Preparation method of three-layer gradient GIS/GIL supporting insulator

A technology for supporting insulators and insulators. It is used in insulators, auxiliary operations of additional layers, 3D object support structures, etc., which can solve the problems of poor controllability of lamination and centrifugal methods, long processing time of insulators, and limited molding size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

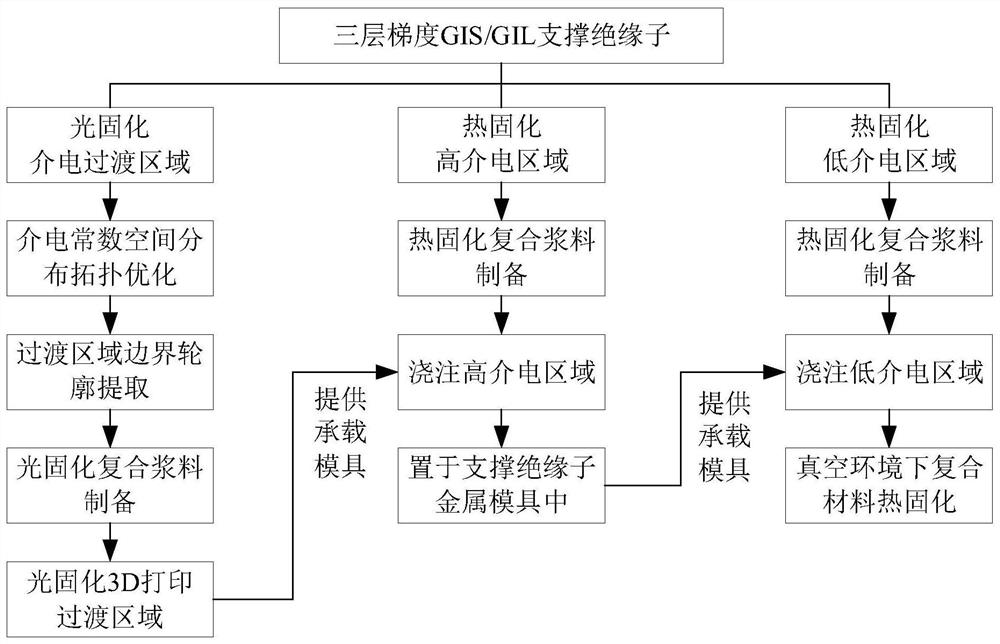

[0055] see figure 1 , a preparation method of a three-layer gradient GIS / GIL support insulator of the present invention, the support insulator is divided into three parts: a light-cured dielectric transition region, a heat-cured high-dielectric region, and a heat-cured low-dielectric region; the specific steps are as follows :

[0056] S1. Light-cured dielectric transition area: The light-cured dielectric transition area is made of light-cured 3D printing photosensitive composite materials. The main functions include insulating internal gradient dielectric constant transition, metal mold internal support and fixation, and serving as a heat-cured high dielectric area. Mold, its manufacturing steps are:

[0057] S101. With the optimization goal of reducing the electric field along the surface of the insulator and the electric field intensity at the three joint points on the flange side, the insulator is discretized, and the dielectric constant in each tiny unit can be determined ...

Embodiment 1、110k

[0092] Example 1, 110kV disc support insulator

[0093] A method for preparing a three-layer gradient GIS / GIL support insulator, which divides the insulator into three parts: a light-cured dielectric transition region, a heat-cured high-dielectric region, and a heat-cured low-dielectric region.

[0094] The light-cured dielectric transition area is made of light-cured 3D printing photosensitive composite materials. The main functions include insulating the internal gradient dielectric constant transition, internal support and fixing of the metal mold, and acting as a heat-cured high-dielectric area mold. The manufacturing steps are:

