Forming method of photoresist pattern

A photoresist and graphics technology, which is applied in the direction of photoplate making process, optics, and optomechanical equipment on the patterned surface, can solve the problems of increased difficulty and achieve the effect of stable shrinkage and improved line roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

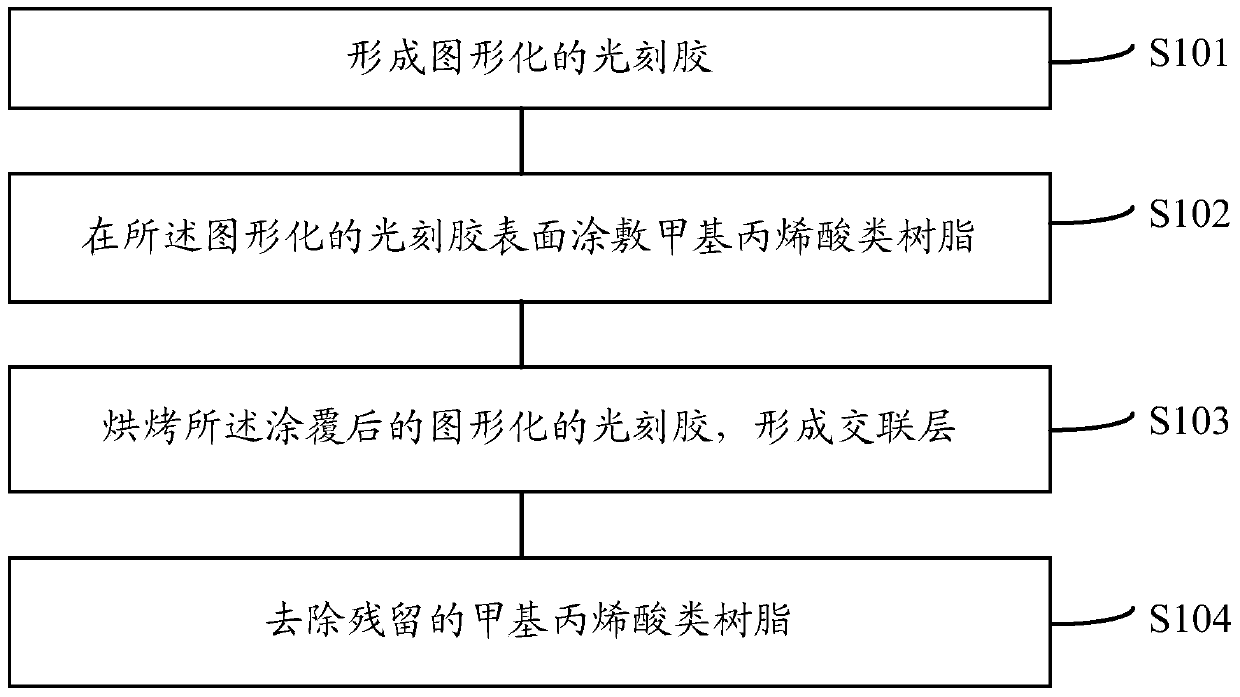

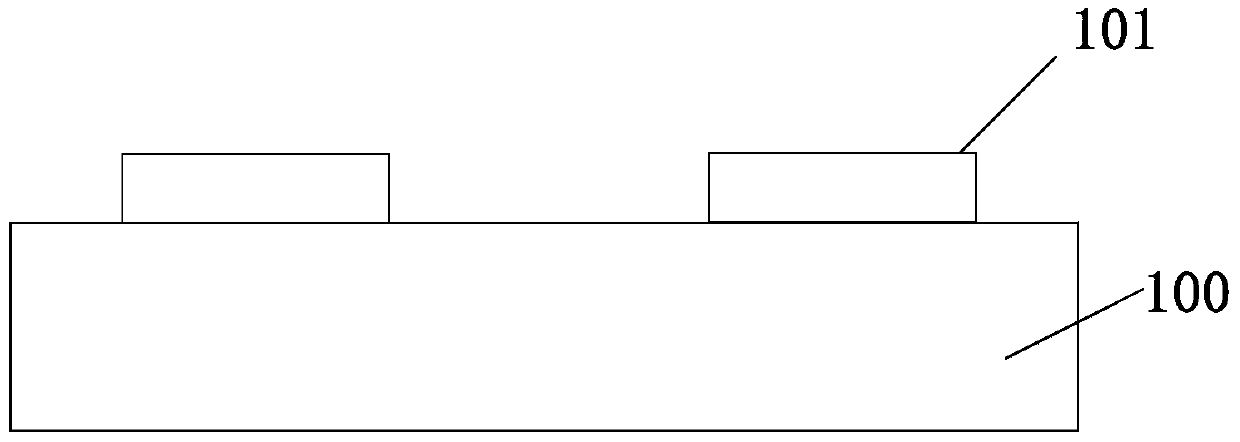

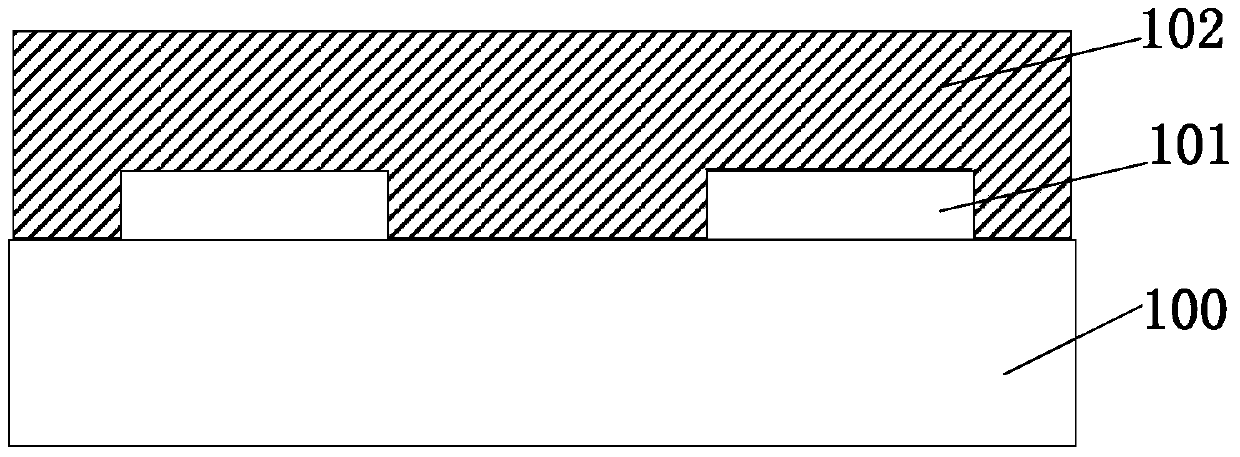

[0029] Since in the prior art, the chemical shrinkage technique performed by RELACS reagent is restricted by the distribution of photoacid, the size of shrinkage has a strong correlation with the concentration of photoacid. The patterned photoresist has a high photoacid concentration in the pattern-intensive area, and a low photoacid density in the pattern-free area, which also determines the method of using the RELACS reagent, and the reduced size will have a large difference. Therefore, the difficulty of Optical Proximity Correction (OPC) increases. Therefore, the inventor has proposed a method for forming a photoresist pattern after research, and the method for forming includes: forming a patterned photoresist; coating a methacrylic resin on the surface of the patterned photoresist and baking the patterned photoresist coated with methacrylic resin, so that part of the patterned photoresist reacts with the methacrylic resin, thereby forming A cross-linked layer is formed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com