Patents

Literature

81results about How to "Increase filler content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

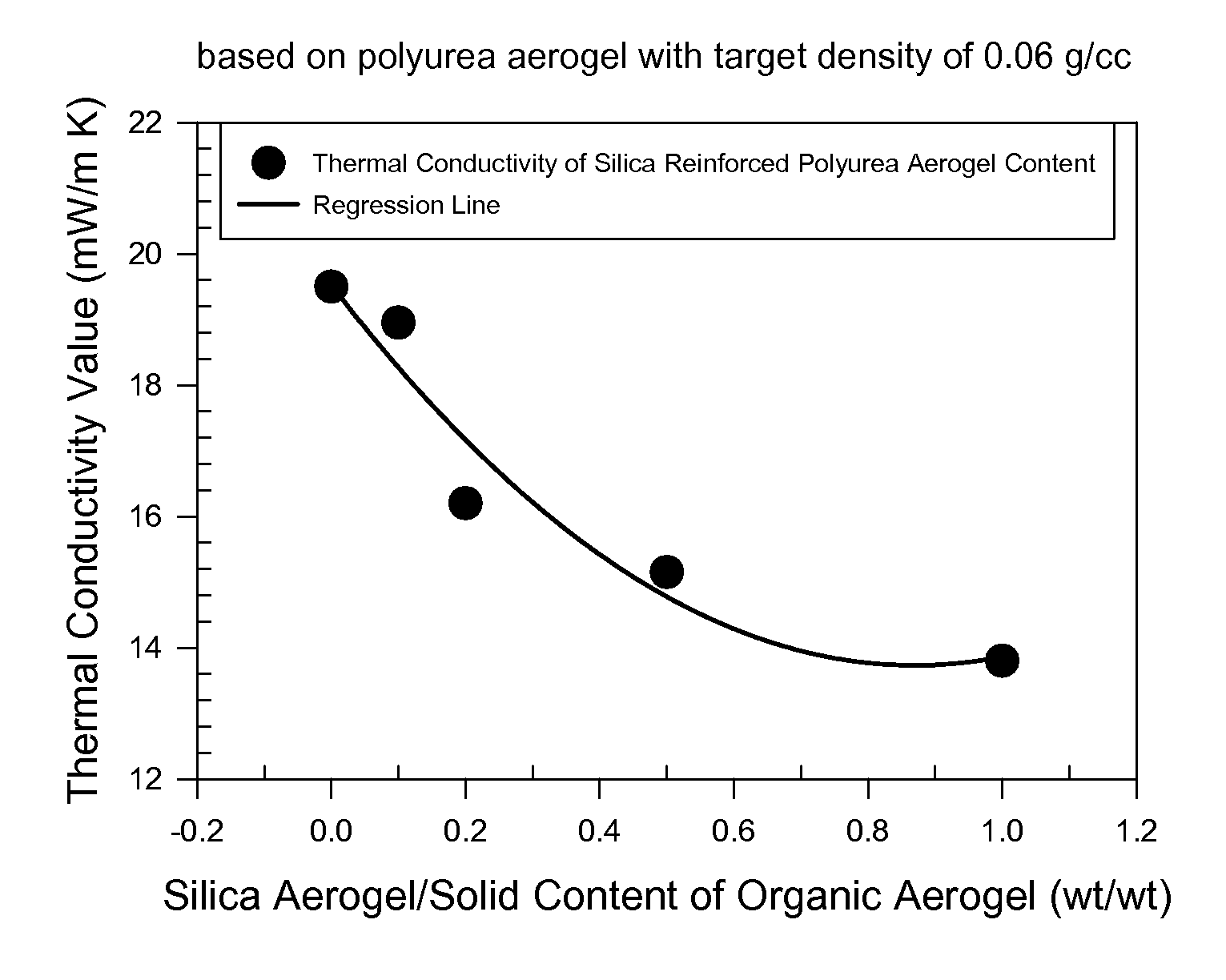

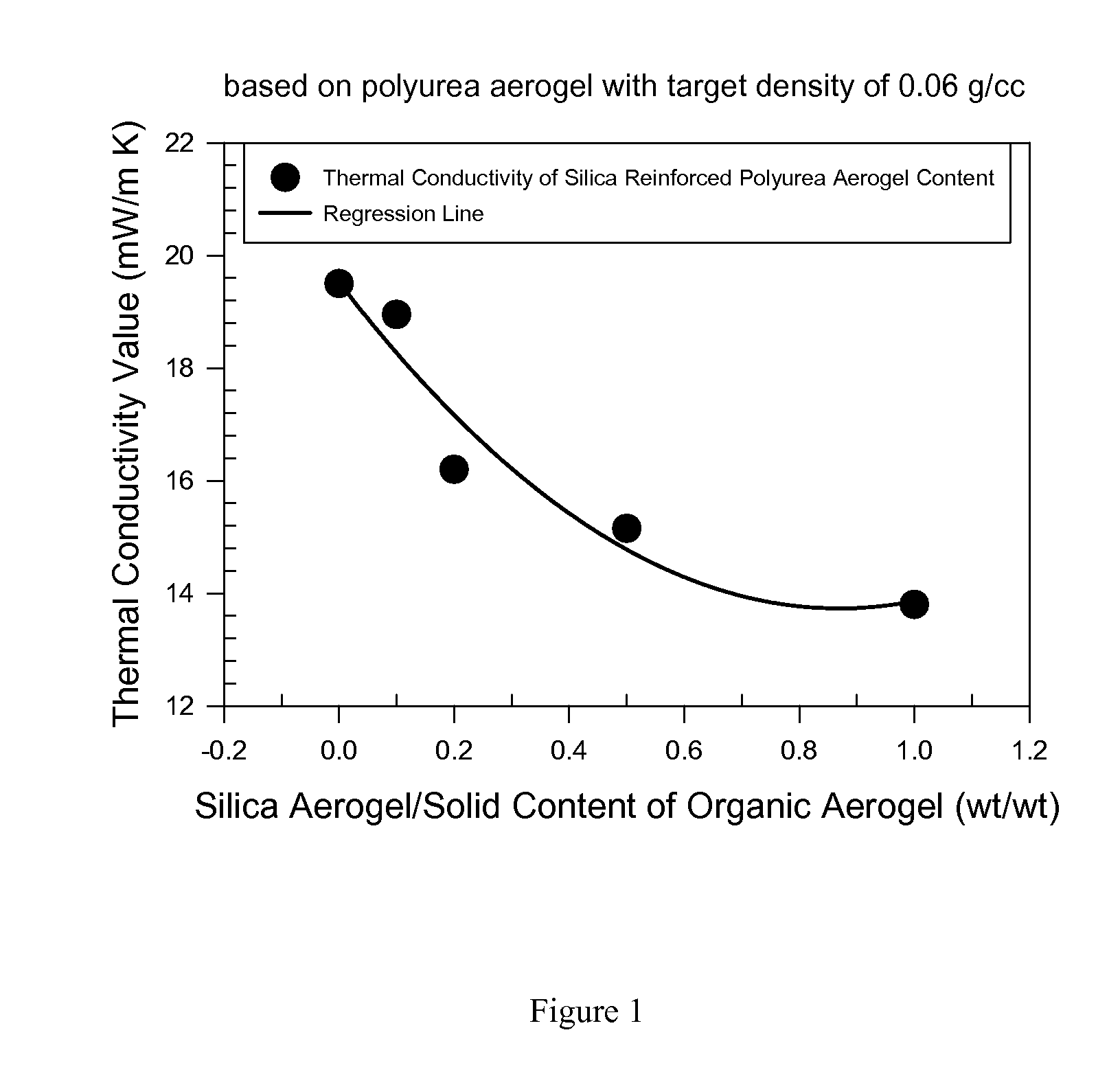

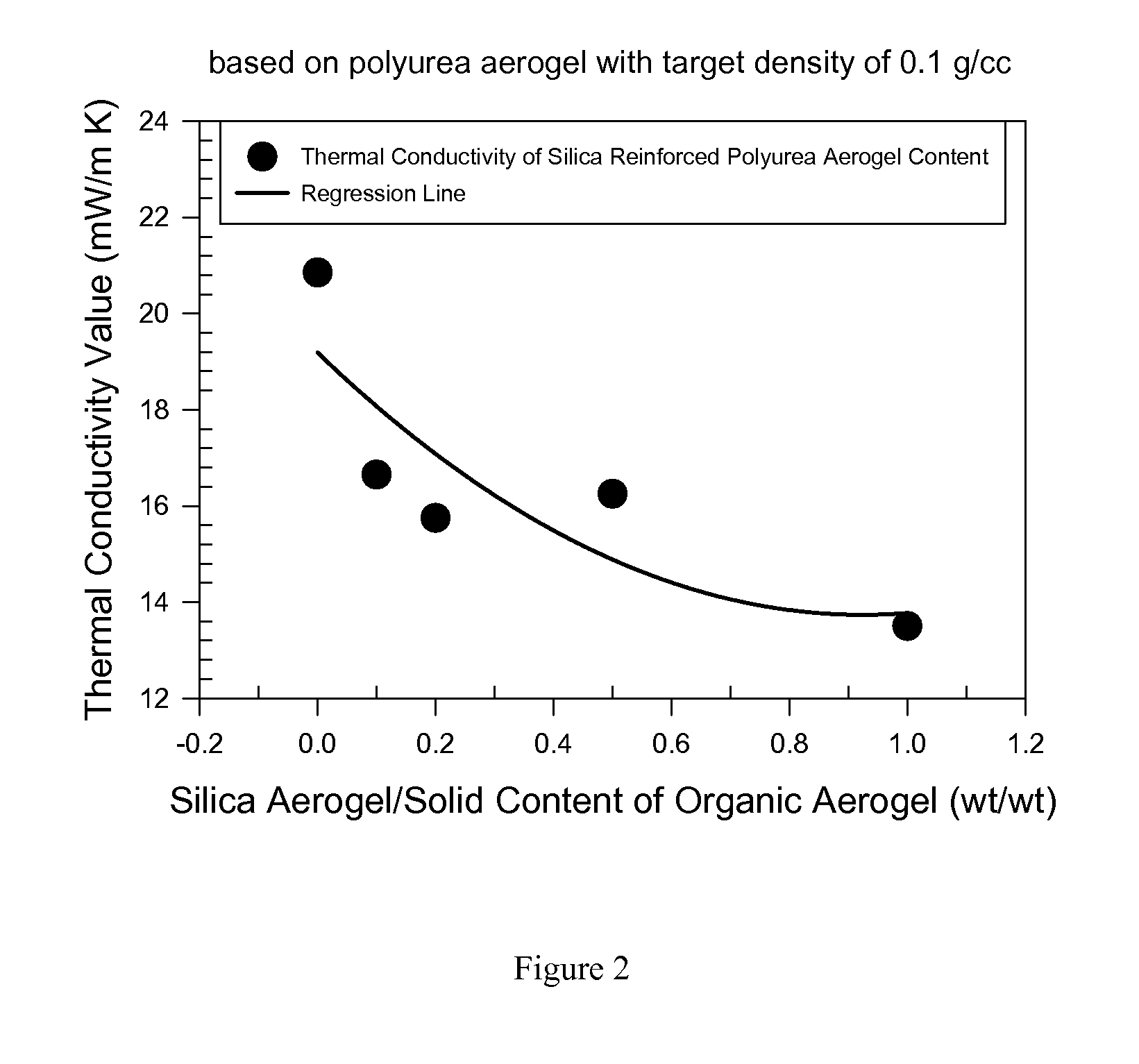

Organic aerogels reinforced with inorganic aerogel fillers

Composites comprising organic aerogel matrix and inorganic aerogel fillers are described. The methods of manufacturing such composite aerogels are also described. Inorganic aerogels fillers are demonstrated to improve the thermal performance of organic aerogels. Composite aerogels with various organic aerogels and inorganic aerogel fillers are described.

