Micro-nano fiber bragg grating refractive index sensor and manufacturing method thereof

A technology of refractive index sensor and Bragg grating, which is applied in the direction of phase influence characteristic measurement, etc., can solve the problems affecting the popularization and application of long-period fiber Bragg grating refractive index sensors, reduce the multiplexing ability of fiber Bragg grating refractive index sensors, limit the accuracy of refractive index measurement, etc. problem, to achieve the effect of fast measurement, simple structure and accurate sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

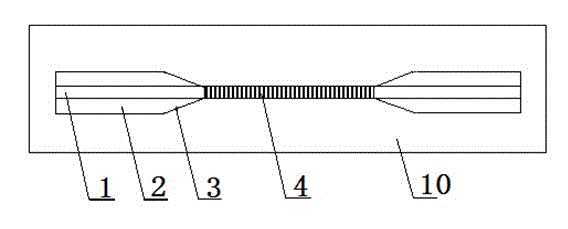

[0031] see figure 1 , a micro-nano fiber Bragg grating refractive index sensor, including a plexiglass plate 10, the plexiglass plate 10 is fixedly connected with the two ends of the fiber Bragg grating 1, and the middle section of the fiber Bragg grating 1 is an unclad core grating region 4 .

[0032] The fiber Bragg grating 1 is an ordinary fiber Bragg grating.

[0033] The fiber Bragg grating 1 is a micro-nano fiber Bragg grating.

[0034] The diameter of the cladding-free core grid region 4 is on the order of 1-8 μm.

[0035] The two ends of the organic glass plate 10 and the fiber Bragg grating 1 are fixedly connected with paraffin.

[0036] The micro-nano optical fiber Bragg grating used in the present invention is an optical fiber Bragg grating with only a core, its diameter is on the order of 1-8 μm, its mechanical strength is relatively good, and the cladding is corroded by hydrofluoric acid.

[0037] A method for manufacturing a micro-nano fiber Bragg grating ref...

Embodiment 2

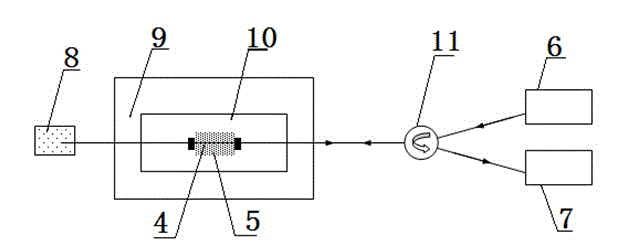

[0050] A method for manufacturing a micro-nano fiber Bragg grating refractive index sensor, comprising the steps of:

[0051] 1) Fix the two ends of the ordinary fiber Bragg grating on the plexiglass of 10cm×5cm×0.5cm, the direction is along the long side direction, and fix it with paraffin, put it in the adjustable thermostat 9, and control the temperature at 17°C constant temperature;

[0052] 2) Add 0.8ml of hydrofluoric acid dropwise to the cladding of the fiber Bragg grating in step 1), and the etching time is 125 minutes to corrode the cladding of the grating, so that the core of the grating is directly exposed;

[0053] 3) Take out the micro-nano fiber Bragg grating corroded in step 2) together with the plexiglass, suck off the residual corrosion solution with a straw, wash it with clean water, and then apply a 40% NaOH solution for 10 minutes to ensure that the residual hydrofluoric acid Be completely neutralized, and finally rinse with deionized water.

Embodiment 3

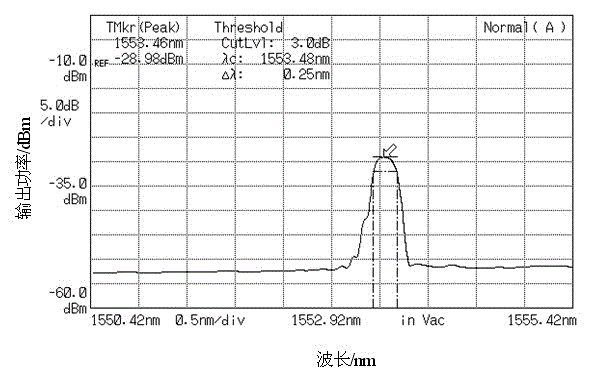

[0055] In this example, by setting the etching time as 15, 30, 45, 60, 75, 90, 105, and 120 minutes respectively, under the constant temperature condition of 20°C, the fiber Bragg The diameter of the grating) of the fiber grating is corroded, and the method and steps used are the same as in embodiment 2. The relationship between the measured diameter of the fiber grating and the change with time is as follows: Figure 4 As shown, the corrosion process is basically in a linear relationship with time, and the linearity reaches 99.5%, and the corrosion rate of the fiber diameter is 0.992 μm / min. Through the above temperature and corrosion rate, the diameter of the micro-nano fiber grating can be controlled, and the required refractive index sensor can be fabricated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com