High-temperature resistant ceramic antibacterial agent coated with inorganic nano-material and preparation technology of high-temperature resistant ceramic antibacterial agent

A technology of inorganic nano-materials and high-temperature resistant ceramics, applied in the field of materials, can solve the problems of large antibacterial active materials, consumption, etc., and achieve the effects of reducing production costs, reducing usage, and reducing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation process includes the following steps:

[0026] (1) Weigh carboxymethyl cellulose and dissolve it in water to prepare a solution with a concentration of 0.1% by weight.

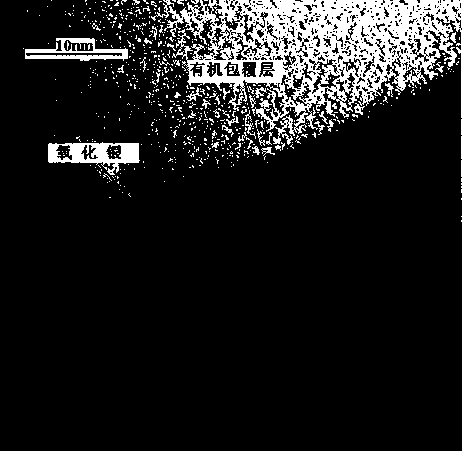

[0027] (2) Add silver oxide with a particle size of 20-150nm as an antibacterial active agent to the carboxymethylcellulose solution prepared in step (1), and the weight ratio of the antibacterial active agent to the volume of the carboxymethylcellulose aqueous solution is 1g : Mix in the proportion of 3mL, stir well at 60°C to form a muddy substance, take it out and air dry at room temperature, and coat the surface of the silver oxide antibacterial active agent with a layer of carboxymethylcellulose film.

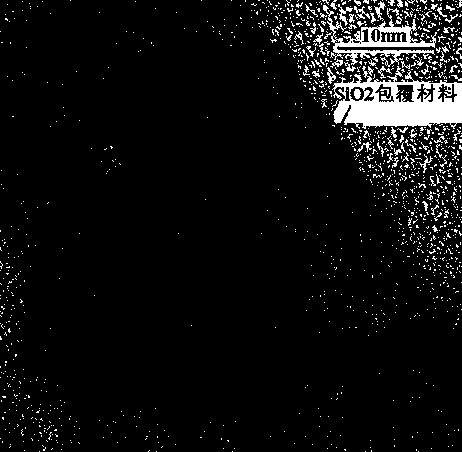

[0028] (3) Mix ethyl orthosilicate and anhydrous ethanol at a volume ratio of 1:1.3. After mixing, add 0.5 times the volume of the mixed solution for dilution to form a clear solution. Mix according to the volume ratio of the mass of the antibacterial active agent powder coated with carbox...

Embodiment 2

[0030] The preparation process includes the following steps:

[0031] (1) Weigh polyacrylamide and dissolve it in water to make a solution with a concentration of 0.3wt%.

[0032] (2) Add the silver oxide antibacterial active agent with a particle size of 20nm~150nm to the above polyacrylamide solution, and mix according to the ratio of the weight of the antibacterial active agent to the volume of the polyacrylamide aqueous solution at a ratio of 1g: 2mL, at 60°C Stir it thoroughly to form a mud, take it out and air dry at room temperature, and coat the surface of the silver oxide antibacterial active agent material with a polyacrylamide film.

[0033] (3) Weigh ZrOCl separately 2 ·8H 2 O and (NH 4 ) H 2 PO 4 Dissolved in deionized water to form ZrOCl with the same concentration of 0.3mol / L 2 Solution and (NH 4 ) H 2 PO 4 Solution; press ZrOCl 2 With (NH 4 ) H 2 PO 4 The molar ratio is 1:1.4 and measure a certain volume of ZrOCl 2 Solution and (NH 4 ) H 2 PO 4 Solution; Weigh the ant...

Embodiment 3

[0035] The preparation process includes the following steps:

[0036] (1) Weigh polyethylene glycol and dissolve it in water to make a solution with a concentration of 0.6 wt%.

[0037] (2) Silver oxide with a particle diameter of 20nm~150nm is added as an antibacterial active agent to the above-mentioned polyethylene glycol organic polymer solution, and the ratio of the weight of the antibacterial active agent to the volume of the polyethylene glycol aqueous solution is 1g:1mL Mix and stir thoroughly at 60°C to form a mud, take it out and air-dry at room temperature, and coat the surface of the silver oxide antibacterial active agent with a polyethylene glycol film.

[0038] (3) Press 0.5Al 2 O 3 -1.25SiO 2 -1.0ZnO-2.0CaO The molar ratio of Si, Al, Zn, Ca in the formula is Si: Al: Zn: Ca = 1.25: 1.0: 1.0: 2.0 to take quantitative amounts of ethyl orthosilicate, aluminum nitrate, and zinc nitrate, respectively , Calcium nitrate, mix the ethyl orthosilicate and absolute ethanol in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com