Owner:ASPEN AEROGELS INC

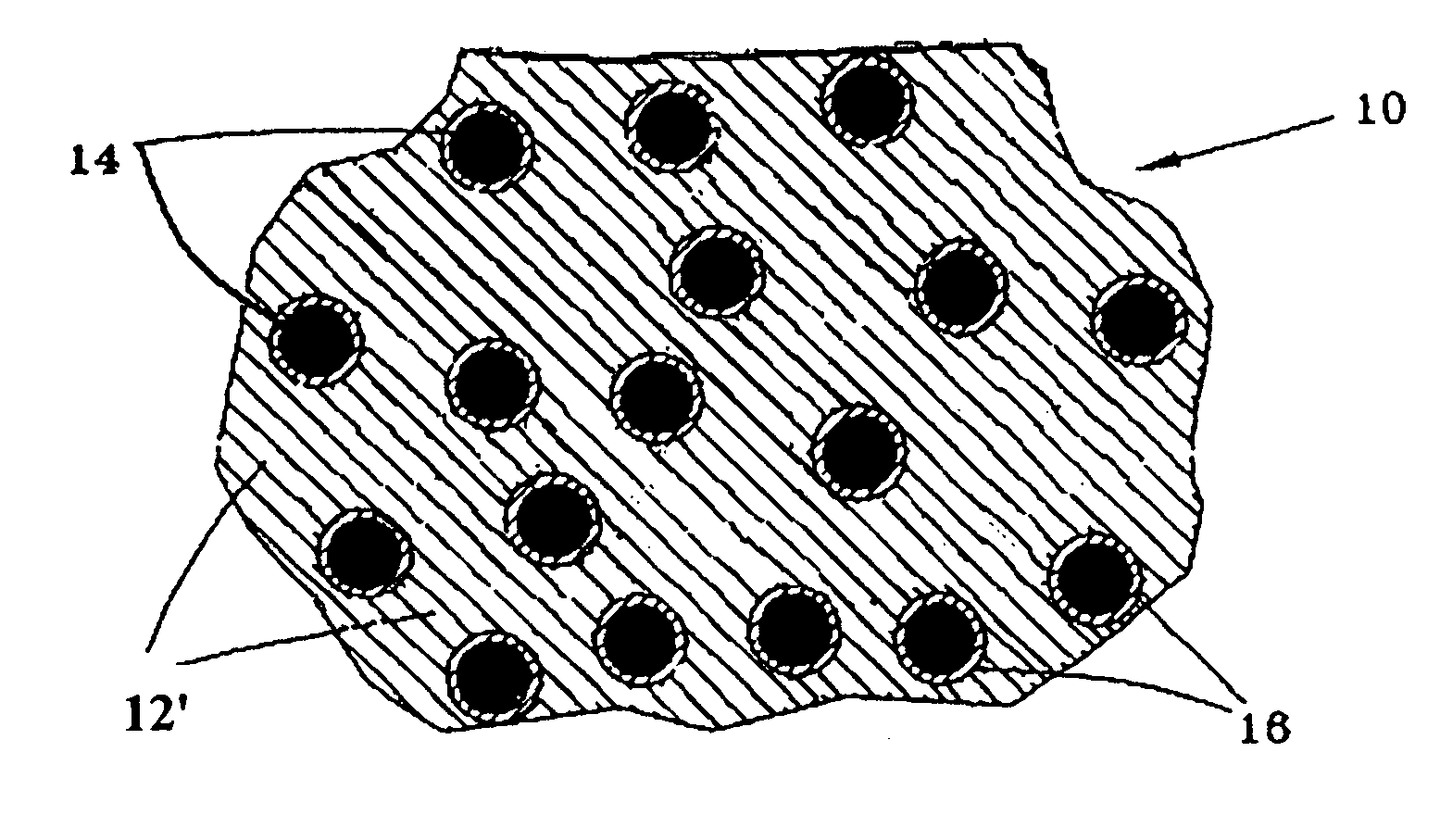

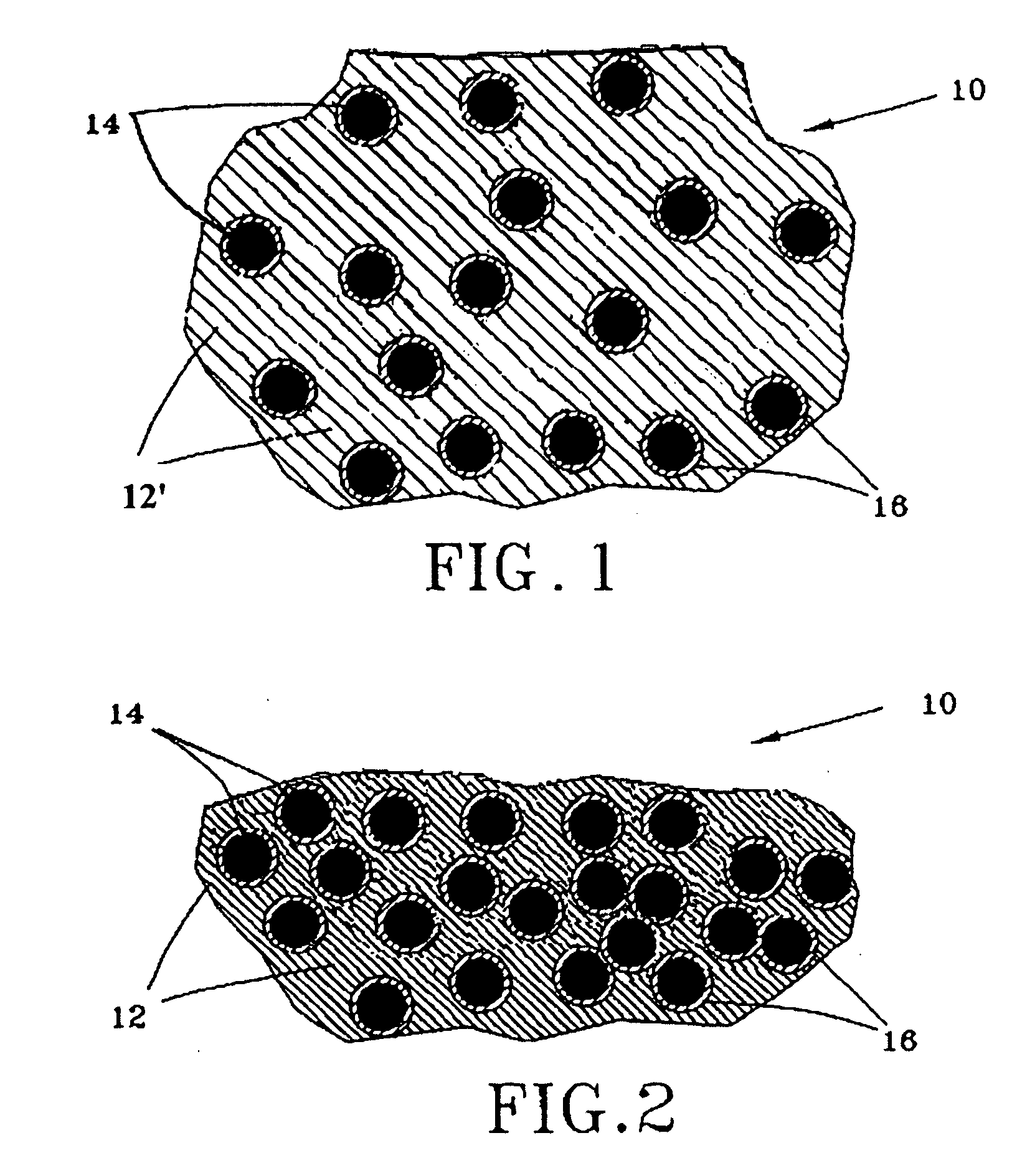

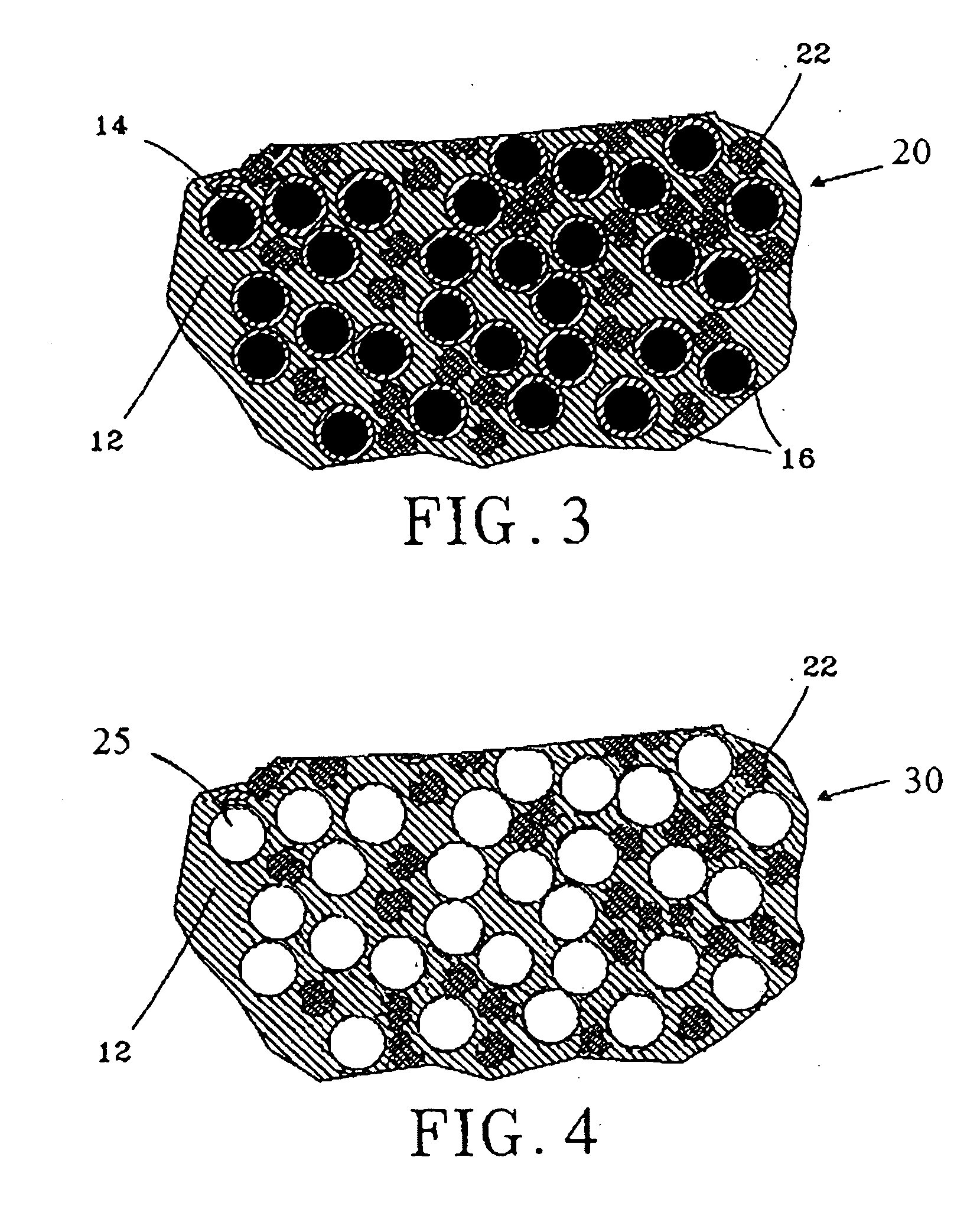

Non-toxic composite projectiles having a biodegradable polymeric matrix for hunting or shooting cartridges

InactiveUS6101949AShort costEasy to produceAmmunition projectilesShotgun ammunitionAliphatic hydrocarbonMetal particle

Composite spherical projectiles are provided for shotgun cartridges which are environmentally compatible, relatively inexpensive and have ballistic properties similar to lead shot or projectiles and which consist of metal particles dispersed in a biogradable polymeric solid matrix which includes a hydrocarbon binder containing ester functional groups which are linked to C1-20 aliphatic hydrocarbon chains, starch, and titanium dioxide.

Owner:SNPE MATERIAUX ENERGETIQUES

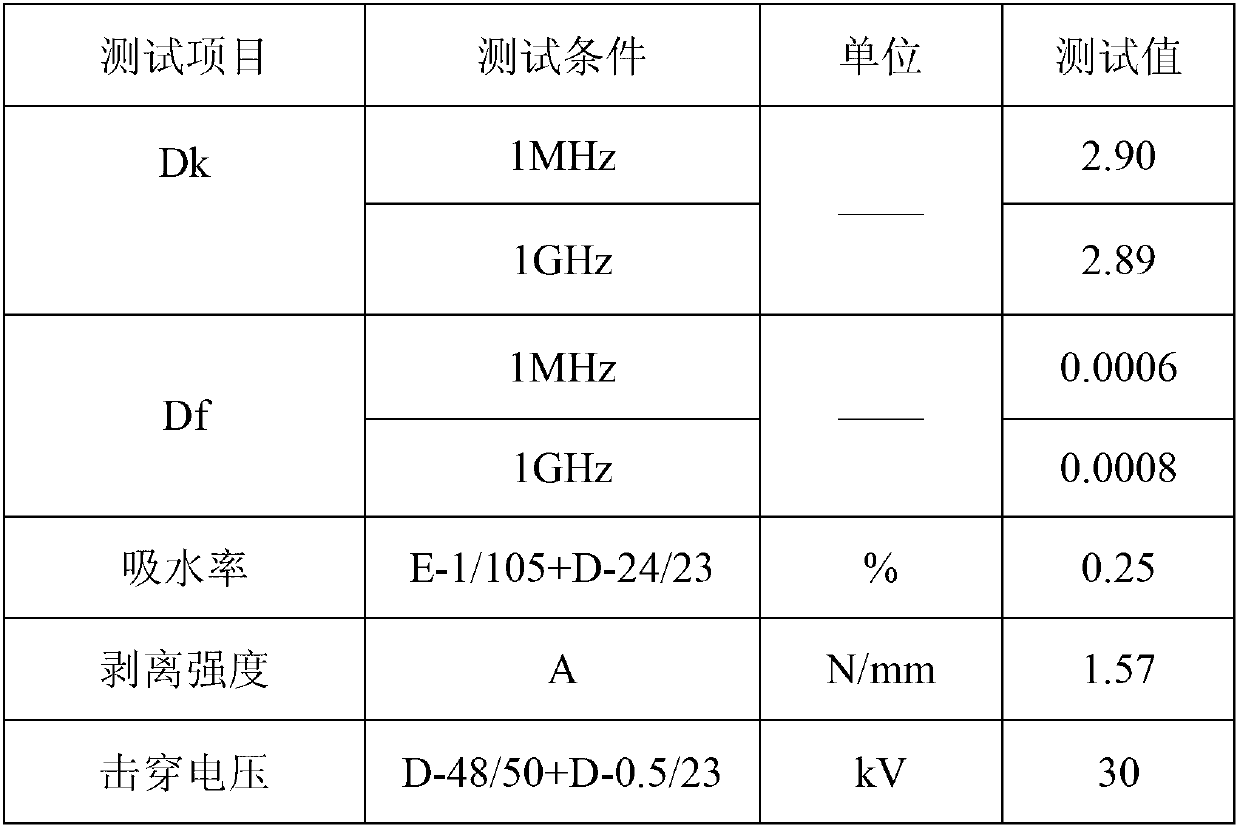

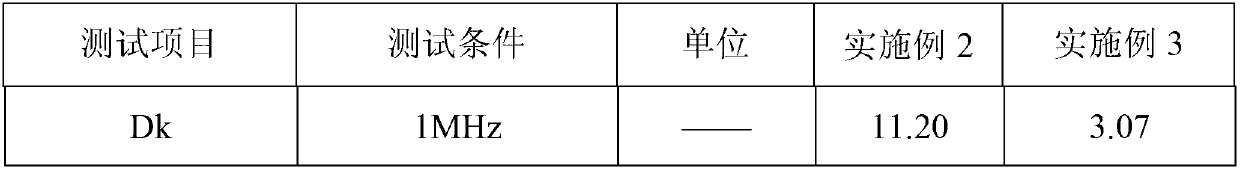

PTFE (polytetrafluoroethylene) base material with high filler content and preparation and application thereof

ActiveCN103102627AImprove performanceWon't happenCircuit susbtrate materialsMetal layered productsEmulsionCopper

The invention provides a preparation method of a PTFE (polytetrafluoroethylene) copper-clad plate with high filler content, which comprises the following steps of: mixing fluororesin powder and inorganic filler, adding a lubricating agent and stirring to obtain a dough-shaped object; performing the extrusion, calendering and the like to obtain a sheet; performing heat treatment on the sheet; stepping the sheet in fluororesin dispersing emulsion; and drying, baking and sintering to obtain a sheet with few pores and covered with a layer of resin film on the surface, wherein a copper-clad plate made from the sheet has good comprehensive performance.

