PVC (Polyvinyl Chloride) microcrystalline wood composite material and preparation method thereof

A composite material and microcrystalline technology, which is applied in the field of PVC microcrystalline wood composite materials and its preparation, can solve the problems of low biomass powder addition, narrow processing temperature range, and weak corrosion resistance, etc., and achieve system stability and processing The effect of changing the process range and good lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

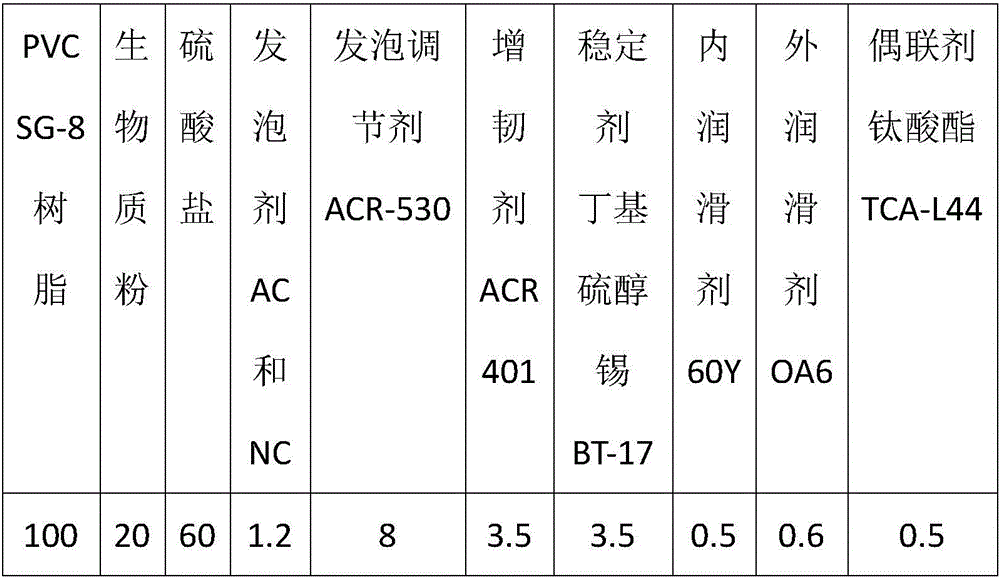

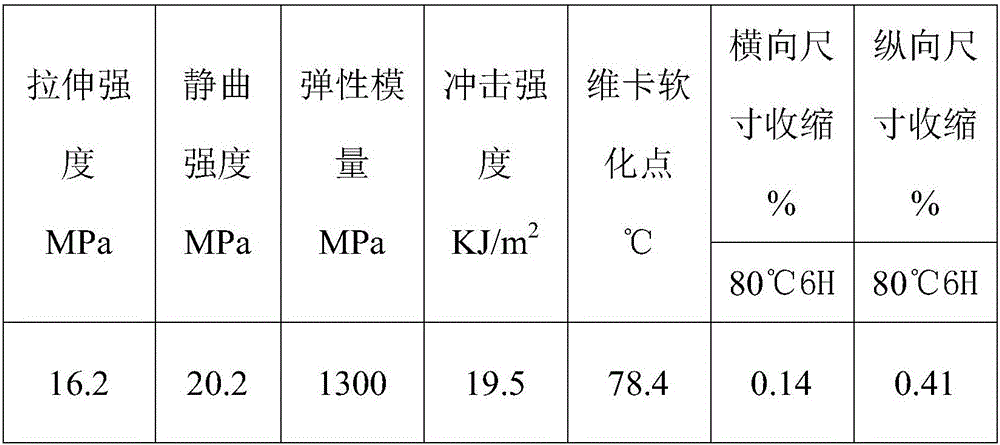

[0034] In parts by weight, the PVC microcrystalline wood composite material formulation of the present embodiment consists of the following table:

[0035] Table 1 Embodiment 1 raw material proportioning

[0036]

[0037] The biomass powder is crop straw powder passed through a 60-mesh sieve.

[0038] The sulfate is anhydrous magnesium sulfate passing through a 400 mesh sieve.

[0039] The foaming agent is a mixture of azodicarbonamide (AC) and sodium bicarbonate (NC) with a mass ratio of 1:2.

