parts of color masterbatch, 3 parts of flame retardant, 15 parts of heat stabilizer, 1 part of toughening agent, terpene 8 parts of resin, 1 part of PEG, 1.5 parts of SEBS-g-MAH, 2 parts of antioxidant, 23 parts of filler;

[0042] (3) Rapid drying: the raw materials are fed into the vacuum drum dryer through the feeder and continuously rolled and stirred, heated by the heating mantle to 140°C~180°C for crystallization for 1 hour, and then dried at this temperature for 4~6 Hours, during which the vacuum pump is used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com