Owner:GUANGDONG SHENGYI SCI TECH

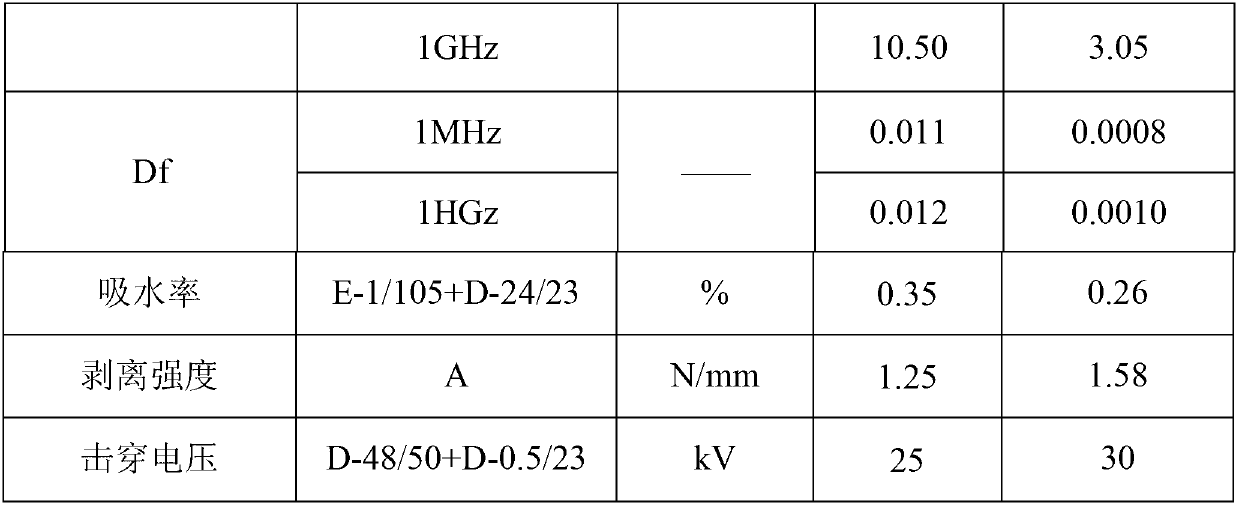

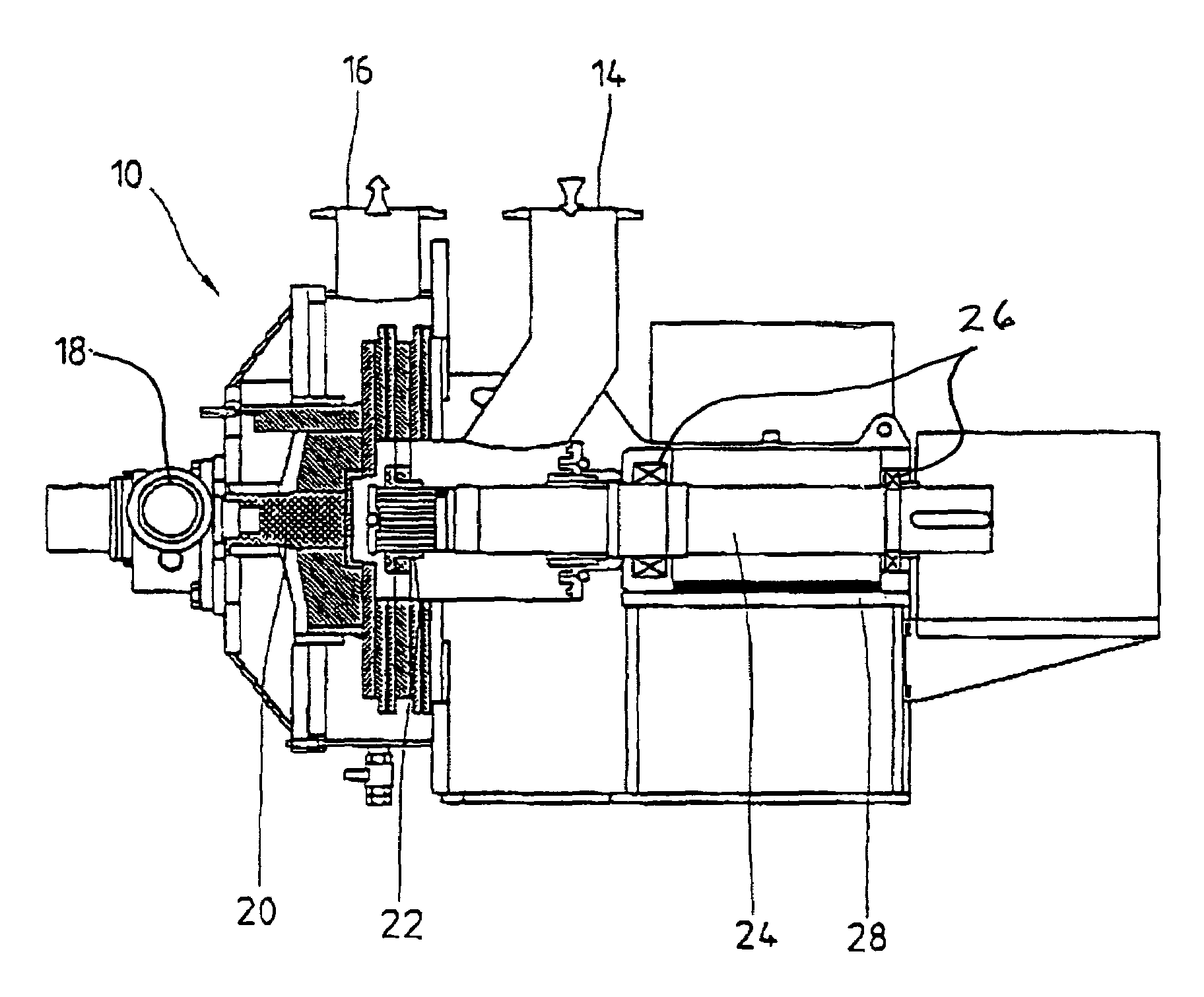

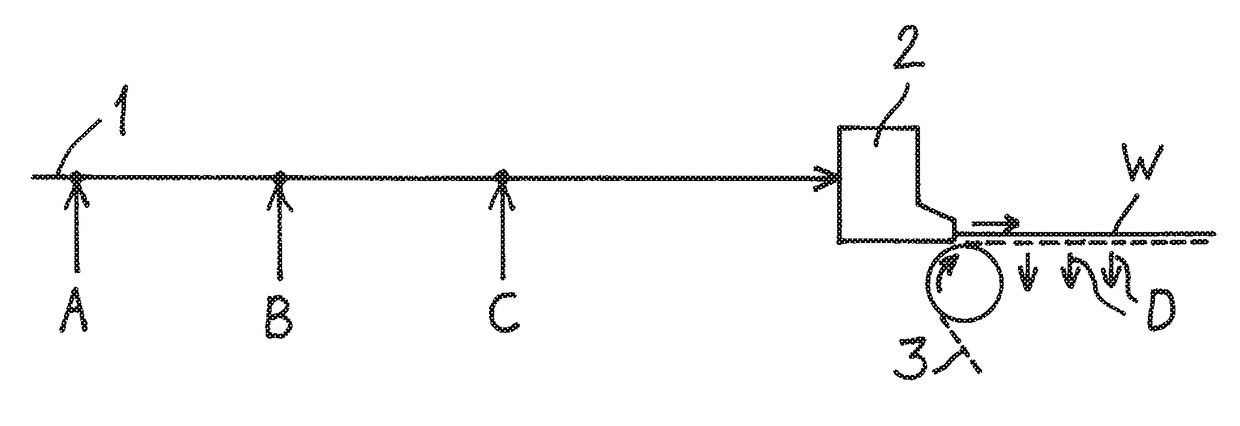

Method for fiber stock preparation

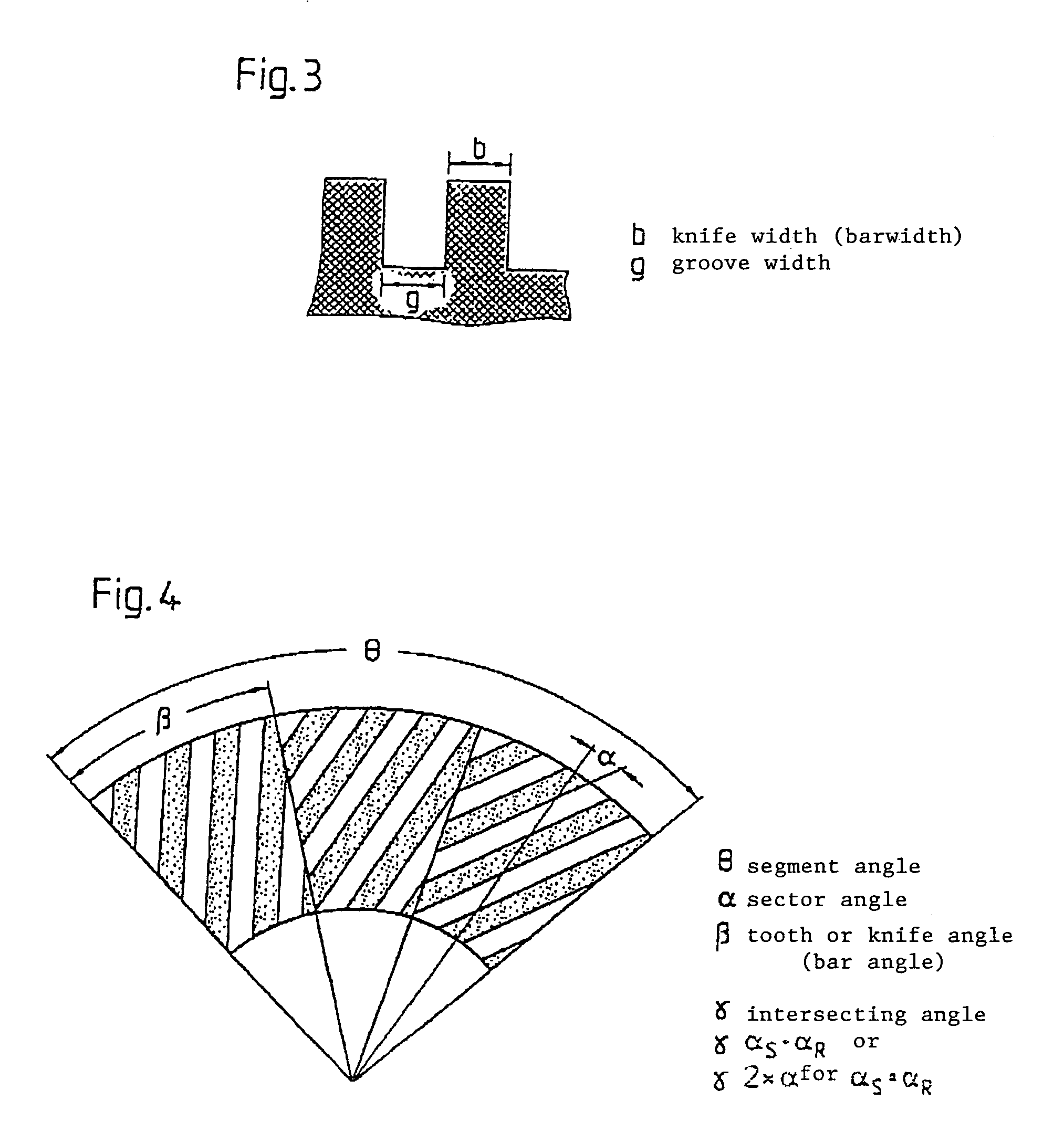

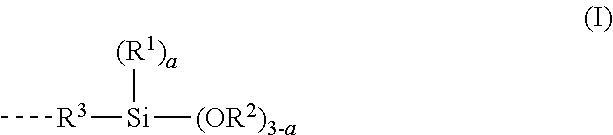

InactiveUS7179347B2Negatively characteristicWeaken energyCellulosic pulp after-treatmentNatural cellulose pulp/paperFiberCardboard

A method for the preparation of fiber stock for the production of paper or cardboard, including the steps of:a) Supplying fibers in the form of a suspension that has a predetermined solids content,b) Loading of the fibers with a precipitation product, without refining the stock,c) Refining of the fibers after completion of the loading process, in order to improve the freeness value and / or to alter the fiber characteristics, andd) Transporting of the fiber stock suspension in direction of the paper machine.

Owner:VOITH PATENT GMBH

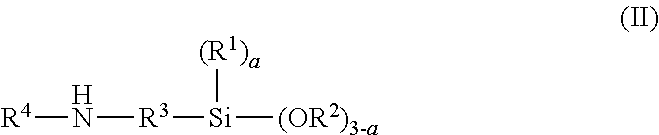

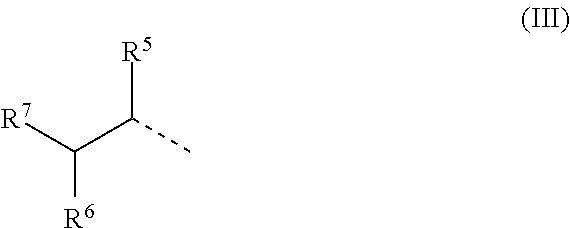

High filler content composition based on silane-terminated polymers

InactiveUS20150166859A1High hardnessLow costPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolymer scienceSilanes

A moisture-cure composition is described that includesa) at least one silane-functional polymer P;b) at least one catalyst for cross-linking of silane functional polymers; andc) at least 65% w / w of at least one filler,wherein the composition in the fully cured state has a Shore A hardness of ≧60, determined in accordance with DIN 53505, and prior to curing has an extrusion pressure of ≦1000 N.

Owner:SIKA TECH AG

Method of increasing filler content in papermaking

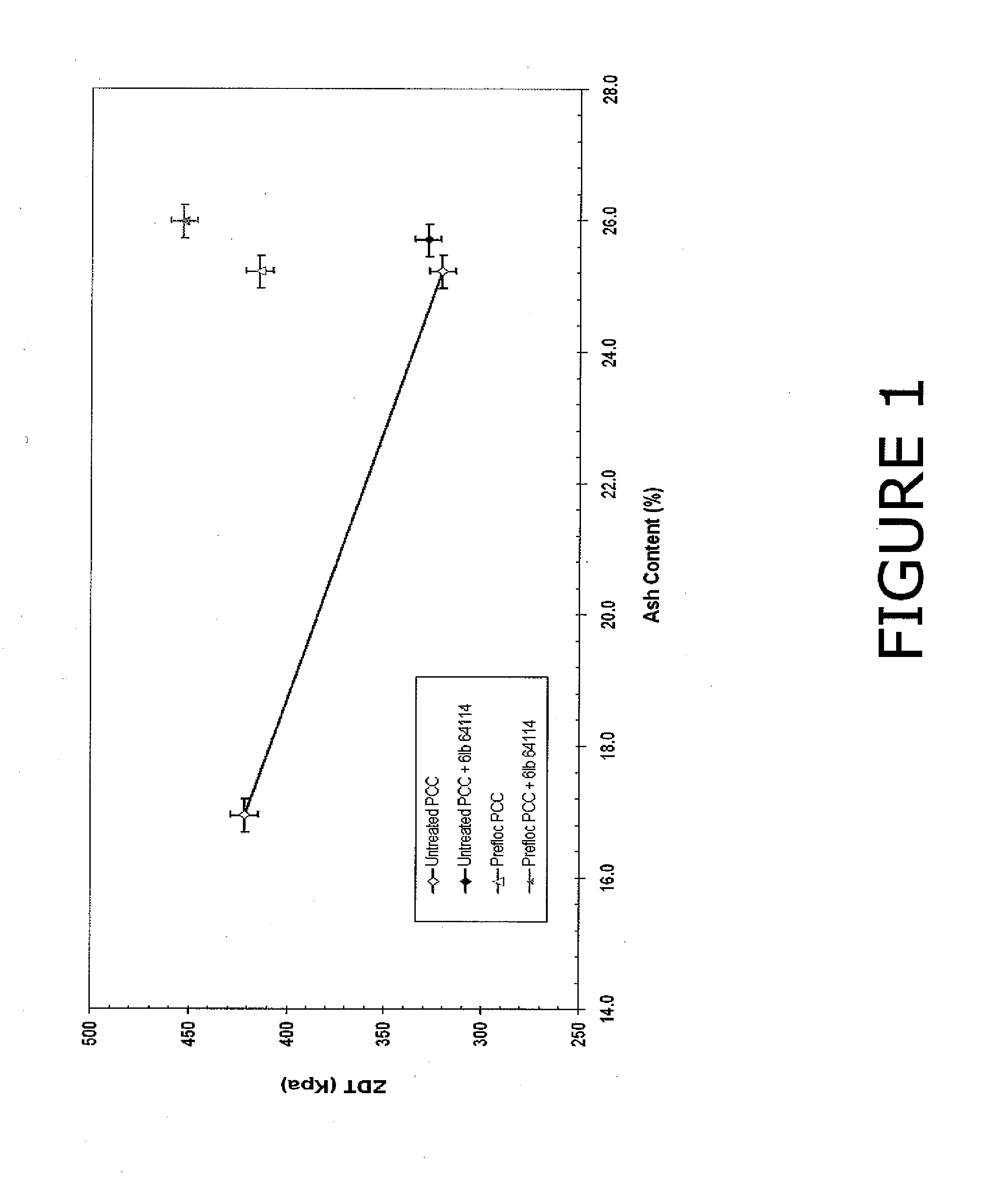

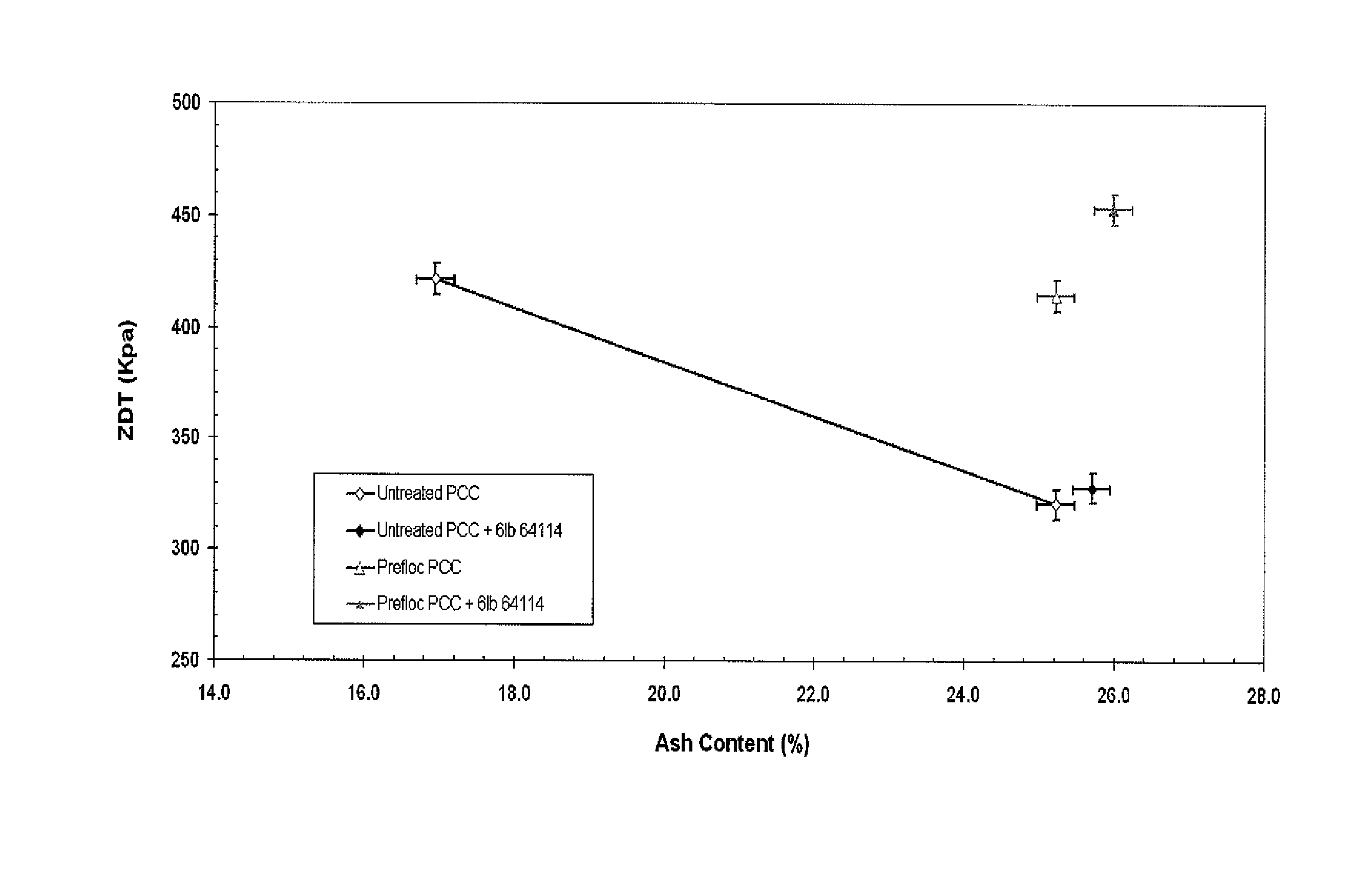

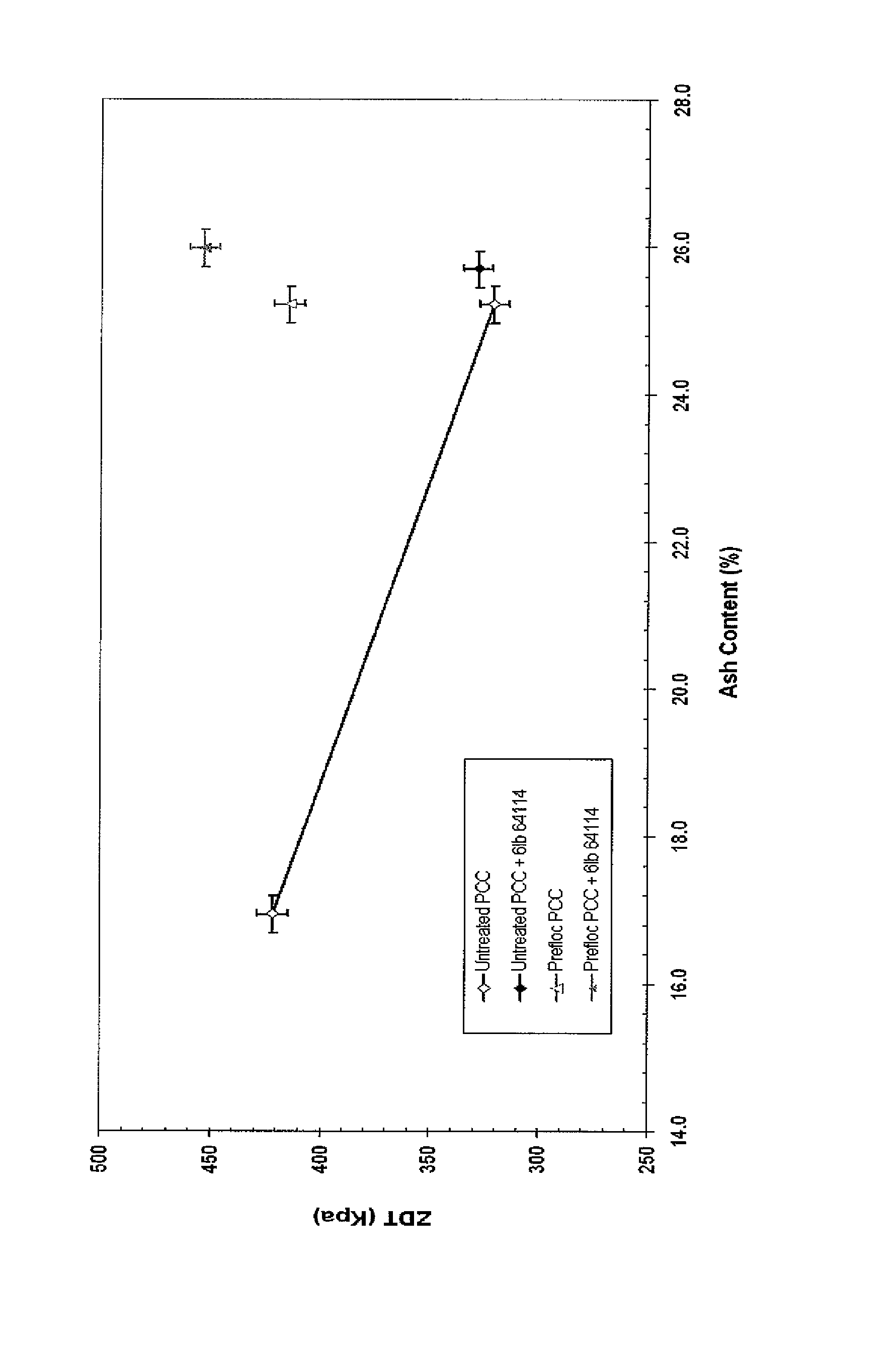

ActiveUS20110226433A1Increase filler contentImprove performanceNatural cellulose pulp/paperSpecial paperFiller particlePapermaking

The invention provides a method of producing paper with a higher proportion of mineral filler particles than is otherwise be possible without the expected loss in paper strength by preflocculating the filler particles. The method allows for the use of the greater amount of filler particles by coating at least some of the filler particles with a material that prevents the filler materials form adhering to a strength additive. The strength additive holds the paper fibers together tightly and is not wasted on the filler particles.

Owner:NALCO CO

Foam sheet-forming composition, heat conductive foam sheet and process for the production thereof

A sheet-forming composition is provided which has a construction comprising a combination of a heat-polymerizable binder component containing at least one (meth)acrylic monomer or its partial polymer, a heat conductive filler, a heat polymerization initiator for the binder component and a foaming agent. A process for making a heat conductive foam sheet also is provided.

Owner:3M INNOVATIVE PROPERTIES CO

High-reliability epoxy bottom filling glue and preparation method thereof

ActiveCN105295796AImprove reliabilityImprove adhesionNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceFirming agent

A high-reliability bottom filling glue consists of the following raw materials in parts by weight: 30-50 parts of liquid epoxy resin, 1-10 parts of an active diluent, 1-10 parts of a toughening agent, 40-60 parts of spherical silica micropowder with different particle diameters, 4-8 parts of a curing agent, 1-3 parts of a curing catalyst, 0.1-1 part of a coupling agent and 0.1-2 parts of a wetting dispersant. The raw materials are added into a stirring container respectively, and are uniformly stirred in the vacuum state to be discharged so as to obtain the product. The prepared fast-flowing high-reliability epoxy bottom filling glue is relatively high in flowing speed, high in modulus and reliability, low in linear expansion coefficient and suitable for packaging of flip chips.

Owner:YANTAI DARBOND TECH

Method of increasing filler content in papermaking

ActiveUS8647472B2Increase filler contentImprove performanceNatural cellulose pulp/paperSpecial paperFiberPrill

The invention provides a method of producing paper with a higher proportion of mineral filler particles than is otherwise be possible without the expected loss in paper strength by preflocculating the filler particles. The method allows for the use of the greater amount of filler particles by coating at least some of the filler particles with a material that prevents the filler materials form adhering to a strength additive. The strength additive holds the paper fibers together tightly and is not wasted on the filler particles.

