Method for synthesizing calcium silicate filler by utilizing desilication solution, paper pulp fibers and lime milk

A technology of pulp fiber and desiliconization solution, which is applied in pulp beating method, fiber raw material treatment, silicate, etc., can solve the problems of paper strength performance decline, uneven dispersion, easy flocculation, etc., and achieve the improvement of filler content and reaction Uniform and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

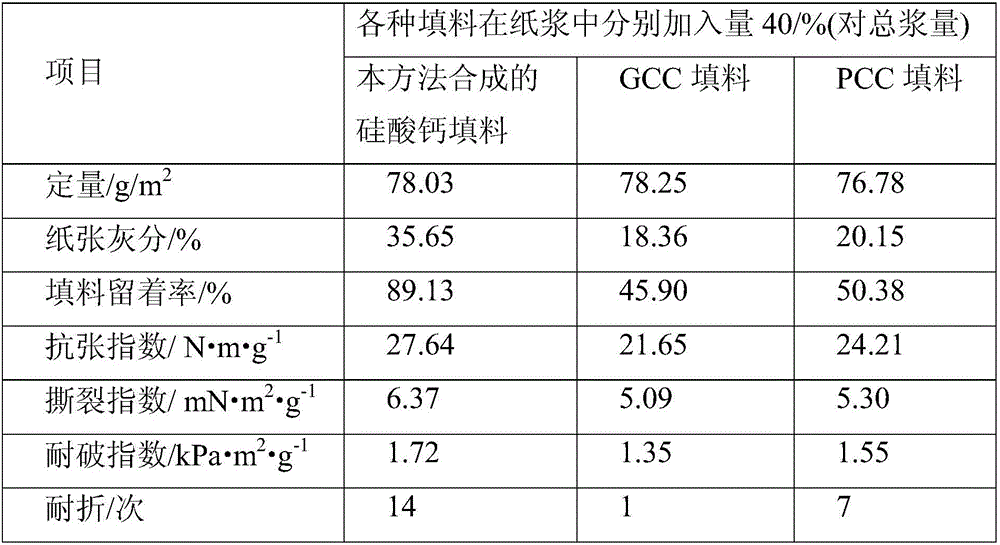

Embodiment 1

[0026] SiO2 concentration is 69.0g / L, NaO2 concentration is 50g / L in desiliconization solution 500ml, add 100g absolute dry coniferous wood pulp, fully mix and soak for 4h, control the pulp concentration in the mixed solution to be 19%, then soak the soaked The fiber desiliconization liquid mixed liquid is decomposed and beaten, and the beating degree is controlled to 56oSR. After the beating is completed, the pulp concentration is adjusted to 6%, and the desilicate is carried out; the desiliconized fiber desiliconized liquid mixed pulp is heated to 75°C for preheating, During the preheating process, the stirring speed was controlled to be 201rpm, and the preheating time was 30min; after the fiber desiliconization liquid mixed slurry was preheated, the heating temperature was kept constant, and the stirring speed was increased to 301rpm, and the lime milk suspension was slowly added at the same time. The concentration of calcium oxide in the milk of lime added is CaO: 225g / L, a...

Embodiment 2

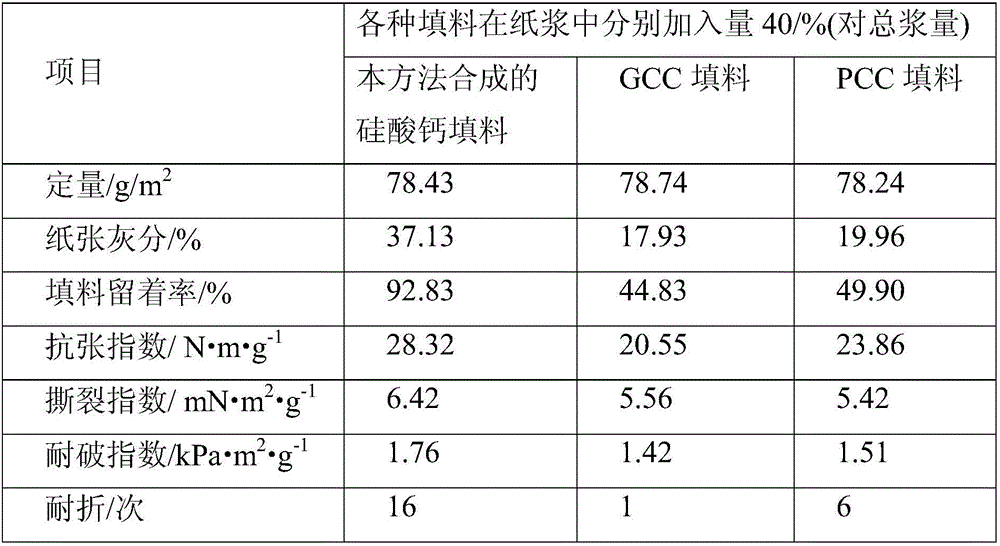

[0031] SiO2 concentration: 79.0g / L, NaO2 concentration: 500ml of desiliconization solution of 60g / L, add 100g absolute dry softwood wood pulp, mix fully and soak for 8h, control the pulp concentration in the mixed solution to be 25%, and then moisten The soaked fiber desiliconization liquid mixed liquid is decomposed and beaten, and the beating degree is controlled to 65oSR. After the beating is completed, the pulp concentration is adjusted to 10%, and the desiliconated fiber is desiliconized. Heat, during the preheating process, control the stirring speed to 300rpm, and the preheating time is 30min; after the fiber desiliconization liquid mixed slurry is preheated, keep the heating temperature constant, increase the stirring speed to 310rpm, and slowly add the lime milk suspension , the calcium oxide concentration in the milk of lime added is CaO: 235g / L, the amount of addition is controlled at the CaO in the milk of lime and the SiO2 mass ratio in the desiliconization solutio...

example 2

[0033] This method and GCC, PCC filler paper performance comparison table under table 2 example 2 conditions

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com