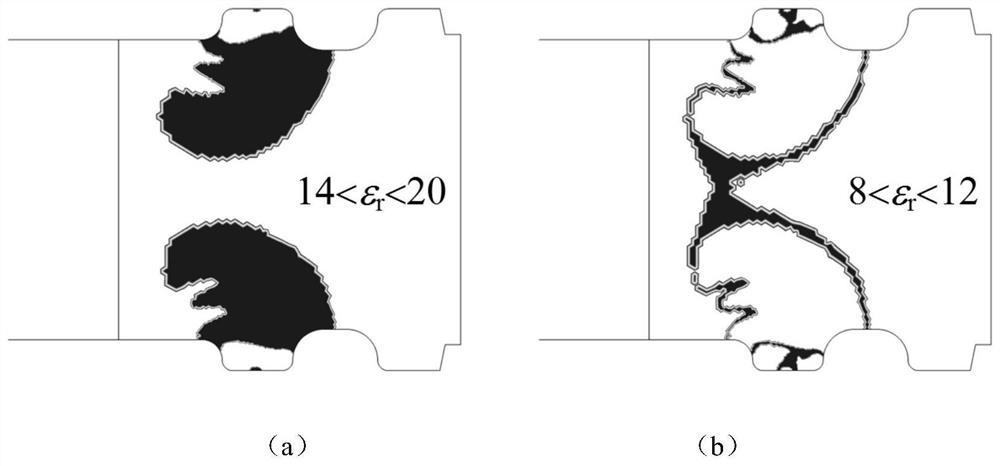

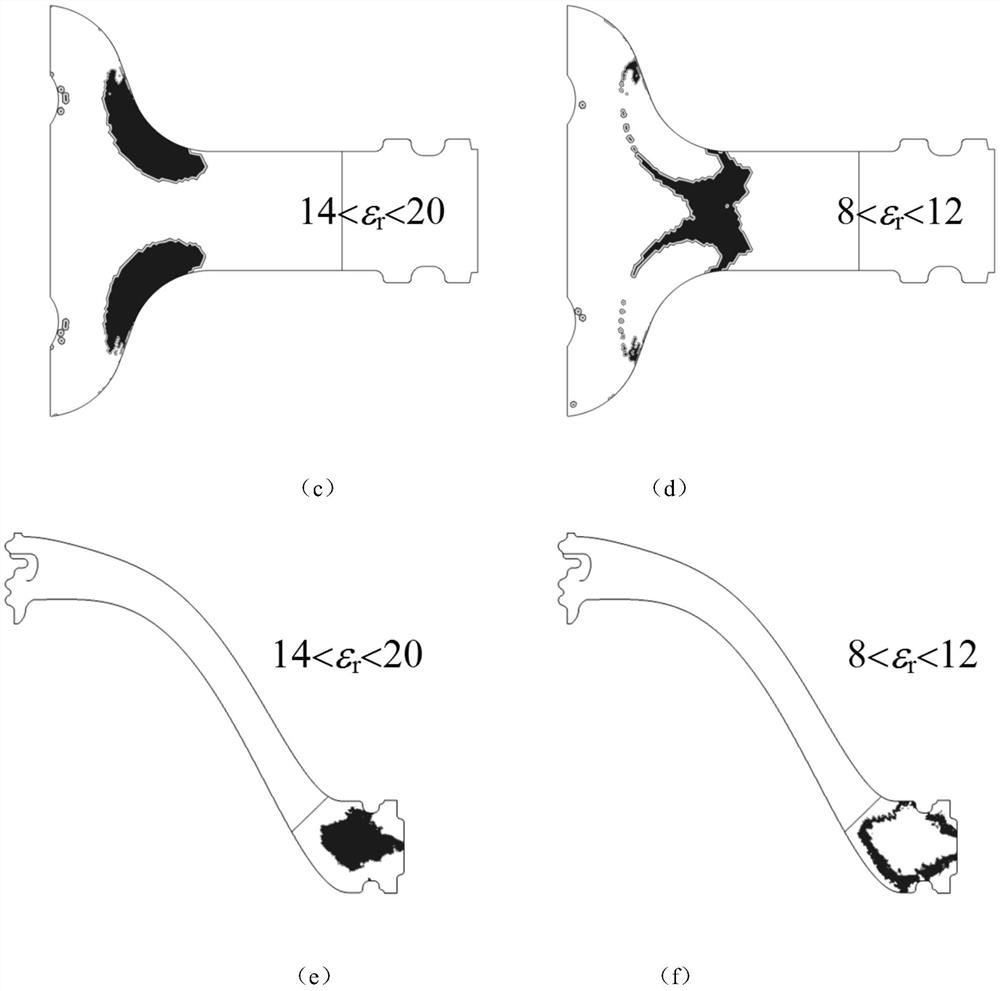

[0095] S101. Taking the reduction of the electric field intensity in the region at the three junction points on the flange side of the 110kV disc support insulator as the optimization goal, the insulators are discretized, and the dielectric constant in each tiny unit can be calculated based on the dielectric constant value of the matrix (here sele...

Embodiment 2

[0115] Example 2: 110kV disc support insulator

[0116] A method for preparing a three-layer gradient GIS / GIL support insulator, which divides the insulator into three parts: a light-cured dielectric transition region, a heat-cured high-dielectric region, and a heat-cured low-dielectric region.

[0117] The light-cured dielectric transition area is made of light-cured 3D printing photosensitive composite materials. The main functions include insulating the internal gradient dielectric constant transition, internal support and fixing of the metal mold, and acting as a heat-cured high-dielectric area mold. The manufacturing steps are:

[0118] S101. With the optimization goal of homogenizing the electric field strength along the surface of the 110kV disc support insulator, discretize the insulator, and the dielectric constant in each micro unit can vary from the dielectric constant value of the matrix (selected as 5.8 here) to the dielectric constant change The upper limit (sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Coefficient of linear thermal expansion | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com