Owner:NALCO CO

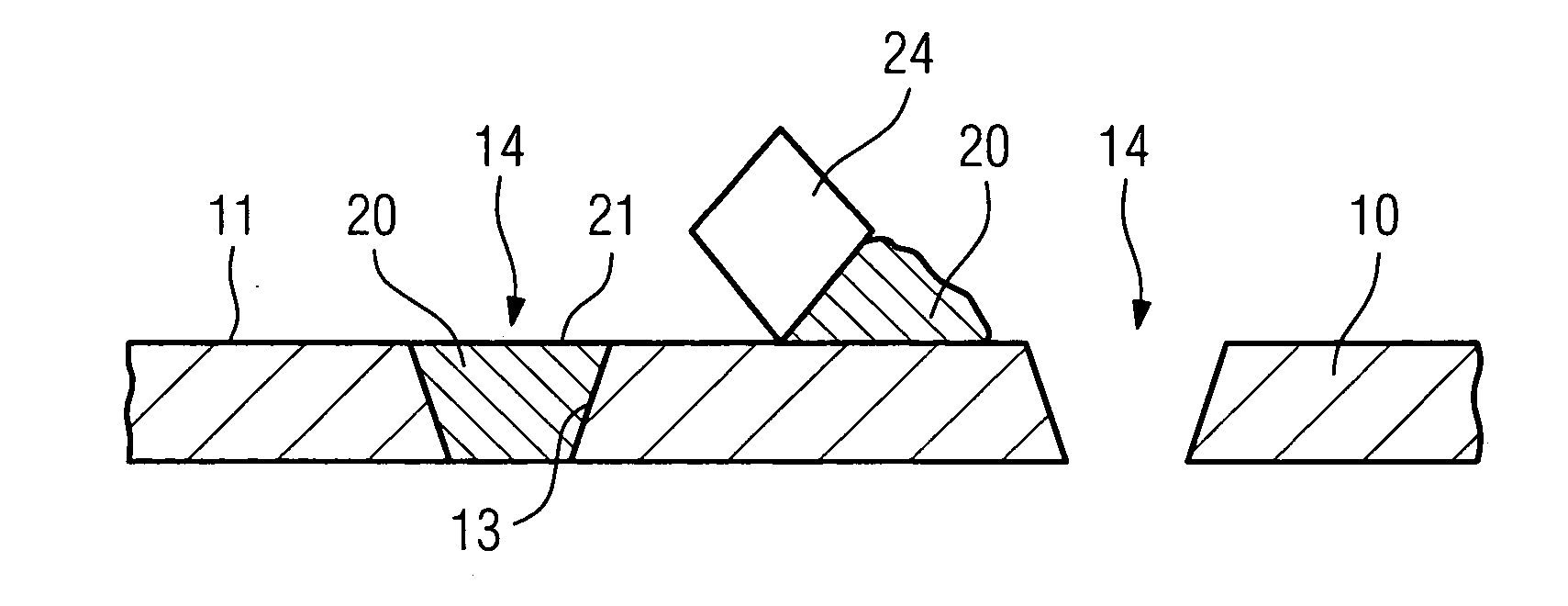

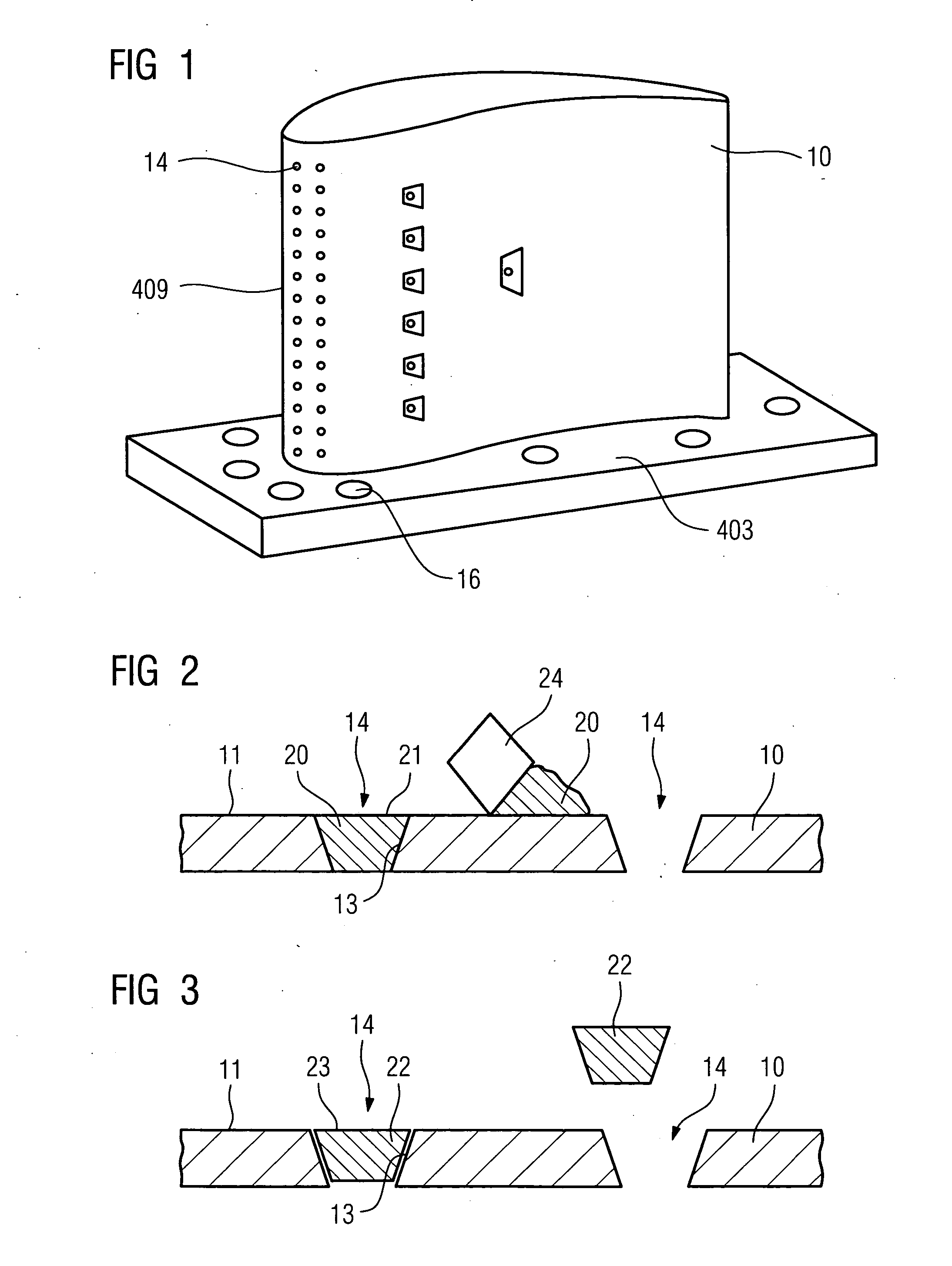

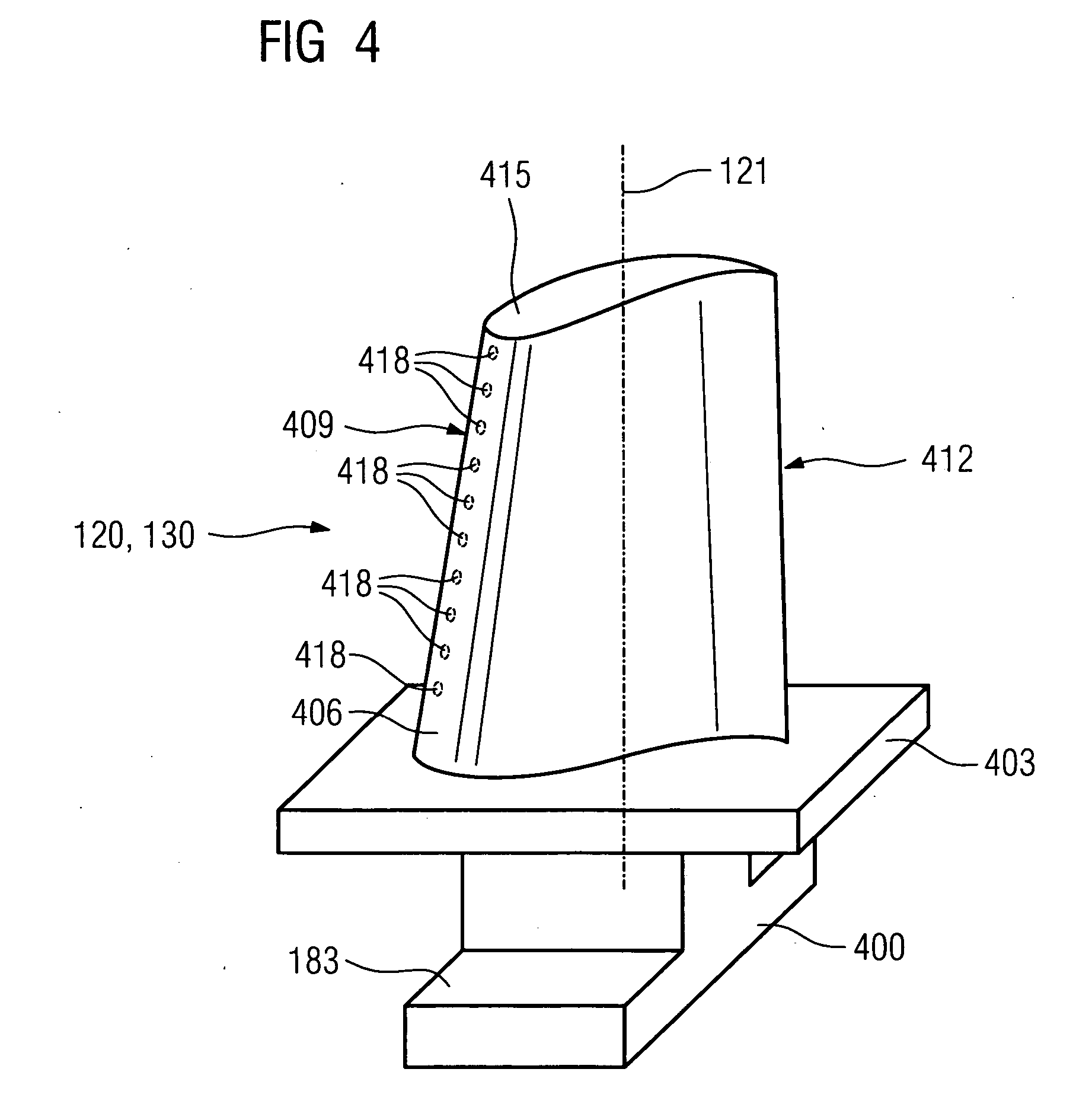

Process for protecting openings in a component during a treatment process, preventing penetration of material, and a ceramic material

InactiveUS20070087117A1Increase filler contentSuitable for useVacuum evaporation coatingPretreated surfacesFilling materialsMetal alloy

In the process according to the invention for protecting openings in a component made from an electrically conductive base material, in particular from metal or from a metal alloy, during a treatment process, preventing penetration of material, prior to the treatment process the openings are closed up using a filling material which is removed again following the treatment process. The process according to the invention is distinguished by the fact that chains of Si—O—Si and / or Si—O—C are used as filling material.

Owner:SIEMENS AG

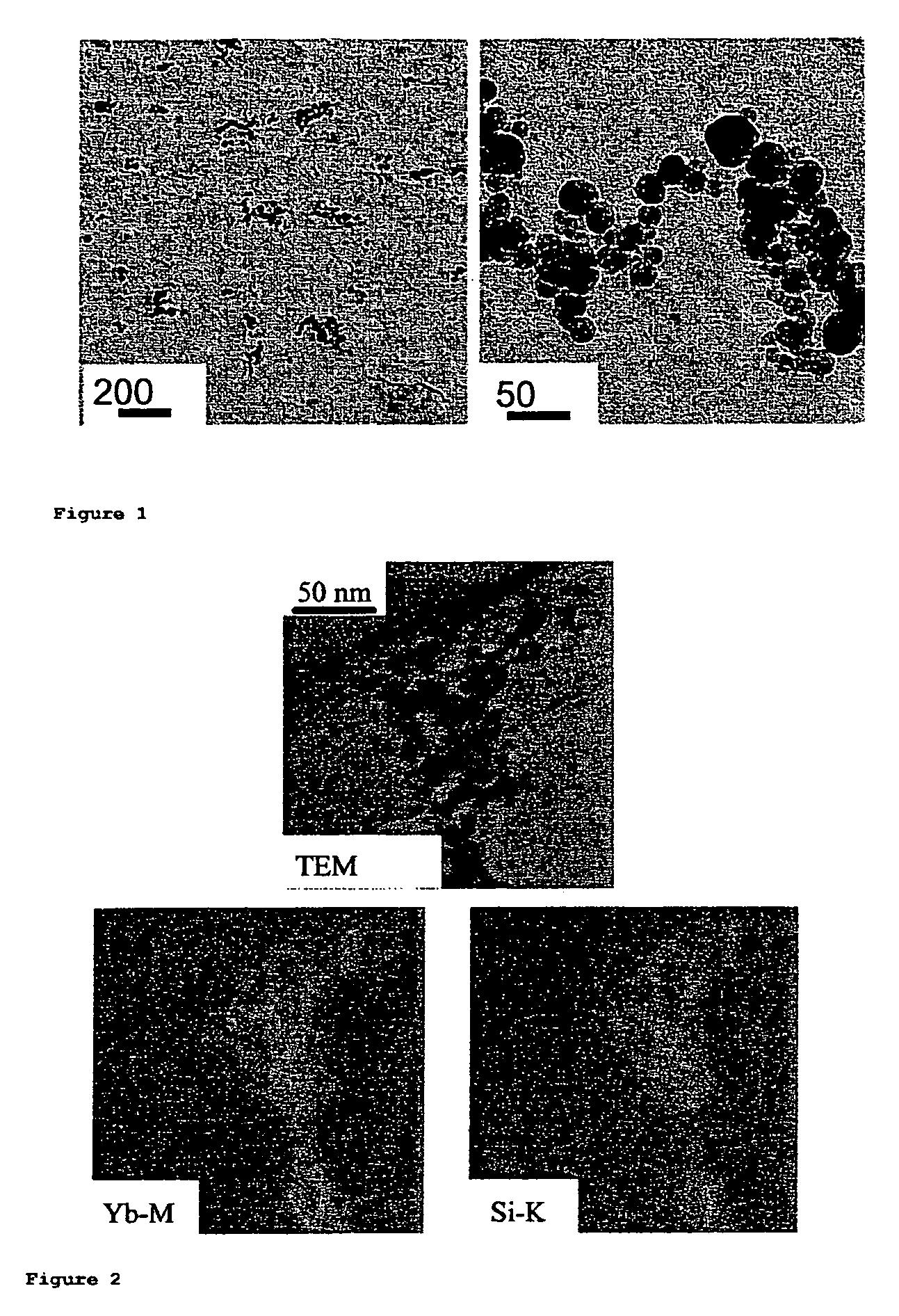

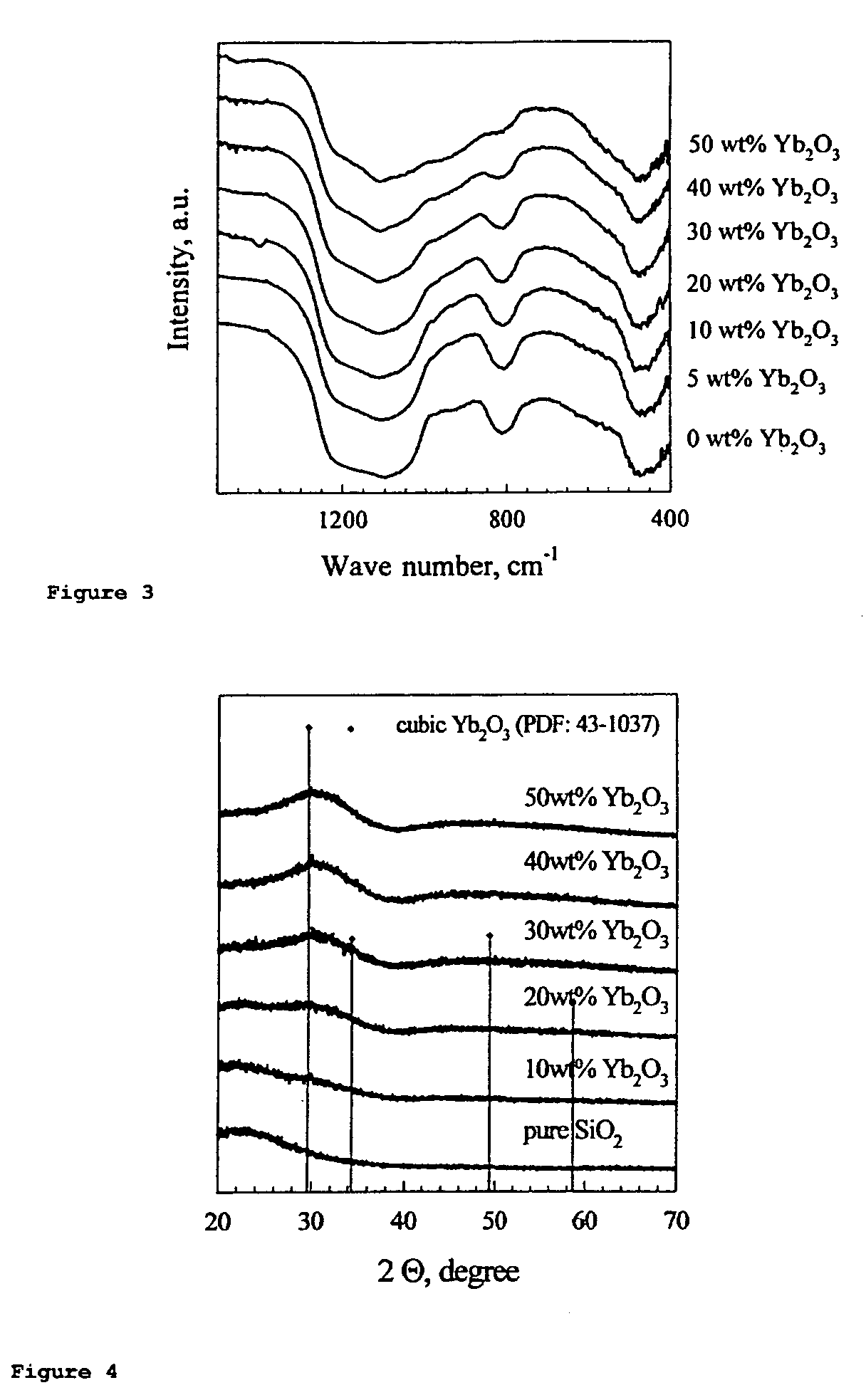

Dental composites based on X-ray-opaque mixed oxides prepared by flame spraying

ActiveUS7335250B2Low intrinsic colorIncrease coverageCosmetic preparationsImpression capsMixed oxideDental composite