[0040] Utilize above-mentioned formula to produce the preparation method of PVC microcrystalline wood composite material as follows:

[0041] Step 1, put the components in Table 1 into the high-speed mixer, mix at a high speed, and the temperature reaches 130°C, then transfer the mixture from the high-speed mixer to a low-speed cold mixing pot, and lower the temperature to 40-50°C to obtain a mixture ;

[0042] Step 2, mixing and extruding the mixture in an 80 / 156 different-to-c...

Embodiment 2

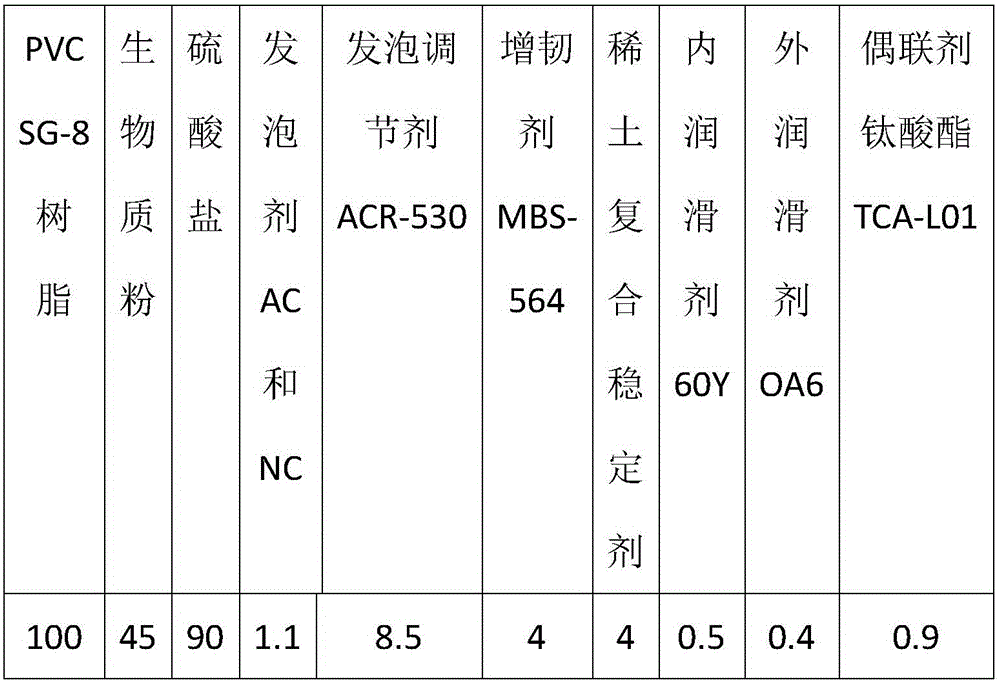

[0051] In parts by weight, the PVC microcrystalline wood composite material formulation of the present embodiment consists of the following table:

[0052] Table 3 Embodiment 2 raw material proportioning

[0053]

[0054] The biomass powder is wood powder passed through a 60-mesh sieve.

[0055] The sulphate is anhydrous calcium sulphate passing through a 400 mesh sieve.

[0056] The foaming agent is a mixture of azodicarbonamide (AC) and sodium bicarbonate (NC) with a mass ratio of 1:3.

[0057] Utilize above-mentioned formula to produce the preparation method of PVC microcrystalline wood composite material as follows:

[0058] Step 1, put the components in Table 1 into the high-speed mixer, mix at a high speed, and the temperature reaches 130°C, then transfer the evenly mixed mixture from the high-speed mixer to a low-speed cold mixing pot, and lower the temperature to 40-50°C, get the mixture;

[0059] Step 2, kneading and extruding the mixture in a counter-rotating ...

Embodiment 3

[0068] In parts by weight, the PVC microcrystalline wood composite material formulation of the present embodiment consists of the following table:

[0069] Table 5 Embodiment 3 raw material proportioning

[0070]

[0071] Described biomass powder is the bamboo powder that passes 60 mesh sieves.

[0072] The sulphate is anhydrous calcium sulphate passing through a 400 mesh sieve.

[0073] The foaming agent is a mixture of azodicarbonamide (AC) and sodium bicarbonate (NC) with a mass ratio of 1:0.5.

[0074] Utilize above-mentioned formula to produce the preparation method of PVC microcrystalline wood composite material as follows:

[0075] Step 1, put the components in Table 1 into the high-speed mixer, mix at a high speed, and the temperature reaches 135°C, then transfer the mixture from the high-speed mixer to a low-speed cold mixing pot, and lower the temperature to 40-50°C to obtain a mixture ;

[0076] Step 2, kneading and extruding the mixture in a counter-rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com