Owner:IVOCLAR VIVADENT AG

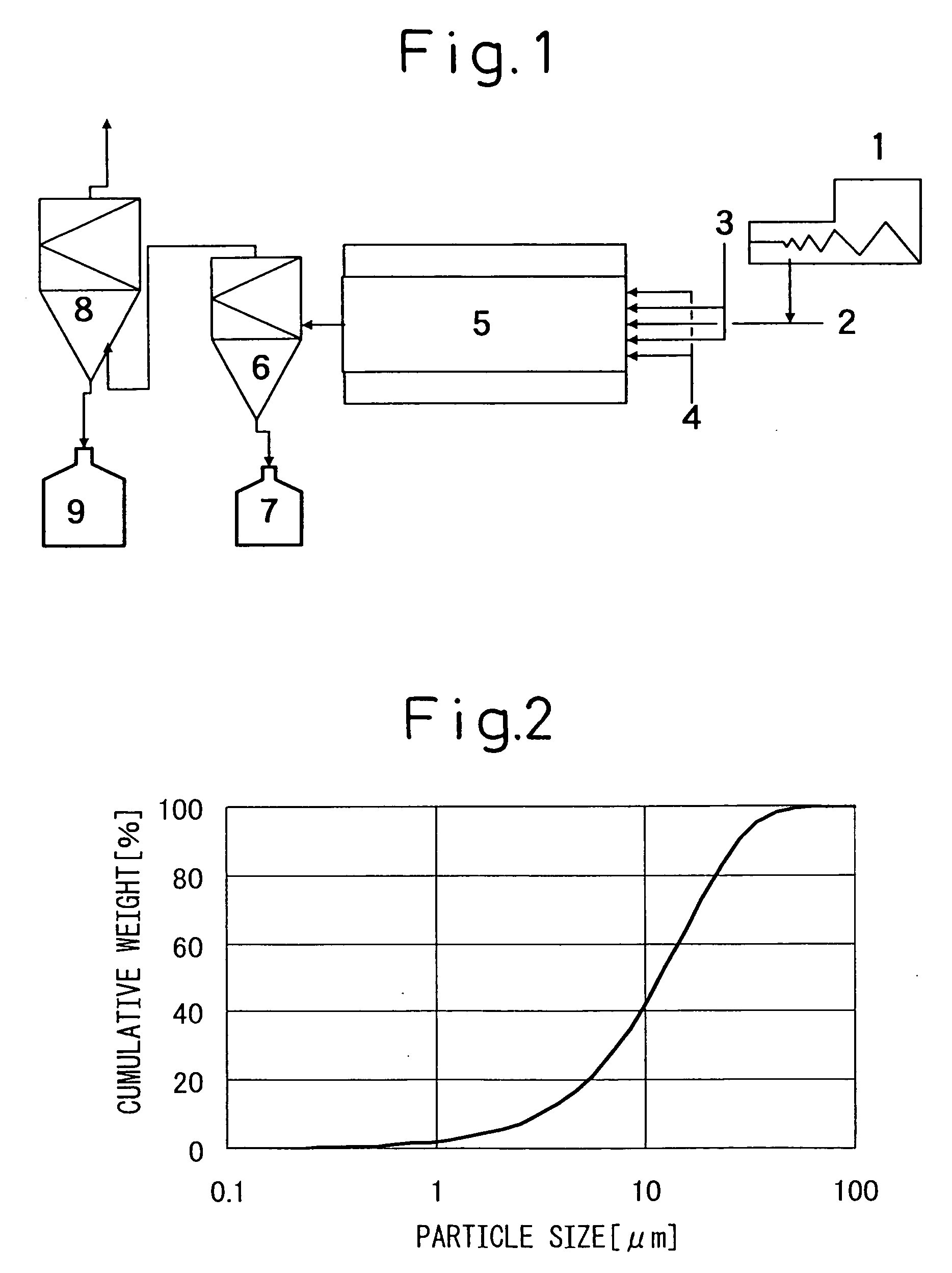

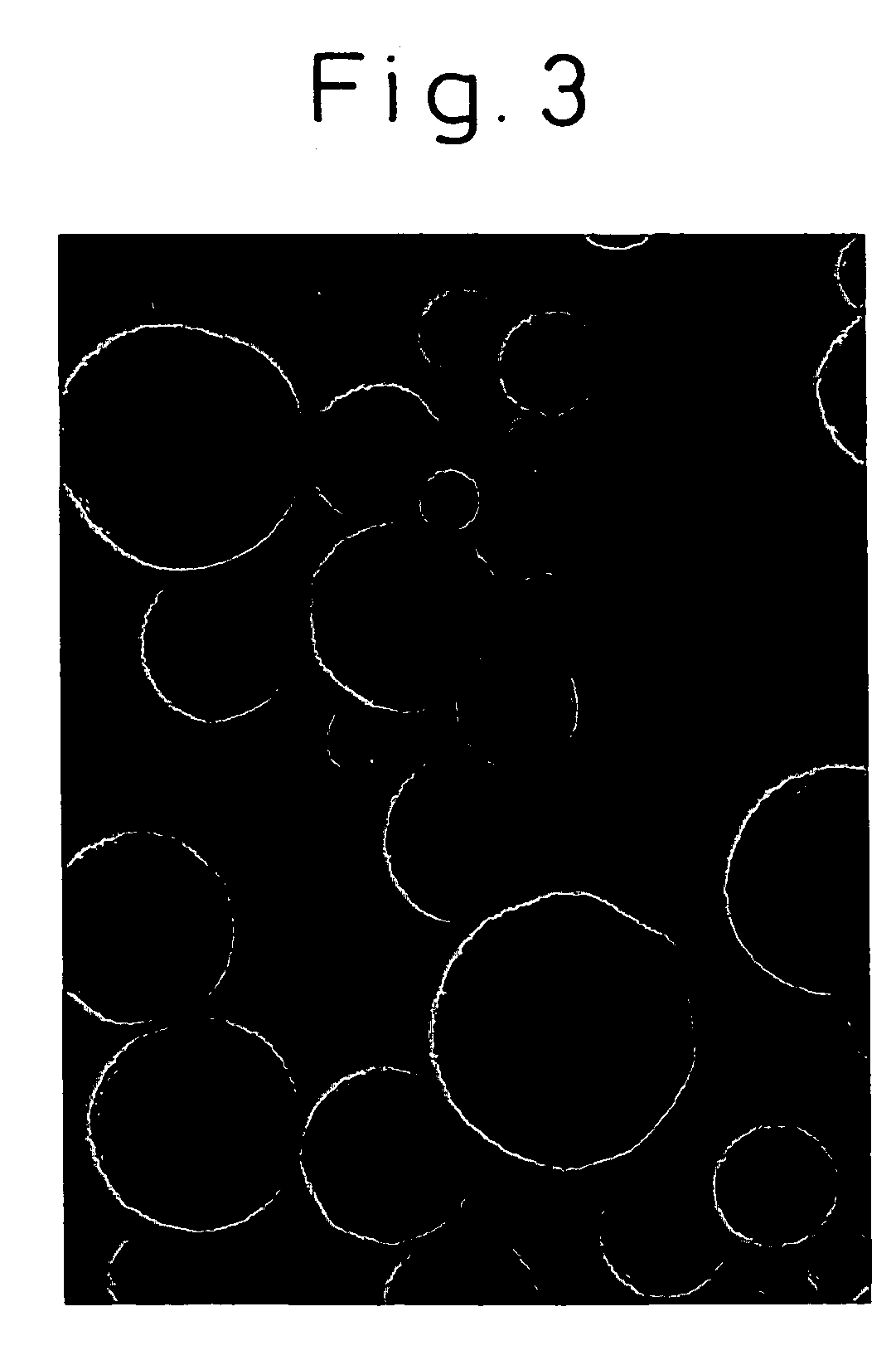

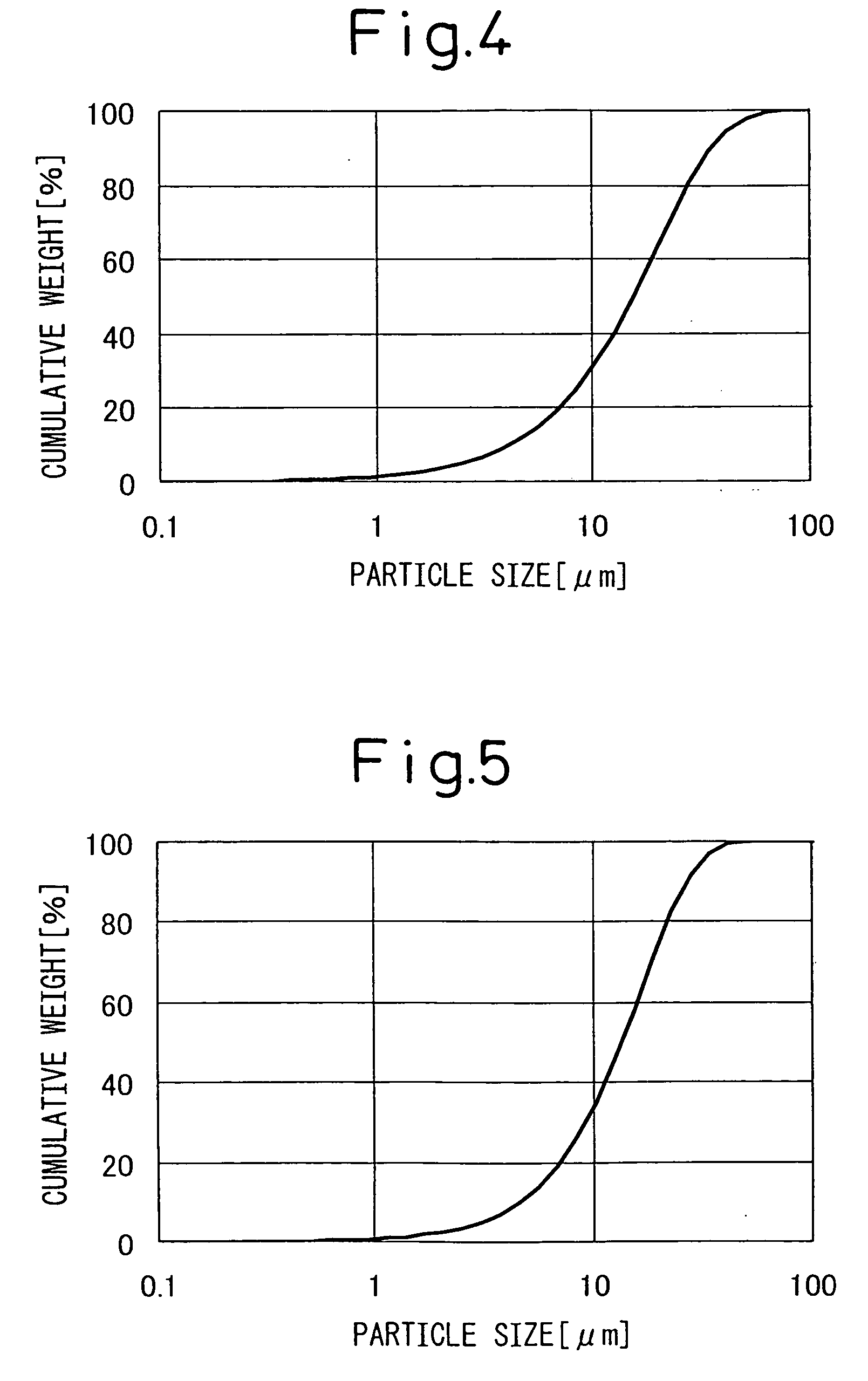

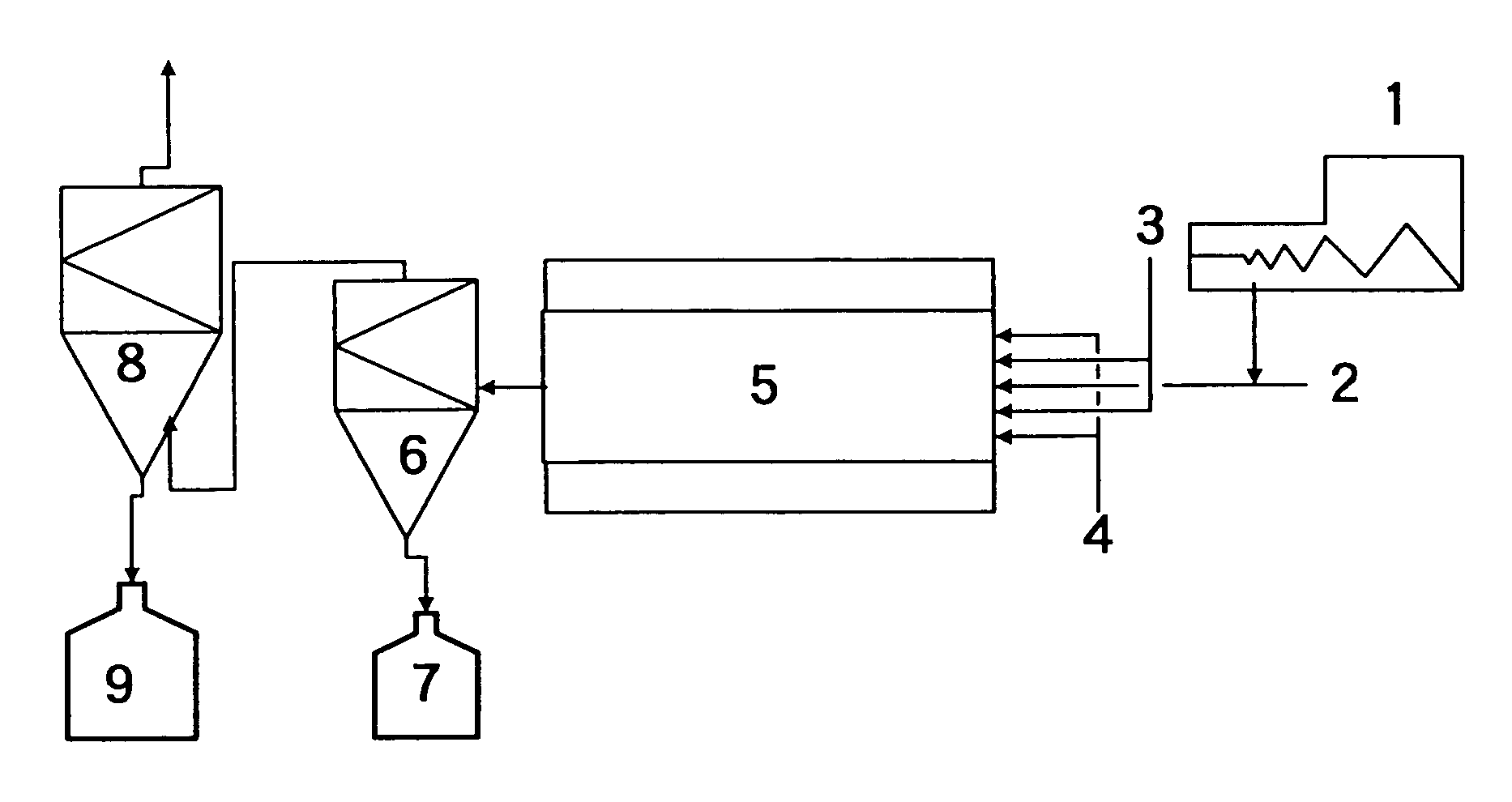

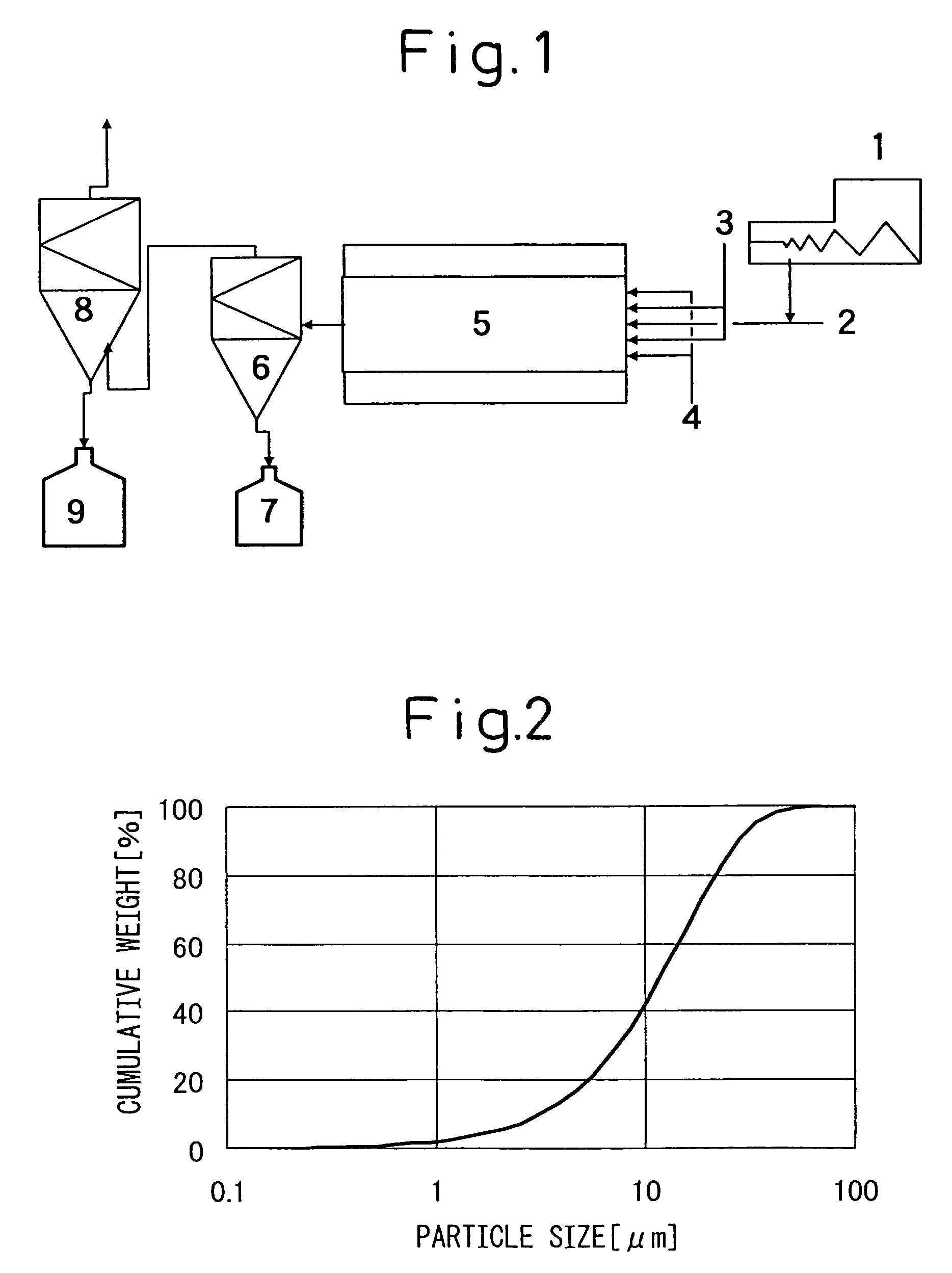

Surface modification method for inorganic oxide powder, powder produced by the method and use of the powder

InactiveUS20060127669A1Improvement ingredientsLow viscosityMaterial nanotechnologyInorganic pigment treatmentMetallurgyCombustible gas

A surface modification method comprising bringing, into a high-temperature flame formed by use of a combustible gas and a combustion-supporting gas, inorganic oxide powder A having an average particle size falling within a range of 0.5 to 200 μm as measured by means of laser diffraction / scattering particle size analysis and inorganic oxide powder B having a particle size calculated on the basis of its BET specific surface area of 100 nm or less, to thereby modifiy the surfaces of particles of the powder A by means of the particles of the powder B. A surface modification method comprising bringing, into a high-temperature flame formed by use of a combustible gas and a combustion-supporting gas, the inorganic oxide powder A; and bringing again the resultant powder into the high-temperature flame, to thereby modify the surfaces of particles of powder A.

Owner:SHOWA DENKO KK

Method for increasing paper strength

ActiveUS20150144282A1Improve dry strengthImprove wet strengthNatural cellulose pulp/paperSpecial paperPulp and paper industryUltimate tensile strength

The present invention provides a method for increasing paper strength in papermaking process comprising adding to a pulp a composition comprising an anionic polyacrylamide (APAM) and a high charge cationic glyoxylated polyacrylamide (GPAM). The present invention also provides paper obtained with said method.

Owner:KEMIRA OY

Thermal transient suppression material and method of production

InactiveUS20050287352A1Lower the volumeContactLiquid surface applicatorsLayered productsThermal energyWax

The present invention provides a high performance polymer-base material capable of dissipating transient thermal energy generated by an electronic module, such as a heat-generating power device. The methods of the present invention involve adding a suitable thinner to reduce the viscosity and increase the volume of a polymer-base matrix material so that a large amount of thermal absorbing particles may be added. The final cured product may have a filler content of more than 80 weight %. Further, the present invention provides a new and reduced cost formulation of a polymer-base thermal transient suppression material containing organic wax particles.

Owner:DELPHI TECH INC

Thermosetting resin composition for semiconductor package and prepreg and metal clad laminate using the same

ActiveUS20160369099A1Good physical propertiesHigh heat resistanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageSlurry

There are provided a thermosetting resin composition for a semiconductor package and a prepreg and a metal clad laminate using the same. More particularly, there are provided a thermosetting resin composition for a semiconductor package capable of improving desmear characteristics by using a cyanate based ester resin and a benzoxazine resin in a thermosetting resin composition based on an epoxy resin and improving chemical resistance by using a slurry type filler to have high heat resistance and reliability, and a prepreg and a metal clad laminate using the same.

Owner:LG CHEM LTD

Method for making paper product and paper product

ActiveUS9702085B2Without strength propertyHigh affinityReinforcing agents additionPaper/cardboardFiberCellulose

Paper product is made starting from aqueous furnish containing fibers and filler. Anionically charged nanofibrillar cellulose and cationic strength additive are added to the aqueous furnish, and the furnish is made to a paper product by dewatering the furnish. Filler content of the paper product can be increased above 40 wt-%.

Owner:UPM-KYMMENE OYJ

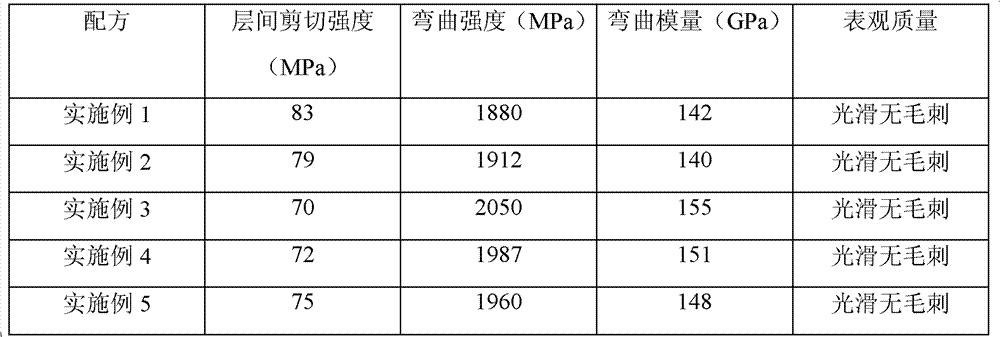

Modified pultrusion composite material and preparation method thereof

InactiveCN103360727AReduce production fluctuationsShorten the production cyclePolyphthalamideFluorine containing

The invention belongs to the scientific and technical field of composite materials, and discloses a modified pultrusion composite material and a preparation method thereof. The material is prepared from the following components in parts by weight: 100 parts of resin, 10-200 parts of a diluter, 0-80 parts of a filler, 0.1-2 parts of an initiator, 0.1-2 parts of a lubricant, 0.1-1 parts of a release agent and 200-1200 parts of inorganic fiber. Compared with the prior art, a fluorine-containing processing agent PPA (Polyphthalamide) is primarily used in the pultrusion composite material in the invention, so that pultrusion composite material can be effectively reduced, and the production period can be shortened. The fluorine-containing processing agent PPA is wide in application and good in effect in production of the pultrusion composite material, and part of the release agent can be replaced, and the content of the filler can be increased, so that the cost is effectively lowered.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

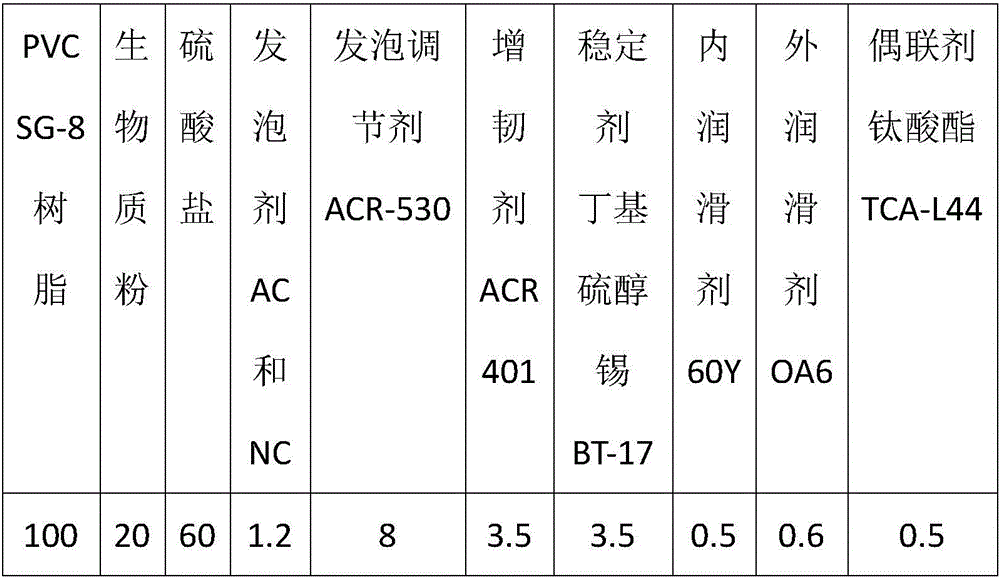

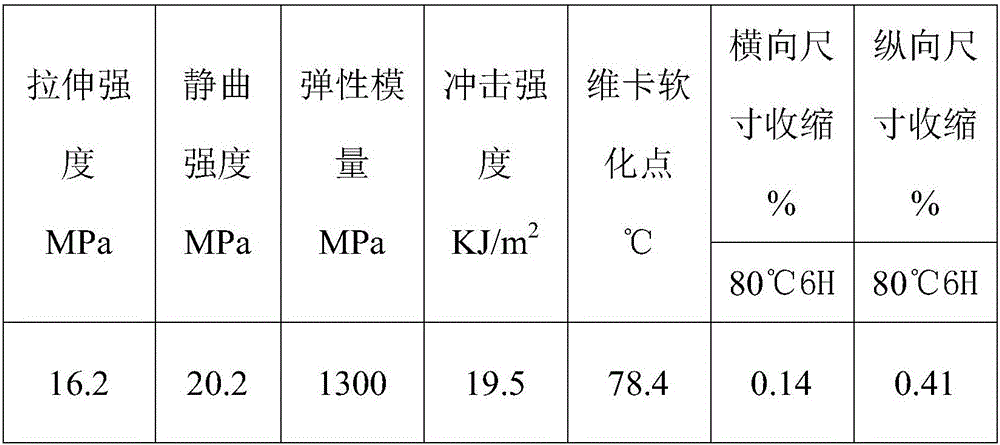

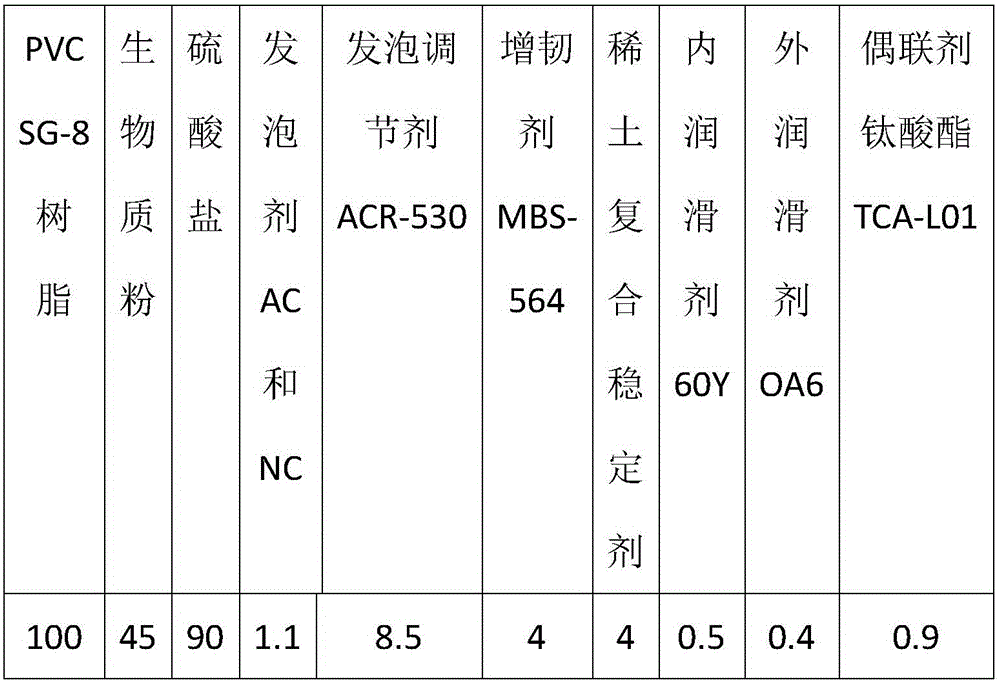

PVC (Polyvinyl Chloride) microcrystalline wood composite material and preparation method thereof

InactiveCN106380742AImprove the lubrication effectEvenly dispersedPlastic materialsPolyvinyl chloride

The invention relates to a PVC (Polyvinyl Chloride) microcrystalline wood composite material and a preparation method thereof. The PVC microcrystalline wood composite material provided by the invention is mainly prepared from the following raw materials: 100 parts of PVC, 10 to 80 parts of pulverized biomass, 10 to 140 parts of sulfate, 2 to 6 parts of stabilizer, 0.4 to 1.5 parts of foaming agent, 4 to 10 parts of foaming control agent, 3 to 8 parts of flexibilizer, 0.3 to 2.0 parts of lubricating agent, and 0.3 to 1.8 parts of coupling agent. The invention also comprises a preparation method of the PVC microcrystalline wood composite material. The toughness and the rigidity of the PVC microcrystalline wood composite material prepared by the method are superior to those of an existing PVC microcellular foaming wood plastic material, especially the shrinking percentage of the material is remarkably reduced, the vicat softening point temperature is remarkably improved, and the PVC microcrystalline wood composite material can be widely applied in building materials such as indoor and outdoor floors, wallboards, top plates and home furnishing.

Owner:HUNAN NORMAL UNIVERSITY

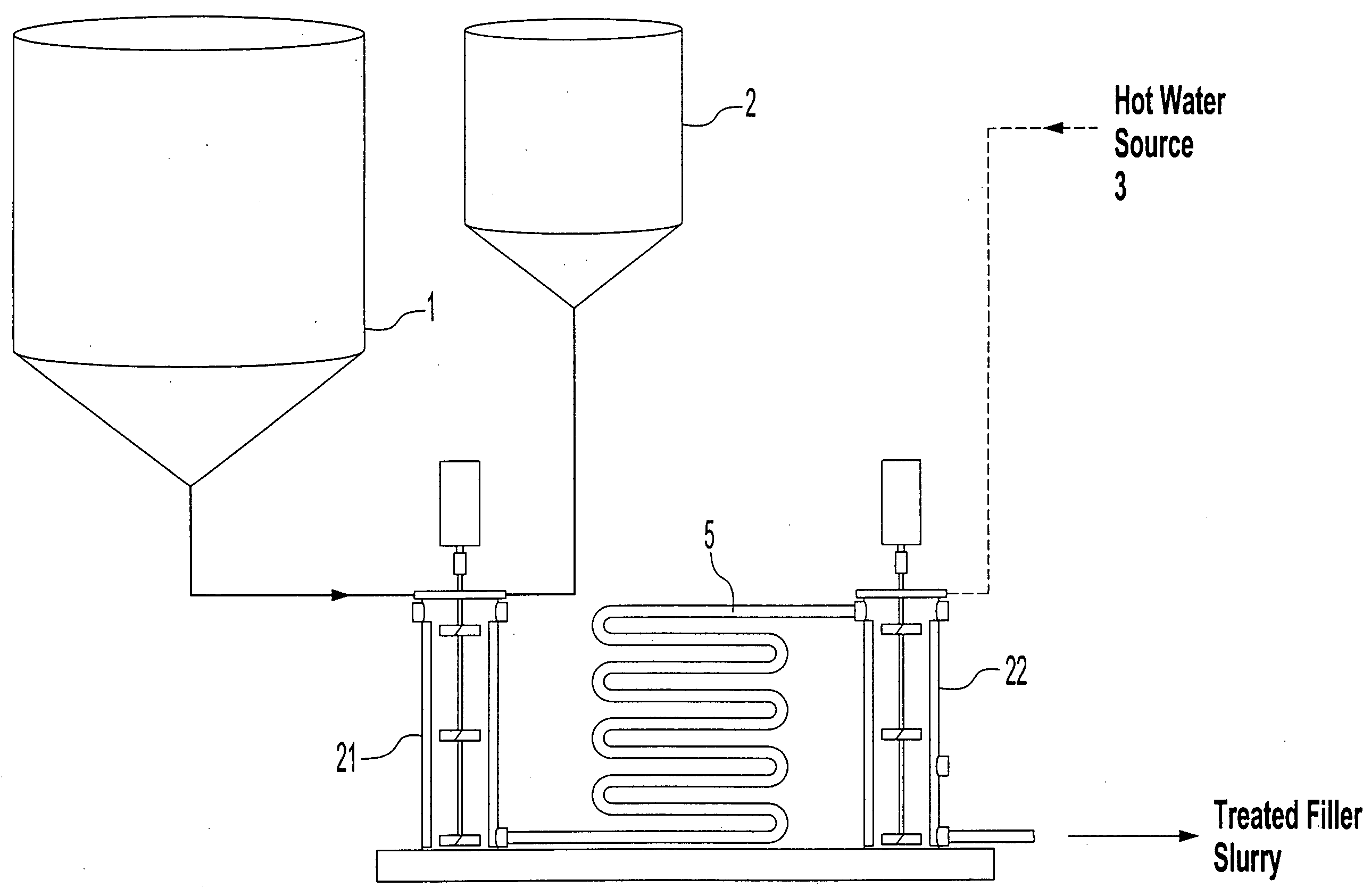

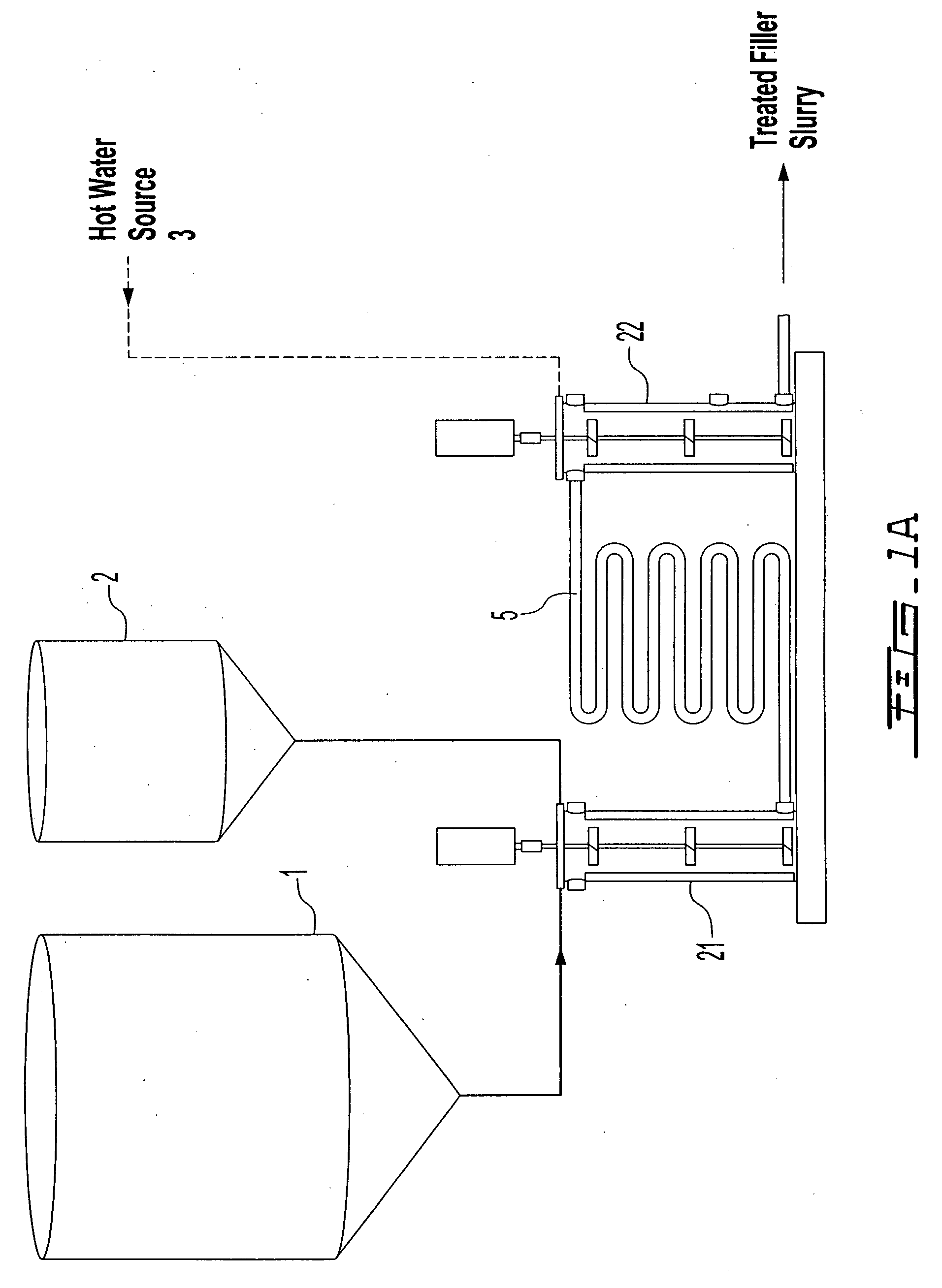

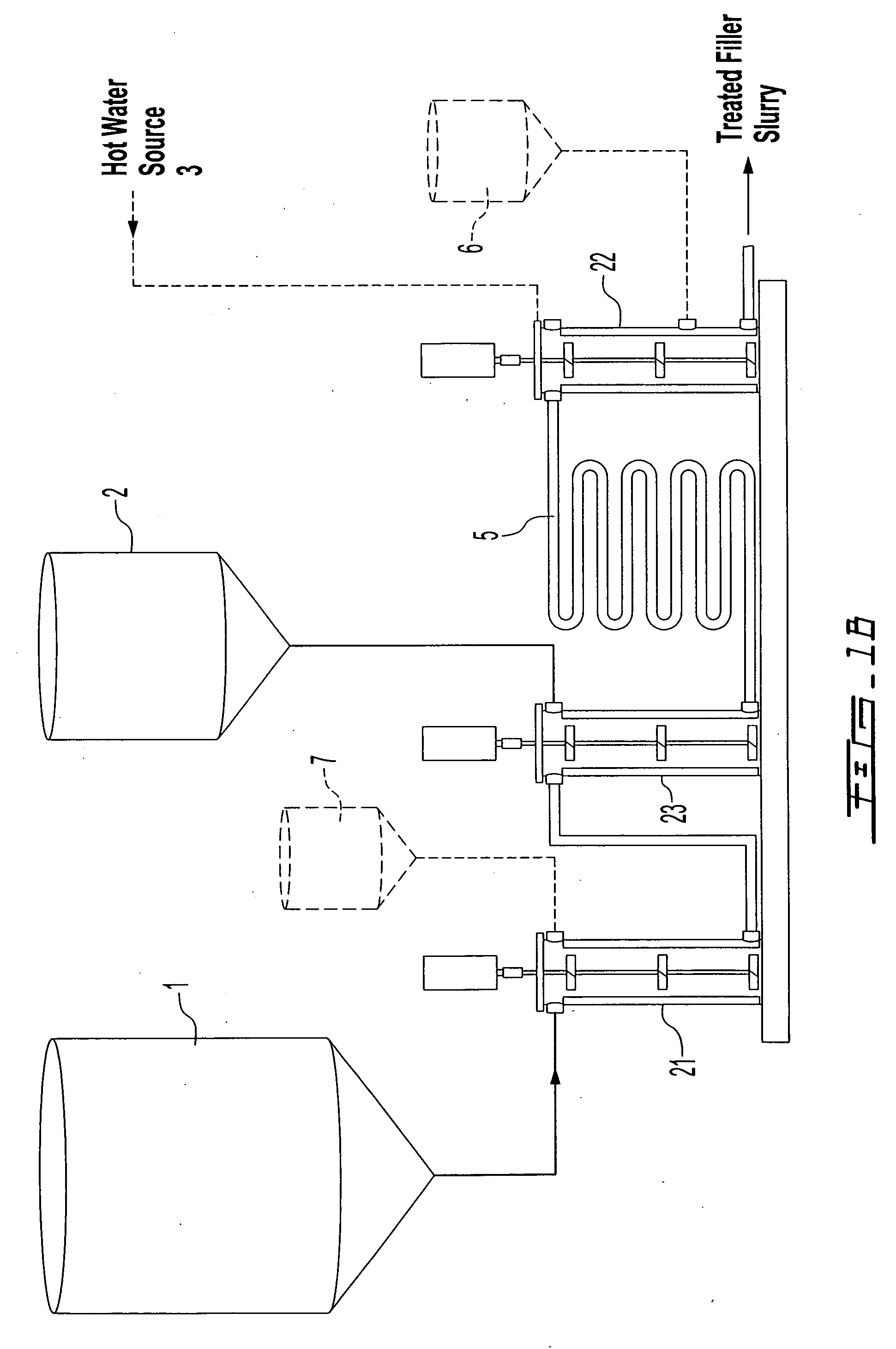

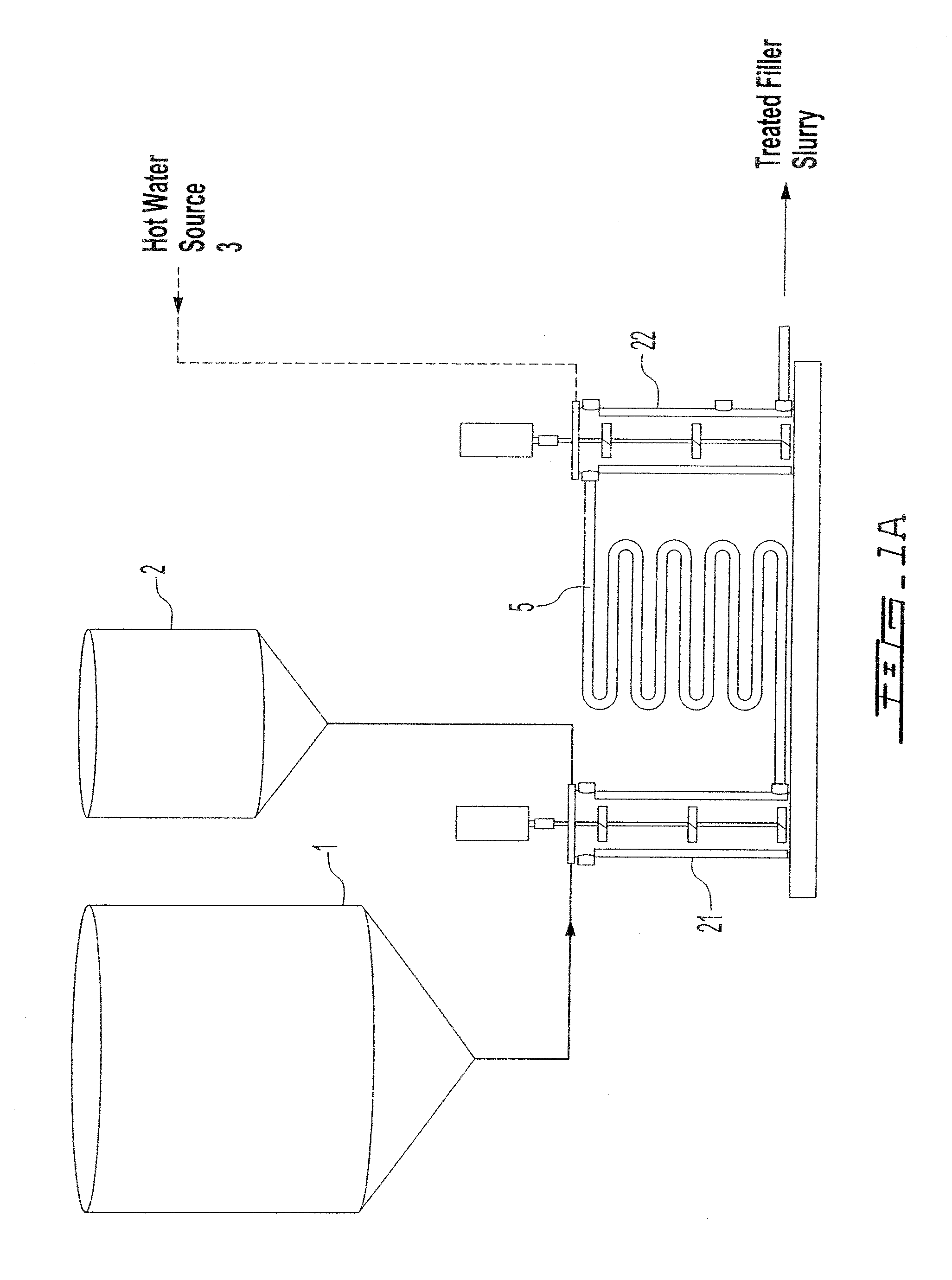

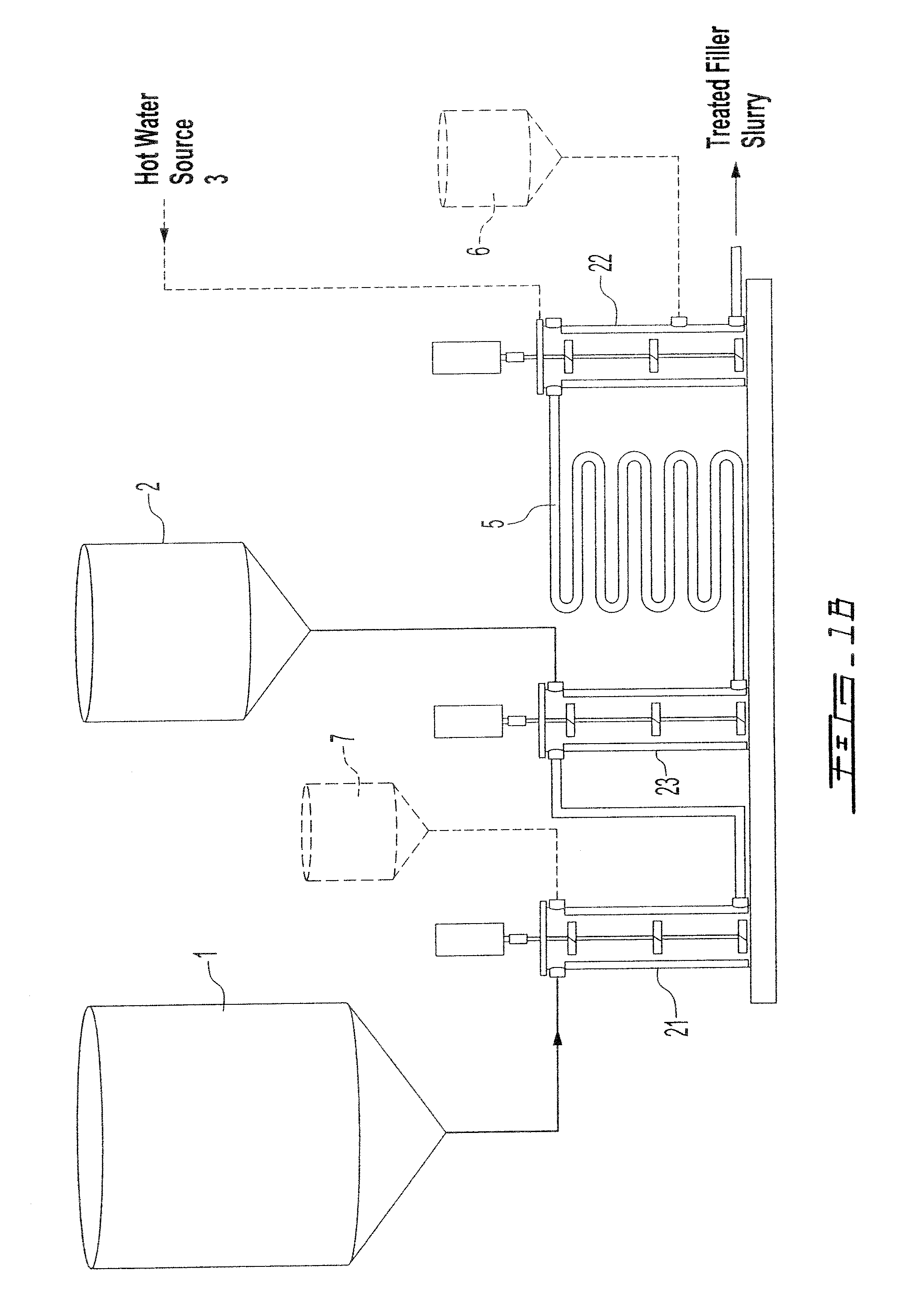

Latex-treated filler slurries for use in papermaking

InactiveUS20080302496A1High retention rateTrend downPigmenting treatmentNatural cellulose pulp/paperPapermakingPaperboard

A continuous filler treatment process has been developed to enhance the fixation of anionic latex on filler in a short time. In this process anionic polymer dispersions (latex) are added to common papermaking filler slurries at ambient temperature and then mixed with water of temperature higher than the glass transition temperature (Tg) of the latex used. To efficiently fix the latex the temperature of the filler / latex mixture must be 30-60° C. higher than the Tg of the latex used. The chemical composition of the resin and the type of surfactant used during the emulsion polymerisation process of the polymer latex dispersions are important factors for efficiently fixing the latex onto the filler by adding hot water and improving the properties of paper made with the treated filler. The enhanced fixation of anionic latex onto filler using hot water is done in mixing vessels that can control shear and mixing time. The anionic latexes applied by this process are totally and irreversibly fixed or bound onto the filler particles and the aggregated filler slurry is stable over time. The latex-treated filler slurry can be added to papermaking furnishes at any point prior to the headbox of the paper machine or stored for later use. It can be added to wood-free or wood-containing furnishes commonly used for making fine papers, mechanical pulp papers, and multi-ply paperboards. The latex-treated filler slurry improves filler retention, only slightly reduces sheet strength and improves sizing performance. Furthermore, latex-treated calcium carbonate filler, such as precipitated calcium carbonate (PCC), is more acid-resistant and, when used in manufacturing mechanical pulp paper under neutral conditions, less acid is needed to control the pH.

Owner:FPINNOVATIONS INC

Elastomeric resin compositions

ActiveUS20060148961A1Low viscosityGood processability without reducing the filler contentSpecial tyresElastomerCompound (substance)

Owner:ELKEM

Method for making paper product and paper product

ActiveUS20150218756A1Improve affinityWithout strength propertySpecial paperPaper after-treatmentChemistryCellulose

Paper product is made starting from aqueous furnish containing fibres and filler. Anionically charged nanofibrillar cellulose and cationic strength additive are added to the aqueous furnish, and the furnish is made to a paper product by dewatering the furnish. Filler content of the paper product can be increased above 40 wt-%.

Owner:UPM-KYMMENE OYJ

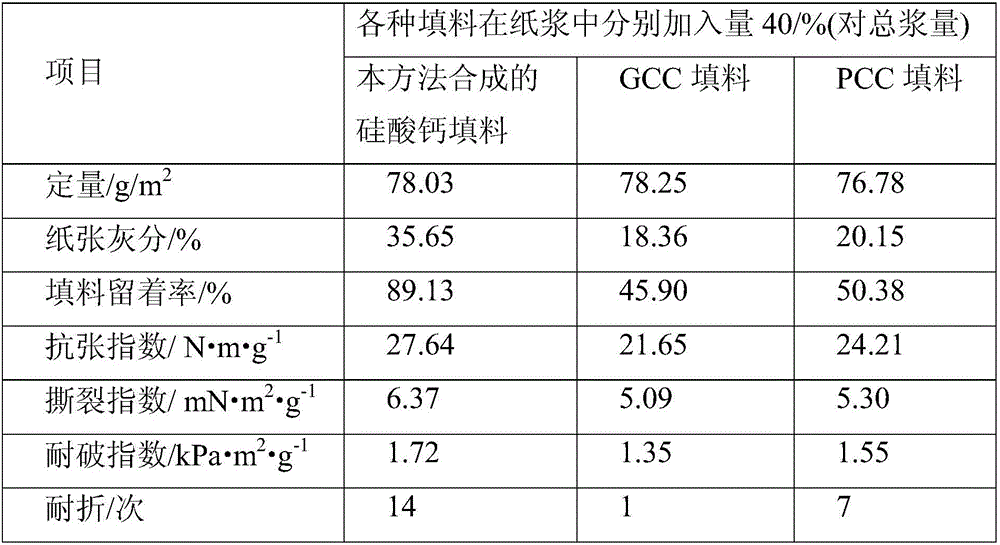

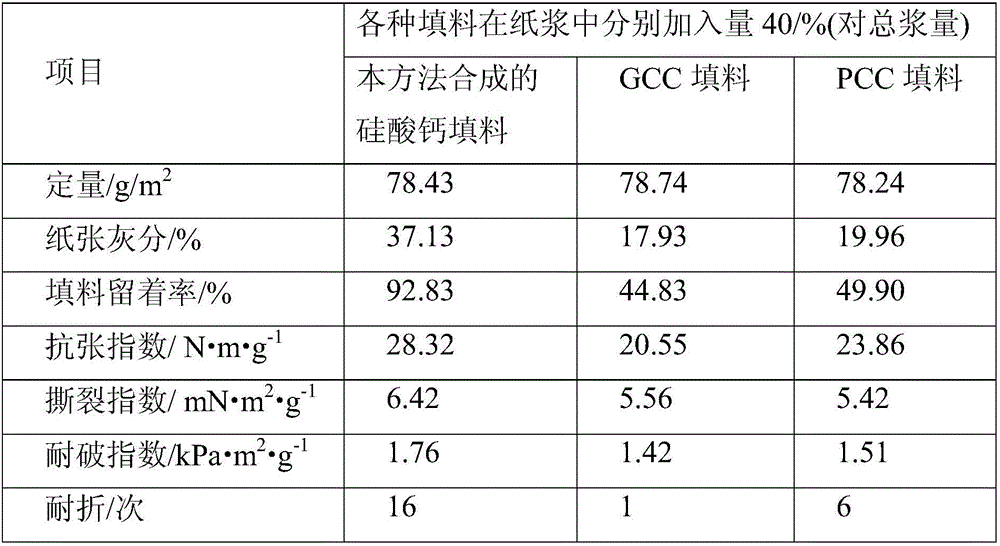

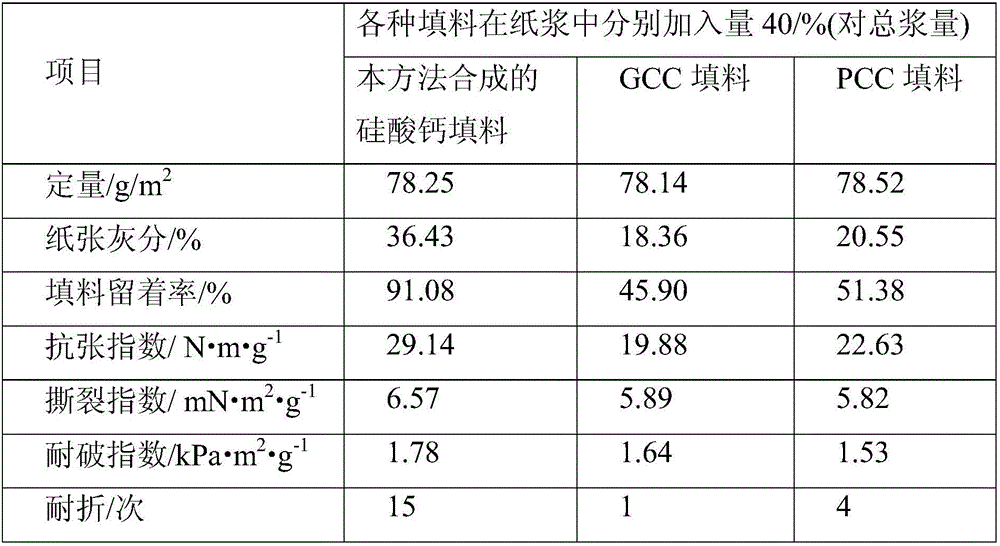

Method for synthesizing calcium silicate filler by utilizing desilication solution, paper pulp fibers and lime milk

ActiveCN105862501AUniform and stable in situ reactionHave binding forceNatural cellulose pulp/paperAlkaline-earth metal silicatesCalcium silicateFiber

The present invention relates to a method for synthesizing a calcium silicate filler by utilizing the desilication solution, paper pulp fibers and the lime milk. The method comprises the steps of mixing up the desilication solution with paper pulp fibers, swelling up, defibering and pulping the obtained mixture, adjusting the concentration of the mixture, adding the lime milk, swapping out the sodium hydroxide solution, and successively conducting the filtering, washing and collecting operation to finally obtain the calcium silicate filler. According to the technical scheme of the invention, the method solves the problem that the calcium silicate and the like, adopted as paper-making fillers in the prior art, are low in retention rate and large in consumption amount. Meanwhile, the method also directly solves the problems in the prior art that the calcium silicate filler is not uniformly dispersed in the slurry after being filled and easy to gather, the paper is reduced in strength performance after being highly filled, and the calcium silicate filler is high in transportation cost. At the same time, the method realizes the recovering and the recycling of the sodium hydroxide solution, thus having great popularization and application value.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

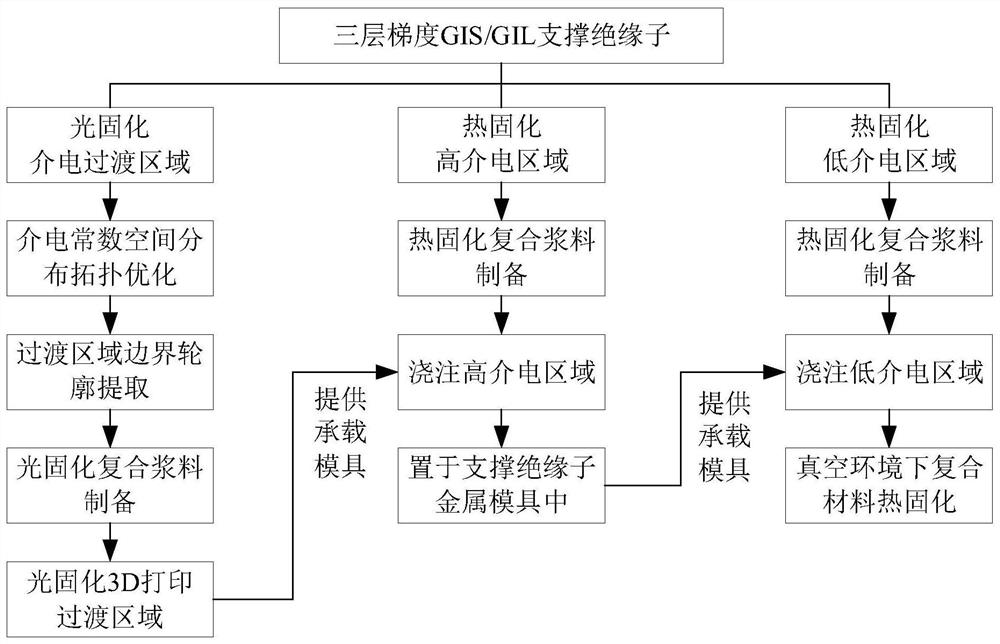

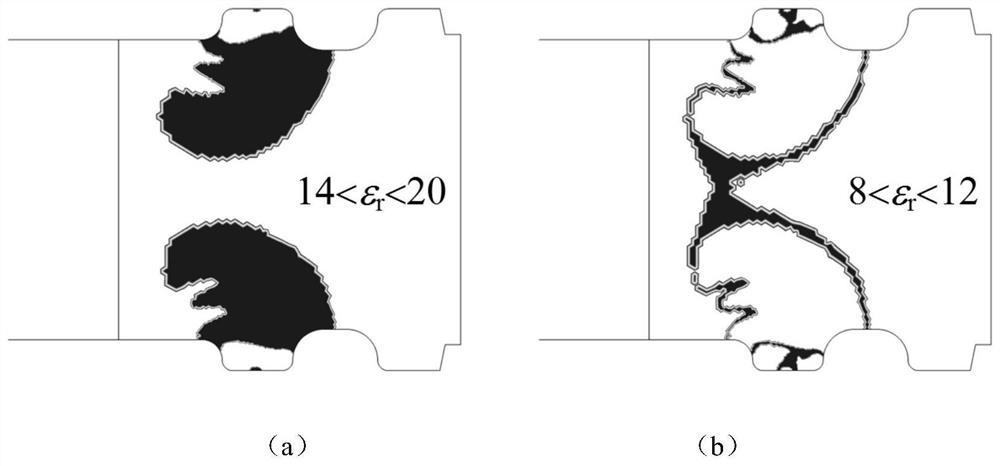

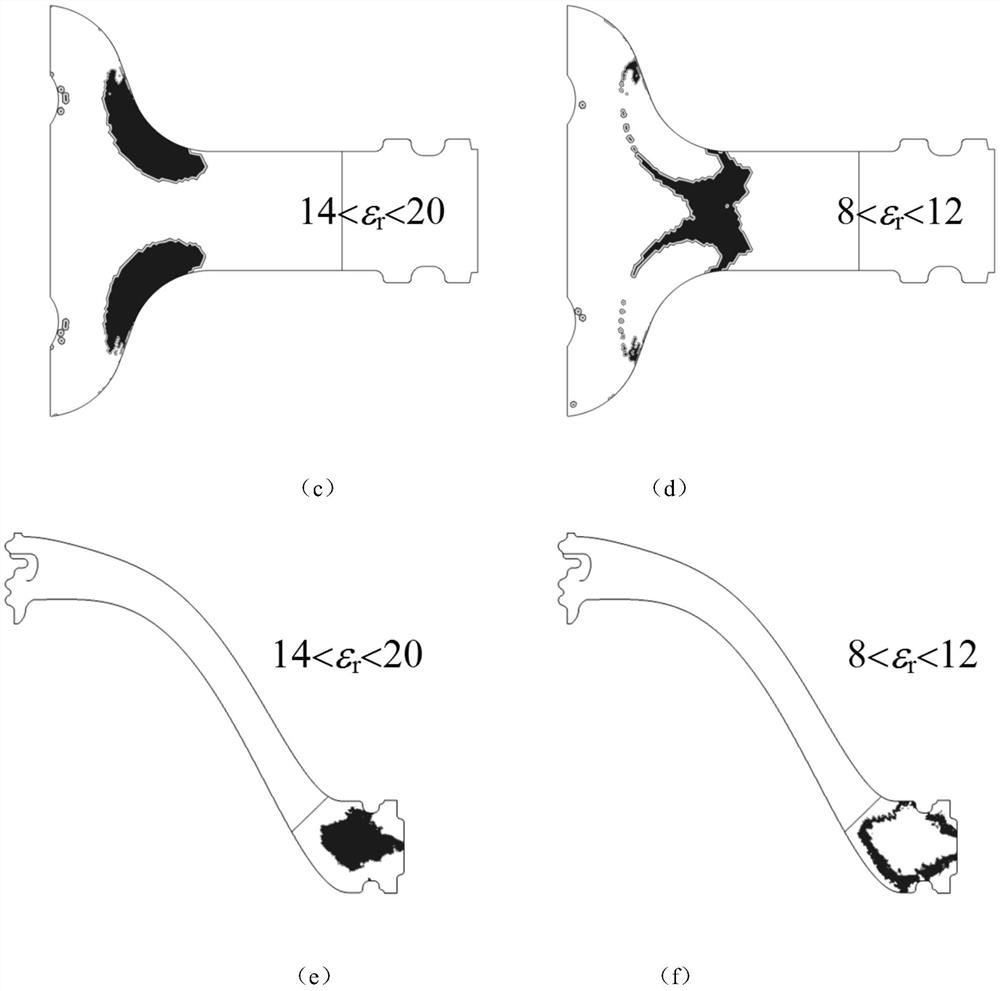

Preparation method of three-layer gradient GIS/GIL supporting insulator

ActiveCN113284684AGuaranteed mechanical strengthImprove electrical strengthAdditive manufacturing apparatusAdditive manufacturing with liquidsDielectricMetal mold

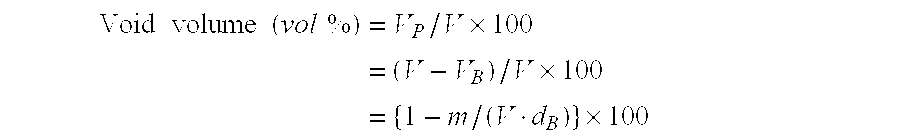

The invention discloses a preparation method of a three-layer gradient GIS / GIL supporting insulator, which aims at reducing the electric field intensity of an insulator along a surface or a local region as an optimization target, and solves the optimal spatial distribution of a dielectric constant in the supporting insulator by using a variable density algorithm. According to the optimization result, the dielectric constant change area is divided into a dielectric constant transition area and a high dielectric area, the combination contour of the dielectric constant transition area is extracted, and then a hollow dielectric constant transition area with a support and a resin sprue gate is generated through photocuring 3D printing; a thermocurable high-dielectric composite material is prepared by adopting a high-dielectric filler / polymer blending mode, and then the high-dielectric composite material is poured into the dielectric constant transition area and integrally put into a metal mold for fixing; and a thermocurable high-dielectric composite material is prepared in a low-dielectric filler / polymer blending mode, then the thermocurable high-dielectric composite material is poured into a metal mold, and the three-layer gradient GIS / GIL supporting insulator can be obtained after curing is completed in vacuum.

Owner:XI AN JIAOTONG UNIV

Foam sheet-forming composition, heat conductive foam sheet and process

A sheet-forming composition is provided which has a construction comprising a combination of a heat-polymerizable binder component containing at least one (meth)acrylic monomer or its partial polymer, a heat conductive filler, a heat polymerization initiator for the binder component and a foaming agent. A process for making a heat conductive foam sheet also is provided.

Owner:3M INNOVATIVE PROPERTIES CO

Manufacture of paper or paperboard

InactiveUS8168040B2High level of fillerLower Level RequirementsNatural cellulose pulp/paperSpecial paperPaperboardPulp and paper industry

A process of making paper or paperboard with improved ash retention relative to total retention comprising the steps of providing a thick stock cellulosic suspension that contains filler, diluting the thick stock suspension to form a thin stock suspension, in which the filler is present in the thin stock suspension in an amount of at least 10% by weight based on dry weight of thin stock suspension, flocculating the thick stock suspension and / or the thin stock using a polymeric retention / drainage system, draining the thin stock suspension on a screen to form a sheet and then drying the sheet, in which the polymeric retention / drainage system comprises, i) a water-soluble branched anionic polymer and ii) a water-soluble cationic or amphoteric polymer, wherein the anionic polymer is present in the thick stock or thin stock suspension prior to the addition of the cationic or amphoteric polymer. The process brings about improved ash retention relative to total retention.

Owner:BASF AG

Latex-treated filler slurries for use in papermaking

InactiveUS20110308753A1Trend downReduce amountPigmenting treatmentNatural cellulose pulp/paperPrillPaperboard

A continuous filler treatment process has been developed to enhance the fixation of anionic latex on filler in a short time. In this process anionic polymer dispersions (latex) are added to common papermaking filler slurries at ambient temperature and then mixed with water of temperature higher than the glass transition temperature (Tg) of the latex used. To efficiently fix the latex the temperature of the filler / latex mixture must be 30-60° C. higher than the Tg of the latex used. The chemical composition of the resin and the type of surfactant used during the emulsion polymerisation process of the polymer latex dispersions are important factors for efficiently fixing the latex onto the filler by adding hot water and improving the properties of paper made with the treated filler. The enhanced fixation of anionic latex onto filler using hot water is done in mixing vessels that can control shear and mixing time. The anionic latexes applied by this process are totally and irreversibly fixed or bound onto the filler particles and the aggregated filler slurry is stable over time. The latex-treated filler slurry can be added to papermaking furnishes at any point prior to the headbox of the paper machine or stored for later use. It can be added to wood-free or wood-containing furnishes commonly used for making fine papers, mechanical pulp papers, and multi-ply paperboards. The latex-treated filler slurry improves filler retention, only slightly reduces sheet strength and improves sizing performance. Furthermore, latex-treated calcium carbonate filler, such as precipitated calcium carbonate (PCC), is more acid-resistant and, when used in manufacturing mechanical pulp paper under neutral conditions, less acid is needed to control the pH.

Owner:FPINNOVATIONS INC

Nylon-based high filling master batch and preparation method thereof

InactiveCN102516755AAccurate masterbatch ash contentSimple preparation processChemistryComposite material

The invention discloses nylon-based high filling master batch and a preparation method thereof. The nylon-based high filling master batch is characterized by consisting of 20 to 40 weight percent of nylon-6 resin, 60 to 80 weight percent of filler, 0.1 to 0.5 weight percent of antioxygen, and 0.5 to 1.5 weight percent of lubricating agent. The preparation method comprises the following steps of: adding the nylon-6 resin, the filler, the antioxygen, and the lubricating agent into a high-speed mixer, and uniformly stirring; and adding a mixed material obtained in the step into a reciprocating single-screw extruder, extruding, cooling, drying and cutting into particles. The invention has the advantages that the content of the filler in the master batch can reach over 60 weight percent, the filler is uniformly dispersed in a nylon matrix, the master batch is accurate in ash content, and is suitable for modification and processing of nylon, and a nylon composite material with excellent performance can be prepared from the master batch. Moreover, the master batch has the advantages of simple preparation process, low cost and the like, meets the industrial production requirement and has wide market application prospect.

Owner:SHANGHAI KINGFA SCI & TECH +1

Surface modification method for inorganic oxide powder, powder produced by the method and use of the powder

InactiveUS7425287B2Improvement ingredientsLow viscosityMaterial nanotechnologyInorganic pigment treatmentCombustible gasProduct gas

A surface modification method comprising bringing, into a high-temperature flame formed by use of a combustible gas and a combustion-supporting gas, inorganic oxide powder A having an average particle size falling within a range of 0.5 to 200 μm as measured by means of laser diffraction / scattering particle size analysis and inorganic oxide powder B having a particle size calculated on the basis of its BET specific surface area of 100 nm or less, to thereby modify the surfaces of particles of the powder A by means of the particles of the powder B. A surface modification method comprising bringing, into a high-temperature flame formed by use of a combustible gas and a combustion-supporting gas, the inorganic oxide powder A; and bringing again the resultant powder into the high-temperature flame, to thereby modify the surfaces of particles of powder A.

Owner:SHOWA DENKO KK

Sidewall insert rubber composition for run-flat tire and tire produced using the same

InactiveUS20150298512A1Excellent low fuel consumption performanceEnhanced interactionSpecial tyresInflatable tyresHigh intensityEngineering

A sidewall insert rubber composition for run-flat tire, and a tire produced using the same rubber composition are provided. The sidewall insert rubber composition for run-flat tire can realize excellent low fuel consumption performance by applying a functionalized, solution-polymerized butadiene rubber having a low glass transition temperature and thereby enhancing the interaction with fillers, and can provide a high strength sidewall insert rubber for run-flat tire with less heat generation by increasing the content of a filler.

Owner:HANKOOK TIRE WORLDWIDE

Copolymer blend compositions for use to increase paper filler content

ActiveUS20100071863A1Increase inorganic filler contentNegatively paper strengthNatural cellulose pulp/paperSpecial paperIn situ polymerizationPrecipitated calcium carbonate

Methods for making a heterogeneous polymer blend comprising one or more anionic polymers, one or more cationic polymers, and one or more non-ionic polymers, which method comprises (a) adding to a non-neutral solution a first amount of polymerization initiator and one or more anionic or cationic monomers, wherein each monomer has the same charge; (b) adding a second amount of the polymerization initiator and one or more non-ionic monomers; (c) adding a third amount of the polymerization initiator and one or more ionic monomers that are oppositely charged from the monomers of (a); adding stepwise, a fourth amount of the polymerization initiator to react any residual monomer, and (e) neutralizing the resulting polymer blend. Also claimed are heterogeneous polymer blends containing polymers formed from one or more anionic, cationic, and non-ionic monomers, either polymerized in situ or separately and then combined. Also claimed are methods for increasing the filler content of paper or paperboard, which methods comprises (a) combining the heterogeneous polymer blend with a precipitated calcium carbonate filler; (b) combining the resulting mixture with a pulp slurry; and (c) processing the resulting slurry mixture to form a sheet of paper or paperboard. Finally, also claimed are methods of increasing the filler content of paper or paperboard, which method comprises (1) combining either the heterogeneous blend or the precipitated calcium carbonate filler with a pulp slurry, (2) combining the remaining component with the pulp slurry; and (c) processing the resulting pulp slurry mixture to form a sheet of paper or paperboard.

Owner:SOLENIS TECH CAYMAN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com